Professional Documents

Culture Documents

RANGER 305g Lincoln

Uploaded by

WilfredoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RANGER 305g Lincoln

Uploaded by

WilfredoCopyright:

Available Formats

ENGINE DRIVEN WELDERS

Ranger 305 G and Ranger 305 G EFI ® ®

Processes Output Range HP @ Speed (RPM)

Stick, TIG, MIG, Flux-Cored, Gouging See Back Page 23 HP @ 3600 RPM

25 HP @ 3600 RPM EFI

Product Number Rated Output Current/Voltage/Duty Cycle

305A DC CC/29V/100% Weight/Dimensions (H x W x D)

K1726-5 Ranger® 305 G 300A DC CV/29V/100% 510 lbs. (231 kg)

K3928-1 Ranger® 305 G EFI

Number of Cylinders 29.9 x 21.5 x 42.3 in.

2 (759 x 546 x 1073 mm)

CC: Constant Current

36.2 in. (920 mm) To Top of

CV: Constant Voltage

Exhaust Tube

Ready for a Workout!™ 300 Amp DC Gasoline Engine

The Ranger® 305 G is a powerful multi- Driven Welder/Generator

process stick, TIG, wire and pipe welding

engine-driven welder that is ready for all APPLICATIONS

day, everyday performance. It includes Construction

Lincoln Electric Chopper Technology®

for superior arc performance. Maintenance and Repair

Pipe

FEATURES Ranch/Farm

Kohler® Gasoline Engine Choices

• 23 HP carburetor.

• 25 HP EFI (Electronic Fuel Injection) for

easier starts in cold weather and lower

fuel use!

• Both engines have electric fuel pump

to avoid vapor lock at high altitude

operation.

Multi-Process Welding

• Excellent DC multi-process welding

for general purpose stick, downhill

pipe (stick), TIG, cored-wire, MIG (CO2

FEATURES CONT’D.

and mixed gas) and arc gouging. Peak Single-Phase AC Generator

Power for Motor Starting INPUT OUTPUT

• Only compact gasoline welder in

North America rated at 29V for • 10,500 watts peak; 12,000 for EFI. or

300 amps of stick or CV welding. • 9,500 watts continuous for high

• CV wire welding with up to 5/64 in. capacity needs such as a back-up

generator, powering a Lincoln Electric Powered By:

(2.0 mm) diameter electrodes.

Invertec® inverter welder. Also use for

Digital Weld Meters

lights, a grinder or other power tools.

• Digital weld meters for amps and

• AC generator voltage is constant at

volts makes it easy to precisely LN ELECT

120V or 240V at any weld dial setting. IN

CO RI

pre-set your procedures and monitor

C

L

actual welding output. Skewed Rotor Design

Superior Arc Performance • Skewed rotor design provides AC

power suitable for operating Lincoln

• Lincoln Electric Chopper

Electric inverter power sources.

Technology® – provides easy starts, a Two Year Extended

Lincoln Electric was the first in the

smooth arc, low spatter and excellent Warranty Available in

welding industry with this feature. the U.S.A. and Canada

bead appearance.

Rugged Reliability

• Welding and AC Generator Outputs

rated at 104ºF (40ºC).

THE LINCOLN ELECTRIC COMPANY

Publication E6.117 | Issue Date 06/13 22801 St. Clair Avenue • Cleveland, OH 44117-1199 • U.S.A.

© Lincoln Global, Inc. All Rights Reserved. PH: +1.216-481-8100 • www.lincolnelectric.com

PERFORMANCE

Welding Performance AC Generator Performance

• Lincoln Electric Chopper Technology®. • Up to 40 amps at 240V from the 120V/240V receptacle with weather

- Easy Starts. resistant cover. Circuit breaker protection.

- Smooth Arc. • Two 120V 20 Amp duplex receptacles with weather resistant

covers. Circuit breaker protection. Will operate up to 9 in. grinder.

- Low Spatter.

• Nominal 120V and 240V AC generator voltage is independent of any

- Excellent Bead Appearance. weld dial setting. This is done with one generator system (rotor/

• CC-stick mode is optimized for general purpose stick using E7018 low stator) using Lincoln Electric Chopper Technology®, avoiding the

hydrogen electrodes. complexity of two generator (rotor/stator) systems.

• Downhill pipe welding mode is excellent for cellulosic electrodes, such

as Lincoln Electric Fleetweld® 5P+. This mode delivers fast travel SIMULTANEOUS WELDING AND POWER LOADS

speeds, especially on fill passes.

Welding Output Continuous Power

• Arc force control provides a soft or more forceful digging arc in CC-stick (Amps) (Watts)

or downhill pipe mode and inductance/pinch control in CV wire mode.

300 0

• Built-in “hot” start for easier starts and restrikes minimizing the 250 2,300

electrode “sticking” to the work. 200 4,200

150 5,600

• Touch Start TIG® (DC) - lift tungsten to start the arc. No high 100 7,100

frequency required. Avoids tungsten contamination in the weld. Voltage 0 9,500

sensing output stops the arc when the torch is lifted at the end of the

weld - increased operator appeal.

