Professional Documents

Culture Documents

General Notes

Uploaded by

Junaid ShahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes

Uploaded by

Junaid ShahCopyright:

Available Formats

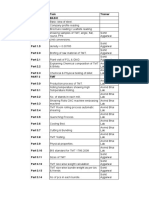

GENERAL NOTES

1. BUILDING DESCRIPTION & DESIGN 8 CONC. PROTECTION & LAPS TO STEEL

a. MIN. COVER TO BARS SHALL BE AS UNLESS GIVEN ON DRAWINGS

16. HOOKED BAR EMBEDMENT

a. TWO STORY SCHOOL BUILDING. DESIGNED AS FRAME STRUCTURE. b. LAPS IN COLUMNS BE PREFFERED AT MID ( COMP. ZONE). LAP BE THE FOLLOWING EMBEDMENT LENGTHS SHALL BE

FOR ZONE - 2B AS TENSION SPLICE UBC 1997, ACI 2005 & B. CODE OF PAK. CONSIDERED FOR ALL HOOKED BARS WITH STANDARD HOOKS,

LAP 50 DIA

b- DESIGN OF STRUCTURE IS BASED ON PAKISTAN BUILDING CODE fy' = YIELD STRENGHT OF STEEL , fc' = CONC STRENGTH UNLESS OTHERWISE SPECIFIED.

MID

(S.P- 2007) , ACI 318-2005 AND UBC 97.

Bar No. #3 #4 #5 #6 #7 #8

Bar Dia (inches) 3/8 1/2 5/8 3/4 7/8 1

STRUCTURAL MEMBER COVER LAP TO BARS

Lap Length (inch) 9 9 10 12 13 15

2. BUILDING LAYOUT FOUNDATIONS 3" TO PCC GRADE -40 STEEL

H

a. BUILDING LAYOUT BE DONE W.R.T TO STRUCTURAL DRAWINGS SLABS , RCC WALLS 3/4" 50 DIA 17. ACCESSORIES

AND ARCH DRAWINGS COLUMNS & BEAMS 1.5"

b. ANY DIFFERENCE BE DISCUSSED WITH STR. DESIGNER. a. BAR SUPPORTS , SPACERS & AND OTHER ACCESSORIES ARE

NOT SHOWN IN DRAWINGS.

b. THE BAR SUPPORTS BE PROVIDES AS APPROVED

BY ENGINEER

3. EXCAVATION AND TERMITE TREATMENT 9. FORMWORK & REMOVEL c. SUPPORTS TO BARS BE SUFFICIENT & STRONG

a. FOUNDATIONS TO BE PLACED ON COMPACTED SOIL a. FORMWORK TO CONCRETE SHALL BE OF METAL SHEETS SUCH THAT THE STEEL REMAIN IN POSITION

OR PLY WOOD. DURING CONCRETING.

b. IN CASE OF FILL / OVERBURDEN REMOVE IT.

b. THE FORMWORK BE DONE AS PER STRUCTURAL FORMS

c. IN CASE OF RAISED PLINTH, FILL WITH SAND / GRAVEL &

c. FORMWORK BE WATER TIGHT.

18. BAR BENDING & HOOKS

COMPCAT BEFORE FLOORING.

d. PROVIDE TERMITE TREATMENT IN FOUNDATIONS AND IN FLOOR d. FORMWORK BE REMOVED AS PER FOLLOWING SCHEDULE

BEFORE LAYING PCC. COLUMNS & SIDE OF BEAMS & WALLS 24 HOURS

SLAB, BOTTOM OF BEAMS 14 DAYS.

db

db

4db

4. W:C:S: AGGREGATES AND SIZES 10. JOINTS 8db

12db

FRESH WATER: IN ACCORDANCE OF UBC 97 SECTION 1903.4

a. EXPANSION JOINTS BE FINALIZED AND GOT APPROVED 4db 4db

CEMENT: FRESH PORTLAND CEMENT TO BE USED FOR ALL WORKS. 2.5 in (mm)

BY THE RESIDENT ENGINEER.

