Professional Documents

Culture Documents

Industrial Maintenance 2nd Edition (By Jeffrey A. Clade and Michael Brumbach)

Uploaded by

Elwy Mustafa50%(24)50% found this document useful (24 votes)

4K views685 pagesIndustrial Maintenance

Original Title

Industrial Maintenance 2nd Edition (by Jeffrey a. Clade and Michael Brumbach)

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document50%(24)50% found this document useful (24 votes)

4K views685 pagesIndustrial Maintenance 2nd Edition (By Jeffrey A. Clade and Michael Brumbach)

Uploaded by

Elwy MustafaYou are on page 1of 685

Industrial

Maintenance

Second Edition

i)

Industrial

Maintenance

SECONOMUITION

bbe

MICHAEL E. BRUMBACH

AND

JEFFREY A. GLADE

‘y DELMAR

Industral Maintenance. 3€

Michal. Brumbach, Jetey A. Clade

Director of Learning Saltions: Sand

irk

NanagngEetor Larry in

Senior Product MaragerjohnFisher

Director, Market Development

Management Debbe Yarnell

Marking Develoment Manager

rs Srennan

Director, Brand Management jason

‘alos

Marketing and Manager: Gin MeNlary

Senor Predction Director. Wendy

Treoger

Production Manager: Mark Semana

Senior ar Drect David Arsenault

Technelogy Project Manager: joe Piss

(© 203, 2098 Delmar, Cngage Leaning

wen: 02:200-208

ALL RGHTS RESERVED No part ins work covered y thecorgh hatch

‘vay reproduced trarsmitta, stored, erueedin an formar oy any msene

[raphe elton or macharea ielising ot mines ie nhetorenyne.

‘ecoréng, scanning, digelangcapirg, Wea cstrbutin,infermation networks

Section 1O7or 1 the 1976 Un tad States Copylant Act without the

For oduct informatien and techrology assistance, contact usa

Cengage leaning Customer & Sales Seppor., 1 860°354-9706

For permission tose materia fromithistext or prec,

ter oh eee olin premrsencnccern fern

Further germisions questone cin be malig ta

Ppermissonrequesnscengage.com

Mcroiot a elteedtradaarkof the Mltesoft Cxpoition,

SON: 97e BRITS

SAN 0:1-98:1319.0,

Delmer

Cliton Park NY 20652919

Usa

Cengeg Letrning fa leading proviserofcustoninesiearng solitons with

oe lations sound he pcb, tusig Singapre the UnteeKingéom,

‘Australi, Mexico, rani ana apa. Locate youocaloficeat:

Intereationalceegagecom/ezion

Toles mere about Denar st www.cengage.comielmar

Purchase ay of ur preductsat your loa collage strear st ourpetered

online torewwavcengegebran-cam

Printed in the United States of America

1234567 14131211 10

PREFACE xi

INDUSTRIAL MAINTENANCE SYLLABUS xxi

ABOUT THE AUTHORS xv

ACKNOWLEDGMENTS xxi

Reem

GENERAL KNOWLEDGE 1

1, Safety 3

Objectives 3

1-1. Workplace Safety 4

1-2. Hazardous Material Handling 12,

1-3 Ladders and Scatfolds 19

Summary 2

Review Questions 2B

2. Tools 25

Objectives 25

2-1 Hand Tools 26

2-2 Measuring Devices 40

2-3. Power Tools 4B

Summary 47

Review Questions 48

3. Fasteners 49

Objectives 49

3-1. Threads 50

3-2. Taps and Dies 4

3-3. Fastener Types 7

3-4 Fastener Grades 58

3-5. Torque Specifications 59

3-6 Retaining Ring Fasteners 62

Summary 64

Review Questions 65

Industrial Print Reading 67

Objectives 67

4-1 Mechanical Drawings 68

4-2. Piping Symbols and Drawings 70

4-3. Hydraulic/Pneumatic Symbols

and Drawings 72

4-4 Electrical Symbols and Drawings 76

4-5. Welding Symbols and Drawings 85

Summary 88

Review Questions 89

Rigging and Mecha

Installations 91

Objectives 1

5-1 Formulae and Weight

Estimations 92

5-2 Load Balancing 99

5-3. Synthetic Slings 101

5-4 Fiber Rope and Securing 108

5-5 Wire Rope and Wire Rope

Stings 114

5-6 Chain and Chain Slings 121

5-7 Prelift Planning 126

Summary 127

Review Questions 127

nnn Bn enn pry eb ed NE

vil

Contents

SECTION 2

MECHANICAL KNOWLEDGE 129

6.

