Professional Documents

Culture Documents

IDL's PT-03

Uploaded by

ingcalderon0 ratings0% found this document useful (0 votes)

8 views4 pagesbull api

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbull api

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pagesIDL's PT-03

Uploaded by

ingcalderonbull api

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Inter-Office Correspondence

@9 onweELL

Divison of Unit States Stee! Corporation

OFFICE: Garland, Texas

fo Date: January 28, 1975

FROM yy, Frengh} Pyne

Senior Des’ i eer

SUBJECT: INFORMATIVE DATA LETTER NO. PT-10

Piston Pump Models 850-PT Thru 1700-PT

and A850-PT Thru A1700-PT - Piston and Piston Rod

Recent discussions with several operators of the subject pumps indicate

a need to supplement or re-emphasize service information as follows:

1. Sketch No. GSK-5093P, attached, shows a partial section through the piston

tod and piston rod stud. For required results, observe the following:

1.1 When used parts are being reconditioned for service, check the

flush water holes for full open diameter. Remove scale as required.

1.2. End of stud to be 2-1/2" from face of piston rod body, as shown.

1.3. Install stud with "Loctite" Grade #271 or equal. Clean stud and

tapped hole threads. Allow partial cure time of 10 to 15 minutes

before assembly of stud into piston rod extension.

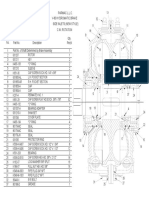

2, Sketch No. GSK-5097P, attached, shows a section through a typical mud pump

piston and partial section through the piston rod back-up wrench. The back-up

wrench is located in the end pipe of the pump skid. The back-up wrench is

used to hold the piston rod and piston while the piston nut is being removed

or torqued at assembly.

2.1 Lubricate piston body inside diameter and the piston rod outside

diameter with a light coating of heavy grade grease. This will

help prevent mud and sand from entering this space and will facilitate

later removal of the piston body.

2.2 Always check the threads on both ends of the piston rod. If threads

show signs of wear or damage, they must be repaired or the piston

rod replaced. The piston rod nut should engage by hand up to the

plastic locking ring.

\_APIES TO: 9-7 Nailing List

hment:

2 Attachments NVAITIONVAL) Product Engineering

P.O. Box 469011

(A ORWELL J Garland 1% 75040.0011

Page 2

Informative Data Letter PT-10

January 27, 1975

2.

Sketch No. GSK-5097P (continued)

2.3 The piston rod nut has a plastic insert which forms a thread

Jock’ to prevent loosening of the nut in service. In normal

service the piston rod nut may be reused approximately six

times until replacement is required. Replace the nut when

the torque required to turn the nut, with only the plastic

insert engaged, is reduced to one-half the value obtained

with a new nut.

2.4 Lubricate the threads of the piston rod nut with suitable

heavy grease or anti-gall compound such as “Molycote",

"Never-Seez" or "Thread Guard”.

2.5 Torque the piston rod nut to 500 ft/Tbs.

Experience has shown that for quick change-out of pump pistons, it is

advisable to have a spare or back-up set of piston assemblies. These

spares should have been previously cleaned and reconditioned as per

Section No. 2 above. Store spare pistons in protective containers.

The piston rod is secured to the piston rod extension by means of a special

1-1/2"-8 thd, stud.* Service manuals call for this connection to be

tightened to 500 ft/Ibs torque. This figure is correct and will remain un-

changed. However, we caution that in the absence of a proper torque wrench

the 500 ft/Ibs torque may be exceeded, and thereby cause the fatigue stress

life of the stud connection to be greatly reduced. Experience has shown that

the two open end wrenches (24" handles) supplied with the pump will provide

the proper torque when one wrench is used as a back-up against the pump

cradle and the other wrench pulled with one hand only. The acceptable range

of torque for this connection can be as Tow as 300 ft/Ibs to a maximum of

500 ft/tbs.

CAUTION: Under no circumstance should the tightening wrench be

struck with a sledge or bar, as this will probably cause

‘the maximum allowable torque to be exceeded,

(* U.S. Patent No. 3,729,219).

