100%(6)100% found this document useful (6 votes)

4K views274 pagesConstruction

Construction PE notes

Uploaded by

tristan1551Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

100%(6)100% found this document useful (6 votes)

4K views274 pagesConstruction

Construction PE notes

Uploaded by

tristan1551Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

Construction

PE Exam Review-Civil Discipline

Prepared by: John W. Strybos, P.E.

Test Masters Educational Services, Inc.

www.testmasters.com

page CON2

THIS PAGE INTENTIONALLY LEFT BLANK

Copyright by www.TestMasters.com. All Rights Reserved,

page CON2

TABLE OF CONTENTS

Tovic Page

Cover Page 1-2

Table of Contents 3-6

References 7-10

Exam Content 11-16

Formulas and Data 17-30

A.M. Topics

Quantity Take-off Methods and Cost Estimating Discussion 31-34

Quantity Take-off Methods and Cost Estimating Problems 35-40

Quantity Take-off Methods and Cost Estimating Solutions 41-44

Project Schedules and Activity Identification and Sequencing Discussion 45-52

Project Schedules and Activity Identification and Sequencing Problems 53-56

Project Schedules and Activity Identification and Sequencing Solutions 57-58

Construction Load, Methods, Temporary Structures and Facilities Discussion 59 - 68

Construction Load, Methods, Temporary Structures and Facilities Problems 69-78

Construction Load, Methods, Temporary Structures and Facilities Solutions 79 - 86

Excavation and Embankment, Construction site layout and control Discussion 87 - 96

Excavation and Embankment, Construction site layout and control Problems 97 — 102

Excavation and Embankment, Construction site layout and control Solutions 103 - 106

Temporary and permanent soil erosion and sediment control (e.g., construction 107- 110

erosion control and permits, sediment transport, channel/outlet protection) and

Impact of construction on adjacent facilities Discussion

Temporary and permanent soil erosion and sediment control (e.g., construction 111- 112

erosion control and permits, sediment transport, channel/outlet protection) and

Impact of construction on adjacent facilities Problems

page CON3 Copyright by www.TestMasters.com. All Rights Reserved, page CON3

TABLE OF CONTENTS (Continued)

Topic

Page

Temporary and permanent soil erosion and sediment control (e.g., construction 113-114

erosion control and permits, sediment transport, channel/outlet protection)

Impact of construction on adjacent facilities Solutions

Safety (e.g., construction, roadside, work zone) Discussion 118-118

Safety (e.g., construction, roadside, work zone) Problems 119-120

Safety (e.g., construction, roadside, work zone) Solutions 121-122

Topics

Earthwork Construction and Layout Problems 123-134

Earthwork Construction and Layout Solutions 136-140

Estimating Quantities and Costs Problems 441-150

Estimating Quantities and Costs Solutions 151-158

Construction Operations and Methods Probiems 199-170

Construction Operations and Methods Solutions 171-176

Scheduling Problems 17-186

‘Scheduling Solutions 187-194

Material Quality Control and Production Problems 198-202

Material Quality Control and Production Solutions 203-212

Temporary Structures Problems 213-218

‘Temporary Structures Solutions 219-222

Health and Safety Problems 223-240

Health and Safety Solutions 241-252

page CON4 Copyright by www.TestMasters.com. All Rights Reserved. page CON4

TABLE OF CONTENTS (CONTINUED)

Topic Page

Engineering Economics Discussion 253-262

Engineering Economics Problems 263-268

Engineering Economics Solutions 269-274

END OF SECTION

page CONS Copyright by www.TestMasters.com. All Rights Reserved, page CONS

page CONG

THIS PAGE INTENTIONALLY LEFT BLANK

Copyright by www-TestMasters.com. All Rights Reserved,

page CONS:

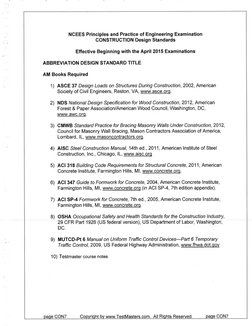

NCEES Principles and Practice of Engineering Examination

CONSTRUCTION Design Standards

Effective Beginning with the April 2015 Examinations

ABBREVIATION DESIGN STANDARD TITLE

AM Books Required

1) ASCE 37 Design Loads on Structures During Construction, 2002, American

Society of Civil Engineers, Reston, VA, www.asce.org

2) NDS National Design Specification for Wood Construction, 2012, American

Forest & Paper Association/American Wood Council, Washington, DC,

www.awe.org.

3) CMWB Standard Practice for Bracing Masonry Walls Under Construction, 2012,

Couneil for Masonry Wall Bracing, Mason Contractors Association of America,

Lombard, IL, www.masoncontractors.org.

4) AISC Stee! Construction Manual, 14th ed., 2011, American Institute of Stee!

Construction, Inc., Chicago, IL, www.aisc.ora

5) ACI 318 Building Code Requirements for Structural Concrete, 2011, American

Concrete Institute, Farmington Hills, MI, www.concrete.org.

6) ACI 347 Guide to Formwork for Concrete, 2004, American Conerete Institute,

Farmington Hills, Ml, www,concrete.org (in ACI SP-4, 7th edition appendix).

7) ACI SP-4 Formwork for Concrete, 7th ed., 2005, American Concrete Institute,

Farmington Hills, MI, www.concrete.org.

8) OSHA Occupational Safety and Health Standards for the Construction Industry,

29 CFR Part 1926 (US federal version), US Department of Labor, Washington,

Oc.

9) MUTCD-Pt 6 Manual on Uniform Traffic Control Devices—Part 6 Temporary

Traffic Control, 2009, US Federal Highway Administration, www.fhwa.dot.gov

10) Testmaster course notes

page CON7 Copyright by www.TestMasters.com. All Rights Reserved. page CON7

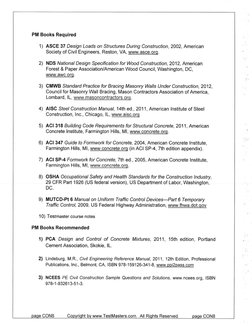

PM Books Required

1) ASCE 37 Design Loads on Structures During Construction, 2002, American

Society of Civil Engineers, Reston, VA, www.asce.org,

2) NDS National Design Specification for Wood Construction, 2012, American

Forest & Paper Association/American Wood Council, Washington, DC,

www.awe.org.

3) CMWB Standard Practice for Bracing Masonry Walls Under Construction, 2012,

Council for Masonry Wall Bracing, Mason Contractors Association of America,

Lombard, IL, www.masoncontractors.org.

4) AISC Stee! Construction Manual, 14th ed., 2011, American Institute of Steel

Construction, Inc., Chicago, IL, www.aisc.org

5) ACI 318 Building Code Requirements for Structural Concrete, 2011, American

Conerete Institute, Farmington Hills, MI, www.concrete.org,

6) ACI 347 Guide to Formwork for Concrete, 2004, American Concrete Institute,

Farmington Hills, MI, www.concrete.org (in ACI SP-4, 7th edition appendix),

7) ACI SP-4 Formwork for Concrete, 7th ed., 2005, American Conerete Institute,

Farmington Hills, MI, www.concrete.ora,

8) OSHA Occupational Safety and Health Standards for the Construction Industry,

29 CFR Part 1926 (US federal version), US Department of Labor, Washington,

DC.

9) MUTCD-Pt 6 Manual on Uniform Traffic Control Devices—Part 6 Temporary

Traffic Control, 2009, US Federal Highway Administration, www.thwa.dot.aov

10) Testmaster course notes

PM Books Recommended

1) PCA Design and Control of Concrete Mixtures, 2011, 15th edition, Portland

Cement Association, Skokie, IL.

2) Lindeburg, M.R., Civil Engineering Reference Manual, 2011, 12th Edition, Professional

Publications, Inc., Belmont, CA, ISBN 978-159126-341-8, www.ppi2pass.com

3) NCEES PE Civil Construction Sample Questions and Solutions, www.ncees.org, ISBN

978-1-932613-51-3.

page CONS __Copyright by www.TestMasters.com. All Rights Reserved. page CONS

Reference categories for Construction depth module

1) Construction surveying

2) Construction estimating

3) Construction planning and scheduling

4) Construction equipment and methods,

5) Construction materials

6) Construction design standards (see above)

END OF SECTION

page CONS Copyright by www.TestMasters.com. All Rights Reserved. page CONS

page CON10

THIS PAGE INTENTIONALLY LEFT BLANK

Copyright by www. TestMasters.com. All Rights Reserved.

page CON10

NCEES Principles and Practice of Engineering Examination

CIVIL BREADTH and CONSTRUCTION DEPTH Exam Specifications

Effective Beginning with the April 2015 Examinations

+ The civil exam is a breadth and depth examination. This means that examinees work

the breadth (AM) exam and one of the five depth (PM) exams.

+ The five areas covered in the civil exam are construction, geotechnical, structural,

transportation, and water resources and environmental. The breadth exam contains

questions from all five areas of civil engineering. The depth exams focus more closely

on a single area of practice in civil engineering.

+ Examinees work all questions in the morning session and all questions in the

afternoon module they have chosen. Depth results are combined with breadth results

for final score.

+ The exam is an 8-hour open-book exam. It contains 40 multiple-choice questions in

the 4-hour AM session, and 40 multiple-choice questions in the 4-hour PM session.