10.

Mechanical Power

Transmission

Objectives

6-1 Belts and Sheaves

6-2 Chainsand Sprockets

6-3 Gears and Gearboxes

6-4 Speed Calculations

Summary

Review Questions

Bearings

Objectives

74 Bearing Loads

7-2 Bearing Construction

73 Seties of Bearings

7-4 Bearing Types

7-5. Bearing Installation and Removal

76 Bearing Failures

Summary

Review Questions

Coupled Shaft Alignment

Objectives

81 Shaft Alignment

8.2 Dial Indicator Method

8-3 Reverse Dial Indicator Method

8-4 Fecler Gauge Method

8.5 Laser Shaft Aligament

Summary

Review Questions

Lubrication

Objectives

9-1 General Terms

9-2 Types of Lubricants

9.3. Methods of Application

9-4 Lubrication Schedules

Summary

Review Questions

Seals and Packing

Objectives

10-1. Packing Seals

10.2. Mechanical Secls

131

131

132

142

144

149

193

134

155

155

156

156

157

158

162

165

166

166

167

167

168

175

180

131

135

186

187

189

189

190

190

191

194

195

195

197

197

10-3 Radial Lip Seals

Suromery

Review Questions

11. Pumps and Compressors

Objectives

11-1 Hydraulic Pumps

11-2 Pump Specifications

11-3 Pump Troubleshooting

11-4. Air Compression

11-5. Compressor Types

116 Compressor Troubleshooting

Suramary

Review Questions

12. Fluid Power

Objectives

12-1 Fluid Power Fundamentals

122

123

Hydraulics

Pneumatics

124 Valves

12.5. Linear Actuators

Summary

Review Questions

13. Piping Systems

Objectives

13-1 Piping Tools

13-2. Piping Systems

133. Fittings

1344. Fitting Allowances

13-5 Pipe Connection Methods

Surmmary

Review Questions

202

203

204

205

205

206

212

214

21s

217

219

219

221

223

223

224

224

228

231

240

249

250

251

251

252

254

256

258

262

266

267

Sao)

ELECTRICAL KNOWLEDGE

14, Electrical Fundamentals

Objectives

141

14-2

143

144

145

‘Atomic Structure

Current

Voltage

Resistance

Resistor Wattage Ratings

and Power

269

271

271

272

274

274

276

280

15.

16.

17,

18.

146

a7

Scientific Notation

Engineering Notation

148 Ohm's Law

14-9, Power Law

14-10 Magnetism

Summary

Review Questions

Test Equipment

Objectives

15-1 Digital Multimeter

15-2. Clamp-On Ammater

15-3. Megahmmeter

15-4 Oscilloscope

Summary

Review Questions

Basic Resistive Electrical

Circuits

Objectives

16-1. Series Circuits

16-2. Parallel Circuits

16-3 Combination Circuits

Summary

Review Questions

Reactive Circuits

and Power Factor

Objectives

17-1 Inductance and Rel Circuits

17-2 Capacitance and R-C Circuits

17-3. ReL-C Series and Parallel Circuits

17-4. Power Factor Correction

17-5. Three-Phase Circuits

17-6 Three-Phase Power Factor

Correction

Summary

Review Questions

Wiring Methods

Objectives

181 Conductor Selection and Sizing

18-2 Conductor Color Code

183. Raceway Selection

18-4 Raceway Sizing

summary

Review Questions

282

282

283

286

290

290

290

291

291

292

296

297

300

309

309

31

311

312

317

323

335

335

337

337

338

348,

360

369

373

374

377

378

379

379

380

383

385

19.

20.

21.

22.

