Professional Documents

Culture Documents

ETL Pressure Relief Valve r3 PDF

Uploaded by

Jayesh SanganiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ETL Pressure Relief Valve r3 PDF

Uploaded by

Jayesh SanganiCopyright:

Available Formats

TECHNICAL DATA

Storage Tank Equipment

Pressure/Vacuum Relief Valves

Application:

Direct acting pressure / vacuum relief valves, or breather valves

are special types of relief valves which are specifically designed

for tank protection. The range includes pressure only, vacuum

only and combined pressure / vacuum valves, all available with

flanged outlets or vented to atmosphere.

Pressure / vacuum relief valves are used extensively on bulk

storage tanks, including fixed roof tanks with floating covers, to

minimise evaporation loss. The valves prevent the build up of

excessive pressure or vacuum which can unbalance the system

or damage the storage vessel.

Principle of Operation Benefits

The valves have a cast body which is flanged for connection • Pressure / vacuum relief valves provide

to the storage tank. A weather hood protects the pressure high gas flow from a compact valve size

exhaust port and a mesh cover is fitted to prevent ingress of • Range of sizes and materials to suit

foreign matter for valves vented to atmosphere. a wide range of applications

Piped-away versions are also available throughout the range. • Wide range of pressure and vacuum settings to provide

Both the pressure and vacuum sides of the valve incorporate maximum tank protection whilst ensuring minimum gas loss

a pallet and diaphragm assembly which rest on an ‘O’ ring seal • Valve sizing service assists optimum

to prevent leakage. This ‘O’ ring can be removed and the seat valve performance / cost specification

machined optically flat, producing a metal to metal seating

arrangement if required. The weight of the pallet pushes the

Elmac Expertise

Elmac Technologies® have been manufacturing protection

diaphragm assembly against the seat to keep it closed. When

equipment since 1948, and bring enhanced levels of flame

the pressure or vacuum increases, the pallet and diaphragm

and explosion protection to a diverse range of applications.

lifts and air/gas is allowed to flow.

Elmac offers considerable technical leadership and using test

facilities along with CFD capabilities, employs research teams

renowned for developing solutions for the most challenging

of industrial applications.

www.elmactechnologies.com Protecting People, Property and Our Planet

Pressure/Vacuum Relief Valves

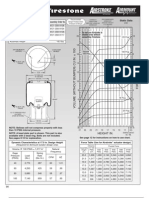

A ‘O’ Ring Seat Solid Seat

10 2 11 11

12

B

3 7 14 14

4

1 13 8 13

Valve Size 6 9 15

Materials & Options

Ref Description Materials / Options

1 Body Aluminium, Cast Iron, Carbon Steel, Stainless Steel, Special (Available on request)

2 Cover Aluminium, Cast Iron, Carbon Steel, Stainless Steel, Special (Available on request)

3 Hood Aluminium, Carbon Steel, Stainless Steel

4, 5 Pressure Guide Post Stainless Steel, Special (Available on request)

6 Vacuum Guide Post Stainless Steel, Special (Available on request)

7, 8 ‘O’ Ring PTFE, Nitrile Rubber, Viton, Special (Available on request)

9, 10 Mesh Stainless Steel, Special (Available on request)

11 Pallet Aluminium, Stainless Steel, Special (Available on request)

12 Pallet Stem Stainless Steel, Special (Available on request)

13 Diaphragm PTFE, Viton, Special (Available on request)

14 Retaining Disc Stainless Steel, Special (Available on request)

15 Weights Lead, Stainless Steel, Special (Available on request)

Connection Flange ANSI 150#, PN16, Special (Flange drilling as required)

Pressure & Vacuum Settings Low flow from High flow to

Dead Weight Valves 0.865” w.c. (2.15 mbar) 30” w.c. (75 mbar)

Spring Loaded Valves 28” w.c. (70 mbar) 200” w.c. (0.5 bar)

Valve Size 2” 3” 4” 6” 8” 10” 12”

A (mm) 362 417 465 602 721 914 1111

B (mm) 254 273 327 423 460 597 737

Width (mm) 213 267 305 416 457 590 722

Approx Aluminium 6 8 12 20 33 50 66

Wt (kg)* Carbon/Stainless Steel 19 29 40 52 80 137 185

* Does not include pallet weights for pressure/vacuum control

Pressure / Vacuum Relief Valve Variations

Pressure Relief to Atmosphere Pressure Relief Vacuum Relief Pressure Relief to Closed Line

