Professional Documents

Culture Documents

BS 3692 PDF

BS 3692 PDF

Uploaded by

Marija Milenkovic0 ratings0% found this document useful (0 votes)

201 views38 pagesOriginal Title

150331273-BS-3692.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

201 views38 pagesBS 3692 PDF

BS 3692 PDF

Uploaded by

Marija MilenkovicCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

* BRITISH STANDARD

ISO metric precision

hexagon bolts, screws

and nuts —

Specification

18 21.060.10; 21,050.20

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

CS EEE ERE aha naan

BS 3692:2001

BS 3692:2001 «

—— — eee :

Committees responsible for this e

British Standard

‘The preparation of this British Standard was entrusted to Technical

Committee, FME/9, Bolts, nuts and accessories (+ QA and hose clamps), upon

which the following bodies were represented:

British Constructional Steelwork Association Ltd

Confederation of British Forgers :

Blectricity Association c

Society of Motor Manufacturers and Traders Limited .

UK Steel Association ‘

‘This British Standard, having

been prepared under the

direction of the Enginesring

Sector Board, was published

tundor tho authority of the

Standards Committee and :

‘comos into effect on .

16 February 2001

© BST 02-2001

First published December 1963 Amendments issued since publication

‘Second edition August 1967

‘Third edition February 2001 Amd.No [Date [Comments _

‘The following BSI references i

relate to the work on thie

British Standard

Committee reference FMI

Draftforeomment 04711040D¢

ISBN 0 580 39262 4

BS 3692:2001

Contents

Page

Committees responsible Inside front cover

Foreword ii

1 Scope 1

2 Normative references 1

3 Finishes 2

4 General dimensions 2

5 Length of bolts and screws 2

6 — Ends of bolts and screws 2

7 Screw threads 2

8 Length of thread on bolts and screws 3

9 Angularity and eccentricity of bolts, screws and nuts 3

10 Chamfering, washer facing and countersinking 4

11 Strength grade designation system for stool bolts and screws 4

12 Material and manufacture of steel bolts and screws 4

13 Mechanical properties of steel bolts and screws 5

14 Strength grade designation system for steel nuts 5

15 Material and manufacture of steel nuts 6

16 Mechanical properties of steel nuts (excluding thin nuts) 6

17 Drilled bolts with split pin holes 6

18 Marking and identification (see also Annex E) 6

19 Inspection and testing 6

20__ Complete designation for the purposo of an onquiry or order 7

Annex A (normative) Recommended gauge for checking squareness of

thread to face of nut (see clause 9) 18

Annex B (normative) Chemical composition of steel nuts (see 16.2) 18

Annex C (normative) Testing of mechanical properties of steel nuts

(eee clauses 16 and 19) 19

Annex D (informative) Association of bolt and screw lengths and diameters

(ee clause 8) 21

Annex E (informative) Basis for the derivation of tolerances 24

Annex F (informative) Manufacturers’ recommended range of sizes 30

Bibliography 32

Figure 1 — Depth of decarburization on steel bolts and screws 5

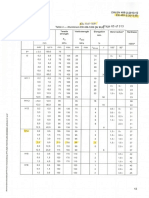

Figure 2 — Hexagon head bolt 7

Figure 3 — Hexagon head screw 8

Figure 4 — Full bearing head washer face 8

Figure 5 — Rounded end 8

Figure 6 — Rolled thread end 8

Figure 7 — Normal thickness nut u

Figure 8 — Thin nut u

Figure 9— Enlarged view of nut countersink 2

Figure 10 — Slotted nut. Sizes Mé to M39 only (Six slots) 4

Figure 11 — Castle nut. Sizes M12 to M39 only (Six slots) u

Figure 12 — Castle nut. Sizes M42 to M68 only (Bight slots) u

Figure A.1— Nut squareness gauge 18

Figure C.1 — Proof load test for nut 19

Figure C.2 — Examples of marking of forged nuts 20

‘© BST 02.2001,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BS en 573-3 PDFDocument22 pagesBS en 573-3 PDFMarija Milenkovic100% (1)

- Test PDFDocument27 pagesTest PDFMarija MilenkovicNo ratings yet

- Review On Four Standard Tests On Flame SpreadingDocument20 pagesReview On Four Standard Tests On Flame SpreadingMarija MilenkovicNo ratings yet

- TN31 Calculcation of NR and NC Curves in The Optimus Sound Level Meter and NoiseTools SoftwareDocument16 pagesTN31 Calculcation of NR and NC Curves in The Optimus Sound Level Meter and NoiseTools SoftwareMarija MilenkovicNo ratings yet

- SuperLite LL-XL 120Document2 pagesSuperLite LL-XL 120Marija MilenkovicNo ratings yet

- En 485-2Document1 pageEn 485-2Marija MilenkovicNo ratings yet

- Plastic TestingDocument4 pagesPlastic TestingMarija MilenkovicNo ratings yet

- NB-CPD SG07 09 063r1 - en 12101 Series - Certification of Smoke and Heat Control SystemsDocument4 pagesNB-CPD SG07 09 063r1 - en 12101 Series - Certification of Smoke and Heat Control SystemsMarija MilenkovicNo ratings yet