Contents

Transformers

Objectives

19-1. Basic Transformers

19-2. Autotransformers

19-3. Current Transformers

19-4 ‘Three-Phase Transformers

19-5. Primary Distribution Systems

19-6 Consumer Distribution System

19-7, Grounding System

Summary

Review Questions

Electrical Machinery

Objectives

20-1 DC Generators

20-2. DC Motors

20-3

20-4

Alternators

Three-Phase Motors

20-5. Single-Phase Motors

20-6 Motor Maintenance

Summary

Review Questions

Control and Controlled

Devices

Objectives

21-1. Pushbuttons

21-2. Rotary Switches

21-3. Limit Switches

21-4

2-5

21-6

2-7

21-8

Proximity Switches

Photoelectric Switches

Relays

Motor Starters

‘Annunciators

Summary

Review Questions

Motor Control Circuits

Objectives

22-1

22.2

223

22-4

22.5

22-6

22.7

Two-Wire Controls

Three-Wire Controls

Multiple Start/Stop Controls

Forward/Reverse Controls

Speed Control

Jog Control

Miscellaneous Control

391

391

392

401

405

406

424

425

425

428

428

431

431

432

436

441

4a

446

452

454

454

455

455

456

458

460

460

462

468

47

472

474

474

475

475

476

476

478

481

484

486

487

x Contents

22-8 Multiple Motor Starter Control 488 RRTSTTeyW

22.9 Sequential Starting Control 489

22-10 Various Starting Methods 492 WELDING KNOWLEDGE 643

22-11 Braking 498 27, Gas Welding 645

Suen, 500 Objectives 645

Review Questions: 501 27-1 Gas Welding Safety 646

23. Basic Industrial Electronics 503 27-2. Setup Procedures 648

Objectives 503 27-3. Shutdown Procedures 649

23-1. Diodes soa 27-4 Types of Flames 649

23-2. Transistors su 275 Pudeling and Running a Bead 650

23-3. Thyristors 519 274 Types of Welds 650

23-4. 555 Timer 525 27-7 Types of Joints 651

23-5 Operational Amplifiers 530 27-8. Welding Positions 652

23.6 Digital Logic 536 Summary 653

23-7 Replacing Solid-State Devices 543 Review Questions 654

summary 544

Review Questions 544 28. Arc Welding 655

24, Electronic Variable-Speed agian o

aoe se 1. Are Welding safely 656

28.2 Arc Welding Components 657

Obpectives ata 28-3. Striking the Arc 658

261 (DG Drvse ad 284 Running a Bead 659

242. Troubleshooting DC Drives. 571 268 Ways eo

24-3. AC (Inverter) Drives 578 286 "peat loins teh

24-4 Troubleshooting Inverter Drives 599 Sapte Rnct wees

Summary oi of Arc Welding 661

Review Questions on summary 662

Fay Riigteniatalel bale Review Questions 663

Controllers 613

Objectives 613

25-1 PLC Components 614

25-2 WOWiring 616 PREVENTIVE MAINTENANCE 665

25-3. Programming 618 ;

Suniel 630 29. Preventive Maintenance—

Review Questions 631 Developing and

Implementing 667

26. Lighting 633 Objectives 667

Objectives 633 2041 History 668

26-1. Types of Lamps 634 29-2 Planning and Coordinating 668

26-2 Luminaires 637 29.3 Hazardous and Confined

26-3. Ballasts 638 Locations oro

26-4 Relamping 638 294. Executing the PAM 671

Summary 641 Suromary 672

Review Questions 641 Review Questions 673

30, Mechanical PM 675

Objectives 675

30-1 Bearings 676

30-2 Gearboxes 676

30-3 Seals 676

304 Belts 677

30:5. Chains and Sprockets 678

30-6 Couplings 678

summary 679

Review Questions 680

681

681

31-1 General Requirements 682

31-2. Inspection Records 682

31.3 Four Rules of Electrical

Maintenance 683

31-4 Maintenance Resporsibility 684

Summary 684

Review Questions 684

Appendix A 685

NEC Tables 310.15(6)(16), 310.1 5(6)(17),

310.1 5(B)(18), and 310.15(B)(19) 686

Appendix B 691

NEC Table 310.15(8)(2)(b) 692

Appendix € 695

NEC Tables C1 through C12 696

Appendix D 743

NEC Table 5 744

Contents xi

Appendix E 747

NEC Table 8 748

The following appendices F through K can be

found on the student campanion website at

wow.cengagebrain.com.

Follow the instructions in the Supplements

section of the Preface for access information.

Appendix F

NEC Table 4

Appendix G

Weights & Measures Conversion

Tables

Appendix H

Weight Estimation Tables

Appendix |

Web Sling ~ Load Capacity Tables

Appendix J

Wire Rope Sling - Load Capacities

and Sately Factors

Appendix K

Chain Property Tables, Chain

Sling ~ Load Capacities, &

Temperature Derating Factors

GLOSSARY 749

INDEX 773

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

il) gape can tan tle

With a combined total of over 25 years experience in the field and more than 40 years

of teaching experience in the subject area, the authors share their knovledge and.

firsthand experiences with the learner,

MICHAEL E. BRUMBACH

Mike is the Industrial Maintenance Department Chair as well as an instructor in the

Industrial Maintenance program at York Technical College in Rock Kill, SC. He has been

employed by York ‘Technical College since 1986, having spent the previous 11 years

workingin industry. Mike possesses an AS degree.