• Arc gouging with up to 3/16 in. (4.8 mm) carbons.

FEATURES

• Simple Controls – Keep training time to a minimum with the • Fully enclosed case for equipment protection and low noise. Noise at

straightforward control panel of the Lincoln Electric Ranger® 305 G. rated load:

The flip-down control panel door keeps less frequently used controls – 101.3 dB sound power (Lwa)

out of the way. – 76.7 dBA sound level at 23 ft. (7 m)

• Single, full-range output control dial. No confusion with taps • Electric fuel pump avoids vapor lock. Assures consistent fuel delivery

and controls! in locations having a combination of high altitude, warm ambient

• 4 welding modes: CC-Stick, Downhill Pipe, CV-Wire, and temperatures, and high anti-pollution additives in gasoline.

Touch Start TIG®. • Combination electric fuel gauge and engine hour meter located on

• Dual digital output meters for presetting weld amps for stick, TIG control panel. Easily check both fuel level and hours of operation. Fuel

or downhill pipe modes, or voltage for CV wire mode. Also displays gauge helps you virtually eliminate running low on fuel during critical

actual outputs while welding. Memory feature holds output readings jobs. Hour meter helps plan for scheduled engine maintenance.

for 7 seconds after welding stops for viewing by the operator.

• Output at welding terminals controlled by electronic contactor. Fuel

Can be switched to “On”, or to “Remotely Controlled.” Hours

• Remote output control is auto-activated when plugged into a 6-pin

connector. For the CC-stick, downhill pipe and Touch Start TIG® modes,

the machine output dial becomes a maximum current limit for more fine

tuning with the remote control dial or Amptrol™.

• Compatible with many Lincoln Electric wire feeders including the • Large top fuel filler neck is easily accessed for refueling.

LN-25 Ironworker™, Activ8™, LF-72™, LF-74, LN-7 GMA, LN-742, LN-8, • Electric start.

wire feeders and Magnum® SG Gun.

• Oil drain valve (no tools required) with removable extension tube.

• Wire feed voltmeter switch matches polarity of wire feeder volt

meter to polarity of electrode. • Convenient truck or trailer mounting with front and rear holes

in base.

• Top-of-the-line Kohler engine choices:

®

- 23 HP CH730 OHV Command® with carburetor.

- 25 HP ECH740 OHV Command® with EFI (Electronic Fuel Injection).

Choke starting not needed.

• 12 gallon fuel capacity allows you to run an extended day.

[ 2 ] | Ranger ® 305 G and Ranger ® 305 G EFI

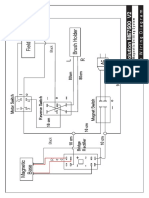

KEY CONTROLS

1. Output Control Dial

18 17 16 15

2. Digital Weld Output Ammeter

3. Weld Mode Switch

4. Arc Force & Inductance/Pinch Control Dial

14 5. Circuit Breakers

1 6. 120 Volt AC Receptacles (NEMA 5-20R)

13 7. Output Stud Covers

2

8. Ground Stud

12

9. 120/240 Volt AC Full KVA Receptacle (NEMA 14-50R)

3 11 10. 6-Pin Remote Control & 14-Pin Feeder Connectors

4 11. Wire Feeder Voltmeter Polarity Switch

12. Welding Terminals Control Switch

5 10 13. Digital Weld Output Voltmeter

6 9 14. Idler Control Switch

15. Pushbutton Start Switch

8

16. Engine Choke Control (not needed with EFI)

17. Run/Stop Switch

7

18. Electric Fuel Gauge and Engine Hour Meter

QUALITY AND RELIABILITY

• P rinted circuit boards are environmentally-shielded using Lincoln

Electric’s engineered potting and protective frame trays.

• O

il dip stick, filters, spark plugs, etc. are easily accessed with left, right • Easy access battery cover.

and top engine doors. Left and right doors are removable for service.

• A djust exhaust direction with top-mounted 360° rotatable exhaust

muffler. Muffler made from aluminized steel for longer life.

• A ttractive red and black powder paint finish offers increased durability

with added protection from rust and corrosion. Also ultraviolet resistant • O

ptional K1690-1 GFCI (Ground Fault Circuit Interrupter) Kit available for

to better retain color and gloss. additional protection from electrical shock.

• L onger engine life, reduced noise emissions and greater fuel economy • D

ependability and long life aided by all-copper windings in rotor and

with automatic engine idler. stator with high quality insulation.

• C

onveniently located engine maintenance label under top • Approved by Canadian Standards Association (CSA).

engine door. • M

anufactured under a quality system certified to ISO 9001 requirements

• Automatic engine shutdown protection for low oil pressure. and ISO 14001 environmental standards.

• R

eliable start-up with Group 58 battery with 435 cold • T hree year Lincoln Electric warranty (parts and labor) on welder (engine

cranking amps. is warranted separately by the manufacturer).

Make the Ranger ® 305 G your portable welding station – general stick and downhill

pipe, Touch Start TIG®, MIG, flux-cored and AC generator to power lights, grinders or

other power tools.