SAND : LAWRANCEPUR / GHAZI. b. EXPANSION JOINT IN THE BUILDING BE PROVIDED AS SHOWN

AGGREGATES:IN ACCORDANCE OF UBC 97 SECTION 1903.3 ON THE DRAWIGS. (PRIMARY REINF.) (PRIMARY REINF.)

MARGALLA STONE CRUSHED AGGREGATES SHALL BE AS:

11. STEEL BINDING

STRUCTURAL ELEMENTS MAXIMUM AGGREGATE SIZE

H

a. STEEL BARS BE PLACED IN THE FORM AS PER DRAWINGS.

2-#6

FOUNDATIONS 1.25 " DOWN GRADED

LAP 50 DIA

b. ALL JUNCTION OF THE BARS / CROSS BE TIED WITH BINDING

MID

COLUMNS & BEAMS 3/4 DOWN GRADED WIRE.

10

SLABS 3/4" DOWN GRADED

db

12. DRAIN PIPES & SLEEVES 2-#6 2-#6

3/4" DOWN GRADED MEANS 1/2" AND 3/8" MIX 1D=4db

a. TOILET WASHING & DRAIN PIPES BE PLACED IN SLAB AT PROPER

DESIGNED POSITION BEFORE CONCRETE. db

b. WHERE PLUMBING AND OTHER PIPES ARE PLACES IN SLAB

5 REINFORCING STEEL ADDITIONAL STEEL BARS BE PROVIDED ABOVE AND BELOW 2-#6

a. DESIGN OF STRUCTURE IS BASED ON STEEL DEFORMED TO COVER THE REDUCED STRENGTH. DUCT OPEN

(STIRRUPS & TIE REINF.) TYP DUCT OPENING DETAIL

MAIN STEEL FOR ASTM A 615

FOUND, COLS, BEAMS, SLAB GRADE - 40

COLUMN TIES, BEAM STIRRUPS GRADE - 40 13. WALL TIES

b. SAMPLES OF STEEL BE GOT TESTED BEFORE USE. a. WALL TIES OF #3 (10MM) BARS BE PLACED IN COLUMNS AS

WALL TIES AT 2' CC TO ANCHOR THE WALLS L1 L2 L3

0.25 X L1 0.30 X L1 0.30 X L2 0.33 X L1 0.33 X L2

0.25 0.25 0.25 0.25

14. BRICK , CONC BLOCK MASONRY EXTRA AT

END SUPPORT

0"

EXTRA AT CONC COVER 1/2" EXTRA AT MID SPPORT

MID SUPPORT

a. FIRST CLASS BRICKS BE USED FOR MASONRY WORK. FOOTING

6 CONC. MIXING & PLACING b. BRICKS BE SOACKED IN WATER A DAY BEFORE USE.

BARS AT SAME LEVEL

a. CONCRETE BE WELL MIXED, VIBRATED, COMPACTED , CURED, c. CONCRETE BLOCKS BE MOISED JUST BEFORE USE. TYP COL. ELE. CON COVER 1/2" BOTT. BARS BOTT. BARS BOTT. BARS

TESTED AND RECORD TO BE MAINTAINED AS PER d. JOINTS BE 3/8" FILLED WITH CEMENT SAND MORTAR.

ACI 318 AND UBC 1997 CHAPTER 19 e. ALL MORTAR BE MACHINE MIXED.

b. MIXED CONCRETE BE PLACED IN POSITION WITHIN 15 MINUTES f. MORTAR FOR WALLS 9" SHALL BE 1:5 TYP BARS CUTOFF DETAIL FOR SLAB

OR OTHERWISE AS INDICATED ON THE DRAWING

c. MIN WATER IN CONC. GIVES MORE STRENGHT. FOR 4.5" SHALL BE 1:4

d. TRY 5 TO 6 GALLONS OF WATER / BAG OF CEMENT g. ALL INTERNAL PARTITIONS 4.5" BRICKS /

e. MIXING TIME OF CONCRETE PER BATCH 1.5 MINUTES AFTER WOODEN PARTITION.

