Professional Documents

Culture Documents

United States Patent (19) : Walker

Uploaded by

1550 ratings0% found this document useful (0 votes)

16 views8 pages55025

Original Title

Us 4473023

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document55025

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views8 pagesUnited States Patent (19) : Walker

Uploaded by

15555025

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

United States Patent (19) 11 Patent Number 4,473,023

Walker 45 Date of Patent: Sep. 25, 1984

54 RELATING TO WINGSAIL CRAFT AND Assistant Examiner-Patrick W. Young

WINGSALS THEREFOR Attorney, Agent, or Firm-Oblon, Fisher, Spivak,

McClelland & Maier

75) Inventor: John G. Walker, Hamble, England

73) Assignee: Walker Wingsail Systems Limited, 57 ABSTRACT

London, England A wingsail assembly in which the pivoting mounting is

21 Appl. No.: 410,553 situated in line with a strengthened portion of the sail

assembly such as a strengthened leading edge of a sail

22 Filed: Aug. 23, 1982 element while still retaining the alignment of the axis of

51) int. C. ............................................... B63H 9/10 pivoting and the center of pressure. A sail assembly is

52 U.S. C. ...................................... 114/103; 114/39; also described in which a locating mechanism, typically

114/124; 114/102 in the form of wire stays, a mechanical linkage or a

58 Field of Search ................. 114/39, 102, 103, 167, hydraulic system, is arranged to act on opposite sides of

114/124, 104, 105, 122 a balancing mass, carried by a boom attached to the

wingsail assembly and arranged to locate the mass in an

56 References Cited approximately horizontal plane. Where the wing or

U.S. PATENT DOCUMENTS wing section is constructed from spars and ribs where

521,388 6/1894 Pool ...................................... 114/39

the latter define the aerofoil section of the wing and lie

1,348,912 8/1920 Ward ......... ... 114/39 in the direction of air flow, the ribs are conveniently

2,170,914 8/1939 Rummler .. ... 114/39 formed from moulded GRP material and include

2,319,999 5/1943 Jennings ........ ..., 114/39 flanges which in selected regions of the periphery of the

2,484,687 10/1949 Carl, Jr. .... ... 114/39 rib subtend an angle of greater than 90 to the plane of

2,813,689 11/1957 Norton et al. ... 14/167 the rib to facilitate removal of the rib from a mould and

3,580,203 5/1971 Martin ................................... 114/39 include other regions in which the flange subtends an

3,934,533 1/1976 Wainwright .......................... 14/39 angle of 90° to the plane of the rib to facilitate its fixing

4,047,493 9/1977 Menegus ............................... 14/39 to a spar. The non 90 angles are conveniently commen

FOREIGN PATENT DOCUMENTS surate with the angle of rake of the edge regions of the

sail or sail element and are situated at points adjacent

318762 2/1920 Fed. Rep. of Germany ........ 114/39 the leading or trailing edges of the sail or sail element.

90247 9/1937 Iceland .................................. 114/39

Primary Examiner-Trygve M. Blix 6 Claims, 14 Drawing Figures

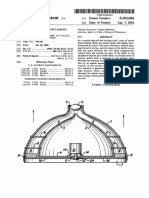

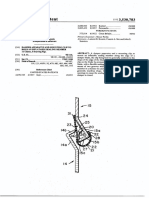

U.S. Patent Sep. 25, 1984 Sheet 1 of 4 4,473,023

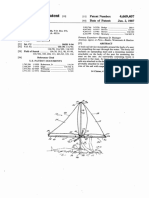

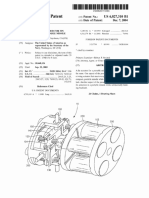

U.S. Patent Sep. 25, 1984 Sheet 2 of 4 4,473,023

Fig. 4. fa /2

G f5.

