Professional Documents

Culture Documents

Me183 PDF

Uploaded by

Sandeep HarshavardhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me183 PDF

Uploaded by

Sandeep HarshavardhanCopyright:

Available Formats

ME183: Manufacturing Processes

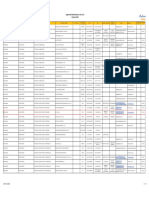

Teaching Scheme Credits Marks Distribution

Theory Marks Practical Marks Total

L T P C Marks

ESE CE ESE CE

3 0 2 5 70 30 30 20 150

Course Content:

Sr. Teaching

Topics

No. Hrs.

1 Basic Machine Tools and Metal Cutting Principles: 05

Classification of machining processes and machine tools, Basic

motions in various machines tools, Cutting tool materials,

Different types of cutting tools, Nomenclature of single point and

multi point cutting tools, Concept of cutting speed, feed, depth of

cut and MRR for various machine tools under consideration.

2 Metal Cutting Lathes: 10

Classification of lathes, Constructional details/elements of engine

lathe, Accessories and attachments, Specifications, Lathe

operations, Methods of taper turning, Thread cutting on lathe.

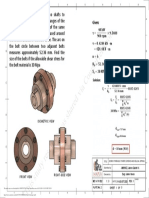

3 Drilling Machines: 05

Fundamentals of drilling operation, Construction of drilling

machines, Types of drilling machines, Twist drill geometry, and

Allied operations performed on drilling machine.

4 Boring Machine: 02

Purpose of boring operation, Horizontal and vertical boring

machines, Jig boring machines.

5 Milling Machines: 10

Principle of milling, Concept of up-milling and down-milling,

Types of milling machines, Construction details of column and

knee type milling machine, Types of milling cutters, Different

types of milling operations, Cutting conditions in milling,

Accessories and attachments, Indexing, Helical milling operation

and its set up.

6 Shaper, Planer, and Slotter: 05

Shaper: Working principle, Classification of shapers, Principal

parts of shaper, Shaper mechanisms, and Shaper operations.

Planer: Working principle, Difference between shaper and planer.

Slotter: Principal parts, Operations performed on slotter.

7 Grinding Machines and Abrasives: 05

Characteristic of grinding process, Classification of grinding

machines, Operations and applications of surface, cylindrical and

centerless grinding processes, Dressing, truing and balancing of

grinding wheels, Abrasives, Grinding wheel designation and

selection.

8 Broaching and Sawing Machines: 03

Broaching: Fundamentals of broaching, broaching tool

terminology, Types of broaching machines, Advantages and

limitations of broaching.

Sawing: Operation, Saw blades, Types of sawing machines.

Total Hrs. 45

Reference Books:

1. Rao P.N., “Manufacturing Technology (Vol. 2)”, Tata McGraw-Hill.

2. Hajra Choudhury S. K., Bose H. K. and Hajra Choudhury A. K., “Elements of

Workshop Technology (Vol. II)”, 12th Edition, Media promoters and Publishers Pvt.

Ltd.

3. Raghuwanshi B. S., “A Course in Workshop Technology (Machine Tools Vol. II)”,

Dhanpat Rai & Sons.

4. Khanna O.P and Lal M., “A Text book of Production Technology (Vol. II)”,

Dhanpat Rai Publications (P) ltd.

5. HMT, “Production Technology”, Tata McGraw-Hill.

6. Chapman W.A.J., “Workshop Technology (Vol. I, II & III)”.

7. Jain R. K., “Production Technology”.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rolling Cutter Bits 02Document54 pagesRolling Cutter Bits 02amin peyvandNo ratings yet

- Ospb, Ospc, PSPF Steering Service ManualDocument32 pagesOspb, Ospc, PSPF Steering Service ManualbenjaminNo ratings yet

- Ardf DF3070 (D630) 111222Document34 pagesArdf DF3070 (D630) 111222william lozadaNo ratings yet