You maye-mail Mike at mbrumbach@comporium.net

JEFFREY (JC) CLADE

IC isan instructor in the Industrial Maintenance program. He has been employed by

York Technical College since 1997, havingspent the previous 15 years serving with the

U.S. Air Force and working in industry. JC possesses an AS degree and is a member

of the International Association of Electrical Inspectors (IAEI) and the National Fire

Protection Association (NEPA),

You may e-mail JC atjelade@comporium.net

\

hip ai Me nk fn ee net in me re tin

ia

il) gape can tan tle

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

GENERAL

KNOWLEDGE

Safety

Tools

Fasteners

Industrial Print Reading

A TYPICAL DAY IN MAINTENANCE

Check It Out

7:00 au, and your shift has begun. You have had your breakfast and coffee,

and itis time to eam your pay. Your supervisor hands you a work order for the

number 3 press. The press operator reports that the press was making a loud

vibration, then the operator smelled a “funny” odor, and now the press will

not run.

You mentally run through several possible causes of the problem. You gather the

relevant prints, personal protective equipment (PPE), hand tools, and test equip-

ment and proceed onto the plant floor to press number 3. It is now 7:20 Aw.

Work It Out

1. What might be the cause of the problem with the press?

2. What types of drawings or prints would be helpful?

3. What PPE do you need?

Which hand tools would you consider taking slong?

ve

What test equipment would be of benefit?

nnd aac a4 Hn Be

pene en

heen A a Rae pe fn sn net cn te a a

Pi apathy NAOT ON MRT NEY =

Safety

This text will delve into the field of industrial maintenance, but before we can do

that, we must begin with safety. Without safety, maintenance would be a deadly

occupation because equipment and machinery are dangerous by nature. A wise

man once said, “An accident is nothing more than an unsafe condition and an

unsafe act that have been combined. If the unsafe condition had been removed,

there would have been no accident. If the unsafe act had been removed, once

again there would have been no accident.” The maintenance mechanic needs

to be safety oriented to avoid unnecessary accidents and bodily harm when

working around equipment and machinery. It takes only one accident, and a

very small moment in time, to lose a life.

OBJECTIVES

After studying this chapter, the student should be able to

Understand the importance of personal protective equipment.

Demonstrate the proper procedure for lifting.

Use lockout and/or tagout when needed.

Discuss the proper use of safety belts, scaffolds, and ladders.

.

.

.

© List several general electrical safety practices.

®

‘= Identify all the organizations that govern the safety of hazardous material

.

List the classifications of fire and the proper method of extinguishing a fire.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

aa

You have either reached a page that is unavailable for viewing or reached your viewing limit for this

book.

image

not

available

use a Class © fire extinguisher, Most industrial

machines have a main disconnect. ‘Ihis is the

point at which the machine can be totallyremoved

from its electrical energy source, ILisimportant to

remember, if a Class C fre does exist, to pull the

main disconnect handie to the off position. Keep

in mind, however, that there may be some remain:

ing stored electrical energy in some elecirical

equipment as you fight the fire. For this reason,

it is always important to consider all electrical

equipment energized. As with the others, there is

a pictograph that represents a Class € five, which

ran he seen in Figure 1-16. A blue circle with a

capital letter C in it may also represent a Class C

classification

A Class D fire is fire that burns combustible

metals, such as magnesium, potassium, powdered

aluminum, zine, sodium,or titanium. Because most

combustible metals are highly volatile to water in

a high-heat environment, @ special dry-powder

extinguishing agent or a foam extinguisher is used

on this class of fie,

Extinguisher Use

Here isa proposed list of the procedures that should

be followed in the event ofa fire,

& Locate and activate the nearest fire alarm. If no

fire alarm is in the immediate area, then yell the

word firees loudlyas possible to get the attention

ofa coworker or a supervisor.

© Make certain thata callto 911 is placed. It ismost

important to notily the local fire department of

the fire

© Make sure that the facility's emergency response

or first responder team is notified,

© Getall nonessential personnel out of harm’s way.

