Professional Documents

Culture Documents

Exp - S2 - Packed Bed Distillation

Uploaded by

Anuj SrivastavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp - S2 - Packed Bed Distillation

Uploaded by

Anuj SrivastavaCopyright:

Available Formats

CHEMICAL ENGG GROUP

PACKED BED DISTILLATION

PACKED BED DISTILLATION

CHEMICAL ENGG GROUP

PACKED BED DISTILLATION

AIM:

To determine the number of theoretical plates equivalent to packed column height

(HETP) using Fenske’s equation.

THEORY:

Packed bed columns are often used for distillation, liquid-liquid extraction and

humidification, as well as for gas absorption. For distillation, the gas phase is continuous

and the liquid phase flows in rivulets over the packing. A packed tower can be used as a

fractionating column for either continuous or batch distillation. The column height is

usually based on the number of theoretical plates and the height equivalent to a

theoretical plate (HETP). In most cases the upper operating line is slightly steeper than

the equilibrium line and the reverse is for the lower operating line. The pressure drop per

equivalent theoretical plate is generally less that that for a sieve or bubble cap tray, which

is an important advantage for vacuum operation. The smaller packing has lower values of

HETP but they also have lower capacity and are not likely to be used in large columns

Packed distillation towers can often be operated over a moderate range of flow

rate at nearly constant separation efficiency. As the capacity parameter increases both the

liquid rate and vapor rate increase because of which HETP is nearly constant. The HETP

decreases in the loading region because of the more rapid increases in liquid hold up and

wetted area, but it then decreases sharply as flooding is approached. With this high

capacity packing, the rise in HETP is believed to be due to the entrainment of the liquid.

Structured sheet metal packing give slightly better separation than dumped packing and

the HETP values are nearly constant over a three to four fold range of flow rates. The

more efficient are the gauze type packing. The gauze is completely wetted even at low

flow rates and then HETP can be predicted from fundamental equations of mass transfer

in wetted channels. Low surface tension tends to increase the wetted area but too low

values may lead to foaming which increases HETP.

PACKED BED DISTILLATION

CHEMICAL ENGG GROUP

PROCEDURE:

Preparing calibration chart:

1. Mix known volume of cyclohexane-toluene (1:0, 1:10, 2:10, 3:10, 4:10, 5:10,

6:10, 7:10, 10:12, 10:10, 10:8, 10:6, 10:4, 10:2, 10:1, and 0:1 ml)

2. Determine refractive index (RI) of the mixture by using refractometer.

3. Determine RI of pure cyclohexane and toluene at room temperature.

4. Convert the volume fractions to mole fractions of cyclohexane (more volatile

components).

5. A plot of RI (Y axis) versus mole fraction of cyclohexane (X axis) is the required

calibration curve.

If RI is known, mole can be obtained from the calibration chart.

Experiments:

1. Feed the SS steal tank with 150 ml cyclohexane and 150 ml of toluene.

2. Allow water to pass through the condenser.

3. Switch on the heater and heat the mixture.

4. Operate the packed bed at total reflux till steady temperature is achieved.

5. Collect the top product from the distillate tank and the bottom product from the

residue tank.

6. Switch off the heater and cool the apparatus.

7. Determine the density/refractive index of both residue and distillate.

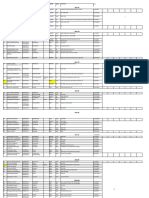

OBSERVATIONS AND CALCULATIONS:

Room temperature = ……………. 0C

Observation Table:

Temperature of Distillate Temperature of Residue

S. No. Time (min)

(oC) (oC)

At steady state,

PACKED BED DISTILLATION

CHEMICAL ENGG GROUP

Refractive index of cyclohexane = μc = ………….

Refractive index of toluene = μt= ………….

