Professional Documents

Culture Documents

Welder-456A-EN-TS Skill Level

Uploaded by

AnilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welder-456A-EN-TS Skill Level

Uploaded by

AnilCopyright:

Available Formats

WELDER

COMPETENCY ANALYSIS PROFILE

Welder

(All unshaded skill sets must be demonstrated/completed except as indicated below)

NOTE: For Skill Sets 6007.0 to 6012.0, 3 out of 6 must be completed

SKILL SETS SKILLS

Use and maintain Use and maintain

USE AND Use shop and Use and maintain

metal working and electrical, pneumatic

MAINTAIN metal forming measuring devices

trade specific hand and hydraulic power

TOOLS & tools & associated

equipment and layout

EQUIPMENT tools and associated equipment

equipment equipment and

supplies

6000.0 6000.01 6000.02 6000.03 6000.04 6000.05

USE AND Select and inspect Position and Select and inspect Operate hoisting Select, inspect and

MAINTAIN rigging equipment employ rigging hoisting and lifting equipment erects scaffolding

MATERIAL equipment

HANDLING AND

SAFETY

EQUIPMENT

6001.0 6001.01 6001.02 6001.03 6001.04 6001.05

Work on Dismantle and

scaffolding and at stores scaffolding

heights

6001.06 6001.07

MAINTAIN Maintain oxy-fuel Maintain arc Store welding

WELDING equipment welding equipment consumables

EQUIPMENT

AND SUPPLIES

6002.0 6002.01 6002.02 6002.03

PREPARE Plan work site Set up work area Communicate/

WORK SITE layout consult with

supervisor,

technical advisor

and other workers

6003.0 6003.01 6003.02 6003.03

Ontario College of Trades ©

WELDER

SKILL SETS SKILLS

LAY OUT, CUT Prepare job layout Cut and gouge Cut metal with arc- Cut metal with Cut metal with

AND FORM metal with oxy-fuel air equipment SMAW cutting plasma arc

METALS TO equipment equipment equipment

SPECIFICATION

6004.0 6004.01 6004.02 6004.03 6004.04 6004.05

Cut metal using Cut metal using Form metal to Prepare welding Select material

hand tools power tools specified design joints preparation method

6004.06 6004.07 6004.08 6004.09 6004.10

FIT SUB- Make jigs, fixtures Check Pre-heat Perform tack Plan for the control

ASSEMBLIES and templates with measurements and components or welding of distortion

AND or without actual fit of components assembly

ASSEMBLIES components

6005.0 6005.01 6005.02 6005.03 6005.04 6005.05

PREPARE Plan sequence of Verify fabricated Prepare job for Ensure correct Check weld joint fit

ASSEMBLY operations materials and welding consumables are on up, tack welds and

FOR WELDING assemblies hand fixture condition

6006.0 6006.01 6006.02 6006.03 6006.04 6006.05

Check that joints to

be welded are clean

and dry

6006.06

Ontario College of Trades ©

WELDER

SKILL SETS SKILLS

WELD WITH THE Select and set up Install electrode Fillet weld using the Groove weld using

SHIELDED Adjust and verify

welding equipment SMAW “stick” the SMAW “stick”

METAL ARC welding process

process process

WELDING parameters

(SMAW) “stick”

PROCESS

6007.0 6007.01 6007.02 6007.03 6007.04 6007.05

Clean welds Measure welds for

completeness

6007.06 6007.07

WELD WITH THE Select and set up Install consumables Adjust and verify Fillet weld using the Groove weld using

GAS METAL ARC welding equipment welding process GMAW/ MIG the GMAW/ MIG

WELDING parameters process process

(GMAW/MIG)

PROCESS

6008.0 6008.01 6008.02 6008.03 6008.04 6008.05

Clean welds Measure welds for

completeness

6008.06 6008.07

Ontario College of Trades ©

WELDER

SKILL SETS SKILLS

WELD WITH Select and set up Install consumables Adjust and verify Fillet weld using Groove weld using

THE GAS welding equipment welding process the GTAW/ TIG the GTAW/ TIG

TUNGSTEN ARC parameters process process

WELDING

(GTAW/TIG)

