Professional Documents

Culture Documents

10 Commandments Gear Failure PDF

10 Commandments Gear Failure PDF

Uploaded by

Sivaraman Visvanathan0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

10_Commandments_Gear_Failure.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 page10 Commandments Gear Failure PDF

10 Commandments Gear Failure PDF

Uploaded by

Sivaraman VisvanathanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

The en Comma dments 0

Gear Failure Ana ys's

Robert Errichello

I. In, pect failed components as soon as possible. If an early

on- ite inspection i not po ible, omeone at the ite mu t pre-

erve the evidence based on your in truction .

II. Make ure no work i done until you arrive. Thi mean

no di a embly, no cleaning (including exterior), or draining of

oil. Verify that gearbox drawing, di a sembly tool and ad -

quate facilitic are available.

III.Devote at lea t two day for the in pecti n. After the fir t

day, collect your though and analyze the collected data. Often

the fir t day'. in pection di clo e a need for other data which

you can gather on the econd day.

IV. Concentrate on collecting evidence, not on determining

the cau e of failure. Regardle s of how obviou the cau e may

appear. do not form conc1u "ions until all evidence icon idered.

V. Document what you ee. Li t all ob ervation , even if

orne eern in ignificant or if you don't recognize the failure

mode. Remember-there i a rea on for everything you ee, and

it may become important later when you con ider all the evi-

dence.

VI. Document what you don't ee. This i helpful to elimi-

nate certain failure mode and cau e . For example. if there i

no cuffing. you can conclude gear tooth contact temperature

wa le s than the cuffing temperature of the lubricant.

VII. Search the bottom of the gearbo . Often thi i where

you find the be t-pre erved evidence, uch as when a tooth fra -

ture and falls free without econdary damage.

VIII. e time efficiently. Be prepared for the in pection.

Plan work carefully to obtain a much evidence as po ible.

Don't be di tractcd by anyone.

IX. ontrol the inve tigation. Watch every step f the disas-

embly. Don't let the technician get ahead of you. Di a embly

hould top while you inspect and document the condition of a

component, then proceed to the next component.

. In i t on privacy. 0 not let anyone di tract you. If a ked

about your conclu ion' an wer that you do not form conclu-

ion until your investigati ni complete. 0

T.1l Us Wha. You Think ...

S.nd •.• iI topIHIfI'''''''''''''''''''t:Mto

Robert Errichello • Rate this articl.

is founder and president of GEARTECH, located • Request 11IOI1Iillfonlltion

in Townsend, MT. and is a technical editor for • CoatIct the author or comPIIY ntioned

Gear Technology magazine. A gear consultant, he

• Mak' a IUIItItion

pecializes in gear failure analysis. gear research

and analysi , and gear design and production.

Orcall (147)437 .• tota. to editors!

62 SEPTEMBER/OCTOBER 2003 • GEAR TECHNOLOGY • www.geartechnology.com • www.powertrsnsmission.com

You might also like

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?From EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?No ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreFrom EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo ratings yet

- Photography of Gear Failures: Robert ErricheuoDocument4 pagesPhotography of Gear Failures: Robert Erricheuorashm006ranjan100% (1)

- Top 10 Rotating Equipment Engineer Interview Questions and AnswersDocument17 pagesTop 10 Rotating Equipment Engineer Interview Questions and AnswersSathishkumar VeluNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Case Studies #4: Professional Services For Proactive MaintenanceDocument13 pagesCase Studies #4: Professional Services For Proactive MaintenanceMiguel VillegasNo ratings yet

- Tension of Pulley AlignmentDocument3 pagesTension of Pulley AlignmentnguyennhatbaoNo ratings yet

- ROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enDocument156 pagesROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enxX1crist1Xx100% (1)

- Bearingfailure PDFDocument22 pagesBearingfailure PDFMohamed Altaf Jaffer100% (1)

- Certified Maintenance & Reliability Technician CMRT Candidate Guide For Certification and Re-CertificationDocument3 pagesCertified Maintenance & Reliability Technician CMRT Candidate Guide For Certification and Re-Certificationlinbaba123No ratings yet

