Professional Documents

Culture Documents

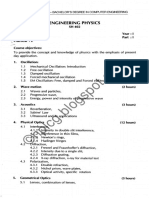

M 1 L 1

M 1 L 1

Uploaded by

baizubiraji0 ratings0% found this document useful (0 votes)

29 views4 pagesHh

Original Title

m1l1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views4 pagesM 1 L 1

M 1 L 1

Uploaded by

baizubirajiHh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

ar Mana for Water Supply Binet by Er Sey

EXPERIMENT NO.4

DETERMINATION OF OPTIMUM pOsk OF COAGULANT (JAR TEST)

APPARATUS REQUIRED

1. Floccutator

2. Jars

3. Pippottes

4, Measuring eytinders (10m!)

5. ‘Turbidimeter

6, Colorimeter

7. ‘Thermometer

8, pl meter 7

CHEMICALS REQUIRED

1.1% Alum [AL(80,)).181 0] solution

Buller solution (ptt 4)

3. Distilled water

THEORY

Coagulants and foe

suspended and colloidal pi

micals added to the water which help in removal of fin

1s. The colloidal particles are characteristically very small ang

and to the electrical charge

ion duc to both their small siz

main in continuous suspe

between particles.

the process of binding small particles in the water together

ino larger, heavier clumps which settle out relatively quickly. Coagulants neutralize the

Isive electrical charges (lypically negative) surrounding particles allowing them

creating clumps or larger particles. Flocculants facilitate the agglomeration of the

forming larger floccules and thereby, increases gravitational setlng.

-ve a dual purpose of both coagulation and flocculation in that they create

repu

togethe

congulated particles

Some congulants s

large floes that readily settle,

‘The coagulant required for treating water, termed as dosage of coagulant, depends upon the

characteristics of water, The dose of coagulant increased the residual turbidity improved. Itis

important to note that the optimum coagulant dose is the dose which meets the specified

turbidity required on the regulatory permit, The addition of excess coagulant may reduct

is required but also could lead to the production of more sludge which

turbidity beyond what

would require disposal

‘The jar test isu ermine the optimum dose of coagulant required at the operating

conditions for water or wastewater. This method helps to predict the functioning of a le?

scale treament operation on a small scale. A jar test simulates the coagulation

that encourage the removal of suspended colloids and organic mate?

flocculation processes th

which can lead to turbidity, odor and taste problems.

12

a Labs, Manual for Water Supply Engineering by ler. Sichu Shrestha

April 19, 2009

‘qhe first step of the jar test involves

ater rapidly (in the flash mix chamts

adding coagulant to the so

luree water and mixing the

he coagulant in the wate

flocculation ba

Finally, the mixer is

imentation basin), In case of

Is upon the type of source water. For

wed to perform jar tests frequently as

very'little turbidity to remove and is

water conditions. Surface water plants,

susceptible to sudden changes in water

to adjust the coagulant dosage and deal with the changing

Particles to cluster together.

ul (as in case of

vater treatment plant, frequency of jar test depen

example, plants which treat groundwater may not in

compared to surface water. Groundwater may have

unlikely to be affected by weather-related changes in

reeds (0 treat water with a high turbidity which is

J quality, especially after rains,

source Water turbidity.

rpm gauge

Flocculator used in Jar Test

ifferent sources of water need different coagulants, but the most commonly used are alum

and ferric sulfate, Aluminum Sulfate is also known as alum, filter alum, and alumina sulfate,

lum is the most widely used coagulant. Alum is available in dry form as a powder or in lump

form or liquid solution. It reacts in presence of alkalinity (optimum range of pH is 6.5 to 8.5).

The reactions obtained are as below.

ity then the reaction will be (without addition of soda ash)

Ip (SO4)3.18 H20 + 3 Ca(HCOs), —*» — 2AI(OH)3 } 3 CaSO, + 6CO2 + 18 H20.

lum ‘Natural Alkalinity Floc

Floc

13

—AI(OH)s } Na2SO4+ 18 H20

apply Engineering DY ES,

ab Manat for Water St Sey

: Ait

Pmt

1

2 3. CaSO. HIB ELO.