+ The exam uses both the Intemational System of Units (SI) and the US Customary

‘System (USCS).

+ The exam is developed with questions that will require a variety of approaches and

methodologies, including design, analysis, and application. Some problems may require

knowledge of engineering economics.

+ The knowledge areas specified as examples of kinds of knowledge are not exclusive

or exhaustive categories

+ The specifications for the AM exam and the Construction PM exam are included

here. The design standards applicable to the Construction PM exam are shown on the

page 6

CIVIL BREADTH Exam Specifications

Approximate

Number of

Questions

|. Project Planning 4

A. Quantity take-off methods

B. Cost estimating

C. Project schedules

D. Activity identification and sequencing

page CON11 Copyright by www. TestMasters.com. All Rights Reserved. __ page CON11

CIVIL BREADTH Exam Specifications Continued

Approximate

Number of

Questions

|, Means and Methods 3

A. Construction loads

B. Construction methods

C. Temporary structures and facilities

Il. Soil Mechanics 6

A. Lateral earth pressure

B. Soil consolidation

C. Effective and total stresses

D. Bearing capacity

E. Foundation settlement

F. Slope stability

IV. Structural Mechanics 6

‘A. Dead and live loads

B. Trusses

C. Bending (e.g., moments and stresses)

D. Shear (e.g,, forces and stresses)

E. Axial (e.g,, forces and stresses)

F, Combined stresses

G. Deflection

H. Beams

|. Columns

J. Slabs

K. Footings

L. Retaining walls

V. Hydraulics and Hydrology 7

A. Open-channel flow

B. Stormwater collection and drainage (e.g., culvert, stormwater inlets, gutter flow,

street flow, storm sewer pipes)

C. Storm characteristics (e.g., storm frequency, rainfall measurement and distribution)

D. Runoff analysis (e.g., Rational and SCS/NRCS methods, hydrographic application,

runoff time of concentration)

E. Detention/retention ponds

F. Pressure conduit (e.g., single pipe, force mains, Hazen-Williams, Darcy-Weisbach,

major and minor losses)

G. Energy and/or continuity equation (e.g., Bernoulli)

page CON12 Copyright by www.TestMasters.com. All Rights Reserved. __ page CON12

CIVIL BREADTH Exam Specifications Continued

Approximate

Number of

Questions

VI. Geometrics 3

A. Basic circular curve elements (¢.g., middle ordinate, length, chord, radius)

B. Basic vertical curve elements

C. Traffic volume (e.g., vehicle mix, flow, and speed)

VII. Materials 6

A. Soil classification and boring log interpretation

B. Soil properties (e.g., strength, permeability, compressibility, phase relationships)

C. Concrete (e.g., nonreinforced, reinforced)

D. Structural steel

E. Material test methods and specification conformance

F. Compaction

Vill, Site Development 5

‘A. Excavation and embankment (e.g., cut and fill)

B. Construction site layout and control

C. Temporary and permanent soil erosion and sediment control (e.g., construction

erosion control and permits, sediment transport, channel/outlet protection)

D. Impact of construction on adjacent facilities

E. Safety (e.g., construction, roadside, work zone)

pageCON13 Copyright by www.TestMasters.com. All RightsReserved. __ page CON13.

CIVIL-CONSTRUCTION DEPTH Exam Specifications

Approximate

Number of

Questions

|. Earthwork Construction and Layout 6

‘A. Excavation and embankment (e.g., cut and fil)

B. Borrow pit volumes

C. Site layout and control

D. Earthwork mass diagrams and haul distance

E. Site and subsurface investigations

II, Estimating Quantities and Costs 6

A. Quantity take-off methods

B. Cost estimating

C. Cost analysis for resource selection

D. Work measurement and productivity

Ill Construction Operations and Methods 7

A. Lifting and rigging

8. Crane stability

C. Dewatering and pumping

D. Equipment operations (e.g., selection, production, economics)

E, Deep foundation installation

IV. Scheduling 5

‘A. Construction sequencing

B. Activity time analysis

C. Critical path method (CPM) network analysis

D. Resource scheduling and leveling

E. Time-cost trade-off

V. Material Quality Control and Production 6

A. Material properties and testing (e.g., soils, concrete, asphalt)

B. Weld and bolt installation

C. Quality control process (QA/QC)

D. Concrete proportioning and placement

E. Concrete maturity and early strength evaluation

VI. Temporary Structures 7

‘A. Construction loads, codes, and standards

B. Formwork

C. Falsework and scaffolding

D. Shoring and reshoring

E. Bracing and anchorage for stability

F. Temporary support of excavation

page CON14 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON14

CIVIL-CONSTRUCTION DEPTH Exam Specifications

Approximate

Number of

Questions

VIL. Health and Safety

A. OSHA regulations and hazard identification/abatement

B. Safety management and statistics

C. Work zone and public safety

3

END OF SECTION

page CON15 __Copyright by www. TestMasters.com. All Rights Reserved.

page CON15

page CON16

THIS PAGE INTENTIONALLY LEFT BLANK

Copyright by www.TestMasters.com. All Rights Reserved,

page CON16

FORMULAS AND DATA

Earthwork Construction and Layout

\V = Volume of Earthwork in cubic yards or cubic feet.

1 cubic yard = 27 cubic feet

L = Distance (spacing) between cross-sections in feet.

L= Length of a triangular spoil pile in feet

R = Angle of Repose in degrees (a property of a soil)

B = Base width of triangular spoil pile in feet.

H = Height of a triangular or conical spoil pile in feet.

D = Diameter of a conical spoil pile in feet

‘A= cross section area in square feet

Average end area method: V = (0.5)(A; + Ag)(L)/27

Prismoidal formula: V = (L/6)*(Ai + 4Am + Aa)

Triangular Spoil Bank: B= (4V/(L*tanR))°*

Triangular Spoil Bank: H = 0.5°B*tanR.

Conical Spoil Pile: D = (7.64Vi(tanR))°?

Conical Spoil Pile H = 0.5*D*tan(R)

Overhaul (cy-stations) = Overhaul volume (cy) * Overhaul distance (stations)

Overhaul distance (stations) = Total haul — Free haul (stations)

Total haul = distance (stations) between centers of mass outside free haul

H = E/O = Excavation cost/Over haul cost

E = Excavation cost in $/cy

O = Overhaul cost in $/ey-ft

Length of economical haul = Free haul distance + H

pageCON17 Copyright by www.TestMasters.com. All Rights Reserved. __ page CON17

FORMULAS AND DATA

Earthwork Construction and Layout

Earthwork volume for a grid (in CF) = (Average cut depth in feet) * (Area of grid in SF)

If multiple grids, then sum volumes of each grid

Q = “Area in a section of a mass haul diagram in cy-stations

\V = Maximum or minimum volume in CY that corresponds with the Q.

Average Haul distance = Q/V

Estim:

ing Quan

Outside Perimeter = 2 x (length + width + recess)

OP =2(L+W+R)

Inside perimeter = OP — 8*footing width

IP = OP -8w

Mean Perimeter = OP -4* footing width = IP +4* footing width

MP = OP -4w=IP +4w

BF = board foot = [Length (feet)]*[nominal size (inches x inches)}(12 inches/foot)

SFCA = square foot of contact area

Formwork Conversions

To Obtain Gross area of Forms Multiply Net Areas by

Industrialize Wall Forms 1.20

Table forms for slabs 1.40

Tunnel and half-Tunnel forms 1.15

page CON18 Copyright by www.TestMasters.com. All Rights Reserved, __page CON18.

FORMULAS AND DATA

‘Scheduling

INTERFERING FLOAT (IF) of activity j = (LATE FINISH (LF) of activity j) - (SMALLEST

EARLY START (ES) OF ALL SUCCESSOR ACTIVITIES)

FREE FLOAT (FF) of activity j = (MINIMUM EARLY START (ES) OF ALL SUCCESSOR

ACTIVITIES) — (EARLY FINISH of activity j)

TR =FF+IF

TF=LS-ES

TF =LF-EF

Forward Pass = (EF) Early Finish, =(ES) Early Start, + (D) Duration,

Backward Pass: = (LS) = Late Start, = (LF) Late Finish, ~ (D) Duration,

Lag = the amount of time an activity must be delayed from the start of finish of a

predecessor.

Lead = the amount of time by which an activity precedes the start or finish of a

successor.

Four precedence relations ships are:

Finish to Start (FS)

Early Start (ES) n+1 = Early Finish (EF), + Lag

Late Finish (LF) » = Late Start (LS) ps1 - Lag

Start to Start (SS)

Early Start (ES) q.1 = Early Start (ES), + Lag

Late Finish (LF) » = Late Start (LS) nt - Lag

Finish to Finish (FF)

Early Start (ES) n.1 = Early Finish (EF), + Lag ~ Duration (D)nv1

Late Finish (LF) . = Late Start (LS) n+1 - Lag

Start to Finish (SF)

page CON19 __Copyright by www.TestMasters.com. All Rights Reserved. __ page CON19

FORMULAS AND DATA.