- How To Analyze Gear FailuresDocument9 pagesHow To Analyze Gear Failuresrobertoalfaro49100% (1)

- Mechanical Seal ProblemsDocument5 pagesMechanical Seal Problemschazz29hkNo ratings yet

- Gear Failure AnalysisDocument22 pagesGear Failure AnalysisKarthick Kumar100% (1)

- Reliability Centered Maintenance A Complete Guide - 2020 EditionFrom EverandReliability Centered Maintenance A Complete Guide - 2020 EditionNo ratings yet

- Failure Analysis For Plain BearingsDocument5 pagesFailure Analysis For Plain BearingsPuchit SpkNo ratings yet

- 12 1989 Shaft StressDocument4 pages12 1989 Shaft StressRonald GeorgeNo ratings yet

- RCA Next Level Failure AnalysisDocument53 pagesRCA Next Level Failure AnalysisJay100% (2)

- 100 Failure Modes of LubricationDocument5 pages100 Failure Modes of LubricationErick PachasNo ratings yet

- Machinery Lubrication OilersDocument0 pagesMachinery Lubrication OilerssatstarNo ratings yet

- Biblio MotorsDocument11 pagesBiblio MotorsMuhammad KaleemNo ratings yet

- How To Inspect Gear BoxDocument11 pagesHow To Inspect Gear BoxSubbarayan SaravanakumarNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Gear Quality - What It's All AboutDocument5 pagesGear Quality - What It's All AboutFemi FadeyiNo ratings yet

- Gear Failures PittingDocument22 pagesGear Failures PittingSridhar IyerNo ratings yet

- Reliability Centered Maintenance Rcm A Complete Guide - 2019 EditionFrom EverandReliability Centered Maintenance Rcm A Complete Guide - 2019 EditionNo ratings yet

- Identification, Disassembly/assembly of Philadelphia Gear Corp. Speed Increaser, P/N 110277Document22 pagesIdentification, Disassembly/assembly of Philadelphia Gear Corp. Speed Increaser, P/N 110277JONATHAN100% (1)

- Reliabilityweb Uptime 20121011Document69 pagesReliabilityweb Uptime 20121011catraioNo ratings yet

- ROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enDocument156 pagesROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enCeliocp PinheiroNo ratings yet

- Bearing Failure Analysis-V2Document9 pagesBearing Failure Analysis-V2Anonymous omGSHUEQNo ratings yet

- EGT001 Roller Bearings Lubrication TrainingDocument10 pagesEGT001 Roller Bearings Lubrication TrainingJom BonhayagNo ratings yet

- Bearing Failure PDFDocument5 pagesBearing Failure PDF01666754614100% (2)

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- FAG Bearing DamageDocument91 pagesFAG Bearing Damagesamir8albinoNo ratings yet

- Machinery Reliability Is A Measure of Perfection Abdulrahman AlkhowaiterDocument16 pagesMachinery Reliability Is A Measure of Perfection Abdulrahman AlkhowaiterAbdulrahman Alkhowaiter100% (1)

- NATCOM Alignment TrainingDocument133 pagesNATCOM Alignment TrainingMohamed M. AfifiNo ratings yet

- Cardan Shaft AlignmentDocument26 pagesCardan Shaft AlignmentconstantinNo ratings yet

- Bearing Failure AnalysisDocument26 pagesBearing Failure AnalysisengrsurifNo ratings yet

- Boralign TRG PPT - 2k3 Aug019Document65 pagesBoralign TRG PPT - 2k3 Aug019propulzi100% (2)

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- Ludeca Best Practices Machinery Alignment ShimmingDocument7 pagesLudeca Best Practices Machinery Alignment ShimmingTimber RamNo ratings yet

- Condition Monitoring of Shovel Equipment Impacts ProfitabilityDocument27 pagesCondition Monitoring of Shovel Equipment Impacts ProfitabilitydhowardjNo ratings yet

- Don't Get Soft: Cover Series: Installation Best PracticesDocument6 pagesDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Why Wind Turbine Gearboxes FailDocument4 pagesWhy Wind Turbine Gearboxes FailasantonyrajNo ratings yet

