Professional Documents

Culture Documents

Pwje9086 Pajero Abcde Chassis 15

Uploaded by

manual0 ratings0% found this document useful (0 votes)

22 views29 pagesingles

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentingles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views29 pagesPwje9086 Pajero Abcde Chassis 15

Uploaded by

manualingles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 29

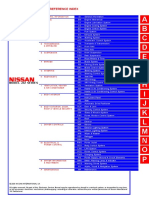

15-1

INTAKE AND

EXHAUST

CONTENTS ena

SPECIFICATIONS cece 2. INTERCOOLER <4M40> ...

General Specifications 2 INTAKE MANIFOLD <6G74> ..

Service Specifications 2

24 VALVE> ...

SERVICE ADJUSTMENT PROCEDURES ...... 3 'NTAKE MANIFOLD <6G72- 24 >

Turbocharger Supercharging Pressure TURBOCHARGER AND EXHAUST MANIFOLD

Inspection <4D86> 3 <4D56> 6

Waste Gate Actuator inspection TURBOCHARGER AND EXHAUST MANIFOLD

<4D56, 4M40> 3 .

Intake Manifold Vacuum Inspection 31

Supercharging Pressure Contro! System EXHAUST MANIFOLD <4G64> .. 8

inspection 3-1 EXHAUST MANIFOLD <6G72- 12 VALVE>.... 9

‘Supercharging Pressure Relief Solenoid Valve EXHAUST MANIFOLD <6G74> ..

Inspection 3-1 EXHAUST MANIFOLD <6G72 - 24 VALVE> ..... 9-2

Variable Induction Control System Inspectio FLER AND me

Variable Induction Control System Inspection eyaaUST PIPE, MUR CATAL

CONVERTER <4G64, 6672 - 12 VALVE> «10

Vacuum Tank Inspection 3-2

svn MY

INTERCOOLER <4D56> . 4 EXHAUST PIPE AND MUFFLER <4D56>

EXHAUST PIPE, MUFFLER AND CATALYTIC

CONVERTER <6G72 - 24 VALVE, 6G74>

EXHAUST PIPE AND MUFFLER

<4M40> ..

(© Mitubiahi Motors Corporation Jun. 1994 Pwseso86 Revise

15-2

INTAKE AND EXHAUST - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items Specifications

Air filter

Type Dry type

Element Unwoven cloth type

Exhaust system

Front exhaust pipe

<4G64, 6672, 6G74> Dual type

<4D56, 4M40> Single type

Muffler Expansion resonance type

Coupling Spherical coupling and flat coupling

Suspension system Rubber hangers and rubber suspenders

Turbocharger

Type, Exhaust gas turbine type

Identification No.

<4D56> TD04-11G-4

<4M40> | To04-12T-4

Supercharging pressure control | Waste gate actuator

Intercooler

Type Air cooled type

SERVICE SPECIFICATIONS exscs.

Items Standard Limit

Intake and exhaust manifolds

Distortion of cylinder head

contacting surface mm (in) | Less than 0.15 (0.0059) | 0.3 (0.012)

Turbocharger |

Initial starting pressure of waste gate | |

actuator kPa (kg/om®, psi)

<4D56> 82 (0.84, 12) -

<4m40> 89 (0.91. 13) =

|© Mitaubiehi Motors Corporation Deo. 1952 PWJES006-E REVISED

INTAKE AND EXHAUST - Service Adjustment Procedures 15-3

SERVICE ADJUSTMENT PROCEDURES

TURBOCHARGER SUPERCHARGING PRESSURE

INSPECTION <4D56> esrDAC

Cautic

The driving test should be carried out by two people at a

place where fully-open acceleration can be done, and

reading of the measurement values on the pressure gauge

should be made by the person in the passenger seat.

(1) Remove the hose that is connected to the fuel injection

pump boost compensator, and install the pressure gauge

via the T-joint, as shown in the illustration

(2) Accelerate the vehicle in second gear (M/T) or L range

(A/T) with the throttle fully open, and take a reading of the

measurement value on the pressure gauge when the

engine speed reaches approximately 3,000 r/min.

(3) If the pressure is not positive pressure, the reason is

probably one of the following, so carry out the following

inspection.

© Waste gate actuator is defective

© Leaking turbo pressure

© Turbocharger is defective

(4) If the turbo pressure is 82 kPa (0.84 kg/om?, 12 psi), the

reason is probably an abnormality in the turbo pressure

control, so carry out the following inspection.

© Waste gate actuator rubber hose is disconnected or

burst

© Waste gate actuator is defective

© Waste gate valve is defective

WASTE GATE ACTUATOR INSPECTION <4D56,

4m40> e1sFEAD

(1) Connect a hand pump (pressurization type) to the nipple.

(2) While gradually increasing the pressure, check the pres-

sure where the waste gate actuator rod begins to move

[approx. Imm (0.04 in.) stroke}]

Standard value:

82 kPa (0.84 kg/om?, 12 psi

89 kPa (0.91 kg/cm?, 13 psi

a Caution

To prevent damage to the diaphragm, do not apply

pressure more than 90 kPa (0.9 kg/cm?, 13 psi

<4D56> or more than 115 kPa (1.17 kg/cm?, 17 psi

.

(3) If the value is widely outside the standard value, inspect

the actuator or the waste gate valve, and replace if

necessary.

(© Miteubihi Motors Corporation Dee. 19

Pwuesone-€ revised

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Em - Engine Mechanical Mr20ddDocument479 pagesEm - Engine Mechanical Mr20ddmanual100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ford Ranger 22mar2016 Ebrochure PDFDocument24 pagesFord Ranger 22mar2016 Ebrochure PDFmanual100% (1)

- Fuel Gauge Returns To Empty After A Full TankDocument2 pagesFuel Gauge Returns To Empty After A Full TankmanualNo ratings yet

- Service AdvanceTrac® Malfunction WarningDocument2 pagesService AdvanceTrac® Malfunction WarningmanualNo ratings yet

- TMDocument338 pagesTMmanualNo ratings yet

- FWD PDFDocument2 pagesFWD PDFmanual0% (2)

- Ha PDFDocument59 pagesHa PDFmanualNo ratings yet

- Warning Chime System: SectionDocument77 pagesWarning Chime System: SectionmanualNo ratings yet

- Wiper & Washer: SectionDocument109 pagesWiper & Washer: SectionmanualNo ratings yet

- Security Control System: SectionDocument205 pagesSecurity Control System: SectionmanualNo ratings yet

- Steering System: SectionDocument38 pagesSteering System: SectionmanualNo ratings yet

- Door & Lock: SectionDocument245 pagesDoor & Lock: SectionmanualNo ratings yet

- ADPDocument138 pagesADPmanualNo ratings yet

- Steering Control System: SectionDocument19 pagesSteering Control System: SectionmanualNo ratings yet

- Rear Axle: SectionDocument6 pagesRear Axle: SectionmanualNo ratings yet

- ECM PINOUT Chevrolet Sail PDFDocument2 pagesECM PINOUT Chevrolet Sail PDFmanual67% (3)