Ranger ® 305 G and Ranger ® 305 G EFI | [ 3 ]

MACHINE SPECIFICATIONS

CC/Pipe Rated Output CV-Rated Output

Product Ordering Current/Voltage/ Current/Voltage/ Generator HxWxL Weight

Name Information Description Duty Cycle Duty Cycle AC Power (2)(3) inches (mm) lbs/(kg)

Ranger® 305 G K1726-5 300 Amp DC Multi-Process DC Constant Current DC Constant Voltage (1) 10,500 Watts Peak 29.9 x 21.5 x 42.3 510

With Arc Welder with 305A/29V/100% 300A/29V/100% 12,000 Watts Peak EFI (759 x 546 x 1073) (231)

Electric Lincoln Electric 20-305A 9,500 Watts Continuous

Fuel Pump Chopper Technology® 14-29 V 60 Hz To top of exhaust tube:

DC Pipe Current Single-Dial Single Phase 36.2 (920)

Ranger® 305 G EFI K3928-1 300A/29V/100% Continuous Control

With 10,500 Watts Peak 40-300A Full KVA

Electric Wire Feeder Power Receptacle

Fuel Pump 9,500 Watts Touch Start TIG® 42V, 60 Hz, 15 Amps 40A@ 240V

Continuous AC Power 250A/30V/100% 120V, 60 Hz, 20 Amps 40A@ 120V ea.

20-250 A Branch Circuit (4)

All Models Single Dial Four 120V

Continuous Control Receptacles

60V DC Max OCV @ 20A per Duplex

3700 RPM 40A Total (4)

(1) DC constant voltage capability provides convenience and added safety when welding in electrically hazardous conditions.

(2) When welding, available auxiliary power will be reduced. Output voltage is within +\- 10% at all loads up to rated capacity.

(3) 120V will operate either 60 Hz or 50/60 Hz power tools, lights, etc.

(4) Circuits cannot be wired in parallel to operate the same device.

ENGINE SPECIFICATIONS

Engine Horsepower & Operating Fuel

Model Description Displacement Ignition Capacities Speeds Consumption

Kohler® OHV (5) 2 Cylinder, 4 Cycle, 23 HP Electric Start, 12V FUEL: FULL LOAD 1.7 Gals/Hr

Command® OHV, Air-Cooled @ 3600 RPM Group 58 Battery, 12 Gals (45 liters) 3,500 RPM (300A) 6.5 liters/Hr

CH730 Gasoline Gasoline Engine 435 Cold Cranking Amps,

Aluminum Alloy Block 44 cu in Pushbutton Start Switch, OIL: HIGH IDLE 1.0 Gals/Hr

with Cast Iron Liners (725 cc) Charging Indicator 2.0 Qts (1.9 liters) 3,700 RPM 3.7 liters/Hr

Electric Fuel Pump

LOW IDLE 0.4 Gals/Hr

2,400 RPM 1.5 liters/Hr

Kohler® OHV (5) 2 Cylinder, 4 Cycle, 25 HP Electric Start, 12V FUEL: FULL LOAD 1.5 Gals/Hr

Command® OHV, Air-Cooled @ 3600 RPM Group 58 Battery, 12 Gals (45 liters) 3,500 RPM (300A) 5.8 liters/Hr

ECH740 Gasoline Gasoline Engine 435 Cold Cranking Amps,

Aluminum Alloy Block 46 cu in Pushbutton Start Switch, OIL: HIGH IDLE 0.7 Gals/Hr

with Cast Iron Liners (747 cc) Charging Indicator 2.0 Qts (1.9 liters) 3,700 RPM 2.6 liters/Hr

Electric Fuel Pump

LOW IDLE 0.4 Gals/Hr

Electronic Fuel Injection 2,400 RPM 1.5 liters/Hr

(5) Kohler engine warranty is 3 years.

SYSTEM SELECTION

One-Pak® Welding Package

Order a Lincoln Electric One-Pak® and get everything

you need to complete a welding package - all with

one order number.

(Package is not assembled.)

Ranger® 305 G K704 Accessory Kit

Each UNASSEMBLED Package Contains:

• Ranger® 305 G (K1726-5 with electric fuel pump)

• Accessory Kit (K704)

• LN-25 Ironworker™ Wire Feeder (K2614-9)

• Gun and Cable (K126-12)

• 5/64 in. (2.0 mm) NR-233 25 lb. (11.3 kg)

Spool (ED033039)

Order: K2353-2 K2614-9 LN-25 Ironworker™ K126-12 Gun and Cable 5/64 in. (2.0 kg) NR-233

Wire Feeder 25 lb. (11.3 kg) Spool

[ 4 ] | Ranger ® 305 G and Ranger ® 305 G EFI

RECOMMENDED ACCESSORIES

GENERAL OPTIONS Small Two Wheel Welder Trailer Remote Output Control with 120V

For heavy-duty road, off-road, plant AC Receptacles

Power Plug Kit

and yard use. Includes pivoting jack Remote weld output control box with

Provides four 120V plugs rated at 20

stand, safety chains, and 13 in. two 120V AC receptacles having

amps each, and one dual voltage,

120V full KVA plug rated at 120/240V, 50 (330 mm) wheels. Stiff .120 in. GFCI (ground fault circuit interrupter)

(3.0 mm) welded rectangular protection. One cord for both remote

amps. 120V plug may not be

steel tube frame construction is and power. 100 ft. (30.5 m) length.

compatible with common household

phosphate etched and powder Permits remote adjustment of weld

receptacles.

coat painted for superior rust and output and power for tools (such

Order K802N

Shown with optional corrosion resistance. Low sway as a grinder) at the work. 20 amp

K2639-1 Fender & suspension gives outstanding capacity.