Moles of feed, F

V A * m V *

B w

M A Cyclohexane M B Toluene

MA= Molecular weight= 84.16 g/mol

MB = Molecular weight= 92.14 g/mol

Density of Cyclohexane= 0.779 g/cc

Density of Toluene = 0.867 g/cc

V A * m

M A Cyclohexane

Mole fraction of cyclohexane, xF

V A * m V *

B w

M A Cyclohexane M B Toluene

PACKED BED DISTILLATION

CHEMICAL ENGG GROUP

Mole fraction of cyclohexane in distillate, xD = …………….. (from calibration chart)

Mole fraction of cyclohexane in residue, xR = …………….. (from calibration chart)

Cyclohexane

Molecular weight: 84.16 g/mol

log PmmHg = 6.8413 – [1201.53/(222.65+T)] where, T is in 0C

Toluene:

Molecular weight: 92.14 g/mol

log PmmHg = 6.95464 – [1344.8/(219.482+T)] where T is in 0C

PACKED BED DISTILLATION

CHEMICAL ENGG GROUP

Determination of number of theoretical plates:

1) Fenske’s equation

x D (1 x R )

log

(1 x D ) x R

Nm 1

log avg

yD= (PA * xD )/ PT1

PT1 = xd*PA1+PB1*(1-xd)

where A1= cyclohexane in the distillate

B1 = toluene in the distillate

yR= (PA * xR )/ PT2

PT2 = xr*PA2+PB2*(1-xr)

where A2= cyclohexane in the residue

B2 = toluene in the residue

y D (1 x D )

Relative volatility of distillate D

x D (1 y D )

y R (1 x R )

Relative volatility of residue R

x R (1 y R )

Average volatility ang D R

Calculate Nm+1=……..

Height of packed bed, Z = 60 cm

HETP × Nm = Z

PACKED BED DISTILLATION

CHEMICAL ENGG GROUP

HETP = Z/Nm = ………cm

Conclusions:

The number of theoretical plates required at total reflux = ................

The Height equivalent to theoretical plate (HETP) is ................cm.

PACKED BED DISTILLATION

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- VLE Curve for Cyclohexane-Toluene MixtureDocument6 pagesVLE Curve for Cyclohexane-Toluene MixtureAnuj SrivastavaNo ratings yet

- CML Assignment 2Document6 pagesCML Assignment 2SimoneLouiseXXNo ratings yet

- 1031 1192105956 13 202109 FGH F Torque Converter Erosion Jory For Cep - PDF 51376613 v1Document7 pages1031 1192105956 13 202109 FGH F Torque Converter Erosion Jory For Cep - PDF 51376613 v1Jesús SarriaNo ratings yet

- DECONTAMlNATlON KIT, INDIVIDUAL EQUIPMENTDocument30 pagesDECONTAMlNATlON KIT, INDIVIDUAL EQUIPMENTChuck AchbergerNo ratings yet

- Exp - S1B - Vapor in Air DiffusionDocument11 pagesExp - S1B - Vapor in Air DiffusionAnuj SrivastavaNo ratings yet

- Exp - S9 - Rotary Vacuum Drum FilterDocument8 pagesExp - S9 - Rotary Vacuum Drum FilterAnuj SrivastavaNo ratings yet

- Basket Centrifuge ExperimentDocument4 pagesBasket Centrifuge ExperimentShivangi PancholiNo ratings yet

- Exp - S8B - Froth FloatationDocument3 pagesExp - S8B - Froth FloatationAnuj SrivastavaNo ratings yet

- Exp - S10A - Forced Draft Tray DryerDocument6 pagesExp - S10A - Forced Draft Tray DryerSenthilNathanNo ratings yet

- Exp - S8A - Plate and Frame FiltersDocument5 pagesExp - S8A - Plate and Frame FiltersAnuj SrivastavaNo ratings yet

- Exp - S6 - CrushersDocument14 pagesExp - S6 - CrushersAnuj SrivastavaNo ratings yet

- Exp - S1A - Solid in Air DiffusionDocument7 pagesExp - S1A - Solid in Air DiffusionAnuj SrivastavaNo ratings yet

- Exp - S4 - Mass Transfer With and Without Chemical ReactionDocument10 pagesExp - S4 - Mass Transfer With and Without Chemical ReactionAnuj SrivastavaNo ratings yet

- Vacuum Tray Dryer CharacteristicsDocument6 pagesVacuum Tray Dryer CharacteristicsAnuj SrivastavaNo ratings yet

- SiriDocument284 pagesSiriAnuj SrivastavaNo ratings yet

- Exp - S3 - Pacekd Bed AbsorptionDocument8 pagesExp - S3 - Pacekd Bed AbsorptionAnuj SrivastavaNo ratings yet