TEMPORARY STRUCTURES FORMWORK

P (psf) = Co*Cy*(150 + 9000R/T) for R <7 fuhr and H < 14 ft

P (psf) = Cc*C,, "(150 + 43,400/T + 2800R/T) for H > 14 ftand 7 |

tor tocol Pen)

Tos ees] To

Pope See oe

pow [ ose

i a a

5 a a

j [ea

7 is [es

7 [66

a

7 a

i 5

ceneerne comes 115

page CON24

Copyright by www.TestMasters.com. All Rights Reserved,

page CON24

Engineering Economics (A.M. and

Factor Table 1 050%

PF Pe PP

ve cet tae

116 cmesmcecomurs

page CON25

Copyright by www.TestMasters.com. All Rights Reserved.

page CON25,

=| Fm

1]

200%

= 7a a

execu semen 117

page CON26 Copyright by www.TestMasters.com. All Rights Reserved. __ page CON26

pews wu ceuey:

118 seenemcscomomes

page CON27 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON27.

Engineering Economics (A. ind P.M. Topit

Factor Table i= 800%

lnsseeuee

meres econoucs 119

page CON28 Copyright by www.TestMasters.com. All Rights Reserved. __ page CON28

Engineer

Factor Table == 1200%

pseseuven

| ees | sa Sime

pe owe eusuusenszeer:

120 ormeemmc ccomomes

page CON29 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON29.

|

iff

fie i

Lot;

E i

—

semen ttl Buon teh See

a] EE Gh ae oi 8 aL

lh ey it a a E

5h) Bea it i Bal Hu

B) Han Hee Hs Hea

‘ P)HAH RE a

sls a 5 a] ie

| 8 elaliel a |i a [His] be | Gly

afi lava) i aU Gecbal|:

e e/a ml a] il] Gf He

| [a balalal gla TEER

ye [state] a fa a fefs [sfa] =

i 1a |

g z ra

i lates | ale [E

ul a [als a ‘

4) e, leales [ode 82,2

Be 2

ah ..|.|!

Fe eee || FI!

el le aly

ulema eR eae Tisclnnar so vou Hy

cam

END OF SECTION

cy ae

page CON30___Copyright by www.TestMasters.com. All Rights Reserved. __ page CON30

A.M. Topics

1. Project Planning - Discussion

A. Quantity Take-off Methods

B. Cost Estimating

page CON31 __ Copyright by www.TestMasters.com. All Rights Reserved. __page CON31

Estimating Quantities and Costs

Outside Perimeter = 2 x (length + width + recess)

OP =2(L + W+R)

Inside perimeter = OP — 8*footing width

IP = OP -8w

Mean Perimeter = OP -4 footing width = IP +4* footing width

MP = OP —4w=IP + 4w

BF = board foot = [Length (feet)]*{nominal size (inches x inches)}/(12 inches/foot)

SFCA = square foot of contact area

Formwork Conversions

To Obtain Gross area of Forms Multiply Net Areas by

Industrialize Wall Forms 1.20

Table forms for slabs 4.10

Tunnel and half-Tunnel forms 4.15

Reinforcement Bar Size and Weights

Bar# Diameter Inch Area (sq. in.) Weight (Ibift)

3 0.375 om 0.376

4 0.500 0.20 0.668

5 0.625 0.31 1.043

6 0.750 044 | 4.502

7 0.875 0.60 2.044

8 1.000 0.79 2.670

9 1.428 1.00 3.400 _|

10 1.270 1.27 4.30

11 1.410 1.56 5.31

14 1.693 2.25 7.65

78 2.257 4.00 73.60

An estimate is the “prediction” of future construction costs. It is the process of looking

into the future and predicting cost and resource requirement. It will need to determine

the anticipated cost of materials, labor, and equipment of a proposed project

page CON32 __Copyright by www.TestMasters.com. All Rights Reserved, _ page CON32

Types of Construction Costs:

Direct costs and Indirect Costs.

Types of Estimates

Conceptual (Rough Order of Magnitude)

Preliminary

Engineer

Bid

Rona

Elements of construction Costs

Labor

Materials,

Equipment

Subcontractors

Overhead and Profit

hens

Labor Costs

To price labor estimate the work hours required to do a unit of work of all trades

involved. (work crew productivity). Multiply the hours required by wages and benefits =

total cost of labor per unit of work.

Factors affecting labor are productivity and availability of qualified labor including

unions.

‘Material Costs

‘Supplies purchased by the contractor and incorporated into the finished construction

project (lumber, windows, concrete, etc.)

Equipment Costs

Cost of equipment including maintenance, taxes and insurance on the equipment,

maintenance, depreciation, and allowance for repairs. Operating costs (cost per hour),

rental costs and depreciation and maintenance.

Overhead Costs

Costs that cannot be attributed to any particular job “Office expenses.” Management

and Staff including salaries, fringe, benefits and transportation. Business offices

including rent, furniture and depreciation, office supplies, communications, telephone,

faxes, and advertising

page CON33 Copyright by www.TestMasters.com. All Rights Reserved. __page CON33

—S Direct Costs of all the resources = Labor + Material + Equipment

5 Indirect Costs include bond premiums, insurance premiums, fees for licenses and

permits, services such as water, electricity, communications, home office overhead

allocation,

Quantity Take-off

Review drawings and specifications

Measure quantities of work to be performed in appropriate units

Loss factors as applicable

vt uerr

Contingency as applicable.

END OF SECTION

page CON34 __ Copyright by www.TestMasters.com. All Rights Reserved. __ page CON34

|. Project Planning - Problems

page CON35:

A. Quantity Take-off Methods

B. Cost Estimating

Copyright by www.TestMasters.com. All Rights Reserved,

page CON35,

Estimating Quantities and Costs Problems

101. A 200-foot by 100-foot room has been prepared for painting. The walls are 7-feet

high and will require two coats of paint on the previously painted surface for proper

coverage. If 1 gallon of paint covers 300-square feet, the number of gallons of paint

needed to paint the walls is most nearly:

A) 14 gallons

©) 67 gallons

D) 81 gallons

102. The outside perimeter of a brick walll is 53 ft Calculate the bricks required to build

this wall if its height is 8 feet and the bricks will all be laid in a running bond, Standard

non-modular bricks have been specified for the project. Assume a 1% waste factor.

Mortar joints are 3/8-inch. Brick size is 3-5/8 inches by 2-1/4 inches by 8 inches.

A) 1,402 Bricks

B) 1,500 Bricks

c)

‘805 Bricks

D) 3,000 Bricks

103. A 250-foot by 125-foot room has been prepared for painting. The walls are 9-feet

high and will require two coats of paint on the previously painted surface for proper

coverage. If 1 gallon of paint covers 325-square feet, the number of gallons of paint

needed to paint the walls is most nearly:

A) 21 gallons

B) 28 gallons

D) 55 gallons

page CON36___ Copyright by www.TestMasters.com. All Rights Reserved. __ page CON36.

104. What is the volume of conerete (cy) required for a 4,500 foot long channel with

10% waste. The channel cross-section is shown below.

A) 235 cubic yards

CB) 6,368 cubic yards > G, DEI cy

©) 57,222 cubic yards

D) 174,666 cubic yards

TIN THICK

‘SIDE SCOPES 2V:3H

7 oe

AF.

“ ~

‘ con ee a. eget

OT AI :

Figure 1. Problem 104 Channel Cross-Section

page CON37___Copyright by www.TestMasters.com. All Rights Reserved. _ page CON37_

Use the Figure shown below to answer problems 105, 106 and 107.

——

30°

15°

15°

3

Figure 2. Problems 105, 106 and 107 Foundation Wall

105. Calculate the outside perimeter of the wall shown in the Figure above,

asin OCs DO+1E +343’ + 18 430%:

B) 60 ft

D) 120 ft

106. The width of the foundation wall shown in the figure above is four feet. Calculate

the volume of concrete required to build this foundation wall if its cross sectional area is

85h

A) 12.25 cy MP Of- Hy, = fo2'~4 (a) = 80-4

B) 18 cy x Peer

page CON38 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON38

1A4 rate HD (Ae of We

107. If the wall shown in the figure above is two feet in height what is the required

formwork in sfca.

0”: 1o7 t+

A) 172 sfca

TP: OP- hw = 1o2- Blu) Fok

B) 200 sfca

Cea (WU) +AN(2) +311 shes

D) 400 sfea (N. Ferme Camnrs ve)

108. Calculate the number of bricks (3.75" x 2.25” x 8") laid in running bond required for

a double wythe wall 8-feet high by 14-feet wide having one penetration 48-inches x 72-

inghes and one opening 32 inches by 48 inches. Mortar joints are 0.5-inches and there

is 3% brick waste. .

rt pci

A) 500 bricks

B) 1,000 bricks

a

C) 1,500 bricks

s D) 2,000 bats

He

109. Calculate the volume of mortar (cf) for the following brick wall. A double wythe wall

B-feet high by 14-feet wide having one opening 48-inches by 72-inches and one

972 opening 32 inches by 48 inches. Mortar joints are 0.5-inches and there is 25% mortar

waste, The joint thickness between the wythes is 0.5-inch. There are 982 total bricks

B75" x 2.25" x 8") for both wythes including 3% brick waste

re

ger a~ yer Ap 43. PE Ger

2 10> bevks

Does? B) 18.3 of 1.0% sed

©) 27.4 cf

vez | | 6, O122-£4 Acie’

D) 366 cf .

