Professional Documents

Culture Documents

Asme Sec Viii, Sa 388 Forging

Uploaded by

RajkumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Sec Viii, Sa 388 Forging

Uploaded by

RajkumarCopyright:

Available Formats

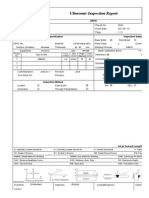

ASME SEC VIII / DIV 02

SA 388 / ACCEPTANCE AS PER AM 203

FORGINGS :

4 INCHS AND OVER IN NOMINAL THICKNESS UT WITH SA388 AND

ACCEPTANCE WITH AM 203 –2c

REFERENCE SPECIMEN SHALL BE THE SAME NOMINAL THICKNESS,

THE SAME COMPOSITION,

P NUMBER GROUPING AS THE FORGING

ST. BEAM: DIA 25 mm , 2.25 MHZ Frequency probe can be used

REF. Keep the 1st Backwall at 75%+/_ 5% of screen.

Scan 2 directions at Rt .angles.

ANGLE BEAM: 45 degree, 1 MHZ F requency , 25 x 25 mm probe shall be used.

REF. NOTCH STD

Depth; 3 % of nominal wall Thickness

Length: 25 mm

Width: not greater than Twice the depth.

Scanning; One circumferential surface ,one Normal to their Axes

UT preferred After HT.

A Forging shall be UNACCEPTABLE

If ST. Beam results show one or more discontinuities which produce indications

accompanied by a complete loss of Back reflection.

If Angle beam results show one or more discontinuities which produce indications

Exceeding in Amplitude the indication from the Calibration notch.

Conditions shall be reported to the purchaser for his consideration and approval .

a) Forging containing one or more discontinuities which amplitude Exceeding adjacent

back reflection.

b)one or more discontinuities which produce travelling indications accompanied by reduced

back reflection.

c) Indications having Amplitude exceeding 50 % of the calibration notch amplitude.

d)Cluster of indications located in a small area of the Forging with amplitude less than

50% of the calibration notch.

Additional NDT procedures or trepanning may be employed to resolve questions of

Interpretations of UT indications.

You might also like

- L3 UT Study Corrrections PDFDocument0 pagesL3 UT Study Corrrections PDFJayaram MVNo ratings yet

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- Astm A578 - 07 PDFDocument5 pagesAstm A578 - 07 PDFMuhammad Maulana100% (1)

- (Asme)Document40 pages(Asme)fracevNo ratings yet

- Basics On Piping LayoutDocument11 pagesBasics On Piping Layoutpuru55980No ratings yet

- Api 5l Test PressrureDocument2 pagesApi 5l Test PressrureSıddık SarıcalarNo ratings yet

- Procedure A578Document3 pagesProcedure A578debduttamallik50% (2)

- Ut Written InstructionDocument6 pagesUt Written Instructionmm100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- Bolted JointDocument9 pagesBolted JointkhanhtruongNo ratings yet

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document41 pagesOf The Nuclear Safety Standards Commission (KTA)Ehab MohamedNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- MPT Mandatory Appendix 6Document2 pagesMPT Mandatory Appendix 6Ashfaq Khan100% (1)

- X-Ray: Radiographic Film SystemsDocument56 pagesX-Ray: Radiographic Film Systemswilliam cordero valverdeNo ratings yet

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- Manual Ultrasonic Inspection of Thin Metal WeldsDocument16 pagesManual Ultrasonic Inspection of Thin Metal WeldsSimon LeeNo ratings yet

- B31.3 Safety Factor PDFDocument4 pagesB31.3 Safety Factor PDFJohn AlvarezNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- Brinell Hardness TestDocument4 pagesBrinell Hardness Testrony_lesbtNo ratings yet

- Digltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDocument14 pagesDigltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardSriniramu SriniramuNo ratings yet

- Daytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryDocument6 pagesDaytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryEnriqueVeNo ratings yet

- Tabla Asme b31.1Document1 pageTabla Asme b31.1agustin100% (1)

- A340-15 Standard Terminology of Symbols and Definitions Relating To Magnetic TestingDocument16 pagesA340-15 Standard Terminology of Symbols and Definitions Relating To Magnetic Testingalmuhandss44 aaNo ratings yet

