Professional Documents

Culture Documents

BLN 9630 PDF

BLN 9630 PDF

Uploaded by

HOryshor0 ratings0% found this document useful (0 votes)

54 views40 pagesOriginal Title

bln-9630.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

54 views40 pagesBLN 9630 PDF

BLN 9630 PDF

Uploaded by

HOryshorCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

TABLE OF CONTENTS

DESCRIPTION

CONFIGURATION: PUMPS AND MOTORS

Heavy Duty Series and Types

Configuration: Pumps and Motors

Specifications and Requirements

CONFIGURATION: CONTROLS

Manual Displacement Control

Manual Displacement Control with Pressure Override

Neutral Start Switch

Hydraulic Displacement Control

Electric Displacement Control

Manual Variable Pressure Control

Hydraulic Variable Pressure Control

Manual Displacement Motor Control

Rotary By-Pass Valve

MAINTENANCE INFORMATION

Fluids

Start Up Procedure

System Maintenance

BASIC OPERATION: HYDROSTATIC TRANSMISSION

Axial Piston, Slipper Pad Design

Tilting Swashplate

Hydrostatic Transmission

BASIC OPERATION: HYDRAULIC SUPPORT SYSTEM

Basic Closed Circuit

Case Drain and Heat Exchanger

Charge System and Inlet Filter

System Relief Valves

Cooling Circuit

Charge Pressure

VARIABLE PUMP-FIXED MOTOR FLOW SCHEMATIC

TROUBLE SHOOTING

Gauge Installation and Information

Neutral Difficult or Impossible to Find

System Operating Hot

‘Transmission Operates in One Direction Only

‘System Response Is Sluggish

‘System Will Not Operate in Either Direction

Inspect Manual Displacement Control

Inspect System Relief Valves

Inspect Shuttle Valve

Inspect Charge Check Valve

Inspect Pump Charge Relief Valve

Inspect Motor Charge Relief Valve

CONTROL ADJUSTMENTS

Manual Displacement Control

‘Spool Centering

Centering Spring

Electric Displacement Control (EDC) and Hydraulic Displacement Control (HOC)

Hydraulic Displacement Control (Crawler Style)

Manual Variable Pressure Control

Maximum Pressure Adjustment

Page 1

PAGE

© OOO BO@BYNVNOOOUTR SDS EOOOD

TABLE OF CONTENTS — CONTINUED

DESCRIPTION

Hydraulic Variable Pressure Control

Maximum Pressure Adjustment

Pressure Override

Maximum Pressure Adjustment

Manual Displacement Motor Control

Control Adjustment

Conversion of a Pump Displacement Control

Motor Pressure Compensator Control

Shift Pressure Adjustment

MINOR REPAIRS

Shaft Seal

Manifold Assembly Components

System Relief Valve

Shuttle Valve

Charge Relief Valve

Motor Manifold

Charge Pump and Charge Check Valves

Control

Pressure Override

Neutral Start Switch Replacement

Neutral Start Switch Check

GENERAL PARTS IDENTIFICATION

Model Number

Serial Number

Parts Kit

Variable Displacement Pump

Variable Displacement Motor

Fixed Displacement Motor

METRIC CONVERSION CHART

Page 2

888888

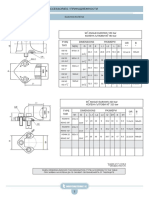

CONFIGURATION: PUMPS AND MOTORS

Heavy Duty Series and Types

The Heavy Duty Family of units consists of eight (8)

different frame sizes (20 through 27 Series). Pumps and

motors of different series (displacements) can be

combined to meet the requirements of a variety of

applications.

Within each series of the Heavy Duty Family of units there

are three (3) configurations available: Variable

Displacement Pumps, Fixed Displacement Motors, and

Variable Displacement Motors.

‘The Variable Displacement Pump can be operated with

fixed or variable input speeds and provides an infinitely

variable output flow between 0 and maximum flow in either

direction. A variety of controls are available for the Variable

Displacement Pumps and Motors which are described on

the following pages.

‘The Fixed Displacement Motor can be operated in either

direction of rotation with infinitely variable output speeds

between its 0 and maximum speed.

The Variable Displacement Motor provides a means for

varying the motor output speed and torque range.

“ee "=" Decreasing displacement results in higher output speed

and lower output torque,

Specifications and Requirements

‘Sauer-Sundstrand Heavy Duty Hydrostatic transmissions

have certain pressures that must be maintained as well

as some requirements and limitations which must be

observed

SPECIFICATIONS SYSTEM REQUIREMENTS

‘Maximum | Max ‘Charge

Model| Displacement | Recommended | Speed Pressure’ | 190-210 Psi | 13-18 BAR,

Working |@ Max (Neutra)

Pressure’ _ | Disp. = -

mney. [ocirev| pst | Ban | (RPM) Freasre | 160-190S1 | 11-125 BAR

‘orward or

2_| 203 | 332 | 000 | 345 | 3.800 =

2 315 | 816 | 6.000 | 345 | 3.500 ase

i} 313 | S18 t soto | 3 | 8 a

35 sas Teo] S000] sas [2.900 Th sme | ao tn ty Max. | 0.7 BAR abs)

24_| 724 | 116.6 | 5.000 | 345 | 2,700. am Ta EGH ncaa.

25-[ roe Lies 8 | S000] sas 2.400 Suction Heron Nominal, No Bypass

26_| 13.87 | 2273 | 5.000_| 345 | 2.100

27_| 2036 | 3336 | 5.000 | 345 | 1.900

*Operation of Series 20 units at 6000 PSI (414

BAR) maximum pressure requires the use of welded

(nor-filled) pistons.

* Above case pressure, Some units may have special

charge pressure settings. Consult machine

specifications.

“Measured at charge pump inlet. (May be exceeded

during cold weather start up)

Page 3

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Pumps Motors and Other Remanufactured Hydraulic Components PDFDocument16 pagesPumps Motors and Other Remanufactured Hydraulic Components PDFHOryshor100% (1)

- HYdrosila Obshij EngDocument8 pagesHYdrosila Obshij EngHOryshorNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Omg80cccceng A 03-1Document64 pagesOmg80cccceng A 03-1HOryshorNo ratings yet

- Brochure by-Pass-Units 20160216 enDocument36 pagesBrochure by-Pass-Units 20160216 enHOryshorNo ratings yet

- Hidraulica Industrial - Catalog Cilindri HidrauliciDocument41 pagesHidraulica Industrial - Catalog Cilindri HidrauliciHOryshorNo ratings yet

- Kinshofer Rotator Line Product FeaturesDocument5 pagesKinshofer Rotator Line Product FeaturesHOryshorNo ratings yet

- F9300 en 0817Document6 pagesF9300 en 0817HOryshorNo ratings yet

- NeB Catalogo2017 PDFDocument108 pagesNeB Catalogo2017 PDFHOryshorNo ratings yet

- Indtechnic AccessoriesDocument6 pagesIndtechnic AccessoriesHOryshorNo ratings yet

- HDSD Mig OTC DM350 PDFDocument72 pagesHDSD Mig OTC DM350 PDFHOryshorNo ratings yet