0.5 "elas

—— S$. 6251S brick

as FOB 4 AY wek

pageCON39___Copyright by www,TestMasters.com. All Rights Reserved. _ page CON39

110. Calculate the longitudinal #6 reinforcing steel in the wall shown below (not the

footing). The wall is 60 ft long and 6 in. of cover is required at each end. The bars

come in 20-ft lengths and will have to be lapped 6 in. How many tons of #6 steel should

be ordered? (i3)« lo’. o 7 of cob

A) 0.298 Tons x Lsort he

B) 0.300 Tons A ! Let va

zo’ Mae’ as

D) 0.600 Tons y 4 TE 58

ho Gu

2” Clear

Space

j+-2” Clear Space

{13 18 cont @12" 06 p>

vertical bars

PEir' ec

"oO

Weep Hole

@ woc

y

Clear

3” Clear Space Space

86"

Figure 3. Problem 110 Wall Cross-Section

END OF SECTION

page CON40___Copyright by www.TestMasters.com. All Rights Reserved. _ page CON4O.

1. Project Planning - Solutions

A. Quantity Take-off Methods

B, Cost Estimating

page CON41 Copyright by www.TestMasters.com. All Rights Reserved. _page CON41

Estimating Quantities and Costs Solutions

101. B) 28

jons

Perimeter = (2*200 ft)+ (2"100 ft) = 600 ft

Wall surface area = 600 ft * 7 ft = 4,200 f?

Number of gallons = (4,200 ft? / coat)(2 coats)/(300 ft?/gallon) = 28 Gal

Reference: Frank R. Walker Company, Walker's Building

Estimator's Reference Book.

102, C) 2,805 BRICKS,

REFERENCE: LINDEBURG PAGE 67-3

USE 0.375 INCH STANDARD MORTAR JOINT

Area of wall = 53x 8 => 424 sq ft

Area of one soldier brick =

A= (24+ 0.375 in.) x (8 + 0.375 in.) 21.98 sq in/144 sq inisf = 0.1526 sfibrick

Briok per sq. ft= (144 sq.in/sf)/(21.98 sq. in./brick) => 6.55 bricks per square foot

Number of bricks without waste =

424 sq ft x 6.55 brick per sq. ft => 2,777 brick

Number of bricks with waste =

2,777 brick x 1.01 = 2,805 bricks

103. C) 42 Gallons

Perimeter = (2°250 ft)+ (2"125 ft) = 750 ft

Wall surface area = 750 ft* 9 ft = 6,750 ff

Number of gallons = (6,750 ft? / coat)(2 coats)/(325 f?/gallon) = 42 Gallons

Reference: Frank R. Walker Company, Walker's Building

Estimator’s Reference Book.

page CON42 Copyright by www.TestMasters.com. All Rights Reserved. __ page CON42

104. B) 6,358 cy

Length of side slopes using 2 vertical to 3 horizontal

141K = 2/3 > X = 21-feet = horizontal length

Side Slope Length = (14? + 217)° = 25.23 ft

Cross-Section Area = (7/12)[2(25.23) + 9]

= 34.68 sf

Volume = (4,500 ff)(34.68 sf)(1.1)(toyl27 of) =

Volume = 6,358 cy

105. _C) 402 ft

Outside perimeter = 2 x (length + width + recess)

Outside perimeter = 2 x (30 + 18 + 3) = 102 ft

108. C) 25.5 cy

Outside perimeter = 2x (30 + 18 + 3) = 102 ft

Mean perimeter = 102-4 (4) = 86 ft

Volume concrete = 86 ft x 8 sf => 688 cf or 25.5 cy

107. C) 344 sfca

Inside perimeter = OP + 4 x (2 x (-4))

Inside perimeter = 102 + 4 x (- 8) > 70ft

Outside forms = 102 x 2 = 204 sfca

Inside forms = 70 x 2 = 140 sfca

Total formwork = 204 + 140 = 344 sfca

page CON43 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON43,

108. B) 1,000 bricks

NET WALL AREA = (8*14) — (46) — (2.67*4) SF

= 77.33 SF

AREA OF ONE BRICK = (2.25 + 0.5)*(8 + 0.5)(144 sq. in/sf)

= 0.1632 SF

N= (77.33/0.1632)'2"1.03 = 982 BRICKS

109. B) 18.3 CF

VOLI BRICK = (0.5 in,)*(8+2.25+0.5 in.)*(3.75 in.)/(1728 cu. In/ef)

= 0.01166 CFibrick

VOL. PER WYTHE = 0.01166(982/2) =5.7 CF

VOL. BETWEEN WYTHE = (0.5 in)(77.33 sf)/(12 in/sf) = 3.2CF

MORTAR REQUIRED = (1.25)*(2°5.7+3.2) = 18.3 CF

110. C. 0.586 Tons

Number of longitudinal bars for 60 ft of wall: 3

space (cover)= 0.5 ft

firstbar = «20.0%

secondbar = 19.5%

thirdbar = 19.5 ft

Cover = O5tt

Total = 600

Number of longitudinal bars: 3 x 13 = 39

Total length of longitudinal bars: 20 ft x 39 = 780 ft of #6 bars

Weight of #6 bars: 780 ft total length x 1.502 Ib per If = 1,171.56 Ib

Weight of #6 bar

586 tons

END OF SECTION

pageCON44 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON44

1. Project Planning - Discussion

C. Project Schedules

D. Activity Identification and Sequencing

NOTE: Critical Path Method (CPM) and network Analysis are identified as PM

Construction Topics. Discussion is included on CPM due to its relationship to Activity

Time Analysis.

page CON45 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON45

Project Schedules Formulas

INTERFERING FLOAT (IF) of activity j= LATE FINISH (LF of activly|- SMALLEST EARLY START (ES) OF ALL SUCCESSOR

ACTIVITIES

FREE FLOAT (FF) of aly = MINMUM EARLY START (ES) OF ALL SUCCESSOR ACTIVITISS ~ EARLY FINISH of cut

TR =FF+IF

TF=LS-ES

TF =LF-EF

Forward Pass = (EF) Early Finish, =(ES) Early Start, + (D) Duration,

Backward Pass: = (LS) = Late Start, = (LF) Late Finish, — (D) Duration,

Lag = the amount of time an activity must be delayed from the start of finish of a

predecessor.

Lead = the amount of time by which an activity precedes the start or finish of a

successor.

Four precedence relationships are:

Finish to Start (FS)

Early Start (ES) nei = Early Finish (EF), + Lag

Late Finish (LF) , = Late Start (LS) n+: - Lag

Start to Start (SS)

Early Start (ES) 41 = Early Start (ES), + Lag

Late Finish (LF) » = Late Start (LS) n+: -Lag

Finish to Finish (FF)

Early Start (ES) n+: = Early Finish (EF), + Lag — Duration (D)n+1

Late Finish (LF) , = Late Start (LS) .+1-Lag

Start to Finish (SF)

page CON46 __Copyright by www.TestMasters.com. All Rights Reserved. _ page CON46:

Objectives include the ability to create a simple bar chart and a simple Critical Path

Method (CPM) logic network and an understanding of how to use a CPM for

determining project status and in identifying float. The ability to calculate resource

needs and an understanding of resource leveling strategies. The ability to create a

velocity diagram. The ability to develop a linear schedule.

‘Acommon technique used to understand and organize complex undertaking is to divide

the problem into smaller subparts. In construction this technique is applied in both

estimating and planning

The critical path method (CPM) is a planning and control technique that provides an

accurate, timely, and easily understood picture of the project. The logic diagram

graphically portrays the relationships between project activities

Planning creates an orderly sequence of events. It serves the manager by pointing out

the things to be done, their sequence how long each task should take and who is

responsible for which tasks or actions. A common technique used to understand and

organize complex undertakings is to divide the problem into smaller subparts. Each

activity is a discrete task.

+ Activities consume time.

+ Activities usually consume physical resources.

+ Activities have definable start and finish points.

+ Activities are assignable.

+ Activities are measurable

The bar chart is widely used as a construction-scheduling tool because of its simplicity,

ease of preparation, and understandable format. Normally the activities are listed in

chronological order according to their start date. Discontinuous bars are sometimes

used on hand drawn bar charts to represent interruptions of activities. It does not clearly

show the detailed sequence of the activities It does not show which activities are critical

to the successful, timely completion of the project

Example Bar Chart

[TASK | JAN | FEB | MAR | APR | MAY | JUNE | JULY | AUG | SEP |

1

2

3

page CON47 __Copyright by www.TestMasters.com. All Rights Reserved. __page CON47

The CPM is a too! that assists the planning, scheduling, & controlling of the project. The

logic diagram graphically portrays the relationships between project activities. With this

information, itis easier to plan, schedule, & control the project. Before the diagram can

be developed, the project must first be constructed mentally to determine activity

relationships.

Figure 4, Example Critical Path Method Schedule

‘OVERALL PROJECT DURATION

page CON48

Figure 5. Example Critical Path Method Schedule

Copyright by www.TestMasters.com. All Rights Reserved,

page CON48:

For each activity ask:

= Can this activity start at the beginning of the project? (Start activities)

Which activities must be finished before this one begins? (Precedence)

For each activity ask:

— Which activities may either start or finish at the same time this one does?

