Professional Documents

Culture Documents

Wellbore Completion

Uploaded by

Azizul Hakim0 ratings0% found this document useful (0 votes)

19 views39 pagesa

Original Title

wellbore completion

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenta

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views39 pagesWellbore Completion

Uploaded by

Azizul Hakima

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 39

Wellbore Completion Concepts

CONTENTS

1 BOTTOM HOLE COMPL2TION TECHNIQUES

1.1 Open Hole Completion

1.2 Screen or Pre-slotted Liner Completions

1,3 Cemented and Perforated Casing / Liner

2. SELECTION OF FLOW CONDUIT BETWEEN

RESERVOIR AND SURFACE

2.1 Tubing Casing Flow

2.2 Casing and Tubing Row

2.3 Tubing Flow Without Annulus Isolation

24 Tubing Flow With Annular Isolation

3 COMPLETION STRING FACILITIES

3.1 Basic Completion Sting Funetions and

Facilities

3.2 Additional Completion String Functions

3.3 Composite Completion String

4 COMPLETION STRING COMPONENTS

4.1 Wellhead / Xmas Tree

42. Production Tubing

43. Provision of an Annular Pressune Seal

4.4. ProvisionofaSeal Between Tubingand Packer

45 Sub-Surface Safety Valves

4.6 Side Pocket Mandrel (SPM)

4.7 Sliding Side Door (SSD)

48 Landing Nipples

49° Perforated Joint

5 WEL. COMPLETION DESIGNS

5.1 Land or Platform Based Completions

5.2. Subsea Completions

SUMMARY

LEARNING OBJECTIVES:

Having worked through this chapter the Student will be able to:

+ Evaluate for a given reservoir scenario the bottom hole completion options and

make a recommendation base¢ on well integrity and reservoir management

requirements

+ Assess and recommend geom«trical configurations for drilled wellbores for

both production and injection applications.

+ Identify, evaluate and recommend functional capability of completion strings

for a variety of situations,

+ Describe the purpose and yeuerie operating principles for major completion

equipment components,

+ Identify limitation of well completion sehematical designe and potential

failure mechanisms/operationa problems with equipment,

+ Assess well safety requirements and capabilities inherent in well design.

Wellbore Completion Concepts 4

INTRODUCTION

inthe development of a hydrocarbon reservoir, a large number of wells are drilled and

“equire to be completed, to allow the structure to be depleted. However, the drilling

and completion operations are crucial tothe long te-m viability of the wells in meeting

hhe specified objectives. The design and completion of both proxtuction and injection

wells are required to satisty a number of objectives including:

1. Provision of optimum production/injection performance.

2. Rnsure safety

3. Maximise the integrity and reliability of the completion over the

envisaged life of the completed well

4, Minimise the total costs per unit volume of fluid produced or injected, ie.

minimise the costs of initial completion, maintaining production and remedial

measures,

Depending upon the reservoir characteristics or development constraints, the

completion may be required to fulfil other criteria, e.g, to control sand production,

The design of a completion can therefore be assumed to proceed concurrently at two

sifferent levels. The initial intention would be to produce a conceptual design, ora

series of alternatives. From these conceptual designs, one or more would be selected

‘or mote detailed development. Thereafter, a detailed design process would be

>ursued with the intention of producing a completion string design which specifiesall

‘components and also assesses the sensitivity of the well and completion performance

‘0 Variations inthe reservoir data used for the desi.

The fundamental design of a completion consists of four principal decision

areas, namely’

1. Specification of the bottom hole completion technique.

2. Selection of the production conduit

3. Assessment of completion string facilities.

4. Evaluation of well performance / productivity-injectivity

These four decision areas, as shown in Figure 1, should provide a conceptual design

‘orthe completion of the wells. However, this design process normally is initiated on

he basis of data from exploration wells and considerable uncertainty may exist as to

he validity and accuracy of that data, Thus a number of alternative designs for well

‘completions will normally be selected and retained as a contingency.