- P178Document9 pagesP178keepmoshingNo ratings yet

- Time Waveform Analysis TechniquesDocument2 pagesTime Waveform Analysis TechniquesManel Montesinos100% (1)

- Acoustic LubricationDocument14 pagesAcoustic LubricationBobyNo ratings yet

- MEE Avoiding Bolt FailuresDocument2 pagesMEE Avoiding Bolt Failuresridwan347No ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Oil Analysis - Noria - ComDocument9 pagesOil Analysis - Noria - ComCorina Stanculescu50% (2)

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- Earned Value Management (EVM)Document8 pagesEarned Value Management (EVM)rashm006ranjanNo ratings yet

- 3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom ListDocument2 pages3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom Listrashm006ranjanNo ratings yet

- 03 - Confined Space EntryDocument18 pages03 - Confined Space Entryrashm006ranjanNo ratings yet

- NCQC 2016 RaipurDocument8 pagesNCQC 2016 Raipurrashm006ranjanNo ratings yet

- Machinery Lubrication I IIDocument12 pagesMachinery Lubrication I IIrashm006ranjan50% (2)

- New Book Launch Schedule 36 Days: Planning Complete!Document1 pageNew Book Launch Schedule 36 Days: Planning Complete!rashm006ranjanNo ratings yet

- Turbine Cooling TemperaturesDocument12 pagesTurbine Cooling Temperaturesrashm006ranjan0% (1)

- 790Document5 pages790rashm006ranjanNo ratings yet

- Energy Audit For Electric MotorDocument4 pagesEnergy Audit For Electric Motorrashm006ranjanNo ratings yet

- Simple FormattingDocument1 pageSimple Formattingrashm006ranjanNo ratings yet

- Annemometer and ThermometerDocument1 pageAnnemometer and Thermometerrashm006ranjanNo ratings yet

- Steam Ejector CalculationsDocument11 pagesSteam Ejector Calculationsrashm006ranjan100% (1)

- National Institute of Technology CalicutDocument14 pagesNational Institute of Technology Calicutrashm006ranjanNo ratings yet

- Bevel & Hypoid Gears:: Measuring BacklashDocument3 pagesBevel & Hypoid Gears:: Measuring Backlashrashm006ranjan100% (1)

- HyperGraph3D TutorialsDocument41 pagesHyperGraph3D Tutorialsrashm006ranjanNo ratings yet

- Coal Mill Heat BalanceDocument2 pagesCoal Mill Heat Balancerashm006ranjanNo ratings yet

- SKF Dry Lubricated Bearings 11358 3 enDocument28 pagesSKF Dry Lubricated Bearings 11358 3 enrashm006ranjan100% (1)

- Compressor and Compressed Air SystemDocument34 pagesCompressor and Compressed Air Systemrashm006ranjanNo ratings yet

- Loss Optimisation in BoilersDocument50 pagesLoss Optimisation in Boilersrashm006ranjanNo ratings yet

- The Condenser Performance Test and Thermal Performance Analysis of Variable Conditions in TQNPCDocument4 pagesThe Condenser Performance Test and Thermal Performance Analysis of Variable Conditions in TQNPCrashm006ranjanNo ratings yet

- Coal Mill Heat BalanceDocument2 pagesCoal Mill Heat Balancerashm006ranjanNo ratings yet

- Paper 2 - Set B Solutions: General InstructionsDocument14 pagesPaper 2 - Set B Solutions: General Instructionsrashm006ranjanNo ratings yet

- Assigned Cases For The Coverage of The 4TH ExamDocument9 pagesAssigned Cases For The Coverage of The 4TH ExamNhassie John GONZAGANo ratings yet

- Literary Analysis HandoutDocument3 pagesLiterary Analysis Handoutapi-266273096100% (1)

- MGN 303Document11 pagesMGN 303Arun SomanNo ratings yet

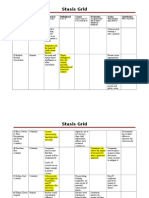

- Cybersecurity Stasis GridDocument6 pagesCybersecurity Stasis Gridapi-302342361No ratings yet