With addition of tim AION |

Al; ($04)3.18 10 #3 Ca(OIDs Bloc ’

‘Alum Lime

Fi i Ki 4 ity of n water Sa

eae cee Temperature, Cotor and Turbidity of ve

Take sO0ml to 1000 ml of water summple (#8 P oy 4

6) , in [

Le See tg Jum is placed on measuring cylinders on side of jars, 5

. Following dose of 1 % alum is |

Tai) per 500 ml of | Concentration I

eae | (mg/l) f

«

Switch on the flocculator ;

Supply the prepared alum dose into the jars at the same time

7. ‘When stiri intially at the speed of 60-80 rpm for | 10 2minutes then at 1510 20pm for

al properties of the water sampl

best floc formation and the sample without add

so that the floc get

rom the ja

ion of coagu

c settled,

having good- better othe

nt.

OBSERVATION

Characteristic of water sample after addition of Alum

see Mee eee |

(NTU)

1

|

3

i

5

6 Loe "

“Record floc formation characteristic a Worse, Poor,

sample indicates poor coagulation, P

Good, Better Best. 0 hazy

formed and dense, with the liquid bety

roperly coagulate

ulated \ floc particles that are well-

ween the particles cle:

megenss

14

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- New Doc 2019-07-21 20.36.52 - 306718157612419146997Document1 pageNew Doc 2019-07-21 20.36.52 - 306718157612419146997baizubirajiNo ratings yet

- CentrsDocument1 pageCentrsbaizubirajiNo ratings yet

- Knowledgeandwi SdomDocument28 pagesKnowledgeandwi SdombaizubirajiNo ratings yet

- Core PrinciplesDocument8 pagesCore PrinciplesbaizubirajiNo ratings yet

- New Doc 2019-04-12 08.43.20 - 61117126522117891130Document1 pageNew Doc 2019-04-12 08.43.20 - 61117126522117891130baizubirajiNo ratings yet

- Chapter 1 Slide 1Document21 pagesChapter 1 Slide 1baizubirajiNo ratings yet

- RDP Highway Drainage PDFDocument5 pagesRDP Highway Drainage PDFbaizubirajiNo ratings yet

- 113 3 Fluid FlowDocument3 pages113 3 Fluid FlowbaizubirajiNo ratings yet

- Tension Member: 5.1 Types of Tension MembersDocument6 pagesTension Member: 5.1 Types of Tension MembersbaizubirajiNo ratings yet

- 6 Highway MaterialsDocument10 pages6 Highway MaterialsbaizubirajiNo ratings yet

- Surface Irrigation: Design PrinciplesDocument14 pagesSurface Irrigation: Design PrinciplesbaizubirajiNo ratings yet

- Limit State DesignDocument4 pagesLimit State DesignbaizubirajiNo ratings yet

- 1st Assessment QuestionDocument13 pages1st Assessment QuestionbaizubirajiNo ratings yet

- 03.9407317revised NoticeDocument1 page03.9407317revised NoticebaizubirajiNo ratings yet

- 13 4828626centersDocument1 page13 4828626centersbaizubirajiNo ratings yet

- Kec TheoryDocument7 pagesKec TheorybaizubirajiNo ratings yet

- 01.7286927msc 1 - 2Document1 page01.7286927msc 1 - 2baizubirajiNo ratings yet

- 40 6630513retotalingDocument1 page40 6630513retotalingbaizubirajiNo ratings yet

- Hydrology Dolalghat FieldDocument20 pagesHydrology Dolalghat FieldbaizubirajiNo ratings yet

- Institute of Engineering Kantipur Engineering College Civil Engineering Department Survey Camp 2075Document2 pagesInstitute of Engineering Kantipur Engineering College Civil Engineering Department Survey Camp 2075baizubirajiNo ratings yet

- Gales TableDocument8 pagesGales TablebaizubirajiNo ratings yet