Professional Documents

Culture Documents

Electric Built-In / Oven: 24" Single Cavity Models .

Uploaded by

david rodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electric Built-In / Oven: 24" Single Cavity Models .

Uploaded by

david rodriguezCopyright:

Available Formats

\

ELECTRIC BUILT-IN

OVEN

24” SINGLE CAVITY MODELS

‘.._~~ (STARTING WITH 1982 MODELS)

Part No. 311435 Rev. D

More user manuals on ManualsBase.com

SUPPORT SURFA

JUNCTION BOX:

SEENOTE 1 ’ *FOR A 36” OPEN OVEN DOOR HEIGHT

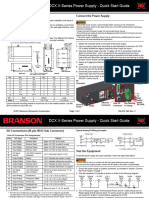

FIGURE 1 --ROUGH-IN DIMENSIONS

DO NOT INSTALL THIS OVEN IN A BASE

CABINET WITH A COUNTERTOP ABOVE IT.

1. CARPENTRY NOTE: Wire sizes and connections must conform with the

Refer to Figure 1 for the dimensions of the oven and the fuse size and rate of the appliance in accordance with the

National Electrical Code and local codes and ordinances.

space necessary to receive the oven. The oven support

Do not use an extension cord.

surface may be solid plywood or similar material but the

contact surface must be level from side to side and from B. The appliance should be connected to the fused discon-

front to rear. This surface is 2%” below the open door nect (or circuit breaker) box through flexible armored or

height. non-metallic sheathed cable. The flexible armored cable

extending from the appliance should be connected directly

NOTE 1: The oven support surface must be flush with the to the junction box. The junction box should be located

bottom of the cabinet cut out. as shown in Figure 1 so that as much slack as possible

remains in the cable between the.box and the appliance

WARNING: TO AVOID DAMAGE TO CABINET so that it can be moved if servicing is ever necessary.

AND/OR POOR BAKE PERFORMANCE, DO NOT

C. A suitable strain relief must be provided to attach the

BLOCK OVEN VENT. flexible armored cable to the junction box.

2. ELECTRICAL REQUIREMENTS D. Electrical Connection.

IMPORTANT: OBSERVE AU GOVERNING CODES It is the personal responsibility and obligation of the

AND OflDlNANCES customer to contact a qualified installer to assure that the

electrical installation is adequate and is in conformance

I SAVE THESE INSTRUCTIONS FOR THE LOCAL

ELECTRICAL INSPECTOR’S USE I

with the National Electrical Code and local code

ordinances.

Electrical ground is required on this appliance.

A. A three-wire or four-wire single phase 120/240 volt 60Hz This appliance is equipped with copper lead wires. If the

AC only electrical supply (or threewire or four-wire 120/206 connection is made to aluminum house wiring, use only special

volt if specified on nameplate) is required on a separate connectors which are approved for joining copper and

crrcuit fused on both sides of the line (time-delay fuse or aluminum wires, in accordance with the National Electrical

circuit breaker is recommended). Do NOT fuse neutral. The Code and local codes and ordinances.

fuse size must not exceed the circuit rating of the appliance

specified on the nameplate. This appliance is manufactured with a white neutral power

supply wire and a frame-connected green ground wire.

More user manuals on ManualsBase.com

If local codes permit connection of the frame ground- 3. INSTALLATION

ing conductor to the neutral (white wire), connect the NOTE:

green and white wire from the supply cable of the Before installing the oven in the cutout, it may be helpful

appliance together and to the neutral (white) wire in to remove the oven door. See details below.

the junction box. Connect the remaining wires from Insert appliance into cut-out. Screws are provided for

the supply cable. matching the colors, to the wires in fastening the front frame of the appliance to the cabinet.

The mounting holes in the front frame of

the junction box. appliance may be used as a template to locate the ap-

pliance mounting screw holes.

If local codes DO NOT permit frame grounding to the CAUTION: For your personal safety, and to minimize

neutral, separate the white and green wires that potential personal injury, this oven must be securely

extend out of the end of the supply cable of the fastened to the cabinet, using the four screws that are

appliance. Connect the white wire from the supply provided.

cable to the neutral wire In the junction box. Use caution when mounting oven in cutout so you do

not overtighten screws and cause porcelain chippage

Connect the black and red wire from the supply cable. or puncture oven cavity.

matching the colors, to the corresponding wires in the TO REMOVE OVEN

lunchon box. The green wire MUST now be used to

ground the appliance In accordance wtth local electri-

cal codes Connect the green ground wire to a

grounded cold water plpe*or to the grounded lead in

the service panel Do not ground to a gas supply pipe.

