Professional Documents

Culture Documents

Ourse Yllabus N630 - Advanced ASME B31.3 Process Piping Code

Ourse Yllabus N630 - Advanced ASME B31.3 Process Piping Code

Uploaded by

rahul vajpayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ourse Yllabus N630 - Advanced ASME B31.3 Process Piping Code

Ourse Yllabus N630 - Advanced ASME B31.3 Process Piping Code

Uploaded by

rahul vajpayCopyright:

Available Formats

COURSE SYLLABUS

N630 - Advanced ASME B31.3 Process Piping Code

Duration

Two classroom days providing 1.6 CEU (Continuing Education Credits) or 16 PDH (Professional

Development Hours)

Summary

This two-day course will cover advanced topics related to the ASME B31.3 Process Piping Code. This

course emphasizes the piping flexibility analysis process, including practice application of simplified

methods and illustration of computer analysis methods. This course also covers requirements for non-

metallic, Category M fluid service, high pressure and high purity piping, as well as in-service inspection

to API 570 and a comparison to ASME B31.1 Power Piping requirements. Participants are encouraged to

bring a copy of the code (not included in course fees) to the session.

Each session is conducted in a lecture/discussion/problem solving format designed to provide intensive

instruction and guidance on understanding Code requirements. The instructor will be available following

each day’s session to provide participants with further opportunity for discussion and consideration of

specific problems.

Who Should Attend

Engineers, senior designers, maintenance and manufacturing personnel who work in depth with process

piping (e.g., in the chemical, petroleum, plastic processing, pulp and paper, and bioprocessing fields) will

find it a time-saving means to broaden and update their knowledge of piping.

Participants will learn to

1. Develop and understanding of how to perform a piping flexibility analysis.

2. Create acceptable arrangements for piping systems with expansion joints.

3. Develop an understanding of special considerations for nonmetallic, lethal service, high

pressure, high purity and underground piping.

4. Formulate inspection plans for piping that has been placed in service.

Course Agenda

Day One

1. Materials

a. Strength of Materials

b. Bases for Design Stresses

2. Introduction to Flexibility Analysis

a. What are we trying to achieve?

b. Sustained loads, Displacement Loads

c. Reaction Design Criteria

PEICE is part of the RPS Group

training.rpsgroup.com

COURSE SYLLABUS

d. Flexibility Analysis Example

e. Stress Intensification

3. Layout and Support

a. Support Spacing, Support Locations

b. Support Elements

c. The Sustained Load Analysis

d. Fixing Problems

4. Flexibility

a. Friction

b. Elbow Flexibility

c. Thermal Expansion

d. Spring Hangers

e. The Displacement Load Analysis

f. Elastic follow-up

g. Fixing Problems

5. Reactions

a. Fabricated Equipment

b. Rotating Equipment

c. Supports

d. Flanged Joints

e. Cold Spring

6. Flexibility Analysis

a. When to Perform a Detailed Analysis

b. Computer Program Attributes

c. Considerations

Day Two

1. Designing with Expansion Joints

a. Types of Expansion Joints

b. Pressure Thrust

c. Installation of Expansion Joints, Metal Bellows Expansion Joints

d. Other considerations

2. Non-metallic Piping Systems

a. Thermoplastics

b. Reinforced thermosetting resins

c. Concrete and glass

d. Piping lined with non-metals

e. Limitations

3. Category M Fluid Service

a. Design, Fabrication

b. Examination and Testing

c. Typical Owner Added Requirements

4. High Pressure Piping

PEICE is part of the RPS Group

training.rpsgroup.com

COURSE SYLLABUS

a. Materials, Pressure Design

b. Limitations, Flexibility Analysis

c. Fabrication

d. Examination and Testing

e. Overpressure Protection

5. High Purity Piping

f. Fabrication and Installation

g. Examination and Testing

h. Category M Fluid Service

6. In-service Piping - Inspection, Repair, Alteration and Rerating

i. API 570 Piping Inspection Code

j. What to Inspect

k. Types of Inspection, Inspection Practices

l. Frequency and Extent of Inspection

m. Remaining Life Calculation

n. Repairs and Alterations

o. Rerating

7. What’s Different in B31.1

a. Scopes

b. Organization of the Codes

c. Bases for Allowable Stresses

d. Piping Component Standards

e. Fluid Service Requirements, Material Requirements

f. Pressure Design and Flexibility Analysis

g. Fabrication and Installation

8. Underground Piping

h. Steel Piping

i. Ductile Iron Piping

j. Non-metallic Piping

Instructor

Don Frikken is an internationally recognized authority in piping design. Now employed by Becht

Engineering, Don had been with Solutia, Inc. and Monsanto Company for 34 years; working on a wide

range of activities including piping and mechanical design, project engineering, and engineering

standards. Don’s principal specialty is piping design, including design of complex piping systems, piping

flexibility analysis, selection of piping components including valves, development of piping standards

and specifications, and developing and teaching numerous piping seminars and workshops.

He is an ASME Fellow and is active on various ASME standards committees. He is a member and past

Chair of the ASME B31.3 Process Piping Code committee, a member and past Chair of the B31 Standards

Committee, which oversees all B31 Piping Code committees, member of the B16 Standards Committee,

past member of the Council on Standards and Certification, which oversees ASME’s codes and standards

development, and a past member of the ASME Board of Governors,.

