Professional Documents

Culture Documents

Transformers

Transformers

Uploaded by

deeplah0 ratings0% found this document useful (0 votes)

8 views2 pagesTransformers

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTransformers

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesTransformers

Transformers

Uploaded by

deeplahTransformers

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

Transformer calculation sheet, by Manfred Mornhinweg

Input data: Iron: Center leg mm: 100 Design decisions:

Stack height mm: 150

Loss W/kg@1T,50Hz: 2

Primary V: 230

Secondary no-load V: 2000

Frequency Hz: 50

Prices:

Output data: Cross section mm2: 15000 Window area mm2: 7500

Turns per Volt: 0.3003 Av. turn length mm: 657.0796

Primary turns: 69.06907 Length m: 45.38388 mm2:

Secondary turns: 600.6006 Length m: 394.6424 mm2:

Input power VA: 9990

Power loss %: 2.965957

Voltage drop %: 1.57857

Loaded Vout: 1968.429

Required thermal transfer coefficient W/m2

Iron weight kg: 69.3

Copper weight kg: 17.60316

Cost $: 503.4106

$/W: 0.050391

Flux Density T: 1

mm2/A: 0.5

Fill factor: 0.4

Temperature rise K: 70

Iron $/kg 3.2

Copper $/kg 16

Copper area mm2: 3000

21.71739 Ampere: 43.43478

2.4975 Ampere: 4.995

Iron loss W: 138.6

Copper loss W: 157.6991

Total loss W: 296.2991

Surface area m2: 0.3154

thermal transfer coefficient W/m2K: 13.42056

7 is easy to get

Convection cooling up to 12

Strong fan up to 30

Oil up to 50?

You might also like

- Blair Exhaust I IDocument2 pagesBlair Exhaust I IRafael ReyesNo ratings yet

- ACSR Current Capacity CalculationsDocument4 pagesACSR Current Capacity Calculationschristophe_guntz100% (2)

- RCC DomesDocument3 pagesRCC Domesvaibhavamore0% (1)

- Lifting Analysis Sleeper FoundationsDocument28 pagesLifting Analysis Sleeper FoundationsSana Ullah100% (2)

- BS7870-4.10 33kv Single Core Un ArmouredDocument3 pagesBS7870-4.10 33kv Single Core Un Armouredrudypl100% (1)

- Sheet 1 (New)Document3 pagesSheet 1 (New)ahmed elbialyNo ratings yet

- Electrical Engineering Principles for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectrical Engineering Principles for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 3 out of 5 stars3/5 (4)

- Electronic Devices and Circuits: In Three VolumesFrom EverandElectronic Devices and Circuits: In Three VolumesRating: 3.5 out of 5 stars3.5/5 (2)

- Transformer DesignDocument9 pagesTransformer DesignHansraj AkilNo ratings yet

- Air Exchanger TDDocument9 pagesAir Exchanger TDRajput PratiksinghNo ratings yet

- 3 Introduction To Technical Loss of Power SystemDocument23 pages3 Introduction To Technical Loss of Power SystemاحمدعليNo ratings yet

- Beam Steel ContentDocument6 pagesBeam Steel ContentsongyanxinNo ratings yet

- RC Cheat SheetDocument3 pagesRC Cheat SheetMatthew ChinNo ratings yet

- F Mini™ Hec 75 Ohm Coaxial Cable Digital Broadband Drop CableDocument1 pageF Mini™ Hec 75 Ohm Coaxial Cable Digital Broadband Drop CableBenito CamelaNo ratings yet

- Two Adjacent Edges DiscontinuousDocument1 pageTwo Adjacent Edges DiscontinuousTim PassNo ratings yet

- Intake Well Bridge DesignDocument58 pagesIntake Well Bridge DesignAjayKumarMishra100% (1)

- CalculatorDocument15 pagesCalculatorYvonne TohNo ratings yet

- Perhitungan Lossess Dan Drop VoltageDocument3 pagesPerhitungan Lossess Dan Drop VoltagerudiNo ratings yet

- One Way / Two Way SlabDocument2 pagesOne Way / Two Way SlabHendra Ardi LesmanaNo ratings yet

- Designed By: Submitted ToDocument46 pagesDesigned By: Submitted To106 MOMENUL ISLAM KHAN 17No ratings yet

- Electrical Cable GuideDocument12 pagesElectrical Cable GuidesunilwadekarNo ratings yet

- Combine Footing DeasignDocument24 pagesCombine Footing DeasignSabir HussainNo ratings yet

- Circuit: Circuit1 (T1-C1-Q1) - CalculatedDocument2 pagesCircuit: Circuit1 (T1-C1-Q1) - Calculatedruhuna013No ratings yet

