Professional Documents

Culture Documents

Espesadores

Espesadores

Uploaded by

13942030310 ratings0% found this document useful (0 votes)

21 views10 pagesespesadores hi rate

Original Title

espesadores

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentespesadores hi rate

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views10 pagesEspesadores

Espesadores

Uploaded by

1394203031espesadores hi rate

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

CONFIDENTIAL

oe

i)

Sés: METALLURGICAL TECHNOLOGY ‘Sec

Ve

PROPOSAL

TO

Heap Leach Consulting SAC

FOR

ONE 200KG/HR MINFURN AND DRYER

For The Attention Of: Mr Oscar Palacios Perez

Heap Leach Consulting SAC

‘Area de Proyectos

Tel: +511 242-7117

Fax: +511 243-1143

Email: opalaciosp@hicsac.com

Direct All Enquiries To: Nick Maritz

Tel: +27 11 709-4094

Mob: +27 82 576-6010

Fax: +27 11 709-4089

Email: nickm@mintek.co.za

—

j Date)

AU J 4 _rgls/or.|

N MAOTL, -L Kedrattit | 14/5707 -|

This proposal and the documents fcluded herein are proprietary, and may contain

information that is confidential to Mintek. Copyright in and to the documents that

comprise this proposal vests in Mintek. The Client may not disclose, copy or distribute

Page 1 of 10

INQ REF: ESC/10000115

QTE REF: ESC/20001187

CONFIDENTIAL

the contents of the proposal to any third party, unless Mintek has expressly agreed to

the contrary in whiting.

1. INTRODUCTION

Oscar Pal

lacios has requested Mintek to provide H.L.C with a proposal for a 200

kg/hr Minfurn’s with a PLC and dryer, for the reactivation of carbon.

2. SCOPE OF WORK

This proposal is for the ‘ex-works’ (Mintek Randburg SA) supply of one 200kg/hr

Minfurn and dryer. Mintek's supply starts with the feed hopper into the Minfurn

(mounted

discharge

on top of the Minfurn) and terminates at the re-activated carbon

box.

The deliverables include the fotlowing:-

Mechanical

Electrical

Complete refractory lined shell

Feedhopper

Electrodes

Re-activated discharge feeder

All structural components to support the various elements making up the

Minfurn

One 200kg/hr Electrical dryer:

- Pre-dryer complete with fluid bed deck, vibrators, underduct and

hanging mounts.

- Heating chamber with elements, blower fans and fiexible connection

to bed, and interlocks

and controls

The thyristor drive and all controls which include:-

Minfum voltage and current AC and DC earth fault detection

Interlocks and over-current protection.

Control panel (not shown on the sketch) including:

Main circuit breaker (supply voltage to be advised by client)

Control transformer if required depending on supply voltage

Variable DC-voltage output selector and voltage indication

Earth leakage detector on output

Terminals for furnace access gate safety-switch interlock, as well as

other interlocks required by the client

Furnace inlet level control (by co-ordination of drier and furnace

operation

Electrical current indication

Page 2 of 10

INQ REF: ESC/10000115

QTE REF: ESC/20001187

CONFIDENTIAL

* PID contro! of vibratory discharge conveyor to keep current and

temperature constant

«Discharge conveyor auto/manual selector

Following indication:

This is displayed on an Allen Bradley panel view: the control of the Minfurn and

indications of status is accessed via the panel view.

* Furnace on/off

* Discharge conveyor on/off

+ Over-current trip and earth-fault trip

‘© Thyristor trip and access gate trip

* Feed low level trip

* Manual and drawings for installation, commissioning, operation and

maintenance.

* Hot commissioning of equipment in Mintek works prior to crating.

Installation and commissioning

The duration and manpower requirements for installation and commissioning are

only estimates at this stage. Should the actual amount or duration vary, Mintek

reserves the right to adjust these costs for the client's account.

Installation and commissioning cost per day will be R3000.00 per person (1 x

Mechanical Engineer and 1 x Instrument Technician) for approximately 5 days,

including travel time = R30 000.00 (Thirty Thousand Rand Excl. VAT)

it is assumed that the client will supply one fitter and one electrician during the

commissioning period

3. PERFORMANCE AND GUARANTEE

Mintek warrants that, operating at design tonnage, the carbon will be maintained

above 750°C for 20 minutes.

The MINFURN will now be started via the touch-screen as well as the control for

the drier. The current controller wil still be used and the current will be

retransmitted into the PLC. Voltage, current and temperature will now be read on

the touch-screen.

Ifa fault should occur, the fault condition will be seen on the touch-screen. A

display screen will be generated to indicate fault as well as corrective action

required,

The PLC used will allow the system at a later stage if required, to be connected to

a local area network (LAN).

Page 3 of 10

INQ REF: ESC/10000115

QTE REF: ESC/20001187

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Celdas OK PDFDocument4 pagesCeldas OK PDF1394203031No ratings yet

- InstruccionesDocument13 pagesInstrucciones1394203031No ratings yet

- Diplomado - Costos y Presupuestos en Minería Superficial y SubterráneaDocument7 pagesDiplomado - Costos y Presupuestos en Minería Superficial y Subterránea13942030310% (1)

- Quote Lining Tolvas HLC 11-2020Document4 pagesQuote Lining Tolvas HLC 11-20201394203031No ratings yet

- Brochure DCTDocument1 pageBrochure DCT1394203031No ratings yet

- Taller CRISTALOGRAFIAYMINEROLOGIAPARTEVIDiap127 184Document29 pagesTaller CRISTALOGRAFIAYMINEROLOGIAPARTEVIDiap127 1841394203031No ratings yet

- ¿Qué Es Un ChillerDocument5 pages¿Qué Es Un Chiller1394203031No ratings yet

- S3749rev HemcoSanJoseReviewReport13082020Document32 pagesS3749rev HemcoSanJoseReviewReport130820201394203031No ratings yet

- Autorescatador AIRSAFETY-1Document1 pageAutorescatador AIRSAFETY-11394203031No ratings yet

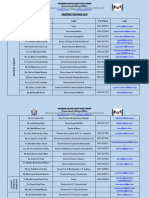

- Directorio Telefonico 2016Document6 pagesDirectorio Telefonico 20161394203031100% (1)

- ProgramaDigital PDFDocument7 pagesProgramaDigital PDF1394203031No ratings yet

- Autorescatador AIRSAFETY-1Document1 pageAutorescatador AIRSAFETY-11394203031No ratings yet

- Apron Feeders PDFDocument4 pagesApron Feeders PDF1394203031No ratings yet

- For Flash Flotation and Flash Roughing: SkimairDocument2 pagesFor Flash Flotation and Flash Roughing: SkimairQuicayCerroNo ratings yet