Professional Documents

Culture Documents

TN017 - Eng Safety of Material Hoists PDF

Uploaded by

Star HOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TN017 - Eng Safety of Material Hoists PDF

Uploaded by

Star HOCopyright:

Available Formats

KMS / TECHNICAL DEPARTMENT

TECHNICAL NOTE 017

Engineering Safety of

Material Hoists –

Double Trouble via Pulleys

· We excel through experience and learning · Version 01, May 2017

Version 01, Mar 2011

Keywords NB –

Material Hoist, Pulley System, Cable Force, Local Effect, Design For structural design of material hoists, various basic load cases

Load Cases have to be considered. This technical note focuses solely on

the load effects caused by the pulley system.

Synopsis

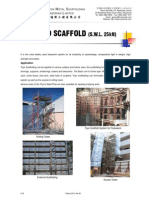

A material hoist is a powered-mechanical plant commonly used 2.0 General Arrangement

on construction sites for vertical transportation of construction The simplest form of a material hoist is shown

materials. The cage (or platform) inside the hoist is hung to a indicatively below. The mast of the material hoist is a laced

cable that runs through a pulley system. The cable is secured strut formed using angle or other sections. The weight ‘W’ is

to a winch or winding drum at ground level. As part of the supported by a cable that runs through a pulley system.

package, the design of the material hoist is usually prepared by

the hoist supplier or their designer. In a recent RAT design Pulley Pulley

review, the design force for the vertical members of the

material hoist was found to be grossly underestimated. It

appears that the designer had somehow omitted the doubled T

load effects caused by the pulley system. For all Chun Wo’s

projects, the load cases shown diagrammatically on page 02 Main frame of

are required to be considered by the material hoist designer(s). material hoist

W

Cable

1.0 Introduction

Incidents of material hoist failure are not uncommon.

The failure could be caused by many reasons under different

circumstances including during load-testing. As shown in the Winding drum

/ winch

photos below, the member supporting the pulley failed and one

of the vertical members of the material hoist buckled. The

reason(s) for material hoist failure could be many, and design

inadequacy could be one. The pulleys are supported at the top end and the cable is

secured to a winch or winding drum at ground level.

It was discovered in a recent RAT design review that the

applied force for the vertical members of the material hoist was

grossly underestimated. Details are explained hereinafter.

Member supporting pulleys Close-up view of a pulley and

supporting members

Member supporting the pulley failed Vertical member of the material hoist

buckled The force ‘T’ in the cable is induced by the weight ‘W’, including

a specified ‘Safe Working Load’ plus the dead weight of the

associated structures such as a platform or a cage.

TECHNICAL NOTE 017

Version 01, May 2017

01

KMS / TECHNICAL DEPARTMENT

Load cases that must be considered:

i) For a cable force of T, the material hoist must be designed,

among other load effects, to resist a resultant force of 2T.

The location of the resultant force shall be determined based

on the setting out dimensions of the pulleys in relation to the

material hoist;

ii) For a cable force of T, the members supporting the pulley

must be designed, among others load effects, to resist an

Free body diagram of

material hoist and cable inclined force resultant of T√2.

3.0 Design Force in Vertical Members

Hence, each leg shall take 138.6 kN. Comparing to the equally

3.1 Design Assumption by Material Hoist Designer shared design force of 42 kN, the material hoist was designed

It is noted in some design reports that the vertical legs to cater for only 30% of the demand!

of the material hoist (4 nos in total) have been designed to

resist a force that is equal to 0.25T, ie, each leg of the material

hoist shares the cable force equally. The relevant part of the 2T

design report is extracted and shown below. In this particular T√2 T√2

case, for a factored load of 166.3 kN, each leg was designed to

resist 42 kN.

a b

T T

It must be pointed out that the above simplifying assumption

ignores the cable load path, causing a very substantial 4.0 Other Observations

underestimation of the design force in the vertical legs of the

material hoist. 4.1 Effectiveness of Lateral Restraint

It is noted in many instances that lateral restraints to

the material hoist mast are provided in the arrangement (plan

3.2 Load Effects caused by Pulley System view) shown below. In essence, the members providing the

Ignoring any frictional resistance in the pulleys, the lateral restraint are not triangulated, meaning that the mast can

cable force caused by the weight ‘W’ is assumed to be T. The translate and rotate freely without stretching any restraint

material hoist is thus subjected to a resultant force of 2T acting members. As such, the lateral restraint is not effective.

at a location depending on the setting out dimensions of the

pulleys in relation to the material hoist. Also, each pulley is

subjected to an inclined force of T√2, and therefore the

members supporting the pulleys are required to cater for this

inclined load effect.

