Professional Documents

Culture Documents

Def Pump

Uploaded by

sidhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Def Pump

Uploaded by

sidhuCopyright:

Available Formats

#1402

All VanHool Coaches with DD13 Engines and EPA 2010 Emissions

January 1, 2014

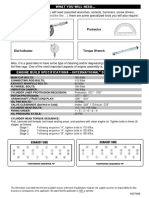

DEF Pump Air Bladder Information

The DEF pump module uses a serviceable air bladder to maintain consistent DEF pressure to the DEF

metering unit. The DEF pump module bladder comes from the factory charged with nitrogen, but empty as a

replacement part.

The DEF pump module bladder must be discharged prior to removal and will be recharged after installation

with clean, dry, oil-free shop air. It does not have to be recharged with nitrogen. The DEF pump module

bladder is recharged with air to 2.8-3.2 bar (40-46 psi) upon installation. The bladder's air pressure needs

to be checked every two years.

To replace the bladder:

Shut off engine and apply the parking brake, chock the wheels, and perform any other applicable safety steps.

Remove the air cap from the DEF pump module air bladder. Release any air contained in the DEF pump

module air bladder by pressing in on the Schrader valve.

Remove the screws attaching the DEF pump module air bladder to the DEF pump module. Pull the DEF pump

module air bladder out of the DEF pump module.

Install the new pump module air bladder into the DEF pump module and torque the screws attaching the DEF

pump module air bladder to the DEF pump module to 3.68 - 4.32 Nm (32.5 - 38.5 lb in).

Using clean, dry, and oil-free shop air, a standard air fitting and an air pressure gauge, inflate the DEF pump

module air bladder to 2.8-3.2 bar (40-46 psi) through the Schrader valve.

You might also like

- Air Bladder Filling Valve and Cap PDFDocument1 pageAir Bladder Filling Valve and Cap PDFsidhuNo ratings yet

- Ultra Phoenix - Ultra Phoenix XL PartesDocument52 pagesUltra Phoenix - Ultra Phoenix XL PartesFrost-Center Ar100% (1)

- Compass Controller 02250167-454Document50 pagesCompass Controller 02250167-454helbert espinozaNo ratings yet

- Mtu TurbochargerDocument6 pagesMtu TurbochargerAyman AhmedNo ratings yet

- Manual SG 3000 Thermo KingDocument210 pagesManual SG 3000 Thermo KingConnie TaibaNo ratings yet

- Cummins Gearing Recommendations for On-Highway VehiclesDocument40 pagesCummins Gearing Recommendations for On-Highway Vehicleskamikazeee100% (1)

- Additions, Revisions, or Updates: Subject DateDocument4 pagesAdditions, Revisions, or Updates: Subject DateBambiNo ratings yet

- 2014 NissanLEAF Owner Manual PDFDocument396 pages2014 NissanLEAF Owner Manual PDFLEDOMNo ratings yet

- Navistar 1Document2 pagesNavistar 1ValBMSNo ratings yet

- VALEO - Engine Cooling and Air Conditioning 2010 - 2011 PDFDocument274 pagesVALEO - Engine Cooling and Air Conditioning 2010 - 2011 PDFgeorge_scala0% (1)

- Volvo ServiceAtaGlanceDocument1 pageVolvo ServiceAtaGlanceأبو خالد الأثرىNo ratings yet

- Foton V7.4en PDFDocument9 pagesFoton V7.4en PDFStiven AyalaNo ratings yet

- Yanmar BulletinsDocument10 pagesYanmar BulletinsBill Carter100% (2)

- Kenworth t880Document36 pagesKenworth t880Himanshu SinghNo ratings yet

- Southeast Diesel Collaborative Clean Diesel Initiatives: Kirk Gavaghan 27-Jun-07Document21 pagesSoutheast Diesel Collaborative Clean Diesel Initiatives: Kirk Gavaghan 27-Jun-07DIEGONo ratings yet

- Ardrox 6514: Safety Data SheetDocument15 pagesArdrox 6514: Safety Data SheetMIGUEL MOSQUERANo ratings yet

- M0087435-13 (en-US) 236D3 Skid Steer Loader - Parts ManualDocument697 pagesM0087435-13 (en-US) 236D3 Skid Steer Loader - Parts ManualLuis MuñozNo ratings yet

- UntitledDocument64 pagesUntitledzawmintun zpeNo ratings yet

- 3135 GHG17 Detroit™ DD13® Engine Software Reprogramming and Emission Label ReplacementDocument3 pages3135 GHG17 Detroit™ DD13® Engine Software Reprogramming and Emission Label ReplacementHamiltonNo ratings yet