- ATG-1914 Crescent FlipNGripDocument3 pagesATG-1914 Crescent FlipNGripMahta SafrullahNo ratings yet

- Elecrical Installation and Maintenance NC Ii: Competencies Interpret Technical Drawing and PlanDocument12 pagesElecrical Installation and Maintenance NC Ii: Competencies Interpret Technical Drawing and PlanSharon AmigleoNo ratings yet

- PCV Cable-Current RatingDocument11 pagesPCV Cable-Current RatingalekyaNo ratings yet

- Combined FootingsDocument17 pagesCombined FootingsLove SemsemNo ratings yet

- Electrical DesignDocument141 pagesElectrical Designakppk1384No ratings yet

- Loads: Short Column With Axial LoadingDocument5 pagesLoads: Short Column With Axial LoadingMohd AftabNo ratings yet

- Electrical DesignDocument151 pagesElectrical DesignalekyaNo ratings yet

- Canal DesignDocument34 pagesCanal Designniranjan100% (2)

- Steel Composite 1 VERY GOOD MahfuzDocument5 pagesSteel Composite 1 VERY GOOD MahfuzLivian TeddyNo ratings yet

- Trafo Cable Sizing-12.5 MvaDocument1 pageTrafo Cable Sizing-12.5 Mvat_syamprasadNo ratings yet

- - transformer-design هات الأكسيل PDFDocument9 pages- transformer-design هات الأكسيل PDFAhmed Mohammed100% (1)

- Cant SlabDocument7 pagesCant Slabsantosh-a-biraj-3307No ratings yet

- FNDDocument3 pagesFNDSujan SinghNo ratings yet

- 50 Kva Distibution Transformer DesignDocument11 pages50 Kva Distibution Transformer DesignJemal MusaNo ratings yet

- Xple Low Voltage Cable Hal58 Nfa2x PDFDocument1 pageXple Low Voltage Cable Hal58 Nfa2x PDFAgung Tri PamungkasNo ratings yet

- 4 Design of Concrete Staircase 23052014Document1 page4 Design of Concrete Staircase 23052014Ahmad Badsha QuadriNo ratings yet

- Design of Pier: Type of Pier: Limit State Method Confirming To IS: 456-2000Document8 pagesDesign of Pier: Type of Pier: Limit State Method Confirming To IS: 456-2000iplogu100% (1)

- Hub Motor Design - 1200WDocument12 pagesHub Motor Design - 1200WPrince KumarNo ratings yet

- Design of DC MotorDocument24 pagesDesign of DC MotorRaja DesinguNo ratings yet

- Combined FootingDocument96 pagesCombined FootingVarad Sonawadekar100% (1)

- Nyfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesNyfgby 2 X (1.5-300) MM 0.6/1 KVRahul DevaNo ratings yet

- N2XBYDocument5 pagesN2XBYcyuenkNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- 1395085433hv and LV 1Document1 page1395085433hv and LV 1Solutions ElectricalNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1No ratings yet

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Modern Electrical Installation for Craft StudentsFrom EverandModern Electrical Installation for Craft StudentsRating: 4.5 out of 5 stars4.5/5 (4)

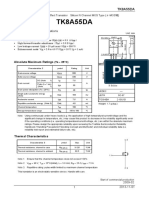

- DatasheetDocument6 pagesDatasheetVictor Javelosa Azuelo Jr.No ratings yet

- Service Manual: Color Television Chassis No. SN-70ADocument25 pagesService Manual: Color Television Chassis No. SN-70AVictor Javelosa Azuelo Jr.No ratings yet

- Sharp Ga1am Chassis cx34n3 PDFDocument44 pagesSharp Ga1am Chassis cx34n3 PDFVictor Javelosa Azuelo Jr.No ratings yet

- PanasonicDocument46 pagesPanasonicVictor Javelosa Azuelo Jr.No ratings yet

- Baofeng Uv-3r SCHDocument1 pageBaofeng Uv-3r SCHVictor Javelosa Azuelo Jr.100% (1)

- CG 818 ManualDocument44 pagesCG 818 ManualVictor Javelosa Azuelo Jr.40% (5)

- RRV2090 DV-515Document50 pagesRRV2090 DV-515Victor Javelosa Azuelo Jr.No ratings yet

- List of All Applicants: Center CodeDocument3 pagesList of All Applicants: Center CodeVictor Javelosa Azuelo Jr.No ratings yet

- Samsung k15d Chassis Ct21v10mnfxrclDocument40 pagesSamsung k15d Chassis Ct21v10mnfxrclVictor Javelosa Azuelo Jr.No ratings yet