Full-KVA Power Plug Light Kit stability with manageable tongue Order K2627-2

One dual voltage plug rated at weight. Wheel bearings are packed

120/240V, 50 amps. NEMA 14-50P. with high viscosity, high pressure,

low washout Lubriplate® grease. TIG OPTIONS

Order T12153-9

Includes a Duo-Hitch®, a 2 in. Pro-Torch™ PTA-26V TIG Torch

(51 mm) ball/lunette eye Air-cooled 200 amp torch equipped

Full - KVA Adapter Kit combination hitch. Overall width with valve for gas flow control.

Provides convenient connection of 60 in. (1524 mm). Overall length 25 ft. (7.6 m) length.

Lincoln Electric equipment having a 110 in. (2794 mm). Order K1783-9

240V AC 1-phase plug Order:

(NEMA 6-50P) to the full-KVA K2635-1 Trailer

receptacle on engine-driven welders. K2639-1 Fender & Light Kit Foot Amptrol™

Order K1816-1 K2640-1 Cable Rack Varies current while welding for

making critical TIG welds and crater

filling. Depress pedal to increase

GFCI Receptacle Kit Polarity/Multi-Process Switch current. Depressing pedal fully

Includes one UL approved 120V For easy polarity switching. achieves maximum set current.

ground fault circuit interrupter Example: DC-stick root pass on pipe Fully raising the pedal finishes the

duplex type receptacle and & DC+ stick for hot, fill and cap weld and starts the afterflow cycle.

installation instructions. Replaces passes. Also for an easy process Includes 25 ft. (7.6 m) control cable.

the factory-installed 120V duplex change. Example: DC+ stick root Order K870

receptacle. Each receptacle of the pass on pipe & DC- Innershield®

GFCI duplex is rated at 20 amps. self-shielded flux-cored wire for

Maximum total current from the hot, fill and cap passes. 6 & 14-pin Hand Amptrol™

GFCI duplex is limited to 20 amps. remote connections can be made Provides 25 ft. (7.6 m) of remote

Two kits required for all 120V to this unit. For all Lincoln Electric current control for TIG welding.

receptacles on the Ranger® 305 G Chopper Technology® engine-driven (6 pin plug connection). Velcro straps

and Ranger® 305 G EFI. welders. Mounts on roof with secure torch.

Order K1690-1 K2663-1 Docking Kit. Order K963-3 (one size fits all

Order K2642-1 Pro-Torch™ TIG torches).

Spark Arrestor Kit

Attaches to muffler exhaust tube. Docking Kit Magnum® Parts Kit for

Virtually eliminates spark emissions. Secures the K2642-1 Polarity/Multi- PTA-26V TIG Torch

Order K1898-1 Process Switch to the engine-driven Provides all the torch accessories

welder roof. Release latch permits you need to start welding. Parts

removal of K2642-1 Polarity/Multi- kit provides collets, collet bodies,

Canvas Cover Process Switch. Made from stainless a back cap, alumina nozzles and

To protect the engine drive when steel for rust-free operation. tungstens in a variety of sizes,

not in use. Made from attractive For all Lincoln Electric Chopper all packaged in an easy to carry

red canvas material that is flame Technology® engine-driven welders. reclosable pack.

retardant, mildew resistant and Order K2663-1 Order KP509

water repellent.

Order K886-2

STICK OPTIONS Square Wave™ TIG 175

Accessory Kit For AC TIG welding with square

All-Terrain Undercarriage For stick welding. Includes 35 ft. wave performance, use the AC

For moving by hand at construction (10.7 m) #2/0 electrode cable, 30 ft. generator of the engine-driven

sites. Maneuvers over obstacles. (9.1 m) #2/0 work cable, headshield, welder to supply the power. Full

Heavy-duty puncture-resistant (inner work clamp and electrode holder. rated output may not be available.

tube and sealant) tires. 400 amp capacity. Easy setup. Includes torch, foot

Order K1737-1 Order K704 amptrol, gas regulator and hose.

Requires the K1816-1 Full KVA

adapter kit.

Factory Undercarriage Accessory Kit Order K1478-5

For moving by hand on smooth For stick welding. Includes 20 ft.

surface floors. Heavy-duty, (6.1 m) #6 electrode cable with lug,

puncture-resistant (inner tube and 15 ft. (4.6 m) #6 work cable with

sealant) tires and front caster. lugs, headshield, filter plate, work

Convenient steering handle. clamp, electrode holder and sample

Order K1770-1 pack of mild steel electrode. 150

amp capacity.