DC not connect to electrlcal power supply until

appliance IS permanently grounded. Connect the

ground wire before turning on the power See ffgure

2

GROUNOEO COLD

COPPER WATER PIPE View a View b

GROUND WIRE (REMOVE PAINT, ETC.)

Open door fully.

Swing the 2 clips located on door in front of hinges so they

cross over the hinge slots (View a).

Close the oven door slowly until you feel it stop.

Lift up slightly allowing the bottom of the door to swing out.

(View b) Note that the top of the door must be tilted toward

the oven at this point to allow hing arms to swing free. if

appliance is so located that you cannot grasp both sides

of door you may grasp the door by handle (View c) and

follow same procedure outlined above.

TO REPLACE OVEN DOOR

GROUND CLAMP

(MUST BE TIGHT

ON PIPE)

FIGURE 2

*Cold water pipe must have metal continuity to electrical

ground and not be Interrupted by plastic, rubber or other

electrically insulating connectors (including water meter

or pcimp) without adding a jumper wire at these connec-

tions.

CAU rlON - If connecting to a four-wire electrical system 1. Grasp door by sides (View b) or by handle and align hinge

arms on door with TOP of slot in oven sides.

(MOBILE HOME) the appliance frame MUST NOT be

connected to the neutral wire of the four-wire electrical 2. Tilt top of door toward the oven (View b) and allow door

to “ride” into position. A slight lifting and inward pressure

system. Separate the white and green wires that extend toward the bottom of the door will make sure it seats pro-

out Jf the end of the supply cable of the appliance perly. (View d).

Connect the white, red and black wires from the supply 3. Open door fully and swing the clips away from the slots

cable, matching the colors, to the corresponding wires in (View a).

the IunctIon box. Connect the green wire from the supply

cable to the ground wire In the )unctlon box.

More user manuals on ManualsBase.com

DOOR ADJUSTMENT (IF NEEDED) 4. CHECKING

Open oven door and loosen the upper adjustrng screw CAUTION: Do not touch the element& They may

(seeview e) on the srde that needs adjustment.

be hot and you may get burned.

Close oven door dnd loosen the lower adjusting screw. THERMOSTAT

Adjust door up and down as needed. Preheat ~ Turn selector switch to PREHEAT and set

the thermostat to 350’ BAKE temperature. The

Fietlghten the lower adjustrng screw. bottom oven element should become red and the

indicator light should glow. The upper oven element

Open oven door and retrghren the upper adjusting should become hot but NOT become red.

screw. Broil Turn selector switch to BROIL and set

thermostat to a high temperature position. The top

Close oven door and double check for proper door element should become cherry-red and the indicator

alignment light should glow.

FRONT Bake Turn selector switch to BAKE and set thermo-

FRAME stat to 350°. The bottom element should become red

and the indicator light should glow.

1

B. CLOCK

Refer to the Use and Care Guide for proper operation of

ADJUSTING the clock.

C. ROTISSERIE (if optional kit has been installed)

1, Positron the spit bar on special rack

2. Insert the point of spit bar into hole in the back of the

OVEN - oven.

DOOR

3. Rotation starts upon Insertion of spit bar.

View e

In the event your WHIRLPOOL appliance should need service, call the dealer from whom

you purchased the app,,ance or a WHIRLPOOL franchised TECH-CARE” serwcecompany.

He 1s I” the Yellow Pages of your telephone directory listed under “Appliances-Households

Major Serwce and Repair.” You can also obtain his name and number by dialmg, free, withln

rhe conrinenral United States the Whirlpool COOL-LINE @ Service (6OOl 253.1301. When

calling from Mlchlgan, dial (800) 632~2243, from Alaska or Hawaii, dial (800) 253-l 121.

&al jut as you normally dial long distance. A special operator will fell you the name and

number of your nearest Whirlpool TECH-CARE sew~cc outlet. During normal working hours,

WhIrlpool consultants at this same number will also answer any questions about operating or

malnta!mng your appliance not covered in your Use and Care Guide.