(Concurrence)

Which activities cannot begin until this one is finished? (Succession)

The two basic logic symbols on the precedence diagram are the node and the

precedence arrow.

Figure 6. CPM Logic Symbols

Forward Pass

+ The earliest time each activity in the network can start and finish.

+ The minimum overall duration of the project.

+ Early Finish, = Early Start, + Duration,

Backward Pass

page CON49__Copyright by www. TestMasters.com. All Rights Reserved. _ page CON49.

+ A backward pass through the logic network will produce the latest point in time

that each network activity can start and finish, and still maintain the minimum

overall project duration.

OURATION

Figure 7. CPM Forward Pass Equation

Figure 8. CPM Node Notation

> Early start time (ES) of an activity is the earliest point in time, taking into

account the network logic, that an activity may start

> Early finish time (EF) is the earliest time the activity may finish.

page CONSO Copyright by www.TestMasters.com. All RightsReserved. __ page CONSO

+ Late finish time (LF) is the latest time that an activity may finish without delaying

the entire project,

[=

[FT 90

Figure 9. Backward Pass Equation

A critical activity can be determined from the logic network by applying either of the

following rules:

> The early start and late start times for a particular activity are the same.

> The early finish and late finish time for a particular activity are the same.

The duration must be equal to the difference between the ES and the EF or the

difference between the LS and the LF.

EF - ES = Duration or

LF - LS = Duration

Critical activities are linked together forming a path from the start activity to the finish

activity called a critical path.

FREE FLOAT = (FF) = The duration of time that an activity can be delayed without

delaying the project's estimated completion time and without delaying the start of any

succeeding activity. Free float is the property of an activity not a network path.

FREE FLOAT (J) = MINIMUM EARLY START OF ALL SUCCESSOR ACTIVITIES ~ EARLY FINISH (J)

INTERFERING FLOAT = (IF) = The time available to delay an activity without delaying

the project's estimated completion time, but delaying an activity into interfering float will

delay the start of one or more following noncritical activities.

INTERFERING FLOAT (J) = LATE FINISH (J)- SMALLEST EARLY START OF ALL SUCCESSOR ACTIVITIES

page CONS1 Copyright by www.TestMasters.com. All Rights Reserved. _page CON51

TOTAL FLOAT = (TF) = The amount of time that an activity can be delayed without

delaying the projects estimated completion time. Total float assumes that all preceding

activities are finished as early as possible and all succeeding activities are started as

late as possible.

TR = FF +IF

TF=LS-ES

TF =LF-EF

Float is the duration of time that is available to complete an activity beyond the activity's

duration,

Late start time (LS) is the latest time the activity may start without delaying the entire

project.

Velocity diagrams present a graphical picture of the relationship between time and the

accomplishment of an activity. The vertical axis of the diagram represents

accomplishment of a work task; cubic yards excavated, miles of road built, miles of

pipeline constructed. The horizontal axis presents construction time.

km 10

production

velocity

IS

LET LL

LA

o 1 2 3 4 5 6 7 8 9 10 month

Figure 10, Example Velocity Diagram

END OF SECTION

page CONS2___Copyright by www.TestMasters.com. All Rights Reserved. __ page CONS2

|. Project Planning - Problems

C. Project Schedules

D. Activity Identification and Sequencing

201. The estimate for a five-story office building included 72 doors on each of the upper

three floors. In developing the bid, the estimator used a production rate of 2.0 carpenter

man-hours to hang a door. The project superintendent is organizing the carpenter

crews to include three carpenters per crew. What is the duration (in days) of the activity

to hang all the doors on the upper three floors? Assume an eight-hour workday.

‘Assume one crew.

A) 6 Days

B) 12 Days

C) 18 Days

D) 24 Days

202. The estimate for a three-story dormitory included 30 plumbing fixtures on each of

the floors. In developing the bid, the estimator used a production rate of 1.6 man-hours

to install a fixture. The project superintendent is organizing the plumbing crews to

include two plumbers per crew. What is the duration (in days) of the activity to install all

the fixtures in the dormitory? Assume an eight-hour workday. Assume one crew.

A) 6 Days

B) 9 Days

C) 18 Days

D) 24 Days

page CONS3 __Copyright by www.TestMasters.com. All Rights Reserved. __page CONS3

203. What type of Gantt chart is illustrated below?

A) Milestones Gantt

B) Gantt with dependencies

C) Baseline Gantt

D) Timeline Gantt

TASK

JAN

FEB

MAR

APR

JUNE

JULY | AUG

‘SEP

oor] | c|13} =|

204. What is the duration in days of the project given the activities below using start to

finish precedence logic?

Activity Duration (Days)

AtoB

Btoc

CtoH

CtoD

DtoE

EtoF

FtoG

GtoH

A) 13 days

B) 17 days

©) 21 days

D) 24 days

page CONS4

3

6

Copyright by www.TestMasters.com. All Rights Reserved,

page CON54

205. Given the following data, how much is spent at the end of the 10" day?

Activit Expenditures ($1,000) Duration (days)

A 5 3

B 10 A 3

c 12.5 B 4

Do 4 A 2

E 3 D 5

A) $27,500

B) $31,500

C) $34,500

D) $36,000

208. In the activity-on-arrow network, below, the early start of Activity N is most nearly:

A) 16

B) 21

©) 23

D) 24

page CON55 Copyright by www.TestMasters.com. All Rights Reserved. __ page CONS

207 A CPM arrow diagram is shown below. Nine activities have been estimated with

durations ranging from 5 to 36 days. The minimum time (days) required to finish the

project is most nearly:

A) 40

B) 42

C) 45

D) 50

ORDER & DELIVER METAL BUILDING

TOE OETA DY

6. PROCURE

/ REINFORCING \

| ste.

i/ rane \

[: vogn REGUS ec TINE

AEXCAVATE \2. FORM S ef

FOOTINGS (5) OCS —~ ONGRADE AX BUILDING ELEMENTS

soar oe es sons “(0 owe" (©) NSH

\ ee

\_ snes _/ |

an /

\

\ _eprocurcuscsumeoussuonsneers /

‘35 DAYS

208. A workforce of six electricians has to install 420 light fixtures in a new office

building. Normally, two electricians working can install one fixture in 20 minutes. The

crews expect to have a 0.8 efficiency factor due to environmental conditions on this job.

The crews will be scheduled for 9 hour work days which include a one hour break for

lunch. The duration of this construction activity (days, hours) is most nearly:

Days hours

AS 8

B65

c)7 3

D218

page CONS8 __Copyriaht by www.TestMasters.com. All Rights Reserved. _page CONS6

|. Project Planning - Solutions

A. Project Schedules

B. Activity Identification and Sequencing

201. C. 18 DAYS

Using the number of doors and the production rate from the estimate:

Production rate: = (1 door/2 man hours)*(3 carpenters) =1.5 doors per hr

Per floor activity duration hours: (72 doors/floor)*(1 hour/1.5 doors) = 48 hr per floor

Per floor activity duration days: = (48 hours per floor/8 hours per day) = 6 days per floor

3 FLOORS * 6 DAYS PER FLOOR = 18 DAYS.

Using the number of fixtures and the production rate from the estimate:

Production rate: = (1 fixture/1.6 man hours)*(2 plumbers) = 1.25 fixtures per hr

Per floor activity duration hours: = (30 fixturesifioor)*(1 hour!1.25 fixtures) = 24 hr per floor

Activity duration days: = (24 hours per floor)/8 hours per day)*(3 floors) = 9 days

203. D) Timeline Gantt

This is a basic timeline Gantt. No milestones, dependencies, or baselines are included

204. D) 24 Days

A (3) B (6) ¢ (4) H

(2) (4)

D (3) EF (2 G

Path A to B to C to H duration = 3 + 6 + 4 = 13 days

Path A to B to C to Dto Eto F to G to H duration = 3 +6 +2+3+4+2+4= 24 days

page CONS7 __ Copyright by www.TestMasters.com. All Rights Reserved. _ page CONS7

205. C) $34,500

A(3) B(3) c(4)

D(2)

E(5)

Path A-B-C duration = 3+ 3 + 4 = 10 days

expenditures = 5,000 + 10,000 + 12,500 = $27,500

Path A-D-E duration = 3 +2 + 5 = 10 days

Expenditures = 4,000 + 3,000 = $7,000

Total Expenditures = 7,000 + 27,500 = $34,500

Do not double count expenditures for Task A.

206. C) 23

The longest path to the start of Activity N is defined by Path C-G-J-L and duration along

that path is 9+3+8+3=23

207. D) 50 days

Activities 7-4-5

30 + 10 + 10 = 50 days

208. C) 7 days, 3 hours.

Duration = (420)/(1/(20*2)*6*0.8*60"8)

Duration = 7.29 = 7 days, 3 hours.

END OF SECTION

page CONS8 __Copyright by www.TestMasters.com. All Rights Reserved. _ page CONS8.

Il, Means and Methods - Discussion

A. Construction Loads

B. Construction Methods

C. Temporary Structures and Facilities

Asphalt Designations

RC = RAPID CURE

MC = MEDIUM CURE

SC = SLOW CURE

PG = PERFORMANCE GRADING

RAP = RECYCLED ASPHALT PAVEMENT

HMA = HOT MIX ASPHALT

AC = ASPHALT CONCRETE

BM = BITUMINOUS MIX

HCM = HOT MIX ASPHALTIC CONCRETE

PG 64-22

PG = Performance Grading

64 = Seven day average high temperature (°C) of the pavement that the project location

will likely experience in its lifetime.