Order K875

Welding Gas Cylinder/

LPG Tank Holder

Holds welding gas cylinder or Remote Control Kit

LPG tank (for products with LPG Consists of a control box with choice

engine). For LPG: Use one holder of two cable lengths. Permits remote

for LPG tank and a second holder adjustment of output.

for welding gas cylinder. Both Order K857 for 25 ft. (7.6 m)

holders will attach to the K1770-1 K857-1 for 100 ft. (30.5 m)

undercarriage.

Order K1745-1

Ranger ® 305 G and Ranger ® 305 G EFI | [ 5 ]

RECOMMENDED ACCESSORIES

TIG OPTIONS, CONT’D. Magnum® PRO 350 Ready-Pak® POWER MIG® 180C

15 ft., .035-5/64 in. Premium compact wire welder with

Invertec® V205-T AC/DC

Magnum® PRO MIG/flux-cored continuous voltage control for MIG

One-Pak® Package

welding guns are rated 100% and flux-cored welding. 30 to 180

For AC TIG welding with square

duty cycle. The guns are designed amp output range. Get input power

wave performance use the AC

for high amperage, high duty from the AC generator of the engine-

generator of the engine-driven

cycle applications in extreme driven welder with the K1816-1

welder to supply the power. Full

environments where heat-resistance Full-KVA Adapter Kit (required). Add

rated output may not be available.

and fast serviceability are key. the K2532-1 Magnum® 100SG

Easy setup. Includes torch, parts kit,

Order K2652-2-10-45 Spool Gun for aluminum MIG

regulator and hose kit, Twist Mate™

welding.

torch adapter, work cable with

Order K2473-1

Twist Mate™ end, and foot

Drive Roll and Guide Tube Kit

Amptrol™. Requires the K1816-1

For .035-.045 in. (0.9-1.1 mm) solid

Full-KVA Adapter Kit.

steel wire. Magnum® 100SG Spool Gun

Order K2350-2

Order KP1696-1 Designed to easily feed 4 in.

(102 mm) diameter 1 lb. (0.45 kg)

spools of .030 in (0.8 mm) or

WIRE FEEDERS

Magnum® SG Spool Gun .035 in. (0.9 mm) diameter

LN-25 Ironworker™ Wire Feeder Hand held semiautomatic wire SuperGlaze® aluminum MIG wire.

Portable CV unit for flux-cored and feeder. Requires SG Control Module Includes gun, adapter kit, .035 in.

MIG welding with MAXTRAC® wire Order K487-25 (0.9 mm) contact tips (qty. 3), gas

drive system. Includes digital meters nozzle, and a 1 lb. (0.45 kg) spool of

for wire feed speed/amperage SuperGlaze® 4043 .035 in. (0.9 mm)

and voltage, gas solenoid, internal SG Control Module MIG wire. Packaged in a convenient

contactor and 5/64 in. (2.0 mm) The interface between the power carrying case.

drive roll kit for cored wire. Has 83% source and the spool gun. Provides Order K2532-1

reduced wire feed speed capability control of wire speed and gas flow.

for 6 o’clock pipe welding with For use with a spool gun.

Innershield® wire. Order K488 PLASMA CUTTING

Order K2614-9

Tomahawk® 1000

Input Cable Cuts metal using the AC generator

(For SG Control Module) power from the engine-driven

Drive Roll and Guide Tube Kit

For Lincoln Electric engine power welder. Requires the T12153-9 Full-

For .068-.072 in. (1.7-1.8 mm)

sources with 14-pin MS-type KVA Power Plug (1-Phase).

cored or solid steel wire.

connection, separate 115V NEMA Order K2808-1

Order KP1697-068

receptacles and output stud

connections.

K126™ PRO Innershield® Gun

Order K691-10

For self-shielded wire with 15 ft.

(4.5 m) cable. For .062-5/64 in.

(1.6-2.0 mm) wire. Includes

K466-10 Connector Kit.

Order K126-12

PRODUCT SPECIFICATIONS

Rated Output Net

Product Product Current/Voltage/ Output Number HP @ HxWxD Weight

Name Number Duty Cycle Range Engine of Cylinders Speed (RPM) inches (mm) lbs. (kg)

Ranger® 305 G K1726-5 305A DC CC/29V/100% 20-305A DC Kohler® OHV 2 23 @ 3600 29.9 x 21.5 x 42.3 510

300A DC CV/29V/100% 40-300A Pipe Command® (759 x 546 x 1073) (231)

20-250A DC TIG CH730 Gasoline To top of exhaust

14-29V CV Electric Fuel Pump tube: 36.2 (920)

10,500 watts peak

Ranger® 305 G K2353-2 12,000 watts peak EFI – –

One-Pak® 9,500 watts continuous

Ranger® 305 G EFI K3928-1 Kohler® OHV 25 @ 3600 29.9 x 21.5 x 42.3 510

Command® (759 x 546 x 1073) (231)

ECH740 Gasoline To top of exhaust

Electric Fuel Pump tube: 36.2 (920)

Electronic Fuel

Injection

For best welding results with Lincoln Electric equipment,

always use Lincoln Electric consumables. Visit www.lincolnelectric.com for more details.

Manufactured at a facility with certified ISO Quality and Environmental Management Systems.