- ASNTDocument5 pagesASNTshifaNo ratings yet

- 1804Document1 page1804816623No ratings yet

- B31.3 Code Case 178 PDFDocument16 pagesB31.3 Code Case 178 PDFmfathi1356No ratings yet

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.No ratings yet

- 0455e - Welding Inspector Visual Acuity Record PDFDocument1 page0455e - Welding Inspector Visual Acuity Record PDFAbu HanifaNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- Application of Power Electronics: WeldingDocument16 pagesApplication of Power Electronics: WeldingshubhamNo ratings yet

- Surface Roughness Significance and SymboDocument18 pagesSurface Roughness Significance and SymboStefan NikolićNo ratings yet

- MQC Screw ThreadsDocument25 pagesMQC Screw Threadsmd.ariful islanNo ratings yet

- Mds-Sparkler Filter F-304Document1 pageMds-Sparkler Filter F-304Vipul Gandhi50% (2)

- RT Asme IxDocument3 pagesRT Asme Ixhernando gelves100% (1)

- How To Determine CRA Thickness For SS CRA Using Ultrasonic TestingDocument7 pagesHow To Determine CRA Thickness For SS CRA Using Ultrasonic Testingjoni Mart SitioNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- Article 4 Metodo UltrasonidoDocument24 pagesArticle 4 Metodo UltrasonidoLessly Lorena Apala RamirezNo ratings yet

- Selenium 75Document0 pagesSelenium 75vrapciudorianNo ratings yet

- OmniSX MX2 Training 17B HydroForm Setup Raster ScanDocument32 pagesOmniSX MX2 Training 17B HydroForm Setup Raster ScanOussama KhelilNo ratings yet

- BS 2452 (1954)Document30 pagesBS 2452 (1954)siswou100% (1)

- ASTM E-1965-98 (2003) Especificación Estándar para Termómetros Infrarrojos para La Determinación Intermitente de La Temperatura Del PacienteDocument17 pagesASTM E-1965-98 (2003) Especificación Estándar para Termómetros Infrarrojos para La Determinación Intermitente de La Temperatura Del PacienteLucio ArmasNo ratings yet

- ASTM A-802 - Falhas de FundiçãoDocument3 pagesASTM A-802 - Falhas de FundiçãoCristian RodeghelNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Is 5334 PDFDocument7 pagesIs 5334 PDFNav TalukdarNo ratings yet

- Acs 03 UsfdDocument7 pagesAcs 03 UsfdPRAVIN DASSNo ratings yet

- CVN Aws D1.1Document1 pageCVN Aws D1.1neilNo ratings yet

- D6-4 Joint Acceptance Criteria DocumentDocument34 pagesD6-4 Joint Acceptance Criteria DocumentZia GondalNo ratings yet

- QuickGuide RoundtestDocument0 pagesQuickGuide RoundtestAngel Alvarez CarrilloNo ratings yet

- Hidden Defects in FittingsDocument3 pagesHidden Defects in FittingsFerlie IndrapatiNo ratings yet

- En 10029Document5 pagesEn 10029PHAMTOAINo ratings yet

- Selenium 75Document5 pagesSelenium 75jimmy david espinoza mejiaNo ratings yet

- Encoder Odi CKG009Document2 pagesEncoder Odi CKG009Anonymous afPplXbcNo ratings yet

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocument11 pagesInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014No ratings yet

- Sa 578 UltrasonidoDocument6 pagesSa 578 UltrasonidoDavid EstradaNo ratings yet

- Ultrasonic Test Procedure: Rev. Date Prepared by Reviewed ApprovedDocument8 pagesUltrasonic Test Procedure: Rev. Date Prepared by Reviewed Approvedkevin desaiNo ratings yet

- Ut Level Spec QB 5 (49L)Document14 pagesUt Level Spec QB 5 (49L)Kingston RivingtonNo ratings yet

- A 577 - A 577M - 90 R96 - Qtu3ny05mfi5ngDocument3 pagesA 577 - A 577M - 90 R96 - Qtu3ny05mfi5ngAdrian GonzalezNo ratings yet