Professional Documents

Culture Documents

Training On ABC - 180317 - S V Reddy PDF

Training On ABC - 180317 - S V Reddy PDF

Uploaded by

nayan vyasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training On ABC - 180317 - S V Reddy PDF

Training On ABC - 180317 - S V Reddy PDF

Uploaded by

nayan vyasCopyright:

Available Formats

Training on activity based Costing by Mr V Srinivasa Reddy -

Place - Kolhapur dated 18 March 2017.

Some highlights if the training are -

1) Activity based costing (ABC) – IT was about the correct loading of overheads on the new part while

giving new quotation. Many times we load the average or same overheads on all part , where as some

parts required lesser Resources and some required higher resources. So overheads must be loaded

based on the resources it eats. This will keep your bottle neck process efficient, which will help to

increase the productivity of the foundry thus increase in overall Contribution.

2) Direct cost - Raw material, Consumable cost, Power Cost.

3) Man power, Depreciation cost

4) Financial Cost, Admin Cost.

5) Maximize utilization of your resources

6) Bench mark for productivity - 30 T per man per month.

7) Utilize space effectively.

8) Create Space

9) Be Organized

10) Use horizontal and vertical space effectively.

11) Compare lowest and highest productivity sources to understand the source of improvement in the

process.

12) Always study lower point of productivity to learn the Improvement points.

13) China is getting orders at any Cost as they are sure of producing casting at lower price by adopting

ABC practices.

14) Do not stuck with old theory and constraints.

15) Adopt new thoughts, processes.

16) You can achieve what you can dream... So dream best...

17) Do not afraid of mistakes, but learn from mistakes to do better

18) Do SWOT analysis to understand your business condition?

19) See / Observe business from various angles...

20) Think logical

21) KPI / Profit Drivers / Summary of ABC -

a) Productibty

b) Casting weight

c) Sand to metal Ratio

d) Power Cost

e) Cost of poor quality

f) Yield %

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

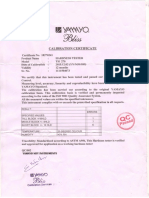

- Hardness CertificateDocument1 pageHardness Certificatenayan vyasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Predictive Maintenance: 1 Induction FurnaceDocument14 pagesPredictive Maintenance: 1 Induction Furnacenayan vyasNo ratings yet

- Part I-Section II-Chapter 1Document4 pagesPart I-Section II-Chapter 1nayan vyasNo ratings yet

- Part I-Section II-Chapter 2Document3 pagesPart I-Section II-Chapter 2nayan vyasNo ratings yet

- Floor Finishes - Tactile Strip: Schedule of Finishes - LD - 90 % Submission Revision B - Issued May 2017Document1 pageFloor Finishes - Tactile Strip: Schedule of Finishes - LD - 90 % Submission Revision B - Issued May 2017nayan vyasNo ratings yet

- TP-7006 Bond TestDocument3 pagesTP-7006 Bond Testnayan vyasNo ratings yet

- UT LEVEL-2 Part-1Document301 pagesUT LEVEL-2 Part-1nayan vyasNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test Certificatenayan vyasNo ratings yet

- 3D Printing Materials - ExOne PDFDocument3 pages3D Printing Materials - ExOne PDFnayan vyasNo ratings yet

- 3D Printing Materials - ExOne PDFDocument3 pages3D Printing Materials - ExOne PDFnayan vyasNo ratings yet

- Film GradientDocument19 pagesFilm Gradientnayan vyasNo ratings yet

- Ultrasonics Level 3ADocument156 pagesUltrasonics Level 3Anayan vyas100% (2)

- Probe CalibrationDocument1 pageProbe Calibrationnayan vyasNo ratings yet

- Ams 2644 QPLDocument33 pagesAms 2644 QPLnayan vyasNo ratings yet