Learn the benefits of using TECH-CARE service for malntainlng the quality originally built

into your WHIRLPOOL appliance.

4

WHIRLPOOL CORPORATION BENTON HARBOR, MICHIGAN 49022

Part No. 311435 Rev. D

You might also like

- Miele Oven H 5140 BP Users Manual 2e - H5140 5240 - BP - HFC - T EC - GBDocument1 pageMiele Oven H 5140 BP Users Manual 2e - H5140 5240 - BP - HFC - T EC - GBshrutiNo ratings yet

- Akai MFC-42 Owners ManualDocument33 pagesAkai MFC-42 Owners ManualJames SpadavecchiaNo ratings yet

- Hfe Nad c540 en de FR Es It Se PTDocument38 pagesHfe Nad c540 en de FR Es It Se PTIvan MojsaNo ratings yet

- VSX-409RDS: Audio/Video Multi-Channel ReceiverDocument40 pagesVSX-409RDS: Audio/Video Multi-Channel ReceiverJosé SomozaNo ratings yet

- Ultra Quiet Oil-Free Air Compressor ManualDocument16 pagesUltra Quiet Oil-Free Air Compressor Manualmmeneses07No ratings yet

- Waynekerr4235 User ManualDocument123 pagesWaynekerr4235 User ManualTrần Hồng Văn50% (2)

- Installation Guide for MT-600/8000 Series HMI DisplaysDocument8 pagesInstallation Guide for MT-600/8000 Series HMI DisplaysKelechi H. HenryNo ratings yet

- MT610i MT6100i MT8100i Installation 101028Document8 pagesMT610i MT6100i MT8100i Installation 101028ali jafariNo ratings yet

- F7SP24S1-Installation ManualDocument10 pagesF7SP24S1-Installation ManualHaris MunirNo ratings yet

- RX-4109 AM/FM Stereo Receiver Setup GuideDocument23 pagesRX-4109 AM/FM Stereo Receiver Setup Guidegoga1990No ratings yet

- DCX V-Series Power Supply - Quick Start GuideDocument2 pagesDCX V-Series Power Supply - Quick Start GuideAdrian TrabajoNo ratings yet

- Pioneer A-109Document12 pagesPioneer A-109JosueNo ratings yet

- 30" Electric Range Installation Instructions: (For 3 or 4 Wire, 60 Hz. Systems)Document4 pages30" Electric Range Installation Instructions: (For 3 or 4 Wire, 60 Hz. Systems)RazvodnikNo ratings yet

- GE Cooktop InstallationDocument16 pagesGE Cooktop InstallationGerard AmentoNo ratings yet

- Ariston Oven ManualDocument16 pagesAriston Oven ManualJoanne JoanneNo ratings yet

- RAX711-L (A) Quick Installation Guide (Rel - 03)Document7 pagesRAX711-L (A) Quick Installation Guide (Rel - 03)Rachid TahiriNo ratings yet

- XV-DV323 XV-DV424 S-DV323 S-DV424: DVD/CD ReceiverDocument74 pagesXV-DV323 XV-DV424 S-DV323 S-DV424: DVD/CD ReceiverGerresNo ratings yet

- CT-W208R: Stereo Double Cassette DeckDocument20 pagesCT-W208R: Stereo Double Cassette DeckGary MaskNo ratings yet

- CT-W208R: Stereo Double Cassette DeckDocument20 pagesCT-W208R: Stereo Double Cassette DeckGary MaskNo ratings yet

- JBL_KX180_UserManual_en_092017Document16 pagesJBL_KX180_UserManual_en_092017loc nguyenNo ratings yet

- Om WD PLDocument9 pagesOm WD PLcompras.lairtechNo ratings yet

- Nad C 320 Owners ManualDocument36 pagesNad C 320 Owners ManualPeter CormackNo ratings yet

- Switch Installation Guide: Warnings and ConsiderationsDocument4 pagesSwitch Installation Guide: Warnings and ConsiderationsAndres PARDO ARAQUENo ratings yet

- Harman Kardon-3458479517-JBL Bar 5.1 Owners Manual PortugueseDocument46 pagesHarman Kardon-3458479517-JBL Bar 5.1 Owners Manual PortugueseJudson BorgesNo ratings yet