- Ball Bearing: Ball (Bearing) Rolling-Element Bearing Balls Bearing Radial AxialDocument6 pagesBall Bearing: Ball (Bearing) Rolling-Element Bearing Balls Bearing Radial AxialMuhamad PriyatnaNo ratings yet

- Envicool Cabinet Air Conditioner Service ManualDocument22 pagesEnvicool Cabinet Air Conditioner Service ManualCONSORCIO TECA 2019100% (1)

- Seiko 4t57Document7 pagesSeiko 4t57DinukaDeshanNo ratings yet

- Ball Screw ChapterDocument17 pagesBall Screw Chaptervyhtran4731No ratings yet

- UPVC Pipe Manufacturer ListDocument338 pagesUPVC Pipe Manufacturer ListAnilNo ratings yet

- Mar 22 AvlDocument1 pageMar 22 AvlBala KrishnanNo ratings yet

- @bonaobra EIM 9 TLE-AS-MELC's #1W 1Q 1Document8 pages@bonaobra EIM 9 TLE-AS-MELC's #1W 1Q 1Editha BonaobraNo ratings yet

- Remove Transmission (Direct Drive)Document51 pagesRemove Transmission (Direct Drive)Sayutie_Anak_A_2175100% (2)

- 8-Device Universal Remote Control: User's GuideDocument44 pages8-Device Universal Remote Control: User's Guidepredator1974No ratings yet

- Electronic Devices: (Vocabulary)Document2 pagesElectronic Devices: (Vocabulary)Avram Paula-roxanaNo ratings yet

- Ena Micro 9 One TouchDocument15 pagesEna Micro 9 One TouchМаксим ПикаNo ratings yet

- URC7962 Complete Manual and Code List PDFDocument196 pagesURC7962 Complete Manual and Code List PDFSergio GrañaNo ratings yet

- Leo XRM Borehole Pump Manual InstructionDocument11 pagesLeo XRM Borehole Pump Manual InstructionReza Salimi100% (1)

- Isometric View: JIMENEZ, James Gabriel VDocument1 pageIsometric View: JIMENEZ, James Gabriel VHansyyy CarantoNo ratings yet

- Key - Period 67-68 (DT12)Document5 pagesKey - Period 67-68 (DT12)phamhaanh2811No ratings yet

- Rep S5DDocument151 pagesRep S5DDoru DariusNo ratings yet

- Brake SystemDocument80 pagesBrake SystemJowNo ratings yet

- Installation: SA GBP 201/202Document19 pagesInstallation: SA GBP 201/202Mostafa MatarNo ratings yet

- 2417 Assembly Guide - EnglishDocument53 pages2417 Assembly Guide - EnglishJose LunaNo ratings yet

- Product Data: Side Discharge AC ModelsDocument12 pagesProduct Data: Side Discharge AC ModelsAlejandro OrdoñezNo ratings yet

- Mini Milling/Drilling Machine: Instruction ManualDocument24 pagesMini Milling/Drilling Machine: Instruction Manualelchuju100% (4)

- AC Automotive System - Gauge ReadingsDocument22 pagesAC Automotive System - Gauge ReadingsPreslav VasilevNo ratings yet

- Rules To Know For Elec EnggDocument1 pageRules To Know For Elec EnggGokulNo ratings yet

- Threadless Coupling Report3Document24 pagesThreadless Coupling Report3Rahul Tripathi100% (1)

- LG SP122CNDocument41 pagesLG SP122CNHenrry LingNo ratings yet

- LH621i Power TrainDocument212 pagesLH621i Power TrainPierre NgoyNo ratings yet

- Indoor Unit Outdoor Unit Cs-Ye9Mke Cs-Ye12Mke Cs-Ye18Mke Cu-Ye9Mke Cu-Ye12Mke Cu-Ye18MkeDocument47 pagesIndoor Unit Outdoor Unit Cs-Ye9Mke Cs-Ye12Mke Cs-Ye18Mke Cu-Ye9Mke Cu-Ye12Mke Cu-Ye18MkejpfalmeidaNo ratings yet