PROCESS

6009.0 6009.01 6009.02 6009.03 6009.04 6009.05

Clean welds Measure welds for

completeness

6009.06 6009.07

WELD WITH Select and set up Install consumables Adjust and verify Fillet weld using Groove weld using

FLUX CORED welding equipment welding process the FCAW or the FCAW or

(FCAW) OR parameters MCAW process MCAW process

METAL CORED

(MCAW) ARC

WELDING

6010.0 6010.01 6010.02 6010.03 6010.04 6010.05

Clean welds Measure welds for

completeness

6010.06 6010.07

Groove weld using

WELD WITH Install consumables Adjust and verify Fillet weld using Clean welds

the SAW process

SUBMERGED welding process the SAW process

ARC WELDING parameters

(SAW) PROCESS

6011.0 6011.01 6011.02 6011.03 6011.04 6011.05

Measure welds for

completeness

6011.06

Ontario College of Trades ©

WELDER

SKILL SETS SKILLS

WELD WITH Set up welding Install consumables Adjust welding Groove weld using Clean welds

THE PLASMA equipment parameters the PAW process

ARC WELDING

(PAW)

PROCESS

6012.0 6012.01 6012.02 6012.03 6012.04 6012.05

Measure welds for

completeness

6012.06

BRAZE METAL Select and Obtain Braze lap and tee Carry out shut

configure oxy-fuel- consumables joints down procedure

gas heating

equipment

6013.0 6013.01 6013.02 6013.03 6013.04

WELD STUDS Select and set up Install consumables Weld studs Remove ferrules Repair a failed

welding equipment from welded studs weld

6014.0 6014.01 6014.02 6014.03 6014.04 6014.05

CONTROL FOR Comply with Ensure ongoing Benchmark weld

QUALITY company quality weld quality quality

WHILE control standards,

WELDING customer standards

and code

requirements

6015.0 6015.01 6015.02 6015.03 6015.04 6015.05

CARRY OUT Visually inspect Perform post-weld Correct excessive Perform any non- Prepare weld

POST-WELD welds product control of welding distortion destructive check samples and

QUALITY weldment perform destructive

CONTROL temperature tests

6016.0 6016.01 6016.02 6016.03 6016.04 6016.05

Ontario College of Trades ©

WELDER

SKILL SETS SKILLS

DEMONSTRATE Identify and take Handle, store and Comply with Wear and maintain Practice good

SAFE WORKING corrective action dispose of workplace personal protective housekeeping in

PRACTICES against potential hazardous legislation relating equipment the workplace

AND workplace health workplace to health & safety

PROCEDURES and safety hazards materials

6017.0 6017.01 6017.02 6017.03 6017.04 6017.05

Ontario College of Trades ©

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Weld Reinforcement - ImportanceDocument1 pageWeld Reinforcement - ImportanceAnilNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- What We Will CoverDocument4 pagesWhat We Will CoverAnilNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 21719Document1 page21719AnilNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 167452Document1 page167452AnilNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 146560Document1 page146560AnilNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Bend of Material - ThickDocument1 pageBend of Material - ThickAnilNo ratings yet

- Overlap - WeldDocument1 pageOverlap - WeldAnilNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mig WireDocument1 pageMig WireAnilNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 11Document1 page11AnilNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 12Document1 page12AnilNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Mag Weld ConcaveDocument1 pageMag Weld ConcaveAnilNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Bend DefectDocument1 pageBend DefectAnilNo ratings yet

- DP Colour ContrastDocument1 pageDP Colour ContrastAnilNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Welder Test WPQDocument1 pageWelder Test WPQAnilNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Multi Pass 3GDocument1 pageMulti Pass 3GAnilNo ratings yet

- DP Test InspectionDocument1 pageDP Test InspectionAnilNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Bend DistortionDocument1 pageBend DistortionAnilNo ratings yet

- Butt Joint in High ThickDocument1 pageButt Joint in High ThickAnilNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- T JointDocument1 pageT JointAnilNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Joint GeometryDocument1 pageJoint GeometryAnilNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Poor Joint FitupDocument1 pagePoor Joint FitupAnilNo ratings yet

- Dent Mark - VisualDocument1 pageDent Mark - VisualAnilNo ratings yet

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document12 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Anil100% (1)

- 11Document1 page11AnilNo ratings yet

- MTC JSPLDocument2 pagesMTC JSPLAnil0% (1)