‘Deparment of Perloum Enginaerng, Heriot Watt University 3

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Kar Yaku: NON Resi DEN Ui TM Shah AlamDocument1 pageKar Yaku: NON Resi DEN Ui TM Shah AlamAzizul HakimNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Sun Jun 23 03:37:25 2019 Case: Activity 3.hsc Flowsheet: Case (Main)Document1 pageSun Jun 23 03:37:25 2019 Case: Activity 3.hsc Flowsheet: Case (Main)Azizul HakimNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- GGDocument2 pagesGGAzizul HakimNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 4.0 Processes Are Employed in The Treatment Plant and Detailed Description On The Size of The Treatment UnitsDocument5 pages4.0 Processes Are Employed in The Treatment Plant and Detailed Description On The Size of The Treatment UnitsAzizul HakimNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Buzzer Order List: Name Qty. Price Total 2 RM10/qty RM20Document1 pageBuzzer Order List: Name Qty. Price Total 2 RM10/qty RM20Azizul HakimNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- ResultDocument2 pagesResultAzizul HakimNo ratings yet

- Lab 6 RecommendationDocument1 pageLab 6 RecommendationAzizul HakimNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- New Doc 2019-04-16 09.24.29Document1 pageNew Doc 2019-04-16 09.24.29Azizul HakimNo ratings yet

- Doorknob With Security Access Key Lock AccessDocument3 pagesDoorknob With Security Access Key Lock AccessAzizul HakimNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- CGE669 - Assigment HYSYS Activity 3Document1 pageCGE669 - Assigment HYSYS Activity 3Azizul HakimNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Full Report EDITED 4.0Document94 pagesFull Report EDITED 4.0Azizul HakimNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- New Doc 2019-04-16 09.24.29 PDFDocument257 pagesNew Doc 2019-04-16 09.24.29 PDFAzizul HakimNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Benefit of Waste Measurement and ReportingDocument2 pagesBenefit of Waste Measurement and ReportingAzizul HakimNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

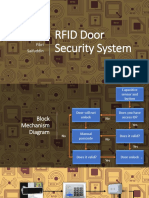

- RFID Door Security System Rev02Document8 pagesRFID Door Security System Rev02Azizul HakimNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- App 1Document1 pageApp 1Azizul HakimNo ratings yet

- Unit 2: Creativity, Innovation and Technology Entrepreneurship Unit 2: Creativity, Innovation and Technology EntrepreneurshipDocument32 pagesUnit 2: Creativity, Innovation and Technology Entrepreneurship Unit 2: Creativity, Innovation and Technology EntrepreneurshipAzizul HakimNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RFID Trend CanvasDocument10 pagesRFID Trend CanvasAzizul HakimNo ratings yet

- 08 Drilling Engineering Part 4 DrillbitsDocument35 pages08 Drilling Engineering Part 4 DrillbitsAzizul HakimNo ratings yet

- SwotDocument6 pagesSwotAzizul HakimNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Full Report EDITED 2.0Document97 pagesFull Report EDITED 2.0Azizul HakimNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SwotDocument2 pagesSwotAzizul HakimNo ratings yet

- EraDocument1 pageEraAzizul HakimNo ratings yet

- Tutorial 1 - Azizul Hakim Bin Sabri (2017466046)Document13 pagesTutorial 1 - Azizul Hakim Bin Sabri (2017466046)Azizul HakimNo ratings yet

- Casing Data PDFDocument6 pagesCasing Data PDFAzizul HakimNo ratings yet

- CGE443: Computer Application in Oil & Gas Engineering: Noraida Amin Binti MD Taib March 2017Document41 pagesCGE443: Computer Application in Oil & Gas Engineering: Noraida Amin Binti MD Taib March 2017Azizul HakimNo ratings yet

- Bus Order Summary: YjrkfhoqDocument7 pagesBus Order Summary: YjrkfhoqAzizul HakimNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Full Report EDITED 4.0Document94 pagesFull Report EDITED 4.0Azizul HakimNo ratings yet

- Transient Flow Because of Time Dependent Flow: o o o o o o o o o oDocument5 pagesTransient Flow Because of Time Dependent Flow: o o o o o o o o o oAzizul HakimNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)