Professional Documents

Culture Documents

Alloy Selection For Caustic Soda Service PDF

Uploaded by

Eng Alf0 ratings0% found this document useful (0 votes)

111 views12 pagesOriginal Title

Alloy selection for caustic soda service.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

111 views12 pagesAlloy Selection For Caustic Soda Service PDF

Uploaded by

Eng AlfCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

NiDI

Need

Pert cud

resis

Alloy selection for caustic

Pyele rea (er)

ret eo ae

Ree La)

The material presented in

this publication has been

prepared for the general

information of the reader

and should not be used or

relied on for specific

applications without first

securing competent advice.

‘The Nickel Development

Institute, its members, staff

and consultants do not

represent or warrant its

suitablity for any general or

specific use and assume no

liability or responsibilty of

any kind in connection with

the information herein.

Alloy selection for caustic

soda service

by C.M. Schillmoller*

Caustic soda (ie., sodium hydroxide, NaOH) and chlo-

rine are co-produced by the electrolysis ofa sodium chloride

solution. Both chemicals find world-wide application in the

chemical and related process industries. (Alloy selection for

Chlorine is discussed in the NiDI publication #10020,

“Alloys to Resist Chlorine, Hydrogen Chloride and

Hydrochloric Acid.”) Caustic soda ranks third in tonnage

production among the inorganic chemicals; some 13.2

million tons were used in the USA alone in’ 1986.

Roughly half of all caustic produced is used in the

‘manufacture of other chemicals. Another 16% is consumed

by the pulp and paper industry. Other important uses are

in the production of rayon, cellulose, textiles, petroleum

products, soaps and the refining of Bauxite ore in the

production of aluminum.

CRITERIA FOR MATERIALS SELECTION

A number of materials of construction may be used to

produce and handle caustic solutions. Their suitability for

specific applications will depend upon factors associated

With the concentration and use of the caustic and the

process variables involved

In general, factors to be considered in materials selec

tion include practicality, availability, mechanical properties,

corrosion resstance, risk/benefit considerations and eco-

nomics.

Critical factors in caustic service include:

1. The concentration of the caustic solution,

2. The temperatures to be encountered (including pos-

sible excursions)

3. The presence of other chemicals which may be

present in the caustic, as contaminants or additives.

4, Tolerance limits for metallic ion contamination of the

caustic itself (or of the process end-product)

5. Residual or applied tensile stresses, which may affect

corrosion resistance.

66. The economics of costlife considerations.

Metals and alloys most frequently considered for use in

caustic soda are carbon steel, stainless steels, nickel and

high-nickel alloys. Some alloys, with their generic names,

common trade-names, UNS numbers and nominal com-

positions are given in Table 1

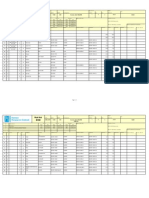

Table 1

‘Alloys commonly used in caustic soda systems

| Reterence Nominal Composition, 9 AST | UNS |Most Common

Mater intext” [Wr] Cr] Fe] Mo| [7 B) | Numbers | ‘Tradenames.

Nickel

Nickel ‘oy 200 | 99. 161-165 | 102200 | Nickel 200

Lomearbon Nickel ‘iy 201 | 99. eictes_| No2201_| Nickel 201

Nickel Copper Alloys

Nickel-copper alloy ‘Alley 400 | 67 15 3i 163-165 | 1o4s00 | Monel 400

‘Nicke-Cromiumon Alloys

Nicketehwomium alloy Atoy 600 | 76 | 15] 8 169-168 | 106600. | Incone 600

Niekeliron-chromium alloy ‘Ay 600 | 32 | 21) 46 4es.407 | Noee00 | incoley” 600

Nekeron-chromium-

‘molycopper alloy Mloy 2s | a2 | 21] so] 9 | 23 163.423 | Noee25 | Incoloy* 825

Nicketiren chromium

‘molycopper alloy aey20 | 36 | 20] 39 | 25 | 39 484-468 | NoB020 | Carpenter:

20.003"

‘Siaiiess Steels

‘Chromiumnicksl stainless type 304 | 10 | 19) 72 s20400 | Type 204

Ghromiumnicketmoly staniess | Typo set | 12 | 18) 70 531003. | Type ste.

Ghromium stanioss ‘Type 490 17] 83 543000 | Type 430

Ghromium-moly stains 26.4 as| 73| 4 5626-1

Titanium

Tianium, grade 2 Tanium Gre +) 398 Tianium G2

"Mana acre! and Tas are Padarames othe inaratoal Mekal Ga

"*Carpente’and 20 C23 are vadenames of CARTECH

*Schitimoller Associates, Houston, TX; Consultant to NiDI

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- HRC STD 6100 004 M 01 PDFDocument6 pagesHRC STD 6100 004 M 01 PDFEmir MujićNo ratings yet

- En 15906Document11 pagesEn 15906Emir MujićNo ratings yet

- SWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhDocument21 pagesSWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhEmir MujićNo ratings yet

- S690QL - Hemiska Analiza PDFDocument7 pagesS690QL - Hemiska Analiza PDFEmir MujićNo ratings yet

- HRC STD 6100 001 B 03 PDFDocument3 pagesHRC STD 6100 001 B 03 PDFEmir MujićNo ratings yet

- Transfl Spoj KRDocument32 pagesTransfl Spoj KREmir MujićNo ratings yet