OWF:md

4-2 60C CD, 2f) La00Liv 71s0sgy _1a0011 /la0s@ :

V|_d-260S-¥S9 wi HONZEM GN- OVE BOY NOISid

* NMOHS SV‘ UBLWVI LOTId 40

H1d30 T1N4 OL dow NOLsid LYISNI “GMS 40 GNA aNVYs YIMOd NO

GBLWWIOT ATIVIIAL* GOY NOLSId JO K3H HOS HONAYM dN-yOvVE

“dWnd OW 40 Bawa as

Ms JO adid GN3

ATAWASSY NOISid WIIdAL MHL NOILIaS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Emsco T-3750 Rotary Table C&oDocument22 pagesEmsco T-3750 Rotary Table C&oingcalderonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Magneto Cat Tool Peak DetectDocument8 pagesMagneto Cat Tool Peak DetectingcalderonNo ratings yet

- EmbudoDocument6 pagesEmbudoingcalderonNo ratings yet

- Comap BifuelDocument16 pagesComap BifuelingcalderonNo ratings yet

- 544k IntervalsDocument53 pages544k IntervalsingcalderonNo ratings yet

- Application 72201560552 PM 637Document3 pagesApplication 72201560552 PM 637ratheeshNo ratings yet

- Magneto Test Bench Electrode DesignDocument1 pageMagneto Test Bench Electrode DesigningcalderonNo ratings yet

- Series: Table 1: Available Styles - Materials Proco "Chemical To Elastomer Guide"Document6 pagesSeries: Table 1: Available Styles - Materials Proco "Chemical To Elastomer Guide"ingcalderonNo ratings yet

- Oteco Standpipe Manifold FittingsDocument4 pagesOteco Standpipe Manifold FittingsingcalderonNo ratings yet

- Catalogo de Winch Fa5a PDFDocument60 pagesCatalogo de Winch Fa5a PDFingcalderonNo ratings yet

- Natural Gas CarDocument12 pagesNatural Gas CaringcalderonNo ratings yet

- Parmac L.L.C. V-80 Hydromatic Brake Side Inlets (New Style) C.W. Rotation REPAIR KIT 1-U632348-XDocument1 pageParmac L.L.C. V-80 Hydromatic Brake Side Inlets (New Style) C.W. Rotation REPAIR KIT 1-U632348-XingcalderonNo ratings yet

- LockDocument1 pageLockingcalderonNo ratings yet

- Tapa AcopleDocument2 pagesTapa AcopleingcalderonNo ratings yet

- MOTORTECH Product Guide 01.00.001 EN 2017 03 PDFDocument230 pagesMOTORTECH Product Guide 01.00.001 EN 2017 03 PDFS M NaveedNo ratings yet

- 46mpa PDFDocument1 page46mpa PDFingcalderonNo ratings yet

- Parmac L.L.C. V-80 Hydromatic Brake End Inlets (Old Style) C.C.W. Rotation REPAIR KIT 1-U632348-XDocument1 pageParmac L.L.C. V-80 Hydromatic Brake End Inlets (Old Style) C.C.W. Rotation REPAIR KIT 1-U632348-XingcalderonNo ratings yet

- Model pl5 Service Manual PDFDocument31 pagesModel pl5 Service Manual PDFingcalderonNo ratings yet

- Condiciones Severas C15Document3 pagesCondiciones Severas C15ingcalderonNo ratings yet

- Dpa SensorsDocument14 pagesDpa SensorsTamer RabieNo ratings yet

- Martin DeckerDocument7 pagesMartin DeckeringcalderonNo ratings yet

- L495-113 Operating and Maintenace ManualDocument13 pagesL495-113 Operating and Maintenace Manualingcalderon100% (1)

- Governor and ActuatorDocument36 pagesGovernor and ActuatorPonraj Govindarajan100% (1)

- Dse8610 Data SheetDocument2 pagesDse8610 Data SheetmkNo ratings yet

- Strippers JU y JU H PDFDocument5 pagesStrippers JU y JU H PDFingcalderonNo ratings yet

- Drill Collar and Casing SlipDocument7 pagesDrill Collar and Casing Slipingcalderon100% (1)

- Strippers JU y JU H PDFDocument5 pagesStrippers JU y JU H PDFingcalderonNo ratings yet

- Emsco T-2050 Parts ListDocument5 pagesEmsco T-2050 Parts ListingcalderonNo ratings yet

- Elevator LinksDocument1 pageElevator Linksedinson0520No ratings yet