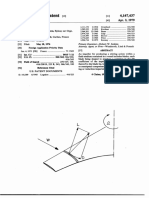

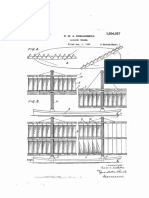

U.S. Patent Sep. 25, 1984 Sheet 3 of 4 4473,023

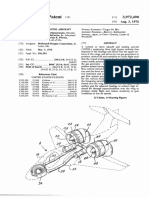

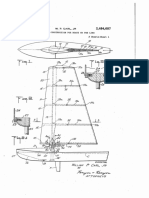

U.S. Patent Sep. 25, 1984 Sheet 4 of 4 4,473,023

4,473,023

2

RELATING TO WINGSAL CRAFT AND

the center of pressure zone and the shape and/or config

WINGSALS THEREFOR uration and/or the angle of rake of the wingsail is se

lected so as to bring the region of principal strength

FIELD OF INVENTION directly over the bearing assembly by which the wing

sail is mounted in the craft, so that the sail is attached to

This invention concerns wingsail craft and particu the bearing assembly, at its point of maximum strength.

larly the mounting, construction and balancing of wing Using this aspect of the invention ensures a strong

sails.

and reliable mounting for the wingsail.

BACKGROUND OF THE INVENTION 10 According to another aspect of the present invention

It is known to construct a craft, typically a ship, in a wingsail propelled craft in which a balancing mass

having a so called wingsail in which the sail is formed as is mounted on a boom attached to the wingsail assembly

a more or less rigid aerofoil section as in an aircraft locating means is provided, acting on opposite sides of

wing. In such arrangements it is usual to mount the sail the balancing mass, to locate the latter in an approxi

on the vessel about an approximately vertical pivot axis. 15 mately horizontal plane.

This pivot axis normally comprises a single lower bear The locating means may comprise a pair of wire

ing about which the wingsail is rotated in order to ad stays, a mechanical linkage using a pushpull rod, or

just the trim angle of the sail to the wind. hydraulic means or the like, in which the final balance

In both servomechanically rotated and tail trimmed position is assured by a fixed or manually adjustable

wingsails, it is desirable to minimize the trimming work 20 ratio system. Where a computer is incorporated the

needed. For this reason the axis of the trim bearing is latter may be supplied with information relating to the

usually arranged to pass through the narrow zone in

which the center of pressure of the sail is found in the sailing conditions and the craft to allow the computer to

normal working range. However, for most cambered compute the optimum balance position.

and high thrust sections this zone will lie approximately 25 According to a further aspect of the invention in a

35% back from the leading edge, while even in symmet wing, particularly a wingsail for wind ship propulsion,

rical sections it will be some 25% back from the leading which is constructed in a conventional manner using

edge. Its vertical position is approximately at the half spars and ribs which latter define the aerofoil section,

height for wingsails of rectilinear design, while simple and lie broadly in the direction of air flow, the ribs are

geometrical constructions are commonly used to locate 30 constructed from moulded glass reinforced plastics

the zone vertically for wingsails of tapered or elliptical (GRP) material.

shape.

The strongest part of the wingsail, most suitable for Preferably each rib includes at least one side flange

mating with the vertical bearing assembly, is usually a which subtends over part of its length an angle which is

Dbox leading edge section, which may occupy only the 35 greater than 90° to the remainder of the rib, to facilitate

leading 20% perhaps of the total wingsail chord. the removal of the rib from mould, and the angle and

In the case of a wingsail having two elements, it is said part of the rib, are selected so that the flange angle

normally assumed that the leading element is the princi corresponds to the angle of the rake of the edge of the

ple strength member. sail with which it is to co-operate.

Many wingsail propulsion sets need to be carefully 40 Preferably the flange angle reduces to 90 where it is

balanced about their vertical or near vertical axes of to be attached to a spar or the like.

rotation to enable optimum control of angle of attack to

be achieved, and the invention is in part concerned with BRIEF DESCRIPTION OF THE DRAWINGS

wingsail balancing.

In complex wingsails, composed of two or more ele 45 The invention will now be described by way of exam

ments hinged or otherwise connected, three distinct ple with reference to the accompanying drawings in

which

types of conformation may be obtained:

These are: FIG. 1 illustrates a wingsail craft,

Symmetrical and all-in-line, FIGS. 2 and 3 illustrate wingsail constructions em

Cambered for port tack sailing, and 50 bodying the first aspect of the invention,

Cambered for starboard tack sailing. FIGS. 4, 5 and 6 illustrate a twin element sailset in the

