Professional Documents

Culture Documents

ASNZ 4680 Standard Specification For HDG PDF

Uploaded by

Nang Truong0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

ASNZ-4680-Standard-Specification-for-HDG.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageASNZ 4680 Standard Specification For HDG PDF

Uploaded by

Nang TruongCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

After-Fabrication Galvanizing Specification Details

AS/NZS 4680:2006

‘Hot dip galvanized (zinc) coatings on fabricated ferrous articles’

Standard Specification for Hot Dip Galvanized Coatings to be used in

conjunction with the Australian/New Zealand Standard 4680 for use

with materials specifications.

Scope

This specication covers the afte-fabrication galvanized cating apoio’

to general ste! articles, structural sections, angles, channels, beams,

columns, fabricated steel assembles, castings, threaded fasteners, tel

reinforcement and other steel components

This specication does not apy to tbe galvanized coating on semi-

finished prodets suchas wire, tube or sheet ganized in continous,

semi-continuous specialised plats

Galvanizing

All attics to be galvanized stall be handled in such a manner as to

avoid any mechanical damage and to minimise distortion,

Design features that may lead to cficulties during galanin should

be pointed out prior o dipping

Galvanizing parameters such as galvanizing temperature, time of

immersion and withdrawal speed shal be employed to suit the

requirements of the acl.

‘The composition of the zine inthe galvanizing bath shall not be less that

8.0% zine

Coating Requirements

1. Thickness.

The thickness ofthe galvanized coating shall conform to Table 1 and

Table 2 in ASINZS 4680

‘rice thiokness Loca easing

‘eage coming Average cong

= ‘ices Mirae cere Means mae

1 Siam or ess S 6 x0

OwriSwann 5 0

Over 10 8m s 50

0

‘var Bn 70

Requirements for coating thickness and mass for articles that

are centrifuged,

‘rice thickness Local coating Average coating Average contin

mm Ahokness Microns—teknoteMirone ase gn?

Less than 8mm B 5 260

Brimand wer o 5 30

‘The thickness ofthe galvanized coating shall fist be tested bythe

putchaser/designer atthe gavanize’s works, using an approved magnetic

‘measuring device. In the event of ary dispute, an independent test shal

be carried aut in accordance with AS/NZS 4680, Appendix

2 Surface Finish

‘The galvanized coating shal be continuous, adherent, as smooth

‘and evenly distributed as possible, and fee from any defect that is

etrmental tothe stated end use ofthe coated article. On silicon killed

stools the coating may be dll grey, provided the coating is sound and

continous.

‘The integrity ofthe coating shall be determined by vsval inspection

and coating thickness measurements.

Where slip factors ae required to enable high strength fiction tip

bolting, thse shall be obtained after galanin by suitable mechanical

‘treatment of to fying surfaces.

‘Where a pant finish i to be applied t the galvanized coating, his

shuld be advised at the time of order, Galvanized coatings shall have

all spikes removed and all edges shall be fee from lumps and rns.

3. Adhesion

The galvanized coating shall be sufficient adherent to withstand

norma handing during transport and erection,

‘Woonona pears nfs onl apace ei, orem nd pens oft op gas

"24 Bhbten test eben Via 00 Taegan C8 841285 Fase 0 135

{a gay.com au Wed page

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

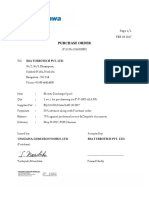

- Purchase Order: Page 1/1 FEB 18 2017 (P.O.No.G1602885)Document1 pagePurchase Order: Page 1/1 FEB 18 2017 (P.O.No.G1602885)Paulkumar RamaiahNo ratings yet

- Valve Sizing TablesDocument5 pagesValve Sizing TablesPaulkumar RamaiahNo ratings yet

- TG-73, DS - TM7301 - en - Co - 2146Document15 pagesTG-73, DS - TM7301 - en - Co - 2146Paulkumar RamaiahNo ratings yet

- Differential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionDocument4 pagesDifferential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionPaulkumar RamaiahNo ratings yet

- Engine Data SheetDocument6 pagesEngine Data SheetPaulkumar RamaiahNo ratings yet

- Performance DataDocument2 pagesPerformance DataPaulkumar RamaiahNo ratings yet

- Data SheetDocument7 pagesData SheetPaulkumar RamaiahNo ratings yet

- Eot Spec - BhelDocument2 pagesEot Spec - BhelPaulkumar RamaiahNo ratings yet

- PR VesselDocument9 pagesPR Vesselsheikhyasir11No ratings yet