- CashlessConsumer - UPI Applist, Issuer PSP List, VPAs, StatsDocument25 pagesCashlessConsumer - UPI Applist, Issuer PSP List, VPAs, Statsphone2hireNo ratings yet

- HVAC Specs NewDocument57 pagesHVAC Specs NewMohamed ElmohamedyNo ratings yet

- Selecion de Fusibles para Proteccion de TransformadoresDocument14 pagesSelecion de Fusibles para Proteccion de TransformadoresfreddyriveraNo ratings yet

- Essay QuestionsDocument5 pagesEssay QuestionsMark Imperio100% (1)

- Copper-Brazed Steel Tubing: Standard Specification ForDocument4 pagesCopper-Brazed Steel Tubing: Standard Specification ForMartuaHaojahanSaragihSidabutarNo ratings yet

- Palm Beach County Property Appraiser PTO Balance Report 4-30-2012Document7 pagesPalm Beach County Property Appraiser PTO Balance Report 4-30-2012LynnKWalshNo ratings yet

- Types of Steam BoilersDocument6 pagesTypes of Steam BoilersAbelNo ratings yet

- Coordinate Computation: Calculating Length, Bearing, Angles and CoordinatesDocument13 pagesCoordinate Computation: Calculating Length, Bearing, Angles and CoordinatesYoussif SedeakNo ratings yet

- Fargo Inc. Payroll Processor Payroll ProcessorDocument4 pagesFargo Inc. Payroll Processor Payroll ProcessorrexziegenNo ratings yet

- Solved Problems On Transistor Audio Power AmplifiersDocument10 pagesSolved Problems On Transistor Audio Power Amplifiersgowri thumburNo ratings yet

- Brickwork and Stonework SupportDocument20 pagesBrickwork and Stonework SupportSanel GrabovicaNo ratings yet

- 54LS138/DM54LS138/DM74LS138, 54LS139/DM54LS139/DM74LS139 Decoders/DemultiplexersDocument8 pages54LS138/DM54LS138/DM74LS138, 54LS139/DM54LS139/DM74LS139 Decoders/DemultiplexersakulNo ratings yet

- Service Copy NewDocument86 pagesService Copy NewSKS MOTERS DEVARA HIPPARGINo ratings yet

- Release of RTR Exam Schedule at Chennai, New Delhi, Hyderabad and Kolkata Centres For The Year 2022 - 0Document19 pagesRelease of RTR Exam Schedule at Chennai, New Delhi, Hyderabad and Kolkata Centres For The Year 2022 - 0Abhinav RawatNo ratings yet

- GE - LV Cable and BusductDocument36 pagesGE - LV Cable and BusductaimizaNo ratings yet

- Data Models and Business RulesDocument60 pagesData Models and Business RulesJM RosaldesNo ratings yet

- Precision 6T70 Parts Catalog 2024Document4 pagesPrecision 6T70 Parts Catalog 2024Альфир АптикаевNo ratings yet

- Acoustic sciences corp designs revolutionary soundproof roomDocument1 pageAcoustic sciences corp designs revolutionary soundproof roomAcoustics GlobalNo ratings yet

- The 4 Ms of OperationDocument14 pagesThe 4 Ms of OperationGodwill Jireh L. Patindol100% (7)

- En 14511-3Document92 pagesEn 14511-3Krittapas WorapimratNo ratings yet

- Dynamic System Analysis Installation and User's Guide: IBM SystemsDocument62 pagesDynamic System Analysis Installation and User's Guide: IBM SystemsKamalkant YadavNo ratings yet

- ConectadosDocument136 pagesConectadosAnonymous 5J2qhNEeNo ratings yet

- Create DDL Schema of Particular Table To A FileDocument3 pagesCreate DDL Schema of Particular Table To A FileUpender ThatishettiNo ratings yet

- Chaotic Image Encryption Techniques: A Project Seminar OnDocument31 pagesChaotic Image Encryption Techniques: A Project Seminar OnNilesh BhoyarNo ratings yet

- Abb KatalogeditDocument60 pagesAbb KatalogeditSherinSyafarinaSuryanaNo ratings yet

- Engineer InstrumentationDocument4 pagesEngineer InstrumentationmangeshjoNo ratings yet

- Steam Flow Through Safety Valve Vent PipesDocument11 pagesSteam Flow Through Safety Valve Vent PipesminhphuongphamNo ratings yet