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On

occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to inquiries to the best of their ability based on information provided to them by the customers and the knowledge

they may have concerning the application. Our employees, however, are not in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant

or guarantee or assume any liability with respect to such information or advice. Moreover, the provision of such information or advice does not create, expand, or alter any warranty on our products. Any express or implied warranty that might

arise from the information or advice, including any implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains

the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication

methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated

information.

You might also like

- 1 150, 50, 280 & Lever Lock 280 & Lever LockDocument46 pages1 150, 50, 280 & Lever Lock 280 & Lever LocksanachNo ratings yet

- Wiper Servo BTS7960Document1 pageWiper Servo BTS7960Nico VegaNo ratings yet

- Printer Motor v1.0: Plus of Supply Voltage (5V or 12V)Document1 pagePrinter Motor v1.0: Plus of Supply Voltage (5V or 12V)Nico VegaNo ratings yet

- Terex Explorer 5600Document42 pagesTerex Explorer 5600nhar15No ratings yet

- Miller XMT 425 VsDocument36 pagesMiller XMT 425 VsDino JuricicNo ratings yet

- Terex HC165Document62 pagesTerex HC165roman100% (1)

- Technical Data · metric machine dimensionsDocument54 pagesTechnical Data · metric machine dimensionsPHÁT NGUYỄN THẾNo ratings yet

- Troubleshooting-Data: FH 12 380 Model: Motor: D12A 380 / ABS 4 ChannelDocument1 pageTroubleshooting-Data: FH 12 380 Model: Motor: D12A 380 / ABS 4 Channelمحمد يونسNo ratings yet

- Electrical System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuDocument51 pagesElectrical System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This Menuiqbal khairul hakimNo ratings yet

- Sec. M7 LT-7 K227 OR K395 Lightweight Tractor Parts List: Model IndexDocument22 pagesSec. M7 LT-7 K227 OR K395 Lightweight Tractor Parts List: Model IndexJorge Lopez AguilarNo ratings yet

- CDVR 4Document6 pagesCDVR 4wagner_guimarães_1100% (1)

- Esquema Hidraulico Mc50-70Document7 pagesEsquema Hidraulico Mc50-70jAVIER GARCIA MORIANA100% (1)

- 14M3 Electrc PDFDocument37 pages14M3 Electrc PDFAnung NugrohoNo ratings yet

- Zapi h2 Pump Controller 969Document3 pagesZapi h2 Pump Controller 969SaveliyGovorkovNo ratings yet

- Transpo Low-Res 04152015 PDFDocument1,245 pagesTranspo Low-Res 04152015 PDFJorge Luis Espino CruzNo ratings yet

- GacDocument20 pagesGacRhyzza Cortez100% (1)

- U 1520 Cat DiodeDocument2 pagesU 1520 Cat DiodeRoni SocompiNo ratings yet

- 1995 1996 Blazer Fuse BoxDocument4 pages1995 1996 Blazer Fuse BoxFrancisco MataNo ratings yet

- Sensata CatalogDocument16 pagesSensata Catalogkadir kayaNo ratings yet

- Manual Completo ARM STM32F746ZGDocument1,671 pagesManual Completo ARM STM32F746ZGyuliogaleNo ratings yet

- 6es5942-7ub11 Siemens Manual DatasheetDocument5 pages6es5942-7ub11 Siemens Manual DatasheetchochoroyNo ratings yet

- AVR ManualDocument29 pagesAVR ManualgarridtNo ratings yet

- Aj Power Ats Panels Handbook-En-rev3Document44 pagesAj Power Ats Panels Handbook-En-rev3Fernando QuisberthNo ratings yet

- 17MB21 1 SemaDocument5 pages17MB21 1 SemaCiprianIfrimNo ratings yet

- InteliDrive IPU DatasheetDocument4 pagesInteliDrive IPU DatasheetMuhammad Shoaib HussainNo ratings yet

- XC3 PLC Manual de UsuarioDocument141 pagesXC3 PLC Manual de UsuarioEdú CárdenasNo ratings yet

- Tablas de Carga Demag AC 120-1Document17 pagesTablas de Carga Demag AC 120-1Mauricio Sandoval100% (1)

- Technical Data Sheet: Receiver: FSE 727 RadiobusDocument1 pageTechnical Data Sheet: Receiver: FSE 727 RadiobusMARTIN ALBAN100% (1)

- kst42, kst43 Fairchild PDFDocument6 pageskst42, kst43 Fairchild PDFAhmed Sherif CupoNo ratings yet

- Compressors SandenDocument43 pagesCompressors SandenMahasiswa007No ratings yet

- GAC 608 Generator Wire Diagram 3Document1 pageGAC 608 Generator Wire Diagram 3Leo Burns100% (1)

- Liebherr LR 13000 Load ChartsDocument68 pagesLiebherr LR 13000 Load ChartsArkadiusz100% (1)

- Pioneer Avh p6600dvd p6650dvdDocument218 pagesPioneer Avh p6600dvd p6650dvdxxxkillerNo ratings yet

- Harish Machines Brochure DesignDocument3 pagesHarish Machines Brochure DesignVamsi RajaNo ratings yet