For a factored load of 166.3 kN, ie, T = 166.3 kN, the material

hoist is subjected to a resultant force of 2T, ie, 332.6 kN. The

sharing of this force by the vertical legs depends on the

dimensions of ‘a’ and ‘b’. For instance, if the ratio of a:b is 5:1,

the two vertical legs next to the winch or winding drum will

take the following share of the resultant force: Ineffective lateral restraint Material hoist is free to rotate and

(without triangulated members) translate on plan

5

( ) × 332.6 = 𝟐𝟕𝟕. 𝟐 𝐤𝐍

5+1

TECHNICAL NOTE 017

Version 01, May 2017

02

KMS / TECHNICAL DEPARTMENT

Triangulated

lateral restraint

system for a

tower crane mast

When compared to the lateral restraint to a tower crane mast, The requirement on the member and system slenderness is

it becomes apparent that an additional member is required to found not followed by the designer(s), causing potential local

be installed to enhance the restraint effectiveness. buckling failure of hoist members.

Le (Local)

Le (System)

System buckles

Triangulated lateral restraint (orange in Additional member (green in colour)

colour) to a tower crane mast should be added to restrain the Local buckles

material hoist mast

4.2 Local and System Buckling

According to the Code of Practice for Structural Use of

Steel 2011, the mast of the material hoist should be structurally

designed as a laced strut as per Cl. 8.12. One of the key

requirements is that the spacing of lacing should so be

arranged such that local buckling failure of the main component NB –

is prevented to happen before system buckles. This is enforced This technical note covers only the engineering safety aspects

by the following clause in the code: of material hoists. There are other statutory, health and safety,

and testing requirements which need to be dealt with

Cl. 8.12.1 g) The slenderness λc of the main components sufficiently. Please feel free to discuss with the Technical

about their minimum radius of gyration between consecutive Department regarding your particular issues regarding the use

points where the lacing is attached should not exceed 50. If of material hoists.

the overall slenderness of the system is less than 1.4 λc the

design should be based on a slenderness of 1.4λc. - End -

Pc

Pc 1 – Pc 2 –

Local > System

Buckling Stress Buckling Stress

Pc 1 This technical note is for internal circulation only.

For enquiry, please contact

Pc 2

Gary Chou

KMS / GM (Technical)

Technical Department

Chun Wo Construction & Engineering Co Ltd

λ E gary.chou@chunwo.com

λc 1.4λc T 3758 8379

F 2744 6937

TECHNICAL NOTE 017

Version 01, May 2017

03

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- All Physics Formula and Glossary - GCE Study Buddy - The Best O Level Revision ResourceDocument13 pagesAll Physics Formula and Glossary - GCE Study Buddy - The Best O Level Revision ResourceVei Adoptante100% (2)

- Fine Tuned UniverseDocument36 pagesFine Tuned Universeiryll78e2100% (3)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Introduction To Quantum Metrology by Waldemar Nawrocki (2015)Document287 pagesIntroduction To Quantum Metrology by Waldemar Nawrocki (2015)Vallik TadNo ratings yet

- Design of Concrete Airport PavementDocument64 pagesDesign of Concrete Airport Pavementaeroalan100% (4)

- 0318 Gearsolutions PDFDocument68 pages0318 Gearsolutions PDFdesetekNo ratings yet

- Guide On Design of Post-Installed Anchor Bolt Systems in HKDocument87 pagesGuide On Design of Post-Installed Anchor Bolt Systems in HKAhsan SattarNo ratings yet

- Deep Excavations FoundationsDocument182 pagesDeep Excavations Foundationsbannasengineer94% (18)

- +steel SECTION PROPERTIESDocument54 pages+steel SECTION PROPERTIESStar HONo ratings yet

- Guide To Trench ExcavationsDocument43 pagesGuide To Trench ExcavationsmlakkissNo ratings yet

- Note On: Second-Order Direct Analysis by NIDADocument29 pagesNote On: Second-Order Direct Analysis by NIDAPauloAndresSepulvedaNo ratings yet

- Hydraulic Design On SlopesDocument16 pagesHydraulic Design On SlopesEm MarNo ratings yet

- Mm326 System Dynamics Hw3 SolutionDocument7 pagesMm326 System Dynamics Hw3 SolutionOğulcan AytaçNo ratings yet

- Technical Note 015 PDFDocument4 pagesTechnical Note 015 PDFUthayakumar Kovarth100% (1)

- TN010 - Raft FootingDocument2 pagesTN010 - Raft FootingStar HONo ratings yet

- TECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelDocument3 pagesTECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelRaed Naim Khammash100% (1)

- Method Statement of Plate Load TestDocument5 pagesMethod Statement of Plate Load TestStar HONo ratings yet

- Technical Note TN01Document7 pagesTechnical Note TN01bosnia76No ratings yet

- Some Myths of Consolidation Settlement - Philip Chung PDFDocument21 pagesSome Myths of Consolidation Settlement - Philip Chung PDFStar HONo ratings yet

- Toyo ScaffoldDocument8 pagesToyo ScaffoldStar HONo ratings yet

- 01 Nec Ecc PN V1.0 201610 PDFDocument120 pages01 Nec Ecc PN V1.0 201610 PDFghjtyu0% (1)

- Enchanted ForrestDocument80 pagesEnchanted ForrestStar HO100% (1)

- IStructE Appraisal of Existing Structure (2nd Edition)Document54 pagesIStructE Appraisal of Existing Structure (2nd Edition)Star HO100% (3)