22 = Seven day average low temperature (°C) of the pavement that the project location

will likely experience in its lifetime

Productivity Rate(R), is the total quantity to be installed (Q) divided by the total

installation time (T)

Efficiency Factor = Actual working Time/ Total Time

Production Cost = Equipment costs per hour! Equipment production per hour

Backhoe (hoe) Productivity Example Problem 1

With a 45 minutes per-hour efficiency what is the best probable production in LCY/hr for

a 3.5cy short stick hoe excavating well blasted rock (fill factor =0.75)? The average

depth of excavation is 12 feet and the angle of swing is 50° (Cycle time = 22 seconds).

page CON5S9 _Copyright by www.TestMasters.com, Alll Rights Reserved. _page CONS9

Bucket size (Ley) 3.5 cy

Material well blasted rock fill factor 0.75 (given information)

Cycle time, (load, swing load, dump and swing empty) = 22 seconds (given information)

Looking for @ LCY solution, so do not need to apply a swell factor.

Efficiency = 45 minutes/60 minutes =0.75

Probable Production

= (Capacity)*(Efficiency)*(Fill Factor)/(Cycle Time)

3.5 CY * (0.75) * 0.75/ (22 seconds/60 seconds per minute)*(60 minutes/hour)

= 322 LCY/HR

Backhoe (hoe) Producti

Example Probl

2

If the loose well blasted rock weighs 2,640 pounds per cubic yard, what is the

productivity in tons per hour.

P = (322 LCY/HR)*(2,640 pounds/LCY)*(1 ton/ 2,000 pounds) = 425 tons per hour

To estimate loading time you need to know:

> Payload capacity of the hauling unit

> Payload of the hoe bucket

> Hoe cycle time

Payload will be limited by either the heaped (volumetric) capacity or by the load weight

(gravimetric).

Total loading time = (number of bucket passes) x(hoe cycle time)

Number of bucket passes = Payload of Hauler/Payload of Bucket

ox |

Number of bucket passes =

page CON60___Copyright by www.TestMasters.com. All Rights Reserved. _ page CON60

page CON61

Figure 12. Vertical Formwork - A Layered System

Copyright by www.TestMasters.com. All Rights Reserved.

page CON61

A temporary Structure is any means or methods which provide temporary suppor,

access, enhancement, or otherwise facilitate the construction of permanent structures,

These include:

v

Concrete Formwork

Scaffolding

Falsework/shoring

Cofferdams

Underpinning

Diaphragmislurry walls

Earth-retaining Structures

Construction Dewatering

v

vvvvvyY

Horizontal pressure on the surface of the forms, proportional to the density and depth of

the conerete in a liquid or semiliquid state.

Lateral pressure of concrete on vertical forms. Figure (a) shows a full liquid head

pressure. Figure (b) shows a situation where the concrete began to harden, thus

exerting a pressure at the lower part of the form that is less than the full liquid head

pressure (depth of fluid concrete from top of placement is fy). Figure (c) shows a

situation similar to Figure (b), but with a lower rate of filing the forms; this results in yet

a lower maximum pressure and a smaller height of liquid head pressure, hz < Mn

(a) (b) (o)

page CONG2 __Copyright by www.TestMasters.com. All Rights Reserved. __ page CONG2

BCWS = Budgeted Cost of Work Scheduled = Planned Value

BCWP = Budgeted Cost of Work Performed = Earned Value

ACWP = Actual Cost of Work Performed = Actual Value

Variances

SCHEDULE VARIANCE =SV= — BCWP-BCWS

‘SV > Ois good (ahead of schedule)

The SV will be 0 at project completion because then alll of the planned values will have

been earned

COST VARIANCE =CV= BCWP - ACWP

CV > 0 is good (under budget).

Indices

Cost Performance Index = CPI = (BCWP/ACWP) = (Eamed/Actual)

CPI < 1 means that the cost of completing the work is higher than planned (over budget)

GP1=1 means that he cost of completing the work is right on plan (good)

CPI > 1 means that the cost of completing the work is less than planned (under budget)

(good or sometimes bad)

‘Schedule Performance Index = SPI = (BCWP/BCWS) = (Earned/Planned)

SPI > 1 is good (ahead of schedule).

Forecasting

BAC

Budget at Completion = Original Project Estimate

ETC = Estimate to Complete = (BAC - BCWP)/CPI

EAC = Estimate at Completion = (ACWP + ETC)

‘To-Complete Performance Index (TCP!)

page CON63 __Copyright by www.TestMasters.com. All Rights Reserved. _ page CON63

The TCPI provides a projection of the anticipated performance required to achieve

either the BAC or the EAC. TCPI indicates the future required cost efficiency needed to

achieve a target BAC (Budget At Completion) or EAC (Estimate At Complete). Any

significant difference between CPI, the cost performance to date, and the TCPI, the cost

performance needed to meet the BAC or the EAC, should be accounted for by

management in their forecast of the final cost.

For the TCPI based on BAC (describing the performance required to meet the original

BAC budgeted total)

TCPI = (BAC — BCWS)BAC — ACWP)

For the TCPI based on EAC (describing the performance required to meet a new,

revised budget total EAC):

‘TCPI = (BAC - BCWP)(EAC — ACWP)

Independent Estimate At Completion (IEAC:

The IEAC is a metric to project total cost using the performance to date to project

overall performance. This can be compared to the EAC, which is the manager's

projection

IEAC = ACWP + (BAC - BCWP)/CPI

Equipment Productivity

LOADER PRODUCTION = (3600°Q*F*E)/[T*60*(1+SWELL)] (Units are CY/hour)

LOADER PRODUCTION = (3600*Q"F*E*W)/[T*60*2000] (Units are Ton/hour)

Q = Heaped bucket capacity (LCY)

F = Bucket fill factor

E = Efficiency (minutes per hour)

T= Cycle time (seconds)

W= Aggregate weight (LB/CY)

National Pollutant Discharge Elimination System (NPDES)

page CON64 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON64

1. Load with exchange

3. Dump and

maneuver

Figure 13. Earthwork Operations

Manufacturer's specification sheets will list both struck and heaped capacities.

‘Struck material measured straight across the top of the body.

SSsnnonnn

Figure 14. Dump Truck with Struck Material

Figure 15. Heaped material based on a 2:1 slope above hauler bodies.

page CON65 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON65

‘Trucks Required = (Truck Cycle Time)/Loader Cycle Time

Tower Cranes

The flexibility of its freely suspended hook moving in three planes provides a

tremendous advantage in terms of load pick-up and positioning. Advantage of having

both the operator and jib above the construction site. The hoist cable runs from the hoist

drum located on the crane's counter jib, through the jib and then to the trolley and down

to the hook.

SLEWING RING LOCATION

Fixed tower-type crane has the slewing ring located at the top of the tower and the jib

slews around the vertical axis of the tower

Slewing ring located at the base of the tower and both the tower and jib slew relative to

the base.

Fixed base (stationary) — either free standing or braced to the building structure

Climbing ~ lifts itself on the building structure as the work progresses. Usually climbs

through an opening within the structure. Must insure that the structure's framing has

sufficient load carrying capacity to support the added stresses of the combined weight

of the crane and the lifted loads.

Traveling — on rails or wheels

Maximum free standing height is the height to which a tower crane can safely rise from

its base without the need of external bracing for lateral stiffing. Maximum braced height

is the height to which a tower crane can safely rise from its base with additional external

bracing for lateral sttfing

page CON66__Copyright by www.TestMasters.com. All Rights Reserved. _page CON66.

page CON67

Boom tip extension (jib)

__— Crawler mounting

+——Hook

Copyright by www.TestMasters.com. All Rights Reserved.

page CON67

Trt

Horizontal jib Ling boom Articulate >

FIGURE 3-29. Major types of tower cranes.

‘pane

FIGURE S-30, Terminology of horizontal jib tower crane. (Courtesy of Manitowo:)

END OF SECTION

page CON68___Copyright by www.TestMasters.com. All Rights Reserved. __ page CON68.

Mh Means and Methods - Problems

A. Construction Loads

B. Construction Methods

C. Temporary Structures and Facilities

301. Which of the following would a cast-in-place ground slab or floor not use to

separate steel reinforcing bars or wire mesh from the ground?

|. Precast cementitious blocks

Il Metal chairs

Ill. Wood risers

IV. Wire bolsters

V. Plastic bar supports

VI. Cellulose spacer blocks

A) Iiland VI

B) |, Il, and VI

C) LIV, and V

D) Hi, 1V, Vand VI

302. Which of the following types of joints typically does not use dowels?

|. Construction joints

N. Control joints

I. Contraction joints

\V. Expansion joints

V. Isolation joints

A) land V

B) land V

©) Illand iv

D) 1, Ml, Vand V

page CON69___Copyright by www.TestMasters.com. All Rights Reserved. _page CON69

303. In addition to location of the pour, tremie concrete poured underwater differs from

common conerete poured in the air primarily in its

‘A) placement method and equipment

B) components and additives

C) specific gravity

D) aggregate size

304. In very hot weather, thin floor slabs of newly poured concrete would most normally

be:

A) Sprinkled with rock salt or potassium chloride

B) Sprayed with or submerged with water

C) Kept insulated by dry burlap insulation

D) Covered by cube or slush ice.