Such a sailset may be balanced about a vertical or three different modes,

near vertical axis by a mass mounted on a boom and FIGS. 7 and 8 illustrate locating means according to

pivoted to the leading edge of the leading sailset section. the second aspect of the invention applied to such a

The actual construction of a wingsail or the various 55 sailset,

elements of a multiple element wingsail is important, in FIG. 9 illustrates this aspect of the invention applied

that weight and strength are of primary importance. to a sailset in which the leading sailset section is hinged

The invention is therefore also concerned with the ac to the trailing sailset section.

tual construction of a wingsail and of the elements FIG. 10 is a perspective view of an open tray section

which make up a multiple element wingsail. 60

the sides of which form the flanges of a rib, for a wing

SUMMARY OF THE INVENTION sail,

According to one aspect of the present invention in a FIG. 11 is a detail of the side of the rib, of FIG. 10,

wingsail of symmetrical single element design having a FIGS. 12 and 13 show parallelogram shaped wings

region of principle strength (typically its leading edge) 65 employing the third aspect of the invention, and

or in a wingsail having two or more elements in which FIG. 4 is a cross section on the center of a forwardly

one of the elements includes a region of principal raked sail element, employing this aspect of the inven

strength, the bearing axis is arranged to pass through tion.

4,473,023 4.

3

the fins around which wires 23 and 24 pass. The wires

DETAILED DESCRIPTION OF THE are connected to the trailing section 12 at lugs 25, 26

PREFERRED EMBODIMENTS and to the counterweight boom at lugs 27 and 28.

FIG. 1 shows a sailing craft hull having a wingsail B Spring elements 29, 30 in the wires maintain wire ten

pivotally mounted in a bearing assembly C for rotation 5 sion. Dotted lines 22 show the trailing section 12 fully

about an axis D. deflected.

In FIG. 2, two wingsail assemblies have been shown When the trailing section 12 is moved relative to 11 in

superimposed, both having the same center of pressure order to develop camber, say in the clockwise direction

Zone 2, in which one has been drawn in chain dotted in the plan view drawn, wire 23 pulls the counterweight

outline as a simple rectangle, and the outer in solid 10 to the correct position to maintain balance. In this case

outline as a parallelogram. The two sail assemblies have wire 24 maintains tension. The opposite action will

the same height, area and center of pressure position. occur upon counterclockwise rotation.

The strong leading edge member, 3, shown cross FIG. 8 shows alternative versions of the lugs 25, 26.

hatched, is arranged, by correct choice of forward The alternative lugs shown at 31 and 32 are slotted to

sweep angle, so that its lower end is located exactly 15 allow fine adjustment of the balancing effect.

over the position of the bearing assembly 4, whilst the In some wingsail designs the trailing section 22 is

axis 5 of the bearing 4 still passes through the center of mounted on the vessel via the axis 14, and the leading

pressure zone 2. The strong leading edge member is section 11 is then hinged to the trailing section 12. FIG.

provided with a flange or other arrangement to mate 9 shows such a case. Here an end plate structure 23

with the shaft or other rotating element of the bearing 20 broadly similar in principle to the structure 18, 19 of

assembly. FIG. 7 carries the counterweight boom pivot 17.

In wingsails of multielement design, it may be pre The pivot 13 between sections 11 and 12 could also be

ferred that the second or other element of the aerofoil mounted on end plate structure 33, but for reasons of

section shall contain the strong spar member. FIG. 3 bending moment optimization is more likely to be

shows a double element of such a wingsail configura 25

mounted on separate hinge arms 34, working through

tion. Here the leading element 1 is hinged to the trailing clearance slots in 11. Wires 35 and 36 are now con

main strength element 2 by hinge assemblies 3. The nected at one end via lugs 27, 28 to the counterweight

center of pressure zone of this complex assembly is at 4, boom and at the other end to adjustable lugs 31, 32 on

and as before, to minimize trimming work, the approxi the leading section 11. The wires adjust the position of

mately vertical axis 5 of the bearing 6 is arranged to pass 30

the counterweight to maintain balance.

through this zone. While bracing wires such as 23, 24 and 35, 36 are

In this case, the main strength member of the wingsail illustrated, the same action of broadly horizontal move

is the leading edge 7 of the trailing element 2 shown ment of the counterweight may also be achieved by:

cross hatched. This is now arranged so that its lower a mechainical linkage using a pushpull rod, or

end falls into the best relationship for strong and reliable 35

hydraulic or other means in which the correct final

mating of the bearing assembly by raking the entire balance may be assured either by a fixed or manu

assembly aft as shown. ally adjustable ratio system.