- Updated Flash Procedure For All Caterpillar Products (1920, 7610, 7620)Document2 pagesUpdated Flash Procedure For All Caterpillar Products (1920, 7610, 7620)Adel FawziNo ratings yet

- SafiDocument2 pagesSafiCharly RamosNo ratings yet

- Product Advantages Mobile Crane LTM 1250/1Document12 pagesProduct Advantages Mobile Crane LTM 1250/1Mezzabotta0% (1)

- Thermal Recirculation Valve Installation InstructionsDocument7 pagesThermal Recirculation Valve Installation InstructionsSean DuncanNo ratings yet

- Det 84626 Dd13 Brochure WebDocument10 pagesDet 84626 Dd13 Brochure Webramsi17No ratings yet

- Alliance - Filter CatalogDocument82 pagesAlliance - Filter CatalogSamNo ratings yet

- DDRS BasicsDocument9 pagesDDRS BasicsMar MendNo ratings yet

- DTM-4 Install Instr Rev B-1Document30 pagesDTM-4 Install Instr Rev B-1Jorge AriasNo ratings yet

- 854E-854F Disassebly and Assebly Section UENR0624-02Document196 pages854E-854F Disassebly and Assebly Section UENR0624-02Mesay GeremewNo ratings yet

- HINO VIN Code - LT-0013 Quick Reference Counter CardDocument2 pagesHINO VIN Code - LT-0013 Quick Reference Counter CardVerónica Maila FigueroaNo ratings yet

- Camshaft Gear - Remove and InstallDocument4 pagesCamshaft Gear - Remove and InstallAndy PircaNo ratings yet

- Service Parts List: Diesel EngineDocument44 pagesService Parts List: Diesel EngineTamer MoustafaNo ratings yet

- Manual Reductora IVECO TM 265 - TM 265ADocument31 pagesManual Reductora IVECO TM 265 - TM 265ARomà ComaNo ratings yet

- Waukesha Gas Engines: Control SystemsDocument15 pagesWaukesha Gas Engines: Control SystemsKilienNo ratings yet

- Service Manual Trucks Group 87 Air Heater Espar D1LC CompactDocument58 pagesService Manual Trucks Group 87 Air Heater Espar D1LC CompactNeojai jaiyuNo ratings yet

- ISX15 Product Enhancements 20132016Document73 pagesISX15 Product Enhancements 20132016TahirNo ratings yet

- 2014 Truck Products Catalogue (Usa)Document28 pages2014 Truck Products Catalogue (Usa)Adolfo CisnerosNo ratings yet

- Guide To Sync & Load Share Part2Document69 pagesGuide To Sync & Load Share Part2Naing Min HtunNo ratings yet

- VP44 Fuel Pump Engine Sync TroubleshootingDocument6 pagesVP44 Fuel Pump Engine Sync TroubleshootingEnrrique LaraNo ratings yet

- 2018 ColoradoDocument421 pages2018 ColoradoJosue Cruz100% (1)

- Motor Plants: Diesel Engines (Generic)Document39 pagesMotor Plants: Diesel Engines (Generic)Ana CaixetaNo ratings yet

- Reliability. The Single Integrated and Engine Mounted Control Module Replaces TheDocument2 pagesReliability. The Single Integrated and Engine Mounted Control Module Replaces TheJaafar Fadhil.AbboodNo ratings yet

- DDC SVC Bro 0001Document38 pagesDDC SVC Bro 0001David PomaNo ratings yet

- Coach & Bus EngineDocument2 pagesCoach & Bus EngineClegivaldoNo ratings yet

- Volvo - I-Shift (2010) .2010 Model YearDocument8 pagesVolvo - I-Shift (2010) .2010 Model YearGyula HorváthNo ratings yet

- 62 10601 PDFDocument44 pages62 10601 PDFpechnicNo ratings yet

- Air Conditioning Type & Capacity SpecsDocument2 pagesAir Conditioning Type & Capacity SpecsMeadows TruckNo ratings yet

- Nexiq Pocket Iq HW SW ManualDocument195 pagesNexiq Pocket Iq HW SW ManualGNo ratings yet

- 001Document2 pages001Nacer Mezghiche50% (4)

- D13 800 PDFDocument2 pagesD13 800 PDFkhalidfarooq009No ratings yet

- Waste Gate RegulaciónDocument4 pagesWaste Gate RegulaciónKelvin RamirezNo ratings yet