- Waukesha Gas Engines: GE Power & Water Distributed PowerDocument4 pagesWaukesha Gas Engines: GE Power & Water Distributed PowerdfmolinaNo ratings yet

- Whirlpool Calypso Service ManualDocument68 pagesWhirlpool Calypso Service ManualBrian D Smith100% (1)

- HW-C430 Xu FM 00 Eng 230206Document39 pagesHW-C430 Xu FM 00 Eng 230206ddr95827No ratings yet

- Warning: FP Panel Instructions Instructions Pour Panneau FP Instrucciones Del Panel FPDocument8 pagesWarning: FP Panel Instructions Instructions Pour Panneau FP Instrucciones Del Panel FPjorge castroNo ratings yet

- Upgrade Home Electrical Panel and ServiceDocument90 pagesUpgrade Home Electrical Panel and ServiceNeil Menezes100% (1)

- RP21DDocument69 pagesRP21DRobson DiasNo ratings yet

- Technics RS-B605Document8 pagesTechnics RS-B605NanoUrraNo ratings yet

- Thông số dòng I customDocument12 pagesThông số dòng I customVăn Long NguyênNo ratings yet

- MT6070iH ManualDocument8 pagesMT6070iH ManualFranco Cossio RamirezNo ratings yet

- DD-12020.02 (Ic Type)Document3 pagesDD-12020.02 (Ic Type)Ana Belén Martínez BaltazarNo ratings yet

- Stereo Integrated Amplifier: GB F D E I P SDocument36 pagesStereo Integrated Amplifier: GB F D E I P SmhalmhNo ratings yet

- AKA304 (Akai-S3200XL) PDFDocument318 pagesAKA304 (Akai-S3200XL) PDFJh CtNo ratings yet

- Sony STR DA 333ES User ManualDocument52 pagesSony STR DA 333ES User ManualGabriel PiticasNo ratings yet

- Kac 8403Document20 pagesKac 8403Manuel Olmos RabagoNo ratings yet

- SH-GE70: Operating InstructionsDocument12 pagesSH-GE70: Operating Instructionsmiliindianu100% (1)

- MT-8000 Installation GuideDocument8 pagesMT-8000 Installation Guidebassit82No ratings yet

- HS-4000 OM VD PDFDocument152 pagesHS-4000 OM VD PDFAmirNo ratings yet

- Abbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualDocument7 pagesAbbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualdanielvillagrapNo ratings yet

- FM Stereo FM-AM Receiver: STR-DE975 STR-DE875Document72 pagesFM Stereo FM-AM Receiver: STR-DE975 STR-DE875gepetosdNo ratings yet

- Dual-Engine Multi-Effects Processor: User's GuideDocument23 pagesDual-Engine Multi-Effects Processor: User's GuideDiego Smash MusicNo ratings yet

- Install 10Document2 pagesInstall 10dwight_mcgowenNo ratings yet

- InstallDocument5 pagesInstallNothing is EverythingNo ratings yet

- Installation Instructions: For EVS Security SystemsDocument14 pagesInstallation Instructions: For EVS Security SystemsMichel TanusNo ratings yet

- LG j10hd Owner S ManualDocument39 pagesLG j10hd Owner S ManualZdravko Lučić100% (1)

- Toca Discos Aiwa Pxe850Document8 pagesToca Discos Aiwa Pxe850Cdsbarbosa BarbosaNo ratings yet

- FM Stereo FM-AM Receiver: STR-DE575 STR-K502Document54 pagesFM Stereo FM-AM Receiver: STR-DE575 STR-K502Eduardo da Costa LeiteNo ratings yet

- Instruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineDocument20 pagesInstruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineLauraNo ratings yet

- KRK10s Subwoofer User GuideDocument24 pagesKRK10s Subwoofer User GuidedemonclaenerNo ratings yet

- Yamaha Power Amp ManualDocument12 pagesYamaha Power Amp ManualRNo ratings yet

- Sony VX550 PDFDocument59 pagesSony VX550 PDFcrm102bNo ratings yet

- Compact Disc Player: GB F D E I P SDocument45 pagesCompact Disc Player: GB F D E I P SHéctor Torres HinojosaNo ratings yet

- Samsung PS42A410 PrecautionDocument6 pagesSamsung PS42A410 PrecautionTiago GonçalvesNo ratings yet