- CamLogic General Catalogue2010Document34 pagesCamLogic General Catalogue2010lin2m3No ratings yet

- Multipack 3000 filling machineDocument6 pagesMultipack 3000 filling machineÁgost VitaNo ratings yet

- Códigos Error mx230Document12 pagesCódigos Error mx230ERMINSUL VICUÑA SALASNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Pool Reyes LiviaNo ratings yet

- Installation Manual RM30110 RectifierDocument13 pagesInstallation Manual RM30110 RectifierJuan Felipe MartinezNo ratings yet

- Product Manual CANcockpitDocument174 pagesProduct Manual CANcockpitJoao Silva100% (2)

- TtaDocument2 pagesTtaJorge Andres UrraNo ratings yet

- Ecm C18 PDFDocument9 pagesEcm C18 PDFomarNo ratings yet

- AC50-1 Data SheetDocument18 pagesAC50-1 Data SheetJonp4ul_MiddletonNo ratings yet

- SED MAN GC2599 002 Manual For GC2599 ControllerDocument78 pagesSED MAN GC2599 002 Manual For GC2599 ControllerkrishnaNo ratings yet

- Construction: 3.1. Images of The Vehicle Control Adaption Module ADM2Document18 pagesConstruction: 3.1. Images of The Vehicle Control Adaption Module ADM2Basem ElhosanyNo ratings yet

- Bag Making Machine ManualDocument11 pagesBag Making Machine Manualgiacomo pedicinoNo ratings yet

- SL1168 Instruction ManualDocument51 pagesSL1168 Instruction ManualBruno Diaz100% (1)

- InteliDrive-IPU DatasheetDocument4 pagesInteliDrive-IPU DatasheetMaylen Rivas100% (1)

- Manual de Servicio OTPCDDocument220 pagesManual de Servicio OTPCDSamuel CastroNo ratings yet

- Terex RT230Document22 pagesTerex RT230Cosmina Sălăjean100% (2)

- Me7500 110v 230vDocument2 pagesMe7500 110v 230vMohamed ShabanNo ratings yet

- Ensamble Motor 21422844Document84 pagesEnsamble Motor 21422844jlsebastianrNo ratings yet

- KohlerDocument5 pagesKohlerRajesh S BhattNo ratings yet

- Instruction Manual For Yamaha Diagnostic Tool: Doctor ApiDocument30 pagesInstruction Manual For Yamaha Diagnostic Tool: Doctor Apiwotti DankulNo ratings yet

- Yukleyici ZF Şanzıman Arıza Kodları PDFDocument22 pagesYukleyici ZF Şanzıman Arıza Kodları PDFRemzi CerenNo ratings yet

- Hydraulic Pump Instructions and Parts ManualDocument25 pagesHydraulic Pump Instructions and Parts ManualDean mark rey luzonNo ratings yet

- Codigo de Falla 0091 Fmi 08Document1 pageCodigo de Falla 0091 Fmi 08José100% (1)

- Lincoln Ranger 225Document6 pagesLincoln Ranger 225fdpc1987No ratings yet

- Diesel Power, Expanded Capabilities: Ranger 305 DDocument8 pagesDiesel Power, Expanded Capabilities: Ranger 305 DRobinson Manuel Acuña MalcaNo ratings yet

- Pipeliner 200D: Rich Heritage - 200 Amp DC Diesel WelderDocument4 pagesPipeliner 200D: Rich Heritage - 200 Amp DC Diesel WelderTelstonPrinceNo ratings yet

- EX350i Service Manual PDFDocument155 pagesEX350i Service Manual PDFkojcanNo ratings yet

- Servicemanual, Vp5000, EngDocument60 pagesServicemanual, Vp5000, EngAugusto Vieira50% (2)

- IEC Guide (English)Document357 pagesIEC Guide (English)Truc NguyenNo ratings yet

- 12-Basic Knowledge of LDO Voltage Regulator enDocument19 pages12-Basic Knowledge of LDO Voltage Regulator enKirti Susan VargheseNo ratings yet

- ST3 6kVA-10kVA UPS Service ManualDocument15 pagesST3 6kVA-10kVA UPS Service Manualjorfamei50% (2)

- Design Your Own Raw LiFePO4 Cell Battery Solar Power SystemDocument5 pagesDesign Your Own Raw LiFePO4 Cell Battery Solar Power Systemfr33mumiaNo ratings yet

- Usyd Electrical Engineering ThesisDocument5 pagesUsyd Electrical Engineering Thesisafbtbegxe100% (1)

- Unit-Ii SGTDocument19 pagesUnit-Ii SGTSadhvi ReddyNo ratings yet

- Coolcept X StecaGrid 1800x 4200x Datenblatt ENDocument2 pagesCoolcept X StecaGrid 1800x 4200x Datenblatt ENStefan IlicNo ratings yet

- Arduino Power Inverter CircuitsDocument8 pagesArduino Power Inverter CircuitsjuliocastNo ratings yet

