Professional Documents

Culture Documents

Inconel 622 Ernicrmo-10 Uns n06022

Uploaded by

wi0 ratings0% found this document useful (0 votes)

51 views1 pageINconel 622

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

51 views1 pageInconel 622 Ernicrmo-10 Uns n06022

Uploaded by

wiYou are on page 1of 1

Tee Ma Cahir

INCONEL’ Filler Metal 622

INCONEL Filler Metal 622 is used for gas-tungsten-are and gas-metal-arc welding of

INCONEL alloys 22 and 625, INCOLOY alloy 25-6MO, and INCOLOY alloy 825. This is also

‘an excellent dissimilar metal welding product that offers protection against preferential weld

metal corrosion when used for joining molybdenum-containing stainless steels, INCONEL

alloy C-276, and INCONEL alloy 625. The high chromium content, clong with the tungsten

‘and molybdenum, give good resistance to pitting and crevice corrosion. INCONEL Filler

Metal 622 is useful for many dissimilar joints involving INCONEL and INCOLOY alloys, and

cg, Rane erenel tinea Ae begedlns nelllagreed eacifiariew a tome

with INCOFLUX NTI20 Submerged Arc Flux.

Specifications

AWS AS5.14 ERNiCrMo-10 (UNS NO6022)

ASME Il, Part C, SFA~5.14, ERNiCrMo-10 (UNS NO6022)

ASME IK, FeNo.43

“{EN) ISO 18274 - SNi6022 (NiCr2IMol3Fe4W3)

“Supply to these specifications available upon request

For manufacture to ASME Ill (NCA3800, NB2400), and other specifications

please refer your inquiry fo the Technical Department prior to order placement.

Approvals

VdTUV - 926/032088

Other apprevals may be applicable, Please confirm details of current scope of

copprovals with the Technical Department prior to order placement.

Li ing Nickel ume Remainder Eman w- 0.50 max.

Chemical c nrc 0.015 max. Co. 7 woe 2.5 max.

Composition Mn 0.50 max. Be weve 20,0-22.5

Mo as woe 12.5-14.5,

We 0.35 max.

Ww. 25-35

Si Others: 0.50 max.

Typical Tensile Strength, psi 115,000

Mechanical MPa 793

Properties Elongation, (4d) % 40

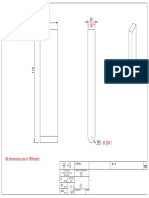

Filler metals avilable on spool and in cut straight lengths in a variety of sizes selected

from the following diameters:

ON etd

mm | 08 | 09 10 ud 12 16 | 24 | 32

in | 0.030 | 0.035 | 0.040 | 0.045 | 0.047 | 0.062 | 0.093 | 0.125

Straight Lengths - 915 mm (36 in} or 1000 mm (39 in)

=

Co

25

INCONEL’ Filler Metal 622

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- General PA Procedure For Detection and SizingDocument46 pagesGeneral PA Procedure For Detection and Sizingwi100% (5)

- WPS PqrchecklistDocument1 pageWPS PqrchecklistrodofgodNo ratings yet

- AWS D10 4 86R Recommended Practices PDFDocument44 pagesAWS D10 4 86R Recommended Practices PDFwi100% (1)

- Asnt-Tc1a Cambios PDFDocument20 pagesAsnt-Tc1a Cambios PDFwiNo ratings yet

- TOFD PA Procedure For 301 PDFDocument49 pagesTOFD PA Procedure For 301 PDFwiNo ratings yet

- Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesDocument8 pagesSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubeswiNo ratings yet

- Impact Toughness of The Duplex Stainless Steel SAF 2304, With HeatinG 1100-1300 CDocument9 pagesImpact Toughness of The Duplex Stainless Steel SAF 2304, With HeatinG 1100-1300 CwiNo ratings yet

- Effect of PH, Temperature and Chloride Concentrations 316lDocument17 pagesEffect of PH, Temperature and Chloride Concentrations 316lwiNo ratings yet

- Order 114-3711903-9862655 Colonia PDFDocument1 pageOrder 114-3711903-9862655 Colonia PDFwiNo ratings yet

- Techalloy 276 ERNiCrMo-4Document2 pagesTechalloy 276 ERNiCrMo-4wiNo ratings yet

- SWX - 110 Iso 14174Document4 pagesSWX - 110 Iso 14174wiNo ratings yet

- Hobart Subarc CatalogDocument2 pagesHobart Subarc CatalogwiNo ratings yet

- BendTestJig UpperBody 1 PDFDocument1 pageBendTestJig UpperBody 1 PDFwiNo ratings yet

- BendTestJig LowerBody 1 PDFDocument1 pageBendTestJig LowerBody 1 PDFwiNo ratings yet

- Order 114-1661038-0533809 Baterry PDFDocument1 pageOrder 114-1661038-0533809 Baterry PDFwiNo ratings yet

- Improving Surface Mine Profitability With Phased Array UltrasonicsDocument14 pagesImproving Surface Mine Profitability With Phased Array Ultrasonicswi100% (1)

- Repairing The Roller of A Rolling Machine Used in SMAW Welding ProcessesDocument7 pagesRepairing The Roller of A Rolling Machine Used in SMAW Welding ProcesseswiNo ratings yet