- Hole DrillingDocument1 pageHole DrillingAnilNo ratings yet

- WPS ISO 15609 TemplateDocument1 pageWPS ISO 15609 TemplateSatish Keskar100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- How To Do Visible Dye Penetrant TestingDocument2 pagesHow To Do Visible Dye Penetrant TestingSrikanth Kabbal MNo ratings yet

- WPS ISO 15609 TemplateDocument1 pageWPS ISO 15609 TemplateSatish Keskar100% (5)

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document12 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Anil100% (1)

- UG PipingDocument41 pagesUG PipingphuongnhsfcNo ratings yet

- SWMS For Hoarding GateDocument9 pagesSWMS For Hoarding GateSam LimNo ratings yet

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- Curriculum of Competency Unit (Cocu)Document22 pagesCurriculum of Competency Unit (Cocu)yeopsagorNo ratings yet

- Estimation (Steel Work)Document21 pagesEstimation (Steel Work)Poorti JainNo ratings yet

- KM Welding FundamentalsDocument42 pagesKM Welding FundamentalsJignesh GunasegerenNo ratings yet

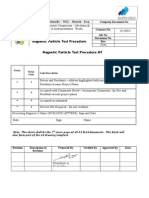

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDocument14 pagesMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- MecsyllDocument152 pagesMecsyllArun C DixitNo ratings yet

- K.bender - Case Study - A Collaborative Approach Between DuPont and Renault - 2015Document13 pagesK.bender - Case Study - A Collaborative Approach Between DuPont and Renault - 2015anacarol09No ratings yet

- Application Manual: Torch ServicesDocument44 pagesApplication Manual: Torch ServicesGrahamNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Document405 pagesCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- DSWD SMAW NC Training Budget: Total Amount P147,050.00Document1 pageDSWD SMAW NC Training Budget: Total Amount P147,050.00Ramil Raquit0% (1)

- Tig Torç Kataloğu PDFDocument40 pagesTig Torç Kataloğu PDFwenigmaNo ratings yet

- Welding Cost, Economics - GMAW & MMAW Process & QualityDocument6 pagesWelding Cost, Economics - GMAW & MMAW Process & Qualityratneshkumar2004No ratings yet

- Ctef Sts Group 4Document23 pagesCtef Sts Group 4Tábata PintoNo ratings yet

- Microstructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsDocument8 pagesMicrostructure and Micro-Hardness Analysis of Friction Stir Welded Bi-Layered Laminated Aluminum SheetsMangesh LingampalleNo ratings yet

- Titanium WeldingDocument6 pagesTitanium WeldingMichael ClaphamNo ratings yet

- Resistance Spot Welding: Experiment RSWDocument11 pagesResistance Spot Welding: Experiment RSWAli Raza JuttNo ratings yet

- Aiche-19-008 Ammonia Shift ConverterDocument6 pagesAiche-19-008 Ammonia Shift ConverterHsein WangNo ratings yet

- STT LincolnDocument32 pagesSTT LincolnedwinNo ratings yet

- B361-08 Standard Specification For Factory-Made Wrought Aluminum and Aluminum-Alloy Welding FittingsDocument6 pagesB361-08 Standard Specification For Factory-Made Wrought Aluminum and Aluminum-Alloy Welding FittingsmithileshNo ratings yet

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Material Data Sheets For Piping: 1 ForewordDocument50 pagesMaterial Data Sheets For Piping: 1 ForewordMuhammad Ramadhan Ismukada SyahrifNo ratings yet

- Astm A217-2007Document6 pagesAstm A217-2007Rajeev KumarNo ratings yet

- Consumable by AWS D5.1Document8 pagesConsumable by AWS D5.1Fuaz Sukarya Abu Fatih100% (1)

- Quarter4 M 1 SMAW 10 FinalDocument25 pagesQuarter4 M 1 SMAW 10 FinalTitser Ramca100% (1)

- S355G10 GBDocument4 pagesS355G10 GBH41GAMINGNo ratings yet

- Branson Plastic JoiningDocument8 pagesBranson Plastic Joiningapbeese3178No ratings yet

- ASME Sec VIII Div 1 Ed 2010 471Document9 pagesASME Sec VIII Div 1 Ed 2010 471Sankar MukaNo ratings yet