- InFocusDocs - Reinforcement Bars Usage PDFDocument2 pagesInFocusDocs - Reinforcement Bars Usage PDFHector IturbeNo ratings yet

- Monokote MK6Document2 pagesMonokote MK6Star HONo ratings yet

- Keybord ShorkeyDocument6 pagesKeybord ShorkeyAkshay Agrawal100% (1)

- Elastic Deflection CheckDocument2 pagesElastic Deflection CheckStar HO100% (1)

- Elastic Deflection CheckDocument2 pagesElastic Deflection CheckStar HO100% (1)

- Section Factors HPADocument16 pagesSection Factors HPATanmay GorNo ratings yet

- Vibration RollerDocument2 pagesVibration RollerStar HONo ratings yet

- CoP Steel 1987Document46 pagesCoP Steel 1987Star HONo ratings yet

- CF249 - Firecut FM-900 PDFDocument7 pagesCF249 - Firecut FM-900 PDFStar HONo ratings yet

- Kuliah 3-HIDROGRAFIDocument16 pagesKuliah 3-HIDROGRAFIaizatNo ratings yet

- RIYA Physics ProjectDocument18 pagesRIYA Physics ProjectRiya RoheraNo ratings yet

- Achievement 9 FINAL - DDocument3 pagesAchievement 9 FINAL - DJaeha CruzNo ratings yet

- Utility U (X, Y) (XY)Document8 pagesUtility U (X, Y) (XY)MadhunikaNo ratings yet

- Refrigeration & AirDocument20 pagesRefrigeration & AirBadal paridaNo ratings yet

- Adv of XLPE Over PVC in DetailDocument1 pageAdv of XLPE Over PVC in Detailaravin9786No ratings yet

- Ford-Cups Us 2012Document9 pagesFord-Cups Us 2012Engr ShoaibNo ratings yet

- Fric%on Clutches Fric%on Clutches: μ P D d D d μ PDocument2 pagesFric%on Clutches Fric%on Clutches: μ P D d D d μ PAditya Varma YalamanchiliNo ratings yet

- MSCE 509-106-Deep Beams Using Strut and Tie ModelsDocument26 pagesMSCE 509-106-Deep Beams Using Strut and Tie ModelsOtep TimusNo ratings yet

- PervaporationDocument18 pagesPervaporationKaustubh Dhabale50% (2)

- Random Variables and Stochastic Processes - April-2016Document4 pagesRandom Variables and Stochastic Processes - April-2016rajeshkumar_niceNo ratings yet

- Cogon Manuscript ICCBEI 2019 Japan PDFDocument7 pagesCogon Manuscript ICCBEI 2019 Japan PDFRevilo SilecNo ratings yet

- Desain Dan Simulasi Elemen Hingga Gantry Crane Kapasitas 9 Ton Menggunakan Autodesk Inventor 2017Document9 pagesDesain Dan Simulasi Elemen Hingga Gantry Crane Kapasitas 9 Ton Menggunakan Autodesk Inventor 2017Samuel Panda PotanNo ratings yet

- Machinery List GTM-1Document14 pagesMachinery List GTM-1Sabeeh FaruquiNo ratings yet

- Chemical Engineering Graduate Transport - HW 3Document3 pagesChemical Engineering Graduate Transport - HW 3Luthfir RahmanNo ratings yet

- Cat+Bearings PHEJ0032Document2 pagesCat+Bearings PHEJ0032Amjad ShahNo ratings yet

- Mononobe OkabeDocument12 pagesMononobe OkabeIngJonathanGarciaNo ratings yet

- Cryostar I Article Nr. 7150: ManualDocument26 pagesCryostar I Article Nr. 7150: ManualAbraham Casadiego AlverniaNo ratings yet

- SIM Math 2Document17 pagesSIM Math 2Glen Beltran HidalgoNo ratings yet

- Lab 1 Electrical MeasurementsDocument8 pagesLab 1 Electrical MeasurementsHasib Amir0% (1)

- Angewandte Chemie International Edition Volume 14 Issue 11 1975 (Doi 10.1002/anie.197507451) Prof. Dr. Rudolf Criegee - Mechanism of OzonolysisDocument8 pagesAngewandte Chemie International Edition Volume 14 Issue 11 1975 (Doi 10.1002/anie.197507451) Prof. Dr. Rudolf Criegee - Mechanism of OzonolysisSubramanya ByndoorNo ratings yet

- Lubricant Application: Grease Volumes and FrequenciesDocument7 pagesLubricant Application: Grease Volumes and FrequenciesAmjedNo ratings yet

- BimRoad TutorialDocument11 pagesBimRoad Tutorialadera1No ratings yet

- Lab # 3 Analysis of Uniform and Non Uniform Quantization of Speech Signals (U-Law and A-Law)Document13 pagesLab # 3 Analysis of Uniform and Non Uniform Quantization of Speech Signals (U-Law and A-Law)zain islamNo ratings yet

- The Design of Propeller LED Based On AT89S52Document2 pagesThe Design of Propeller LED Based On AT89S52Nong SuriyaNo ratings yet