The design is arrived at by starting with the rectilin FIG. 10 shows a simple form of moulding envisaged

ear design, positioning the center of pressure zone on by the third aspect of the invention, in the form of an

the bearing axis and then replacing the rectangle with a 40 open tray section where the sides 39, 40 of the tray form

parallelogram of the same height and area, whose angle the flanges of the rib. For ease of release from a simple

brings the base of the main spar conveniently over the one piece mould, such mouldings should preferably be

bearing. arranged with a draft angle greater than 0 as shown in

While this aspect of the invention has been described FIG. 11. Such an angle can make the fixing of the skin

for simplicity with reference to parallel, constant chord 45 of the aerofoil to the rib difficult to achieve. However,

wingsails, it is nonetheless applicable to wingsails of if the wing is parallelogram shaped, as shown in FIGS.

tapering or curvilinear outline. 12 and 13 the draft angle may be utilized.

FIGS. 4,5 and 6 show a twin section sailset where 11

is the leading sail section and 12 is the trailing section, ward FIG. 14 is a center line section through a raked for

hinged to leading sail section 11 along an axis 13. The 50 leadingsailedge element such as is shown in FIG. 12 where a

member 41, a main spar 42 and a trailing

whole sailset is mounted to the vessel in this case via

edge 43 are connected

element 11 on a vertical or near vertical axis 14, about and a typical trailing edge by a typical leading edge rib 44

which the sail is trimmed to the wind. rib 45.

In the all in line case, the sailset is balanced about the It will be noted that, because this is swept forward

axis 14 by a mass 15 mounted on a boom 16 pivoted to 55 design, the leading edge rib 44 is fitted with its flanges

the leading edge of the leading section 11 at a pivot 17. upwards, while the trailing edge rib 45 is fitted with its

In the port tack sailing case, illustrated in FIG. 5 it flangesequal downwards. The draft angle of the mould is

will be seen that a new balance may be acheived by made to the desired forward rake angle at leading

moving the weight around in a clockwise manner until edge and trailing edge, but is gradually reduced to zero

equilibrium is restored. 60 so that the flange of each rib is at 90 to the web in the

FIG. 6 shows the opposite tack case. immediate vincinity of the main spar 42.

In accordance with the second aspect of the inven By varying the draft angle in this way along each rib

tion the location of the balance weight in an approxi the rib flanges will in general be coplanar with the skin

mately horizontal plane is acheived by a pair of wire for ease of skin attachment, whilst the mould and

stays, as shown in FIG. 7. 65 moulding techniques are kept simple and reliable.

To this end a streamlined structure having two fins In the case of raked back wingsails, as in FIG. 13,

18, 19 is rigidly fixed to the base of the leading section then the leading edge rib elements will be fitted flange

11 of the sailset. A pair of pulleys 20, 21 are carried by down and the trailing edge ribs will be fitted flange up.

5

4,473,023

6

In the case of multielement wings, where each ele tive axis, said balancing mass on said boom also moves

ment has its own broadly aerofoil shaped section and to balance said assembly.

main spar, the ribs will be fitted as described above in 5. A sailing vessel, comprising a craft;

each individual element, as if it were a complete wing. at least a first and second wingsail, said first sail being

I claim: 5 mounted for rotation about a first generally verti

1. A wingsail assembly, comprising: cal axis, and said second sail being mounted on said

at least a first and second wingsail, said first sail being first sail for rotation about a second generally verti

mounted for rotation about a first generally verti cal axis spaced from said first axis;

cal axis, and said second sail being mounted on said means interconnecting said second sail with said first

first sail for rotation about a second generally verti 10 sail;

cal axis spaced from said first axis; a boom supported on said first sail;

means interconnecting said second sail with said first a balancing mass mounted at a remote end of said

sail; boom; and

a boom supported on said first sail; control means disposed on opposite sides of said

a balancing mass mounted at a remote end of said 15 boom for moving said balancing mass in an approx

boom; and imately horizontal plane as said first and second

control means disposed on opposite sides of said sails move about their respective axis such that said

boom for moving said balancing mass in an approx balancing mass balances said wingsail assembly;

imately horizontal plane as said first and second one of said first and second sails having a region of

sails move about their respective axis such that said 20 principal strength extending between the bottom

balancing mass balances said wingsail assembly. and top portion of said one sail and further com