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Document3 pagesQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- Haldex - Brake Shoe Identification Chart PDFDocument6 pagesHaldex - Brake Shoe Identification Chart PDFYunfan ZhangNo ratings yet

- Multi Company - in Odoo EnterpriseDocument6 pagesMulti Company - in Odoo EnterpriseSparrow SevereNo ratings yet

- 19.1 Description and Operation of The GHG14 DD15 AT Exhaust Gas Recirculation Valve-Hot Pipe PDFDocument1 page19.1 Description and Operation of The GHG14 DD15 AT Exhaust Gas Recirculation Valve-Hot Pipe PDFCuong DinhNo ratings yet

- New Star - Air & HydraulicDocument92 pagesNew Star - Air & HydraulicManuel ChavesNo ratings yet

- Cole Hersee - Littelfuse Master CatalogDocument179 pagesCole Hersee - Littelfuse Master Catalogviemey1952No ratings yet

- GCE - Global Customer Engineering IQA - Installation Quality AssuranceDocument18 pagesGCE - Global Customer Engineering IQA - Installation Quality AssurancekhudoNo ratings yet

- 988F Valve Lash Adjustment (5304)Document7 pages988F Valve Lash Adjustment (5304)John GrayNo ratings yet

- VanHool DEF Pump Bladder ReplacementDocument1 pageVanHool DEF Pump Bladder ReplacementsidhuNo ratings yet

- Def Metering ValveDocument9 pagesDef Metering Valvesidhu100% (2)

- Bid Card ApplicationDocument1 pageBid Card ApplicationsidhuNo ratings yet

- Kenworth Wirring DiagramDocument9 pagesKenworth Wirring Diagramsidhu50% (4)

- Yale Hydraulic ToolsDocument8 pagesYale Hydraulic ToolssidhuNo ratings yet

- Toronto, ON, CAN Auction Site Ritchie Bros. Auctioneers PDFDocument1 pageToronto, ON, CAN Auction Site Ritchie Bros. Auctioneers PDFsidhuNo ratings yet

- Triple S Truck Repair Jan 2019 To April 30 2020Document3 pagesTriple S Truck Repair Jan 2019 To April 30 2020sidhuNo ratings yet

- Gear Cover Lower 2Document2 pagesGear Cover Lower 2sidhuNo ratings yet

- International dt466Document1 pageInternational dt466sidhu100% (1)

- Super Choice Cab InvoiceDocument1 pageSuper Choice Cab InvoicesidhuNo ratings yet

- Fuel RailDocument1 pageFuel RailsidhuNo ratings yet

- Isx 15 Engine BlockDocument2 pagesIsx 15 Engine Blocksidhu100% (1)

- Isx 15 Fuel DiagramDocument3 pagesIsx 15 Fuel Diagramsidhu86% (14)

- Exaust SystemDocument11 pagesExaust Systemsidhu100% (1)

- PCT 283192 PDFDocument270 pagesPCT 283192 PDFsidhuNo ratings yet

- Exaust ManifoldDocument2 pagesExaust ManifoldsidhuNo ratings yet

- Cooling NozzleDocument1 pageCooling NozzlesidhuNo ratings yet

- Exaust ManifoldDocument2 pagesExaust ManifoldsidhuNo ratings yet

- VanHool DEF Pump Bladder ReplacementDocument1 pageVanHool DEF Pump Bladder ReplacementsidhuNo ratings yet

- Cranckshaft Front SealDocument3 pagesCranckshaft Front SealsidhuNo ratings yet

- Armado de Pistones y CamisasDocument34 pagesArmado de Pistones y CamisasMiguel ChaconNo ratings yet

- Cooling NozzleDocument1 pageCooling NozzlesidhuNo ratings yet

- FDocument1 pageFsidhuNo ratings yet

- Inyector n3 TorquesDocument2 pagesInyector n3 TorquesDiego MonroyNo ratings yet

- Código de Falla DD15 SPN 677 FMI 5Document7 pagesCódigo de Falla DD15 SPN 677 FMI 5sofiayniko86% (7)

- FDocument1 pageFsidhuNo ratings yet

- Isx 15 Engine Base TimmingDocument12 pagesIsx 15 Engine Base Timmingsidhu96% (24)

- Isx 15 Fuel System WorksDocument3 pagesIsx 15 Fuel System Workssidhu100% (2)

- Cam Install PDFDocument1 pageCam Install PDFPototoNo ratings yet

- Armado de Pistones y CamisasDocument34 pagesArmado de Pistones y CamisasMiguel ChaconNo ratings yet

- Cooling NozzleDocument1 pageCooling NozzlesidhuNo ratings yet