1 Deenergize all electrical sources that are in the

immediate vicinity of the fie, if possible

© Quickly identify the class of the fire and retrieve

the appropriate extinguisher.

© Always make sure thatyou have an escape route

as you are trying to extingulsh the fire,

© Use the extinguisher properly « achieve the

maximum firefighting capability of the extin.

guisher. Try touse the BA.S.S, method,

+ Pull the pin.

+ Aim at the base ofthe fire.

+ Squeeze the handle or trigger. (Be prepared;

some extinguishers are extremely loud when

the extinguishing agentis released.)

CHAPTER 1 Safety

+ sweep the extinguisher from side to side as 1¢

isused,

& Continue to fight the fire as long as possible, pre-

venting any spreading until the local firefighters.

If you extinguish the fire, keep a watchful eye

unt the fire department arrives to ensure that it

oes not flare up again.

@ IF a fire becomes too large and gets to a point

where it is out of control before the fire depart.

ment’s arrival, evacuate the facility and stand as,

far away from the hire as possible. Remember, a

Joss of life due to a fire isnot acceptable,

Remember, the safety of all personnel is what

is important. These OSHA standards and NFPA

standards are for our safety. Ifa salety violation is

noticed, report it as soon as possible to avoid any

unnecessary injury. Safety is everyone's job! Take it

seriously

WEB LADDERS AND SCAFFOLDS

Ladders

OSHA Standard 1926.1051 (General Requirements)

states thata stairway or ladder shall be provided at

all personnel points of access where there isa break

inelevation of 19 in. (48cm) or more, and no ramp,

runway, sloped embankment, or personnel hoist

is provided, OSHA Standard. 1926.1053 lists the

requirements for the manufacturing or constrac-

tion of a ladder, OSHA Standard 1928.

portable wooden ladders; 1926.26 covers portable

metal ladders; 1926.27 covers fixed ladders; and

1926.103

struction industry, Regarding ANSI ratings, difler-

ent safety codes apply, depending on the type of

material and type of ladder. the ANSI Codes are as

follows:

covers ladders that are used in the con

WoodLadders ANSI

Metalladders — ANSTA42

Fixed ladders ANSIAL43

Fiberglassladders ANSTA4.5

Steel ladders ANSIALAT

Rollingsesffold _ ANSI.A10.3, 2011 edition,

(covered laterin this section)

Duty ratings have also. been established by

ANSI. Ihese ratingsidentify the ladder’sload capac-

ity and its intended use, Allladders must have a rat

ing label.

19

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- What Every Engineer Should Know About Software EngineeringDocument299 pagesWhat Every Engineer Should Know About Software EngineeringElwy Mustafa100% (1)

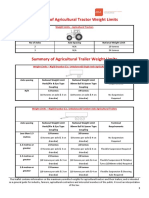

- Ag Vehicle Weights and Dimensions Leaflet - Sept 2015 PDFDocument6 pagesAg Vehicle Weights and Dimensions Leaflet - Sept 2015 PDFElwy MustafaNo ratings yet

- Ag Vehicle Weights and Dimensions Leaflet - Sept 2015 PDFDocument6 pagesAg Vehicle Weights and Dimensions Leaflet - Sept 2015 PDFElwy MustafaNo ratings yet

- Chapter Two: Turning and Related OperationsDocument78 pagesChapter Two: Turning and Related OperationsElwy MustafaNo ratings yet

- Basic of Mechanical EngeneeringDocument144 pagesBasic of Mechanical Engeneeringjhny4444No ratings yet

- Getting Started in Electronics - 3ed - (Forrest M.Mims) PDFDocument128 pagesGetting Started in Electronics - 3ed - (Forrest M.Mims) PDFDavid Corbin100% (9)

- Better Company ProfileDocument9 pagesBetter Company ProfileElwy MustafaNo ratings yet

- محاضرات السيسيDocument94 pagesمحاضرات السيسيElwy MustafaNo ratings yet

- Engineering Drawings Lecture Linear Fits and Tolerances Rev 1 - 2Document15 pagesEngineering Drawings Lecture Linear Fits and Tolerances Rev 1 - 2Elwy MustafaNo ratings yet

- Basic Manufacturing Processes Questions and Answers 07 July 2013Document0 pagesBasic Manufacturing Processes Questions and Answers 07 July 2013Felicia WagnerNo ratings yet