Professional Documents

Culture Documents

Guia Manenimiento

Guia Manenimiento

Uploaded by

Omar Garcia BeltranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guia Manenimiento

Guia Manenimiento

Uploaded by

Omar Garcia BeltranCopyright:

Available Formats

During and after world war two at the time when the advances of engineering and scientific

technology developed, people developed other types of maintenance which were more cheaper

such as preventive maintenance . in addition people in this era classified maintenance as function

of the production system

CONCEPTS AND IMPORTANCE OF INDUSTRIAL MAINTENANCE

Service: Is the utility that a device a physical and moral person provides to satisfy need

Quality of service: is understood as a degree of satisfaction of a need trough the provision of a

service, there are two: one who gives the service, and the one who receives it.

Maintenance: is the human activity whose function is to preserve the quality of the services

Importance: the useful life of equipment and parts depend on the operation time, environment,

work cycles, overloads and maintenances, this is the reason because is very important to establish

a maintenance program, to assure the optimal operation.

Source of failure: 1) the machine itself. 2) Environment. 3) Personal.4) animals .5) poor quality of

material

Conservation: is a human action that through the application scientific and technological

knowledge contributes to the optimal use of existing resource in the human habitat promoting

integral development

Conservation : is divided in two main branches

1. Preservation: it takes care of the needs of the physical resources

2. Maintenances: which is responsible of take care the service that the resource provides

Policies for the maintenance :

1. The service provided by the equipment has priority over all maintenance task

2. There should be constant verification test as a whole

3. Test and verification must be done on the behavior of the equipment to verify that they

can work even In situation of compromise

4. Any intervention in a equipment , machinery or installation must be based on a diagnostic

5. For preventive maintenance work should be used personal with mentality and manual

6. Any diagnostic must be based on thorough testing and analysis

To achieve these goals the company needs to have an organizational chart

Machinery monitoring

Monitoring is the machines that operates in industrial processes is a fundamental part of

maintenance, during monitoring many problems can be determined

One of the most common problems is the vibration

VIBRATION ANALYSIS

In the machines the vibration can be generated by : lack of lubrication in the pieces , natural wear

of the parts in rotation , mismatches , unbalance.

Vibration: it is a periodical movement than repeats itself with all its characteristics after a certain

interval of time called period

Classification:

Periodic: the time of a cycle is the same of the following cycles this may be:

- Harmonic periodic.

- Non- harmonic periodic

- None periodic

Types of vibration systems:

- Free vibration system without damping

- Free vibration system with damping

- Forced vibration system without damping

- Forced vibration system with damping

The systems can be made by masses , springs and shock absorbers and can be subjected to a

force

Free vibration system without damping: this system is of one degree of freedom and is formed by

a spring, mass, and must be limited by guides

Free vibration system with damping: this system is of one degree of freedom and is formed by a

spring, mass and a shock absorber , this system must be limited by guides

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Bank Statement 1 2024Document2 pagesBank Statement 1 2024joelschwartzllcNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- International and Comparative Petroleum Law and Policy Research PaperDocument19 pagesInternational and Comparative Petroleum Law and Policy Research PapernonsookoliNo ratings yet

- ASCP ExceptionsDocument92 pagesASCP Exceptionsbommakanti.shiva100% (1)

- America OnlineDocument18 pagesAmerica OnlineLatika RatnaNo ratings yet

- SAP MM Material Management Training TutorialsDocument5 pagesSAP MM Material Management Training TutorialssaranpcNo ratings yet

- Keith Knutsson of Integrale Advisors Announces That William K. Pingleton Has Joined The Firm's BoardDocument2 pagesKeith Knutsson of Integrale Advisors Announces That William K. Pingleton Has Joined The Firm's BoardPR.comNo ratings yet

- Responsibilities of A FACTORY MANAGERDocument3 pagesResponsibilities of A FACTORY MANAGERPawan KinnalNo ratings yet

- Web Journalism in IndiaDocument14 pagesWeb Journalism in Indiacheatersonu100% (1)

- Rocio D. P. Huaman Ramirez: Bachellor in EconomyDocument3 pagesRocio D. P. Huaman Ramirez: Bachellor in EconomyRocio Huaman RamirezNo ratings yet

- 401Document7 pages401Justine Louise Bravo FerrerNo ratings yet

- The First Questionnaire Is For A Select Group, The Customers of Speedy PhotosDocument4 pagesThe First Questionnaire Is For A Select Group, The Customers of Speedy PhotosAastha PanditNo ratings yet

- 7 Steps To IPO SuccessDocument7 pages7 Steps To IPO Successprabhu sivaNo ratings yet

- 1291-Article Text-3043-1-10-20180308Document49 pages1291-Article Text-3043-1-10-20180308Achdian YusufNo ratings yet

- Fine Lawless Bibian Goodall Eng302 TeamreportDocument45 pagesFine Lawless Bibian Goodall Eng302 Teamreportapi-131293010No ratings yet

- GilletteDocument2 pagesGillettejazzloveyNo ratings yet

- Files 1673253509Document150 pagesFiles 1673253509Indri Wulandari99No ratings yet

- Procurement Basics TutorialDocument23 pagesProcurement Basics TutorialMeme Koka100% (1)

- UPD Manufacturing CaseDocument9 pagesUPD Manufacturing CaseNiña CastroNo ratings yet

- Assignment 8.1 Gerardo R. CabreraDocument5 pagesAssignment 8.1 Gerardo R. CabreraJerymar CabreraNo ratings yet

- BM - Decision Tree - SLDocument5 pagesBM - Decision Tree - SLEvandra Ramadhan Azriel SanyotoNo ratings yet

- Lecture 1 of Software ConstructionDocument115 pagesLecture 1 of Software Constructionp_123abcNo ratings yet

- Construction Materials Retail Price Index PrimerDocument2 pagesConstruction Materials Retail Price Index PrimerShai DelfinNo ratings yet

- EDI Inbount 850 OM AdvisorWebcast 2011 1018Document53 pagesEDI Inbount 850 OM AdvisorWebcast 2011 1018mandeep_kumar7721No ratings yet

- SME'sDocument92 pagesSME'sRana ToseefNo ratings yet

- Parle GDocument26 pagesParle GNikhil Vithaldas Kadam100% (1)

- Partner Code of Conduct ServicenowDocument5 pagesPartner Code of Conduct ServicenowAlex AeronNo ratings yet

- Chapter 19 - Continous ChangeDocument7 pagesChapter 19 - Continous ChangeAzael May PenaroyoNo ratings yet

- Managerial Frozen Poultry Products Food Term ReportDocument24 pagesManagerial Frozen Poultry Products Food Term ReportayeshawaseemNo ratings yet

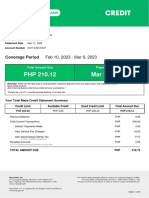

- MayaCredit SoA 2023MARDocument2 pagesMayaCredit SoA 2023MARJan SaysonNo ratings yet

- Internship ReportDocument60 pagesInternship ReportMd Khaled NoorNo ratings yet