Professional Documents

Culture Documents

Installation, Operation, Maintenance & Lub. Manual 36

Uploaded by

Abdul Raheem Syed0 ratings0% found this document useful (0 votes)

4 views1 pageInstallation, Operation, Maintenance & Lub. Manual 36

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInstallation, Operation, Maintenance & Lub. Manual 36

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageInstallation, Operation, Maintenance & Lub. Manual 36

Uploaded by

Abdul Raheem SyedInstallation, Operation, Maintenance & Lub. Manual 36

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

codimco

{QUAL FANS FOR THE WORLD

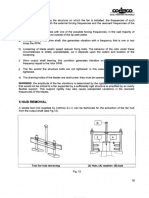

* Place the inclinometer perpendicular to the blade axis, on the top of the blade, 5 mm from

the tip as shown in Fig.3. If the inclinometer base is too short to have a correct position,

insert a rigid steel bar between inclinometer and blade.

+ Rotate the blade on its axis until the required pitch angle is obtained.

‘* Torque screw at a torque setting according to the value indicated in the following tables.

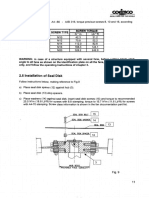

4) Repeat for each blade steps described in point c). Before starting the pitch angle setting

procedure, tum the fan till the blade to be set is at the same point in the fan ring where

previous pitch angle was set. This step helps compensate for any slight departures from a

Vertical rotation axis.

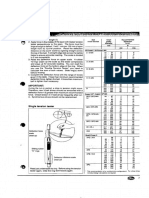

In order to determine the torque setting of the screws, look at the following table for the screw type

set for the hub type of the fan in object (this information is shown on the identification plate of the

fan).

The following tables show the listed screws torque for the screw class.

Warning: the screw class information are shown in the fan documentation part list.

Standard screws: choose torque according to 8.8 or 10.9 stamping on the bolts:

CLASS 8.8 CLASS 10.9

[Nem [tps Nm tbe

Mig 754 56

[Mig ties 88.0 ia ote |

[Mig [79.3 132.2 i942 143.2 |

The blockers (17) (18), are provided by Cofimco already connected to their corresponding flexy

elements, and must not be loosened. However, the following tables show the proper torque

according to their corresponding bolts (16). Choose torque according to 8.8 or 10. stamping on

the bolts

SCREW TORQUE

10

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fateha EnglishDocument3 pagesFateha EnglishAbdul Raheem Syed70% (10)

- CSWIP 3.1 - Welding Inspector WIS5 (2017)Document699 pagesCSWIP 3.1 - Welding Inspector WIS5 (2017)reezman96% (69)

- Yassarnal Quran EN PDFDocument70 pagesYassarnal Quran EN PDFzahiid munir100% (3)

- Yassarnalquranpdfeasydownload 150708175054 Lva1 App6892Document49 pagesYassarnalquranpdfeasydownload 150708175054 Lva1 App6892Abdul Raheem SyedNo ratings yet

- Yassarnal Quran EN PDFDocument70 pagesYassarnal Quran EN PDFzahiid munir100% (3)

- MYK Grout Card 2Document2 pagesMYK Grout Card 2Abdul Raheem SyedNo ratings yet

- Latapoxy SP 100 TDS 1Document3 pagesLatapoxy SP 100 TDS 1Abdul Raheem SyedNo ratings yet

- Spectra Lock Pro Premium Grout Technical Data Sheet 1Document4 pagesSpectra Lock Pro Premium Grout Technical Data Sheet 1Abdul Raheem SyedNo ratings yet

- Laticrete Hydroban Tds NFDocument6 pagesLaticrete Hydroban Tds NFAbdul Raheem SyedNo ratings yet

- L 9237 WaterproofDocument4 pagesL 9237 WaterproofAbdul Raheem SyedNo ratings yet

- All India Dealer Price List III Wef 01.12.18Document4 pagesAll India Dealer Price List III Wef 01.12.18Abdul Raheem SyedNo ratings yet

- Product Recommendation ChartDocument2 pagesProduct Recommendation ChartAbdul Raheem SyedNo ratings yet

- FAQs - LATAPOXY® SP 100Document2 pagesFAQs - LATAPOXY® SP 100Abdul Raheem SyedNo ratings yet

- FF 4620 Anchor BoltsDocument1 pageFF 4620 Anchor BoltsAbdul Raheem SyedNo ratings yet

- Reliability Presentation FormatDocument12 pagesReliability Presentation FormatAbdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 42Document1 pageInstallation, Operation, Maintenance & Lub. Manual 42Abdul Raheem SyedNo ratings yet

- GE Centrifugal and Axial CompressorsDocument28 pagesGE Centrifugal and Axial Compressorsewok2030No ratings yet

- Installation, Operation, Maintenance & Lub. Manual 112Document1 pageInstallation, Operation, Maintenance & Lub. Manual 112Abdul Raheem SyedNo ratings yet

- Gas Turbine Theory MJHDocument29 pagesGas Turbine Theory MJHDee ⎝⏠⏝⏠ DeeNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 27Document1 pageInstallation, Operation, Maintenance & Lub. Manual 27Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 39Document1 pageInstallation, Operation, Maintenance & Lub. Manual 39Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 104Document1 pageInstallation, Operation, Maintenance & Lub. Manual 104Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 37Document1 pageInstallation, Operation, Maintenance & Lub. Manual 37Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 113Document1 pageInstallation, Operation, Maintenance & Lub. Manual 113Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 35Document1 pageInstallation, Operation, Maintenance & Lub. Manual 35Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 38Document1 pageInstallation, Operation, Maintenance & Lub. Manual 38Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 110Document1 pageInstallation, Operation, Maintenance & Lub. Manual 110Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 32Document1 pageInstallation, Operation, Maintenance & Lub. Manual 32Abdul Raheem SyedNo ratings yet

- Installation, Operation, Maintenance & Lub. Manual 102Document1 pageInstallation, Operation, Maintenance & Lub. Manual 102Abdul Raheem SyedNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)