Professional Documents

Culture Documents

CN Wax Roll 1

CN Wax Roll 1

Uploaded by

herlina0 ratings0% found this document useful (0 votes)

2 views1 page.......

Original Title

CN wax roll 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document.......

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageCN Wax Roll 1

CN Wax Roll 1

Uploaded by

herlina.......

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

arzazote (CN101280518A - Formula and production method of textile wax - Google Patenis

Patents 9 e

Formula and production method of textile wax

Abstract

CN101280:

“The eveiton dcose a prescrtion of tate war ard» production meth hate the Seon

resrpion i prepared ie loving ra maleate ecard to the coeaponding weigh ate:

percent pura, 10 percent water-soluble was, 1 percent mira wax 1S peat plastic

wor. 3 percent plytylene way, 13 percent spec wax ané 3 percert boating wax. The

Frosucton had of teste war using the preorsioniecareterzedin hat unde: noma

‘enpne ndwementa rpued tw cde et eh dO Cr anguage: Coen

eget, den he wax lune re outed tote ce ceviy and hen cae for 35 minus,

‘any he old texte was taken Ut The texte wax vlog te preset end prodution overt Se

method hash avartagee of reno no dey, strong stably and good treatin propery Orginal Assignee: 8 Fish

Ponty date: 2007-80

Family oN 0)

Date ‘py Pu Number satus

roaraKes en 200710020137

zooer008 —curoranoston -pepleaton

Infected by (Legal vets, Sina ocumers, Ponty and

Fates Apptentons

tena eks: space los Dasier, Discuss

Claims (2) u

1. texte wax characerze in that mae ofthe allowing ingredients was prepared accorng tthe following weight compostan ai otraw material 45% of

pan, 10% watersoble wax, nirourysine was, 17% 15% ax slat, poly wax 3% yen, 1 spec was ubicatng wat 3%

2. 2.Amethodofrepane etl wa, wheten: t normaltenperture and pressive st formulates wax fed to he elect face wa heated to 50 degrees, then

‘the wax soln gation sytem nth mode. then cooled 36 minutes, making cane removed

Description ‘ranted tom Chirase

-Aworen wax formulations ard production matiods | Talical Field The present invention reso a woven wax formulations tet futher eaes oa method for

protucag the wax Secon, ackgound Curent, convertion ele wax arable on the mare equals very ursabe, easly soften nthe sume ad dig

‘the weevng process, poor beatin cannot fective soke "Hanes ne, ets osu seasonal change, ferent qualies of Yam, dyeing an ashing

1s coefiint of icion The the preset inventions tose the tec prablem of roving a single pocees, good effect yam wan, and potucion of new

Fermulstionaof hein of ete woven wih les wax wat method Obared using ths method wat exile neo hig tbl, od wae Slut goo riety

andthe use otter coat To ahve We bare cjet thecal olion af the preset erin fe woven wax leulion caracteed hat is prepared

fromthe folotng components rss together in weight ato of aw material compostion: 45% of aan 10% water-soluble wax, microrstalie 11% wax ese

wor 15%, 2s pojethylre wax 13% seca wax, iat wax 3% Amethod for reparag be bovedescribs texte wax whch process i The prepares Waxed

ino lc frnace wa estat 89 degree fete lrgaten system inthe wixmedel scion, cased at room terete fr 35 mts, take ot 9 mole

‘x1. The FDA made tere way, efter marethan to yea a experiments show that wh this rege mde tele wat rool, eles, tbl, and good

Chung aroducs a ature, summer an water Wee izes, based on ler Shale oor terseate aust He produto ifeet mating pot hardness rte of

orang ot corte Fourh the beste enbodner of the preset inertin te Wes: 48% pratioway,ewate-souble wax TOX TTX micocrsalire wax paste wax

188.3% ple wat, 13% secilwax Mrcating wax 3%. Example Take 45 pars of praia wax(S8 "C~~ 60° pars ofawacesokble wax, 8 pars of@

ricorytaline wax plas war 1 pars, 5 pars of paleo way, 12 pats of special wax, 2 parts of retin wa ito lec fumace heat then the soon

is bested the gation system mode coled a room empertire fo 30 minutes remove the moling. This method mage prodet fo apap and utr, Example

2 Toda pane af praia wax (6 (T0520) 9 part of water isolate wane, pet ofa mcrocnysaline wa, laste wax ISpae Spars ofpaWedyere wax 3 pers

‘speci wax paso alscstng wax hard waxino 8 prs oan eerchestg furnace, ater hetng the soluon end ten he gto yet, coal atroor

temper 20rnutsin te noel te sling can be removed. ths mathed mae proctor cum Exar take 48 prs of paratn wax 55°58" C).7

arts of a waterslible wax, 9 parts ofamicrocytalin wax, paste wax 13 parts, 3 pars of potion wax, pas ofa spec was, 3 pars of alist wax

woe sof paz fhe nt the eet eating face after esting he eluon andthen he rgaton system cole at oom lepers or 20 minesin he

‘mode the mollng ean be ened preduteobtaoa bythe proces forte wit il peer the man sep ofthe produc exe wax ornate re

-escbed below te wax feed the formulation were placed inan elect eat furnace, ed then eating te slo inte gation system model coong at oom

temper for 30 mints, the acing can be removed wth th above prepared formulation ané peducton methods of waxtetl, norton Test stably resy

and gos, nd tere ae sprig and ute sinner wir and tre 206 of rode. name. adapta he varios eas of dierent uss or fen temperate

anderen ype of Shall I may be appropiate to aust he formule roait ha pirat flee ring pot harness, athe octet of wax wel

sppadieo the reeds of ieren uses.

cited By (4) .

Publeston umber Prony ate Puleton eateAsnce the

cxvanterao4n ameaaae 20120612 EWRAIEROTH) Texte wateuilary and preperation metres heteot

hitpsipatents. google.comipatentiCN101280516A/en 18

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rekap Harga PompaDocument21 pagesRekap Harga PompaherlinaNo ratings yet

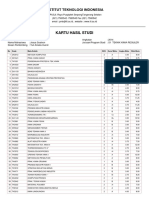

- Kartu Hasil Studi: Institut Teknologi IndonesiaDocument2 pagesKartu Hasil Studi: Institut Teknologi IndonesiaherlinaNo ratings yet

- Bulk Oil in Tanks: Wax BleachingDocument1 pageBulk Oil in Tanks: Wax BleachingherlinaNo ratings yet

- Test 123Document11 pagesTest 123herlinaNo ratings yet