PEICE is part of the RPS Group

training.rpsgroup.com

COURSE SYLLABUS

Don has received a number of awards, including the ASME Melvin R. Green Codes and Standards Medal,

which recognizes outstanding contributions to the development of documents used in ASME programs

of technical codification, standardization and certification, as well as the ASME B31 Forever Medal for

Excellence in Piping. Don graduated with a B.S.M.E. from Kansas State University and has a master’s

degree in civil engineering from the University of Missouri-Rolla.

Course Dates

Please visit the course details webpage for currently scheduled course dates.

Available for In-House Group Delivery

This course is available for In-House Training and the content can be customized to suit the needs of

your organization. For more information or to request a proposal, please email

inhouserequests@peice.com or call 713-482-3858 (USA), 403-284-1250 (Canada).

PEICE is part of the RPS Group

training.rpsgroup.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Method Statement - FinalDocument6 pagesMethod Statement - FinalJustin Joy0% (1)

- List of Codes & Standards - MechanicalDocument5 pagesList of Codes & Standards - MechanicalinderNo ratings yet

- American Welding Society StandardsDocument2 pagesAmerican Welding Society StandardsGeorge Nicolaides100% (1)

- Sa 216Document4 pagesSa 216AnilNo ratings yet

- 01-Samss-039 18122016Document14 pages01-Samss-039 18122016ELNA83No ratings yet

- Common Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentDocument11 pagesCommon Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentEngr Arfan Ali DhamrahoNo ratings yet

- HTTP - WWW Red-Bag Com Engineering-Guides HTMLDocument4 pagesHTTP - WWW Red-Bag Com Engineering-Guides HTMLmashudi_fikriNo ratings yet

- IET - ProfileDocument18 pagesIET - ProfileAlbinbaby ChennaiNo ratings yet

- WPSASMEDocument76 pagesWPSASMERama TamaNo ratings yet

- DW Asme Bpe Us 0Document37 pagesDW Asme Bpe Us 0Haries Bugarin Garcia100% (2)

- Pressure Vessel Design, Formula and Calculators - Engineers EdgeDocument16 pagesPressure Vessel Design, Formula and Calculators - Engineers EdgeLeDzung0% (1)

- Section 9-Inspection-Philosophy PDFDocument20 pagesSection 9-Inspection-Philosophy PDFWinsonLimHuiWahNo ratings yet

- Asme Iii-1 NF 2013Document186 pagesAsme Iii-1 NF 2013Torres Ivan100% (1)

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584No ratings yet

- George Morris: Mechanical Engineer Having Rich Experience of Above 3years in Oil and Gas Construction ObjectiveDocument6 pagesGeorge Morris: Mechanical Engineer Having Rich Experience of Above 3years in Oil and Gas Construction Objectivedavidgeorge143No ratings yet

- Piping CodesDocument47 pagesPiping CodesSankar MukaNo ratings yet

- 10.0000@Www - Onepetro.org@conference Paper@ISOPE I 14 112Document5 pages10.0000@Www - Onepetro.org@conference Paper@ISOPE I 14 112FelipeNo ratings yet

- Inspection & Test Plan For Fabrication, Erection & Testing of Piping SystemDocument4 pagesInspection & Test Plan For Fabrication, Erection & Testing of Piping SystemAbdullah Al Jubayer100% (5)

- Below-the-Hook Lifting Devices: ASME B30.20 - 2013 ASME BTH-1 - 2014Document1 pageBelow-the-Hook Lifting Devices: ASME B30.20 - 2013 ASME BTH-1 - 2014Leonardo MedranoNo ratings yet

- SEC VIII InterpretationsDocument55 pagesSEC VIII InterpretationsKrishna VachaNo ratings yet

- Welding InspectionDocument40 pagesWelding InspectionnazarasimNo ratings yet

- AWS Lecture NotesDocument4 pagesAWS Lecture NotesAsad Bin Ala Qatari0% (1)

- Asme B107.16M-1998Document20 pagesAsme B107.16M-1998thorek24No ratings yet

- Resume For Mechanical Engineer With EPC CompanyDocument3 pagesResume For Mechanical Engineer With EPC CompanyShivaji DhonnarNo ratings yet

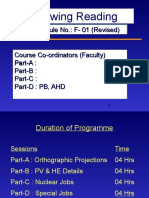

- Drawing Reading: Module No.: F-01 (Revised)Document96 pagesDrawing Reading: Module No.: F-01 (Revised)Ashish GhadiyaNo ratings yet

- Asme PTC 1Document25 pagesAsme PTC 1barun1977No ratings yet

- Autopipe New Features & Enhancements (v9.61 To v6.20)Document17 pagesAutopipe New Features & Enhancements (v9.61 To v6.20)NopparutNo ratings yet

- Visual Weld InspectionDocument7 pagesVisual Weld InspectioninsiderrNo ratings yet

- Internal Misalignment SpecDocument12 pagesInternal Misalignment Specmegastar0604No ratings yet

- ASMEDocument25 pagesASMEAnonymous bENWheBNo ratings yet