2. A wingsail assembly as claimed in claim 1, wherein prising a bearing at said bottom portion of said one

one of said first and second sails has a region of principal sail by means of which said one sail is mounted in

strength extending between a bottom and top portion of 25 said craft, said bearing also defining an axis of piv

said one sail and further comprising a bearing at said oting of said one sail wherein the axis of pivoting of

bottom portion of said one sail by means of which said said one sail passes through a zone in which a cen

sail can be mounted in a craft, said bearing also defining tre of pressure of said one normally lies and

an axis of pivoting of said one sail and wherein the axis through said region of principal strength and

of pivoting of said one sail passes through a zone in 30 wherein said region of principal strength extends to

which a centre ofpressure of said one sail normally lies said bearing.

and through said region of principal strength and 6. A sailing vessel, comprising;

wherein said region of principal strength extends to said a craft;

bearing. at least a first and second wingsail, said first sail being

3. A wingsail assembly as claimed in claim 1, wherein 35 mounted for rotation about a first generally verti

said control means further comprises a wire stay dis cal axis, and said second sail being mounted on said

first sail for rotation about a second generally verti

posed on each side of said assembly and extending later cal axis spaced from said first axis;

ally from said boom, around a fixed point on said assem means interconnecting said second sail with said first

bly, and back to one of said first and second sails such sail;

that when said sails move about their respective axis, 40 a boom supported on said first sail;

said balancing mass on said boom also moves to balance a balancing mass mounted at a remote end of said

said assembly. boom; and

4. A wingsail assembly as claimed in claim 1, wherein control means disposed on opposite sides of said

said control means further comprises a wire stay dis boom for moving said balancing mass in an approx

posed on each side of said assembly and extending later 45 imately horizontal plane as said first and second

ally from said balancing mass, around a fixed point on sails move about their respective axis such that said

said assembly, and back to one of said first and second balancing mass ::balances said wingsail assembly.

sails such that when said sails move about their respec k s :: k

50

55

60

65

You might also like

- US4624203Document11 pagesUS4624203524No ratings yet

- United States Patent (19) : PreticDocument5 pagesUnited States Patent (19) : Pretic63No ratings yet

- Patent for Parasail Glider DeviceDocument5 pagesPatent for Parasail Glider Device63No ratings yet

- US4388888Document19 pagesUS4388888524No ratings yet

- United States Patent: (54) SailboatDocument5 pagesUnited States Patent: (54) Sailboat155No ratings yet

- United States Patent (19) : VicardDocument4 pagesUnited States Patent (19) : Vicard155100% (1)

- US Patent 7090236 Land SailingDocument8 pagesUS Patent 7090236 Land SailingDimas MaulanaNo ratings yet

- United States Patent (19) : JohnsonDocument6 pagesUnited States Patent (19) : JohnsongorgiNo ratings yet

- United States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001Document8 pagesUnited States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001155No ratings yet

- Horizontal tail for aircraft generates increased pitch controlDocument9 pagesHorizontal tail for aircraft generates increased pitch controlgorgiNo ratings yet

- United States Patent (19) : Hood Et Al.Document5 pagesUnited States Patent (19) : Hood Et Al.8787No ratings yet

- United States Patent (19) : Ammen Et AlDocument9 pagesUnited States Patent (19) : Ammen Et Al55No ratings yet

- US5918832Document8 pagesUS5918832engine wangNo ratings yet

- United States Patent (19) : Debarge Dec. 17, 1985Document9 pagesUnited States Patent (19) : Debarge Dec. 17, 198563No ratings yet

- United States Patent (19) : (21) Appl. No.: 927,123Document7 pagesUnited States Patent (19) : (21) Appl. No.: 927,123155No ratings yet

- United States Patent: Fournier Et AlDocument9 pagesUnited States Patent: Fournier Et AlfakernevernoNo ratings yet