- MT-506T, MT-506L Installation Instruction GuideDocument8 pagesMT-506T, MT-506L Installation Instruction GuideFelipe Polix BarbosaNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Tomas Lebduska CVDocument3 pagesTomas Lebduska CVTomas LebduskaNo ratings yet

- T655 InspectionDocument2 pagesT655 InspectionjcbueranoNo ratings yet

- Orizont Didactic Proiect LB Engleza 8Document6 pagesOrizont Didactic Proiect LB Engleza 8inflexionNo ratings yet

- Smarty-2 6 9-DocsDocument170 pagesSmarty-2 6 9-Docsosman100% (1)

- Short Circuit Current Calculation (Base KVA Method)Document4 pagesShort Circuit Current Calculation (Base KVA Method)Pramod B.WankhadeNo ratings yet

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- China High Speed Rail, Bullet Train Tickets Booking OnlineDocument3 pagesChina High Speed Rail, Bullet Train Tickets Booking OnlineJiayiNo ratings yet

- Applications To Sizing Circuit Breakers (ANSI C37)Document22 pagesApplications To Sizing Circuit Breakers (ANSI C37)freddy riveraNo ratings yet

- Aws Cwi Some Question 2 PDFDocument49 pagesAws Cwi Some Question 2 PDFninatenaNo ratings yet

- Erosion and Erosion-Corrosion of Metals: A.V. LevyDocument12 pagesErosion and Erosion-Corrosion of Metals: A.V. LevyPritha GuptaNo ratings yet

- Lock Out Relay PDFDocument10 pagesLock Out Relay PDFshaikhsajid242No ratings yet

- Object Object - Oriented Systems Oriented Systems Development DevelopmentDocument16 pagesObject Object - Oriented Systems Oriented Systems Development DevelopmentSrm E-LearningNo ratings yet

- XPC Target UgDocument450 pagesXPC Target UgliznNo ratings yet

- Spare Parts Catalog: 12 AS 2331 TD Material Number: 1353.041.012 Current Date: 12.11.2013Document90 pagesSpare Parts Catalog: 12 AS 2331 TD Material Number: 1353.041.012 Current Date: 12.11.2013Андрей АндрусенкоNo ratings yet

- ULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysDocument39 pagesULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysRadoNo ratings yet

- Siemens Hydrogen-Cooled Generators With Water-Cooled Stator WindingsDocument3 pagesSiemens Hydrogen-Cooled Generators With Water-Cooled Stator WindingsPradeep_VashistNo ratings yet

- BX2750Document18 pagesBX2750Mike BurdNo ratings yet

- Creating A Safe Home Routine - 19477Document2 pagesCreating A Safe Home Routine - 19477徐海东No ratings yet

- CAT 01181 Catalogue POK Complete enDocument448 pagesCAT 01181 Catalogue POK Complete enIkhsan NurfajarNo ratings yet

- Securiton Smoke Detector Performance DeclarationDocument2 pagesSecuriton Smoke Detector Performance DeclarationAnonymous YWmB9HDgNo ratings yet

- CoatingDocument16 pagesCoatingPubg fansNo ratings yet

- Empowerment Tech MidtermDocument4 pagesEmpowerment Tech MidtermcocopitlabmixNo ratings yet

- 1 SECTION 16425 Switchboards (600 V and Below)Document4 pages1 SECTION 16425 Switchboards (600 V and Below)Ahmed AliNo ratings yet

- Learning Mastercam X8 Step by Step LATHEDocument180 pagesLearning Mastercam X8 Step by Step LATHEatgordon167% (3)

- C FunctionsDocument48 pagesC FunctionsSayantan PalNo ratings yet

- Forbo Acoustic Vinyl Environmental Datasheet Aug 2015 UKDocument2 pagesForbo Acoustic Vinyl Environmental Datasheet Aug 2015 UKIvan PopovicNo ratings yet

- eYt2Kr3P PDFDocument458 pageseYt2Kr3P PDFalexrock4444100% (1)

- J Kurozawa Marketing ResumeDocument3 pagesJ Kurozawa Marketing ResumeJon KurozawaNo ratings yet

- A1 Principles of Teaching - Ans.KeyDocument11 pagesA1 Principles of Teaching - Ans.KeyJam Uly Gasty100% (2)