- Comparing Portfolio Rebalancing Strategies YCharts 2021Document10 pagesComparing Portfolio Rebalancing Strategies YCharts 2021santosh kumarNo ratings yet

- 02 AaltoBeyondFinland2015Document17 pages02 AaltoBeyondFinland2015Yesy Arrieta KesinovicNo ratings yet

- Americanah by Chimamanda Ngozi AdichieDocument19 pagesAmericanah by Chimamanda Ngozi AdichieRandom House of Canada35% (31)

- Twilight Struggle Solitaire VariantDocument2 pagesTwilight Struggle Solitaire VariantKarlo Marco Cleto100% (1)

- Relevancy of New York Convention With Respect To Foreign Awards in IndiaDocument7 pagesRelevancy of New York Convention With Respect To Foreign Awards in IndiaSmriti SinghNo ratings yet

- Category Design Drives Markets by Mark DonniganDocument15 pagesCategory Design Drives Markets by Mark DonniganMark DonniganNo ratings yet

- Website Development Fundamentals CourseDocument5 pagesWebsite Development Fundamentals CourseMihigo ER AnajaNo ratings yet

- PHD Thesis by Publication - MD IRTEJA ISLAM - 0061107404 - 200521Document228 pagesPHD Thesis by Publication - MD IRTEJA ISLAM - 0061107404 - 200521Tanvir Ahmed NayeemNo ratings yet

- Walmart Value Chain AnalysisDocument21 pagesWalmart Value Chain AnalysisRafaa DalviNo ratings yet

- User Administration in Wincc ProfessionalDocument59 pagesUser Administration in Wincc ProfessionalDario ŠkaronNo ratings yet

- Patriarchy in Flux and The Invisible Women of The Mexican WomenDocument49 pagesPatriarchy in Flux and The Invisible Women of The Mexican WomenTeresa100% (1)

- The Barber of Seville - BeaumarchaisDocument4 pagesThe Barber of Seville - BeaumarchaisAngelica FenechNo ratings yet

- Mental Health 30 Day ChallengeDocument31 pagesMental Health 30 Day Challengemeklit fekadeNo ratings yet

- Dyson - Presentation About Company and Case StudyDocument17 pagesDyson - Presentation About Company and Case StudyPiotr Bartenbach67% (6)

- Swing DanceDocument7 pagesSwing DanceRodel MirandillaNo ratings yet

- Worksheet 1Document3 pagesWorksheet 1Hend HamedNo ratings yet

- DigestDocument30 pagesDigestyguhbnijmokp32No ratings yet

- Menu Design: Class: CLN2400 Lecturer: Bruno Baumann Project By: Caroline, Debby, GlebDocument9 pagesMenu Design: Class: CLN2400 Lecturer: Bruno Baumann Project By: Caroline, Debby, GlebCaroline Elia0% (1)

- Beyond Mobile Payments: Exploring The Evolution and Future of FintechDocument6 pagesBeyond Mobile Payments: Exploring The Evolution and Future of FintechInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Đề Số 44 Có Giải Chi Tiết-RDocument16 pagesĐề Số 44 Có Giải Chi Tiết-Rntt102286No ratings yet

- Anne Marie B. Bahr-Religions of The World-ChristianityDocument239 pagesAnne Marie B. Bahr-Religions of The World-ChristianityGheorghe Mircea67% (3)

- Test Bank For American Politics Today Essentials 6th Edition William T Bianco David T CanonDocument20 pagesTest Bank For American Politics Today Essentials 6th Edition William T Bianco David T Canonmingarannikj100% (12)

- Jurnal Pengembangan Kawasan Pertanian-DikonversiDocument9 pagesJurnal Pengembangan Kawasan Pertanian-DikonversiFauzan Dzakwan 19No ratings yet

- Vertigo TestDocument6 pagesVertigo Testalam saroorNo ratings yet

- Strategic Analysis Tools & TechniquesDocument14 pagesStrategic Analysis Tools & TechniquesAbdel Moneim HassanNo ratings yet

- MCQsDocument2 pagesMCQsAbdul B BarikzaiNo ratings yet