305. Which statement about the placement of asphalt is NOT true?

A) The hotter the mix temperature above 300°F at the time of initial compaction, the

better the results.

B) In general, too low a percentage of air voids results in a shortened roadway life.

C) Poor compaction will result if the mix is too cold at the time of initial compaction.

D) The mix is usually in the temperature range of 260°F to 280°F at the time of

spreading,

306. If the water-to-cement ratio of concrete is decreased, which statement about the

concrete is NOT true?

‘A) Water tightness is decreased.

B) Workability is decreased

C) Strength is increased

D) Durability is increased.

page CON70 Copyright by www.TestMasters.com. All RightsReserved. _ page CON70

307. When a concrete slab is placed on a hot windy day, it is NOT permissible to:

‘A) Add field water as needed to obtain the desired consistency and workability

B) Keep mix water cool and aggregate moist by shading and sprinkling,

C) Spray or protect the concrete surfaces with wet burlap to retard hardening.

D) Moisten the forms and the reinforcement prior to placement of concrete to

minimize evaporation.

308. A four lane concrete highway is to be paved in two passes, two adjacent lanes at a

time. To facilitate connecting with the subsequent pour, the edge of the concrete is fitted

with concrete dowels running transverse to the direction of travel, and the edge is

keyed. This joint would most likely be referred to as a

A) Transverse, tied and keyed expansion joint

B) Transverse, tied and keyed construction joint

©) Skewed contraction joint

D) Longitudinal tied construction joint

309. It is 100° F and you are placing concrete. In order to keep your aggregate cool,

which of the following methods are applicable?

|. Add ice to the conorete mix

II. Shade and cool (spray water on) your aggregate piles.

Ill, Paint your equipment white

Al

B) Il

©) land tl

D) 1,1. And tit

page CON71 Copyright by www.TestMasters.com. All RightsReserved. _page CON71

310. The compressive strength of concrete depends primarily on which of the following

factor(s):

1 Shape of aggregate particles

MV Water- cement ratio

Ml Conditions of mixing

IV. Curing and aging time

A) land il

B) Honly

C) |, Wand iv

D) All of the above

311. Without taking special precautions, water used in mixing concrete must be:

A) Clean and free of substances deleterious to concrete or reinforcement

B) Non potable

C) Deionozed

D) Salty

312. A loader has a full-bucket capacity of 3 cubic yards and the average time required

to place one bucket load of soil into a truck is one minute. The loader is supported by

four trucks with a volume of 15 cubic yards each and a cycle time of 12 minutes plus the

time to load the truck.

What is the ideal productivity of this system?

A) 180 cy/hr

B) 212 cy/hr

C) 277 cyfhr

D) 300 cy/hr

page CON72 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON72

Use the following information to work Problems 313 and 314.

A backhoe with a bucket capacity of 1 cubic yard has a standard production rate of 960

cubic yards per day for an 8 hour day with a 30 second cycle time. The following work

conditions at the site affect the productivity of the backhoe.

Work Conditions at the Site Factors

Bulk Composition 0.954

Soil Properties and water content 0.983

Equipment idle time for worker breaks 0.800

Management efficiency 0.700

313. Determine the job site productivity of the backhoe.

A) 504 CY

B) 637 CY

c) 800 CY

D) 960 CY

314, Determine the actual cycle time of the backhoe.

‘A) 30 seconds

B) 40 seconds

C) 50 seconds

D) 87 seconds

page CON73 Copyright by www.TestMasters.com. All Rights Reserved. _ page CON73.

Use the following information to work Problems 315 and 316

A dump truck with a capacity of six cubic yards is used to dispose of excavated

materials. The distance from the dump site is 4 miles and the average speed of the

dump truck is 30 mph. The dump truck standard dumping time is 30 seconds. The job-

site productivity of the backhoe is 504 cubic yards per 8-hour day with a cycle time of 57

seconds. The backhoe has a bucket with a capacity of 1 cubic yard, The job site

productivity of the backhoe is modified by a swell factor of 1.1. The only factors affecting

the job-site productivity of the dump truck are 0.80 for equipment idle time and 0.70 for

management efficiency.

315. Determine the job site productivity of one dump truck per 8 hour day.

A) 60.0 CY

B) 72.6CY

C) 80.0 CY

D) 92.0 CY

316, Determine the number of trucks needed daily.

A) 6 Trucks

B) 7 Trucks

C) 8 Trucks

D) 9 Trucks

page CON74 __Copyright by www.TestMasters.com. All Righls Reserved. _ page CON74

317. In shored construction, which factors do not influence the length of time between

pouring concrete and stripping the forms?

I

Ml

I.

v.

Vi

Weather

Project specifications

Developed concrete strength

ACI 347

Project schedule

Local ordinances

A) land Ill

B) land IV

©) Hand IV

D) Vand VI

318, What is the design load for an 8-foot tall concrete wall to be poured at a rate of 4

fthr, internally vibrated at a temperature of 90° F? The conorete mixture will use Type |

cement without retarders and is estimated to weigh 150 pef.

A) 275 PSF

B) 550 PSF

C) 600 PSF

D) 1100 PSF

page CON75 Copyright by www.TestMasters.com. All Rights Reserved. _page CON75.

319, Determine the maximum design wall pressure (psf) on concrete forms that will be

used for the following data.

Conerete weight = 180 pef

Height of wall = 124t8in

Rate of Placement (R) = 5 ft/hr

Concrete Temperature = = 80°F

A) 600 psf

B) 712 psf

C) 1,900 psf

D) 2,000 psf

320. Normal weight concrete with a 3-inch slump is poured at the vertical rate of 4-feet

per hour into the form for a 12-foot high retaining wall. The concrete is vibrated to a

depth of 4-feet. The temperature is 60 °F. Most nearly, what is the design hydrostatic

pressure experienced by the formwork?

A) 500 PSF

B) 600 PSF

C) 750 PSF

D) 1,800 PSF

321. Per ASCE 37-02, the formwork for slabs must be designed to resist all but which

one of the following:

‘A) Impact loading from the placement of concrete.

B) Weight of the concrete

C) Construction loads

D) Additional live load generated by workers and equipment.

page CON76 __ Copyright by www.TestMasters.com. AllRights Reserved. __ page CON76

322, Recently your company was awarded a large commercial office building project

which is comprised of a reinforced concrete superstructure. You have the task of

designing the formwork. If you use Douglas-fir-larch (d-F) for the basis of your design

calculations, the proper value to use for the load duration factor Cx for the wood is most

nearly:

A) 0.90

B) 1.00

©) 1.15

D) 1.25

323. You are designing a free-standing masonry wall that is 16 feet in height. It will be

laterally braces during construction. According to CMWB 2012, the required strength of

masonry elements and connections to bracing systems must be designed in

accordance with which of the following load combinations:

1.0.90 + 1.3W

I. 1.20 + 1.6W

Ill, 0.9D + 1.6W

IV, 1.20 + 1.3W + 1.2P

A) | only

B) | and IV

C) Ill and IV

D) Il only

324. The minimum factor of safety against rotational failure for permanent slopes under

long-term, non-seismic conditions influence occupied structures is closest to:

A) 1.0

B) 14

co) 1.5

D) 3.0

page CON77 __Copyright by www. TestMasters.com. All Rights Reserved. _ page CON77.

325. A wall form is subjected to a wind load of 20 psf is prevented from overturning by

diagonal braces spaced at 8 feet on center along the length of the wall form as shown

in the figure. The connection at the base of the form at Point A is equivalent to a hinge.

Ignore the weight of the form. The axial force (in pounds) resisted by the brace is most

nearly:

‘A) 2,050 pounds

B) 2,560 pounds

C) 2,900 pounds

D) 4,525 pounds

326. A crane with a 100-foot boom is being used to set a small load on the roof of the

building shown. The minimum standoff (Point A) from the center of the building to the

centerline of the boom is indicated. What is the maximum distance (in feet) from the

edge of the building that the load can be placed on the roof?

A) 16 feet

B) 25 feet

C) 30 feet

D) 36 feet

crane boom foot

BUILDING

5 ft 10 fils

®

centerline

crane

END OF SECTION

page CON78 Copyright by www.TestMasters.com. All RightsReserved. _ page CON78.

ll. Means and Methods - Solutions

A. Construction Loads

B. Construction Methods

©. Temporary Structures and Fa

page CON79___ Copyright by www.TestMasters.com. All Rights Reserved. __ page CON79.

301. A. IILAND VI

After curing, wood and cellulose products would absorb moisture and attract termites.

They are not used to support bars in slabs. All of the other listed items are used to

separate steel reinforcing bars or wire mesh from the ground.