- US3981460Document5 pagesUS3981460MERIWON SURTAN JOHN / UPMNo ratings yet

- Tow Target Line Reel (2005)Document19 pagesTow Target Line Reel (2005)CAP History LibraryNo ratings yet

- United States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 1993Document10 pagesUnited States Patent (19) : 11) Patent Number: 5,181,477 45 Date of Patent: Jan. 26, 199312348No ratings yet

- United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989Document7 pagesUnited States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989155No ratings yet

- United States PatentDocument6 pagesUnited States Patent155No ratings yet

- United States Patent (19) : (54) Roll-Reefing JibsailDocument8 pagesUnited States Patent (19) : (54) Roll-Reefing Jibsail63No ratings yet

- United States Patent (19) : GravelineDocument15 pagesUnited States Patent (19) : Graveline155No ratings yet

- Us 4812080Document10 pagesUs 4812080JonNo ratings yet

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 pagesUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348No ratings yet

- United States Patent 19: TaylorDocument6 pagesUnited States Patent 19: Taylor63No ratings yet

- United States PatentDocument13 pagesUnited States Patent155No ratings yet

- Automatically Rotating Sail Rig for SloopsDocument18 pagesAutomatically Rotating Sail Rig for Sloops155No ratings yet

- United States Patent (19) : Gazalel, 72 8Document7 pagesUnited States Patent (19) : Gazalel, 72 8Mihai RobertNo ratings yet

- US5762060Document9 pagesUS5762060Radek HoffmannNo ratings yet

- May 25, 1943. R. V. Jennings. 2,319,999: Filed Dec. 13, 1939 - 2 Sheets-Sheet 1Document6 pagesMay 25, 1943. R. V. Jennings. 2,319,999: Filed Dec. 13, 1939 - 2 Sheets-Sheet 163No ratings yet

- United States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995Document11 pagesUnited States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995155No ratings yet

- Vickers Vendace Training Biplane Gets Detailed LookDocument10 pagesVickers Vendace Training Biplane Gets Detailed Lookrritter78No ratings yet

- Way Cases: Nov. 9, 1965 W. E. Schoenborn 3,216,699Document5 pagesWay Cases: Nov. 9, 1965 W. E. Schoenborn 3,216,699Thyaga RajNo ratings yet

- Precise control body sail with adjustable boomDocument8 pagesPrecise control body sail with adjustable boom63No ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Flying Saucer Vehicle Controls Attitude With Pressurized Air JetsDocument8 pagesFlying Saucer Vehicle Controls Attitude With Pressurized Air JetsSINGLE KIFNo ratings yet

- Tug Boat Cover Rolling Apparatus Optimized for SEODocument5 pagesTug Boat Cover Rolling Apparatus Optimized for SEOاحمد عبدالكريمNo ratings yet

- US3870253Document8 pagesUS3870253gorgiNo ratings yet

- United States Patent (19) : A26%/A A2%2W2 Azaa2%2Document17 pagesUnited States Patent (19) : A26%/A A2%2W2 Azaa2%2fitri auliyatinNo ratings yet

- United States PatentDocument13 pagesUnited States Patent63No ratings yet

- Ballesta Con Redirección de CuerdaDocument7 pagesBallesta Con Redirección de CuerdaDamian CampilloNo ratings yet

- Diseño de Impulsores para Mezcla de SuspensionesDocument9 pagesDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdNo ratings yet

- United States Patent (19) : (73) Assignee: Mcdonnell Douglas Corporation, STDocument13 pagesUnited States Patent (19) : (73) Assignee: Mcdonnell Douglas Corporation, STgorgiNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Cloth Tow Target Sleeve (1991)Document25 pagesCloth Tow Target Sleeve (1991)CAP History LibraryNo ratings yet

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- Night vision goggle battery pack for portable useDocument6 pagesNight vision goggle battery pack for portable useja2ja1No ratings yet

- Unsteady Aerodynamics of Slender Wings and Aircraft Undergoing Large Amplitude ManeuversDocument66 pagesUnsteady Aerodynamics of Slender Wings and Aircraft Undergoing Large Amplitude ManeuversDipendra SenNo ratings yet