ADDING WATER. h. ALL ABOVE ITEM TO BE EXECUTED ,TESTED AND MAINTAINED IN ACCORDANCE

OF UBC 1997 CODE STANDARD CHAPTER 21. L1 L2 L3

15. STEEL BAR SPACING 0.25 X L1 0.30 X L1 or 0.30 X L2

WHICH IS GREATER

0.3 X L1 or 0.3 X L2

WHICH IS GREATER

0.3 X L2 or 0.30 X L3

WHICH IS GREATER

0.3 X L2 or 0.30 X L3

WHICH IS GREATER

EXTRA AT

a. FIRST & LAST BAR IN WALLS & SLAB BE PLACED AT 1/2 OF END SUPPORT TOP BARS EXTRA AT

MID SUPPORT TOP BARS EXTRA AT

MID SPUPORT TOP BARS

THE SPACING OF BARS.OR JUST GIVE COVER AND PLACE THE BAR

7 CONC. STRENGTHS

b. FIRST AND THE LAST HOOP/TIE IN BEAMS & COLUMNS BE

a. CONCRETE BE TESTED AT IMPORTANT PLACES & STRENGTH BE AS BE PLACED AT 2" FROM THE SUPPORT. BOTT. BARS BOTT. BARS BOTT. BARS

b. FOUND. WALLS, SLAB (1:2:4) 3000 PSI 28 DAYS CYLINDER STRENGTH c. COLUMN TIES TO BE PROVIDED THROUNGHOUT FROM

c. COLUMNS, BEAMS (1:2:4) 3000 PSI 28 DAYS CYLINDER STRENGTH FOUNDATION TO TOP.

TYP BARS CUTOFF DETAIL FOR BEAM

OR OTHERWISE AS INDICATED ON THE DRAWING

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 4 Rectangular Concrete TanksDocument15 pages4 Rectangular Concrete Tanksajitgijare92% (12)

- Design of Signage PoleDocument399 pagesDesign of Signage PoleJoshua MagatNo ratings yet

- Overview of Linear and Non-Linear Analysis For Practicing Structural Engineers PDFDocument27 pagesOverview of Linear and Non-Linear Analysis For Practicing Structural Engineers PDFMin Thiha NaingNo ratings yet

- HANDOUTDocument13 pagesHANDOUTAhmadi BOtNo ratings yet

- Software Verification: ACI 318-08 Example 001Document5 pagesSoftware Verification: ACI 318-08 Example 001Junaid ShahNo ratings yet

- ACI Coefficient of ResistanceDocument1 pageACI Coefficient of ResistanceJunaid ShahNo ratings yet

- Etabs RC Slab DesignDocument397 pagesEtabs RC Slab DesignEmanuelRodriguezElera100% (3)

- ETABS Nonlinear Static Pushover AnalysisDocument2 pagesETABS Nonlinear Static Pushover AnalysisJunaid ShahNo ratings yet

- Nonlinear Static Pushover AnalysisDocument67 pagesNonlinear Static Pushover AnalysisJunaid ShahNo ratings yet

- Areas and CentoidsDocument1 pageAreas and CentoidsJunaid ShahNo ratings yet

- Circular SlabDocument7 pagesCircular SlabJunaid ShahNo ratings yet

- Consulting services for building designDocument1 pageConsulting services for building designJunaid ShahNo ratings yet

- Sea OcDocument296 pagesSea OcJunaid Shah100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SHERA - DOSKA Stresne RieseniaDocument5 pagesSHERA - DOSKA Stresne RieseniamohamedaminNo ratings yet

- Phospha TationDocument21 pagesPhospha TationLaila Simpson BlueNo ratings yet

- MoRT&H Specifications For Road and Bridge Works (Fifth Revision) 2013 PDFDocument906 pagesMoRT&H Specifications For Road and Bridge Works (Fifth Revision) 2013 PDFSwapnil Rudrawar100% (1)