302. B) land V

Control joints, as a method of controlling where cracking will occur, are typically created

by saw cutting, Although steel reinforcing may be present at a control joint, dowels will

not, Isolation joints separate concrete slabs from columns, footing, and walls, They are

used to separate elements that experience differences in loading (soil pressure) and

settlement. No connection between the elements should exist. Expansion and

contraction joints can be doweled; the slab slides along the dowel bar as the slab

expands or contracts. Construction joints are doweled to ensure complete load transfer

when subsequent portions of the slab are poured

303. A) Placement method and equipment

Tremie concrete gets its name from the delivery pipe (the tremie) that reaches from

above the water surface to the lowest submerged delivery point. The lower end of the

tremie is kept buried in freshly delivered concrete. The concrete is fairly normal in its

chemistry and components,

304. B) Sprayed with or submerged with water

While ice could be used to reduce temperatures until the cooler night arrives, it is easier

and more cost effective to rely on evaporation of liquid water (that is the swamp cooler

effect) to lower the temperature.

305. A)The hotter the mix temperature above 300°F at the time of initial

compaction, the better thi Its.

If a mix is too hot it will push up in front of the roller and cause poor compaction

Reference (Asphalt Handbook, P. 289).

page CON80___Copyright by www.TestMasters.com. All Rights Reserved. _ page CON80

htness

306.

Water, reased

Water tightness is the ability of concrete to hold or retain water without visible leakage

Generally, less permeable concrete is more watertight. A lower water-cement ratio

reduces permeability, thereby increasing water tightness.

Reference: Portland Cement Association, Design and Control of Concrete Mixtures.

307. A) Add field water as needed to obtain the desired consistency and

workability.

308. D) Longitudinal tied construction joint

The joint runs longitudinally along the highway and is tied by the dowels to the next

phase of construction (that is the next pour). The key is probably an unnecessary detail,

as the dowels will prevent both vertical and lateral separation of the separate pours.

309 D)

All of the above conditions are allowable for keeping your concrete cool. Ice is water

and does not change the actual water to cement ratio of the mix as long as the mix is

designed for the added ice.

310. B) Il only

The compressive strength of concrete depends primarily on the water-cement ratio.

However, other factors such as characterization of the cement, conditions of mixing,

character and grading of the aggregate, size of the aggregate, size and shape of the

specimen, curing and aging, temperature and moisture content at the time of testing

also have bearing on the compressive strength.

344. A) Water for concrete should not contain deleterious substances.

page CON81 __ Copyright by www. TestMasters.com. All RightsReserved. _ page CON81

342, A) 180 cy/he

Time to load one truck = (15 cy)/(3 cy/min) = 5 minutes,

Cycle time for one truck = 5 minutes to load + 12 minutes to travel, dump and return

= 17 minutes

Loading time for four trucks = 4*5 = 20 minutes

Therefore, an empty truck is always available to load

Ideal Productivity = [(60 minutes/hour)/(5 minutes/truck)}*(15 cubic yardsitruck)

= 180 cy/hr

313. A) 504 CY

Productivity = (960 cy)(0.964)(0.983)(0.8)(0.7) = 504 CY

314, D) 57 seconds

Cycle Time = (30 seconds)[0.954*0,983°0.8*0.7) = 57 seconds

315. — B) 72.6 CY

Truck travel time = [(2)(4 miles)(3,600 seconds/hour)}/{(30 mph)(0.8)(0.7)

= 1,714 seconds

Truck fill time = [(67 seconds)/(0.8°0.7)}*(6 oy/1 cy)

= 611 seconds

Truck dump time = (30 seconds)/(0.8*0.7)

= 54 seconds

Total cycle time = 1,714 + 614 + 54 = 2,379 seconds

Job site productivity of one dump truck

= (6 CY)(8 hours)(/3,600 seconds/hour)/(2,379 seconds)

=72.6CY

page CON82 __Copyright by www.TestMasters.com. All Rights Reserved. _ page CON82

346. C) 8 Trucks

N= (1.1)(604 CY)(72.6 CY) = 7.6

Round up use 8 trucks

317. D) V AND VI

The length of time that formwork is left on before being stripped is an engineering

decision, under the jurisdiction of the project engineer. Guidance to the contractor will

be placed in the project specifications. The engineer will consider various factors when

writing the specifications including developed conerete strength and loading. ACI 347

recommendations may be considered in some situations when the actual requirements

are difficult to determine. The specifications may have options dependent on the local

temperature, the need to remove insulating formwork, or cool the conerete during

curing. The project schedule and local ordinances should not be permitted to dictate the

time between pouring concrete and stripping forms

348. C. 600 PSF

REFERENCE: ACI 347, LINDEBURG CH 49

P = Cw'Co"(150 + 9000°RIT)

Cw = 1.0 UNIT WEIGHT COEFFICIENT

Cc= 1.0 CHEMISTRY COEFFICIENT

R=4

T=90

P = 1*1"(150 + 9000*4/90) = 550 PSF

Pmax = WH = 150 * 8 = 1,200 PSF

Pmin = 600(1) = 600 PSF

550 < 600 < 1200

DESIGN LOAD = 600 PSF

page CON83 __Copyright by www.TestMasters.com. All Rights Reserved.

_page CON83

349. B) 712 psf

Reference ACI 347

R= 5 fhr

T=80°F

H= 1267 ft

Cw = 1.0 UNIT WEIGHT COEFFICIENT

Co= 1.0 CHEMISTRY COEFFICIENT

P = Co*Cw*(150 + 9000R/T)

P = (1)(1)(150 + 9000(5)/80))

P=712 psf

Pmax = 150H = 150(12.67) =

900 psf

Pmin = Cw*600 = 1(600) = 600 psf

Pmin < P< Pmax

600 < 712 < 1900

Use P Design = 712 psf

page CONS4 Copyright by www. TestMasters.com. All Rights Reserved.

page CON84

320. C) 750 psf

Reference ACI 347, LINDEBURG P. 49-7

R=4 hr

T= 60°F

H=12¢t

Cw = 1.0 UNIT WEIGHT COEFFICIENT

Co= 1.0 CHEMISTRY COEFFICIENT

P = (1)(1)(150 + 9000R/T) = (1)(1)(150 + 9000(4)/60)

P= 750 psf

Pmax = 150H = 150(12) = 1,800 psf

Pmin = Cw"600 = 1(600) = 600

Pmin < P < Pmax

600 < 750 < 1800

Use P Design = 750 psf

324. D) Addi /@ load generated by workers and equipment.

Reference: Per 4.1.1 of code, Page 11

322, D) 1.25

Reference: NDS Table 2.3.2 Page 11 Construction Load.

323. C) Ill and IV

Reference Page 19 section 5.4.2, eq. 5.4.2-1 and 5.4.2-2

324.C.1.5

References: Day, Geotechnical and Foundation Engineering, 1999 Pages 10-27

page CON85 Copyright by www.TestMasters.com. All Rights Reserved.

325. C) 2,900 Pounds

Reference: Hurd, Formwork for Concrete, ACI SP-4, Seventh Edition, 2005.

w = (20 psf)(8 ft) = 160 Ib/ vertical foot per brace location

ZMa=0

EMa = (160 Ib/t)(16 #)(16 U2) — 10f4(R,)

Rx= 2,048 pounds

Axial Load in brace = (2,048)'2°° = 2,896 pounds

1

326, B) 25 feet

Reference: Shapiro, Shapiro and Shapiro, Cranes and Derricks, Third Edition, 2000,

page 244

Tan@= 40/30 = = 53.13°

(cos 53.13° ) * (100 feet) = 60 feet 40 ft 50 ft

60-35 = 25 feet s0f ©

END OF SECTION

page CON86__Copyright by www.TestMasters.com. All Rights Reserved. _ page CON86

VII, Site Development Discussion

A. Excavation and Embankment (e.g. cut and fill)

B. Construction site layout and control

Earthmoving is defined as the process of moving soil or rock from a location to a new

location to changing its conditions according to engineering requirements of a project,

(grading, elevation, compaction...)

Earthmoving activities are excavating, loading, hauling, placing (dumping and

spreading), compacting, grading, and finishing.

Figure 16. Three Link Earthwork System

Earthwork is based on surveying coordinates (centerline or baseline, stations, horizontal

curves and vertical curves) and the corresponding geometric views (plan, profile and

cross-sections)

Figure 17. Plan View of Highway

page CONS? _Copyright by www. TestMasters.com. All Rights Reserved. __ page CON87

The plan view is looking down on the proposed work and presents the horizontal

alignment of features. The profile view is a cut view typically along the centerline of the

work. It presents the vertical alignment of features.

gle 8

ag a8

a +e PVIELEV = 123.73,

ile Sa] |e, eustasnems al

5g ea] |t8 as

#8) lag 2g

288% | >. & Bla

ce IK] 188 slg

Ss IRB a\e

é

&

5

le Se ge sis ge ais ae a ze |p 5

7-00 Toeo0 Tr Tee 0 ry

Figure 18. Profile View of Highway

Cross-Section View is a view formed by a plane cutting the work at a right angle to its

long axis. When the ground surface is regular, cross-sections are typically taken at

every full station (100 feet). When the ground is irregular, sections must be taken at

closer intervals and at points of change in elevation

page CONS8 __Copyright by www.TestMasters.com. All Rights Reserved. __ page CON88.

}

CLStation = 0+00

CL Road Elevation = 158.00

Sketch not to scale

Figure 19. Cross-Section View

Existing Natural Ground

Finished Grade

Existing Natural Ground

CL Station = +50,

CL Road Elevation = 134.00

Sketch not to scale

Figure 20. Cross-Section View

page CON89___Copyright by www.TestMasters.com. All Rights Reserved. _ page CON89.