- USO05339793A - Bow Stabilizer Dampens Forces When Arrow ReleasedDocument6 pagesUSO05339793A - Bow Stabilizer Dampens Forces When Arrow Releasedwan nazrolNo ratings yet

- US6827310Document6 pagesUS6827310SHANKARNo ratings yet

- United States Patent (19Document19 pagesUnited States Patent (1912348No ratings yet

- PATENTE AIRCRAFT WITH ROTATIVE WINGS CIERVA 1928 US1692081Document3 pagesPATENTE AIRCRAFT WITH ROTATIVE WINGS CIERVA 1928 US1692081Mariela TisseraNo ratings yet

- United States PatentDocument10 pagesUnited States Patent63No ratings yet

- US5304036Document24 pagesUS5304036wen longNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2006/0118021 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2006/0118021 A1sam a g mNo ratings yet

- US3977531Document15 pagesUS3977531Huy Nguyễn Võ XuânNo ratings yet

- US5303813Document7 pagesUS5303813AdailsonNo ratings yet

- Sling GunDocument7 pagesSling GunMinh100% (1)

- United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989Document7 pagesUnited States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989155No ratings yet

- United States Patent (19) : VicardDocument4 pagesUnited States Patent (19) : Vicard155100% (1)

- Fied Feb. 5, 1967: 2. Sheets-Sheet LDocument5 pagesFied Feb. 5, 1967: 2. Sheets-Sheet L155No ratings yet

- EP0746495B1Document9 pagesEP0746495B1155No ratings yet

- Automatically Rotating Sail Rig for SloopsDocument18 pagesAutomatically Rotating Sail Rig for Sloops155No ratings yet

- Patent for improved sailing vessel with rotating masts and sailsDocument10 pagesPatent for improved sailing vessel with rotating masts and sails155No ratings yet

- United States PatentDocument6 pagesUnited States Patent155No ratings yet

- Us 2484687Document7 pagesUs 2484687155No ratings yet

- United States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.Document10 pagesUnited States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.155No ratings yet

- United States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995Document11 pagesUnited States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995155No ratings yet

- Automatically Rotating Sail Rig for SloopsDocument18 pagesAutomatically Rotating Sail Rig for Sloops155No ratings yet

- United States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999Document8 pagesUnited States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999155No ratings yet

- Wells-Coates 1951 Patent for Sailing Craft with Adjustable Sail ArchDocument16 pagesWells-Coates 1951 Patent for Sailing Craft with Adjustable Sail Arch155No ratings yet

- United States PatentDocument13 pagesUnited States Patent155No ratings yet

- EP2404820A1Document18 pagesEP2404820A1155No ratings yet

- United States Patent 19 11 Patent Number: 5,775,249: Samuel 45) Date of Patent: Jul. 7, 1998Document19 pagesUnited States Patent 19 11 Patent Number: 5,775,249: Samuel 45) Date of Patent: Jul. 7, 1998155No ratings yet

- United States Design Patent (10) Patent No.: US D478,598 SDocument5 pagesUnited States Design Patent (10) Patent No.: US D478,598 S155No ratings yet

- W. Castles, JR: Filed Jan. 11, 1957Document3 pagesW. Castles, JR: Filed Jan. 11, 1957155No ratings yet

- United States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: RegDocument24 pagesUnited States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: Reg155No ratings yet

- United States Patent (19) : (21) Appl. No.: 927,123Document7 pagesUnited States Patent (19) : (21) Appl. No.: 927,123155No ratings yet

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Document8 pagesUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155No ratings yet

- United States Design Patent (10) Patent No.:: USD639,239 SDocument9 pagesUnited States Design Patent (10) Patent No.:: USD639,239 S155No ratings yet

- United States PatentDocument18 pagesUnited States Patent155No ratings yet

- United States Patent: (10) Patent No.: US 6,168,383 B1Document17 pagesUnited States Patent: (10) Patent No.: US 6,168,383 B1155No ratings yet

- United States Design Patent (10) Patent No .:: US D807, 823 SDocument9 pagesUnited States Design Patent (10) Patent No .:: US D807, 823 S155No ratings yet

- United States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002Document8 pagesUnited States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002155No ratings yet

- Us 5253828Document12 pagesUs 5253828155No ratings yet

- Us 5253828Document12 pagesUs 5253828155No ratings yet