Vacuum Relief from Atmosphere to Atmosphere from Atmosphere Vacuum Relief from Atmosphere

Pressure Relief Pressure Relief to Atmosphere Pressure Relief to Closed Line Vacuum Relief from Closed Line

to Closed Line Vacuum Relief from Closed Line Vacuum Relief from Closed Line

Customer Support

Elmac Technologies Limited

Greenfield, Flintshire, United Kingdom CH8 9DP

T +44 (0) 1352 717600 F +44 (0) 1352 717642 E sales@elmactechnologies.com Protecting People, Property and Our Planet

All specifications are correct at time of print, are for guidance

Issue No 03 (02/13) purposes only and subject to change without prior notice.

You might also like

- Pressure Vacuum Valves PDFDocument5 pagesPressure Vacuum Valves PDFFelipe Correa MahechaNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- SDV PPTDocument58 pagesSDV PPTSai Kamala100% (2)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- Disc ValvesDocument8 pagesDisc ValvesMahesh KumarNo ratings yet

- 15 Metal Seated Butterfly ValvesDocument8 pages15 Metal Seated Butterfly ValvesrajfmcNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- 5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBDocument4 pages5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBSivareddy InduriNo ratings yet

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- TankerDocument60 pagesTankerlopezdestructionNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- 07 ValvesDocument33 pages07 Valvesshiva_ssk17No ratings yet

- Breather Valve - PV Valve - CNC380Document2 pagesBreather Valve - PV Valve - CNC380mhidayat108No ratings yet

- Enquiry Data in MailDocument20 pagesEnquiry Data in MailNITINNo ratings yet

- Rising DiscDocument8 pagesRising DiscwenigmaNo ratings yet

- 830 SpecDocument2 pages830 Specmonarchy1103No ratings yet

- VD SV Ka 5 GBDocument3 pagesVD SV Ka 5 GBArmando SixtoNo ratings yet

- 2.VD SV Ka 5 GBDocument3 pages2.VD SV Ka 5 GBshanmugamNo ratings yet

- Ball Valve Seat Seal Injection SystemDocument28 pagesBall Valve Seat Seal Injection SystemmudrijasmNo ratings yet

- W01 358 2132Document29 pagesW01 358 2132MROstop.comNo ratings yet

- W01 358 7442Document29 pagesW01 358 7442MROstop.comNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- Top Guide Control ValveDocument32 pagesTop Guide Control Valveachari_swapnilNo ratings yet

- Wedge and Slab Gate ValvesDocument8 pagesWedge and Slab Gate Valvesgad30No ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- W01 358 7751Document29 pagesW01 358 7751MROstop.comNo ratings yet

- Butterfly Valve ConcentricDocument6 pagesButterfly Valve ConcentricpramodtryNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- W01 358 7561Document29 pagesW01 358 7561MROstop.comNo ratings yet

- Lead Free Series SS009 Specification SheetDocument2 pagesLead Free Series SS009 Specification SheetWattsNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Series 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Document12 pagesSeries 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Gopinath GunasekaranNo ratings yet

- 2011 07 Mar00080 en Katalog Typs WebDocument28 pages2011 07 Mar00080 en Katalog Typs WebzayerirezaNo ratings yet

- W01 358 9106Document29 pagesW01 358 9106MROstop.comNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- Autoclave Engineers - Valves Fittings and Tubing - Condensed CatalogDocument16 pagesAutoclave Engineers - Valves Fittings and Tubing - Condensed Catalogchristophedepaepe100% (1)

- Econ Gate ValvesDocument20 pagesEcon Gate ValvesEngr.Mmosaad100% (1)

- W01 358 7092Document29 pagesW01 358 7092MROstop.comNo ratings yet

- W01 358 7091Document29 pagesW01 358 7091MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W02 358 4001Document30 pagesW02 358 4001MROstop.comNo ratings yet

- Flowserve Vlatb001Document20 pagesFlowserve Vlatb001Selva KumarNo ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 8118Document29 pagesW01 358 8118MROstop.comNo ratings yet

- W01 358 7039Document29 pagesW01 358 7039MROstop.comNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Pneumatic VVDocument20 pagesPneumatic VVsaashadanNo ratings yet

- Tom Wheatley Swing Check Valves (New)Document24 pagesTom Wheatley Swing Check Valves (New)Carlos Cardenas SochaNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet