Professional Documents

Culture Documents

DIN 766 - Lanci PDF

Uploaded by

jovica37100%(1)100% found this document useful (1 vote)

288 views4 pagesOriginal Title

DIN 766 - Lanci.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

288 views4 pagesDIN 766 - Lanci PDF

Uploaded by

jovica37Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

UDC 672.61-034.14 : 620.1 DEUTSCHE NORM January 1986

Calibrated and tested grade 3

round steel link chains

Rundstahlketten; Giteklasse 3, lehrenhaltig, geprift ‘This standard, together

with DIN 32891, June 1980 edition,

supersedes DIN 766, July 1954 edition,

In keeping with current practice in standards published by the International Organization for Standardization (ISO),

a comma has been used throughout as the decimal marker.

In clause 5, this standard includes safety requirements within the Gerdtesicherheitsgesetz (Equipment Safety Lawl.

Start of validity

This standard is valid from 1st January 1986.

‘This standard has been prepared in cooperation with the Hauptverband der gewerblichen Berufsgenossenschaften,

Zentralstelle fir Unfallverhitung und Arbeitsmedizin (Federation of Industrial Employers’ Liability Insurance

Associations, Central Office for Accident Prevention and Occupational Medicine), Bonn.

Dimensions in mm,

1. Scope and field of application

‘This standard applies to calibrated and tested grade 3 round steel link chains and

specifies their dimensions and mechanical properties.

Chains as specified in this standard are used in all branches of industry.

Before use it shall be checked whether the chain is test-stamped,

DIN 5684 Part 1 to Part 3 shall apply with regard to chains for power driven lifting

appliances

Chains as specitied in DIN 32891 shall be used for sling chains conforming to DIN 696.

Continued on pages 2 to 4

‘Seutn Verlag GMBH, Bein 0, as excunv ale aria for German Standards (Norman) DIN 766 Engl. Price group 5

06.86 ‘Sales No. 0105.

Page 2. DIN 766

2. Dimensions, designation

et 2

(—OF

aaa 7

ft

Designation of a grade 3 round stee! link chain of nomi

finish (bk

Figure 1

al diameter (size) *) d = 13 mm and pitch f= 36 mm, bright

Chain DIN 766 — 3 — 13 x 36 bk

Table 1. Dimensions and masses

7

Pitch Mi) Gauge lengthof 11 Xt1) |

inside | outside Mass

d t by be

a ' kaim

site | yP%., permit ens | sini | Maxim | romani ceavons | *2!

as emer | eee feeeeasg erate eral | ence | iva ed | erro | ero |

s | io2 | 15 | sce | o2 | 6 | a7 | 2005] fo. | “es | os

ef osor [tes | tee | cos | t2 | aoe | aoas | ios | ces | os

7 | sos | 2 | soe j -o2 | 94 | 238 | 22 | vs | -os | ta

8 os | 2 | tes | <2 | 96 | 272 | 26 | fiz | coe | ta

o | foe | 27 | tes | cos | we | aoe | as | fas | cer | 48

10 ze | ses | -os | 12 | 26 | oop | +m | -ar | 20

" a1} tes | -os | is2 | 40 | a | fis | con | 27

a3 | tos | a0 | toe | cos | ise | 47 | 300 | car | ceo | 39

| coe | at | ver | vee | 50 | 41 | ve | - aa

folate faeces ieraolaal bean es | co Pees || on

48 | tor | 50 | tee [are | 6s | ss | tas | cua | ra

2) se fs: | -o | a | v2 | oe | va °

268 | eee cote |[atect es aera (erect orca (afaoked (baroa\ ele 2

26 213 73 | sae os | 32 94 eos | las 15

28 ea me | ans -os | 336 | tor | 858 | +36 a 18

go | tis | ee | tie | ler | a6 | toe | ove) ces | can | 20

a2 | sie | 90 | tis | cor | ae4 | ats | 990 | cas | caa | 28

SoBe ieee |eiorpal ees a2 [wo fan | + -as | 29

40 | 42 N2 +19 48 144 1232 -28 35

foaled eee ee (ee ele so | ist | tae | vse | -3 | 40

**) Per. dev. = permissible deviations,

1) Perfect meshing ofthe chain and chain whee! is ensured it the toothed chain wheel Is made available to the

chain manufacture.

3. Material

‘Stee! as specified in DIN 17 115, type at the manufac:

turer's discretion; minimum quality: USt 35-2

4 Finish

‘The standard surface finish shall be bright (bk)

Other types of finish shall be subject to agreement.