- Iliadi - Sand Jet Perforation - Presentation 20171018Document16 pagesIliadi - Sand Jet Perforation - Presentation 20171018Asfan100% (1)

- Fixed Ladder and Step-Ladder Inspection ChecklistDocument6 pagesFixed Ladder and Step-Ladder Inspection ChecklistjoesuhreNo ratings yet

- BIS CodesDocument1,318 pagesBIS CodesImran Nowsheri100% (1)

- Materials Today Communications: SciencedirectDocument12 pagesMaterials Today Communications: Sciencedirectsook mun100% (2)

- Exp 4 FlowabilityDocument4 pagesExp 4 FlowabilityNur SyahirahNo ratings yet

- Multi Layer Polymer CapacitorsDocument1 pageMulti Layer Polymer Capacitorshtróia_1No ratings yet

- Xerox Printer-Copier WorkCentre XD Series Parts & ServiceDocument329 pagesXerox Printer-Copier WorkCentre XD Series Parts & ServiceFabricio Castro100% (1)

- Bomba QuintuplexDocument50 pagesBomba QuintuplexChristian DavidNo ratings yet

- M134C Partslist PDFDocument74 pagesM134C Partslist PDFMarcelo AvilaNo ratings yet

- Prepared By:: Benjamin Tan Shervin LeongDocument5 pagesPrepared By:: Benjamin Tan Shervin Leongbenjitan95No ratings yet

- Cable Sizing of Sub-Main Circuits, Working ExamplesDocument7 pagesCable Sizing of Sub-Main Circuits, Working ExamplesmaungsoekhinNo ratings yet

- Uae DataDocument612 pagesUae Dataaya gamalNo ratings yet

- Eutectic AlloysDocument11 pagesEutectic AlloysPranushaNo ratings yet

- Assignment of Electrochemical Grinding MachiningDocument5 pagesAssignment of Electrochemical Grinding MachiningRajesh PuniaNo ratings yet

- Refrigerant Recovery and RecyclingDocument2 pagesRefrigerant Recovery and RecyclingSyed Ali KhanNo ratings yet

- Copeland Screw Compressors Semi-Hermetic Compact Operating InstructionsDocument12 pagesCopeland Screw Compressors Semi-Hermetic Compact Operating Instructionsugas666999No ratings yet

- Aci 234 R-96Document51 pagesAci 234 R-96ArzenaNoregaNo ratings yet

- Process CostingDocument4 pagesProcess CostingAhsaan KhanNo ratings yet

- Steam Oil Iom 2000 0401 - Rev 122311 PDFDocument76 pagesSteam Oil Iom 2000 0401 - Rev 122311 PDFedgardoNo ratings yet

- TM 9-1787a M1 Tractor Allis-Chalmers TD-10WDocument174 pagesTM 9-1787a M1 Tractor Allis-Chalmers TD-10WAdvocate100% (3)

- Bright Green Colored Inhibited Propylene GlycolDocument3 pagesBright Green Colored Inhibited Propylene GlycolChillerCNo ratings yet

- TSN StiffClip CLDocument2 pagesTSN StiffClip CLJon JacobsNo ratings yet

- Anti Foam MSDSDocument3 pagesAnti Foam MSDSsanjayNo ratings yet

- 1iEiJlK7QkNDkkCjeaMTSbqWVCP bfWXE2jW2pn5MhZwDocument4 pages1iEiJlK7QkNDkkCjeaMTSbqWVCP bfWXE2jW2pn5MhZwSuraj ChandelNo ratings yet

- SMC-Curso AutoaprendizajeDocument34 pagesSMC-Curso AutoaprendizajeRaul Guevara TorresNo ratings yet

- Trainer's Profile: Mohd Yazip MatoriDocument81 pagesTrainer's Profile: Mohd Yazip MatoriKalai VarnnanNo ratings yet

- Foote-Jones Lubrication ManualDocument40 pagesFoote-Jones Lubrication ManualbwelzNo ratings yet