- Series AruvDocument42 pagesSeries AruvZergio GomezNo ratings yet

- WINGS Escola de Aviação Civil: Super King Air 200/B200 Séries - Maintenance Training ManualDocument27 pagesWINGS Escola de Aviação Civil: Super King Air 200/B200 Séries - Maintenance Training ManualtanaureNo ratings yet

- Force Commutated InvertersDocument55 pagesForce Commutated InverterssyukurkkNo ratings yet

- Technical Data SheetDocument14 pagesTechnical Data SheetRavi Ranjan VermaNo ratings yet

- Uca News 6Document8 pagesUca News 6Zieya SnenhlanhlaNo ratings yet

- Voltage Stability With The Help of STATCOMDocument6 pagesVoltage Stability With The Help of STATCOMijsretNo ratings yet

- Pcs Ac57l5h04Document154 pagesPcs Ac57l5h04KIM INTER현장No ratings yet

- On-Grid Inverter with Energy Storage Solution GuideDocument2 pagesOn-Grid Inverter with Energy Storage Solution GuideMohd NB MultiSolarNo ratings yet

- Lm201u05 Sla1Document28 pagesLm201u05 Sla1Karwo Is javaNo ratings yet

- Manual Ups Eaton9130Document41 pagesManual Ups Eaton9130Rodrigo Pinillos67% (3)

- Color Monitor: Service ManualDocument39 pagesColor Monitor: Service ManualAndres DugarteNo ratings yet

- Opti-UPS ES-C (RM) User ManualDocument28 pagesOpti-UPS ES-C (RM) User ManualmasbassNo ratings yet

- TUHH - Kreitz - Arriola - Virtual Performance Evaluation For Electro-Mechanical Actuators Considering Parameter UncertaintiesDocument7 pagesTUHH - Kreitz - Arriola - Virtual Performance Evaluation For Electro-Mechanical Actuators Considering Parameter Uncertaintiessvp3761No ratings yet

- Acoma PRO NEXT+iüiIM V1.02E) 20140407Document150 pagesAcoma PRO NEXT+iüiIM V1.02E) 20140407ArNo ratings yet

- 2G Solis InverterDocument15 pages2G Solis InverterMarian MogildeaNo ratings yet

- Delhi - Safdarjung - Project - VC0-Report 1 PDFDocument10 pagesDelhi - Safdarjung - Project - VC0-Report 1 PDFadityaNo ratings yet

- Technological University (Meiktila) Department of Electronic EngineeringDocument62 pagesTechnological University (Meiktila) Department of Electronic EngineeringdarkforceleaderNo ratings yet

- SG110CX: Multi-MPPT String Inverter For SystemDocument2 pagesSG110CX: Multi-MPPT String Inverter For SystemluongttluongNo ratings yet

- Service Manual Acer TravelMate 420 PDFDocument140 pagesService Manual Acer TravelMate 420 PDFmohzgoNo ratings yet

- Motors | Automation | Energy | Transmission & Distribution | CoatingsDocument48 pagesMotors | Automation | Energy | Transmission & Distribution | CoatingsRAJNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersFrom EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (53)

- The Grand Tour A-Z of the Car: Everything you wanted to know about cars and some things you probably didn’tFrom EverandThe Grand Tour A-Z of the Car: Everything you wanted to know about cars and some things you probably didn’tNo ratings yet

- How to Design and Install In-Car Entertainment SystemsFrom EverandHow to Design and Install In-Car Entertainment SystemsRating: 5 out of 5 stars5/5 (1)

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- Automotive Vehicle Strategies and ECM ModesFrom EverandAutomotive Vehicle Strategies and ECM ModesRating: 4 out of 5 stars4/5 (7)

- How to Drive an Exotic Car and get PaidFrom EverandHow to Drive an Exotic Car and get PaidRating: 4.5 out of 5 stars4.5/5 (3)

- Policing the Open Road: How Cars Transformed American FreedomFrom EverandPolicing the Open Road: How Cars Transformed American FreedomRating: 4 out of 5 stars4/5 (10)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Land Rover: The Story of the Car that Conquered the WorldFrom EverandLand Rover: The Story of the Car that Conquered the WorldRating: 4 out of 5 stars4/5 (10)

- Taking Charge of Your Automotive Repairs and Servicing: Save Time and Money Without Doing It YourselfFrom EverandTaking Charge of Your Automotive Repairs and Servicing: Save Time and Money Without Doing It YourselfRating: 5 out of 5 stars5/5 (1)

- Driving Theory Test Questions & AnswersFrom EverandDriving Theory Test Questions & AnswersRating: 5 out of 5 stars5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- How to Design, Build & Equip Your Automotive Workshop on a BudgetFrom EverandHow to Design, Build & Equip Your Automotive Workshop on a BudgetRating: 4 out of 5 stars4/5 (10)

- Making Toys, Revised Edition: Heirloom Cars & Trucks in WoodFrom EverandMaking Toys, Revised Edition: Heirloom Cars & Trucks in WoodRating: 4 out of 5 stars4/5 (3)

- 2 Books in 1: The History of Formula 1 and MotoGP to the Rhythm of Fast LapFrom Everand2 Books in 1: The History of Formula 1 and MotoGP to the Rhythm of Fast LapNo ratings yet