5 Safety requirements

‘The chains shall be heat treated and shall meet the

requirements specified in DIN 685 Part 2.

The dimensions of the chains shall be within the tole

ances given in table 1

Diameter d, of the area affected by welding shall not be

tess than the size (and shall not exceed the latter by

more than 7.5%. The weld points shall be positioned in

the centre of the legs of the chain link, and shall not

‘exceed a length a corresponding to the size.

‘The chains shall reach the values given in table 2 with

‘regard for loadbearing capacity, manufacturing test force

‘and breaking force and deflection f, and those given in

table 3 for the total ultimate elongation.

*) The size of the chain corresponds to the nominal

diameter (d) of the steel bar from which the chain

is made.

‘Table 2. Mechanical properties depending on si

DIN 766 Page 3

“The values given in table 2 are based on the values given

in table 3,

‘The requirements of DIN 685 Part 3 shall apply for in

If agreed upon, acceptance inspection may include the

dimensional check, tensile test and bending test as

Any ather tests shall be agreed at the time of ordering

‘The specifications of DIN 685 Part 4 shall apply for

In addition, the chains of each unit supplied shall be

7 Test stamp of chain

manufacturer as specified

in DIN 685 Part 4

| Size of chain,

[A test certificate conforming to DIN 685 Part 4 shall be

‘The specifications of DIN 685 Part 5 shall apply for the

treatment during use, inspection and maintenance of the

tae | Minima | rca | win

a sel

ee sin Tr getection In-process control

ta) | P| test force t

ka kN KN

process control

4 200 3

5 320 4

4

a i ues 7 Acceptance inspection

7 630 | 6

8 800 7

8 | 1000 7 specified in DIN 685 Part 3.

to | 1250 32 0 8

a1 | 1600 40 6 8

13, | 2000 50 0 n

Fafa etc coos teen os aa Pon ‘2 | 8 Identification marking

16 | 3200 80 125, 13

18 | 4000 | 100 160 15 marking

20 | 5000 | 125 | 200 16

zs | e900 | 120 | 250 3 provided with a white triangular tag (see figure 2}

26 | 8000 | 200 | 320 2

ze | 10000 | 250 | 400 23 F

3o | i120 | 280 | 450 24

32 | 12500 | 320 | 500 28 { \

[ae | 16000 | «00 | 60 | 29

40 | 20000 | 500 | 800 32

42 | 22400 | 560 | 200 34 |

Table 3. Mechanical properties

Figure 2

Mean stress at working

oad limit ia Q

Stress at manufactur i

test force ° imme 200 9 Test certificate

Stress ata specie > iesued.

breaking force edie aay

Ratio of mean stress at

working load limit to stress 10 Use

at manufacturing test force 1:25:24

to strass at a spocitied

breaking force | on

Minimum total

tutimate elongation cea

Deflection mm 1x 08d

Standards referred to

DIN 685 Part2 Tested round steel link chains; safety requirements

DIN 685 Part Tested round ste! link chains: testing

DIN 688 Part 4 Tested round steel link chains; marking, test certificate

DIN 685 Part 5 Tested round stel link chains; use

DIN 695 Round steel link chains; hook-ended slings, ring-ended slings

DIN 5684 Part 1 Calibrated and tested round steel ink chains for lifting purposes; grade 6

DIN. 5684 Part 2 Calibrated and tested round steel link chains for lifting purposes; grade 6

You might also like

- Нису пронађени резултати за dasdafsf df sdsd f: dasdafcfdfsdsdfDocument5 pagesНису пронађени резултати за dasdafsf df sdsd f: dasdafcfdfsdsdfjovica37No ratings yet

- Recnik Masinske TehnikeDocument3 pagesRecnik Masinske Tehnikejovica37No ratings yet

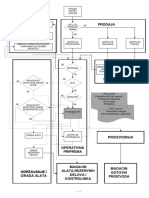

- Algoritam Proizvodnje PDFDocument5 pagesAlgoritam Proizvodnje PDFjovica37No ratings yet

- Metric Bolt and Cap Screw Torque Values PDFDocument3 pagesMetric Bolt and Cap Screw Torque Values PDFjovica37No ratings yet

- GGHHHDocument3 pagesGGHHHjovica37No ratings yet

- TTRRRRDocument4 pagesTTRRRRjovica37No ratings yet

- CXCXCXCCDocument16 pagesCXCXCXCCjovica37No ratings yet

- HHHJJKKDocument2 pagesHHHJJKKjovica37No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)