Professional Documents

Culture Documents

Re77502 2014-4

Uploaded by

orlandolanchipaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Re77502 2014-4

Uploaded by

orlandolanchipaCopyright:

Available Formats

Winch drives

MOBILEX GFT-W

for mobile applications RE 77502

Edition: 02.2016

Replaces: 04.2014

▶ Sizes GFT 17 W to GFT 450 W

▶ Output torques between 14 and 325 kNm

▶ Rope pull forces from 67 to 684 kN

Features Content

▶ Compact, space-saving planetary gearbox design Functional description 2

▶ Planet wheel carried in full-complement bearings Version, overview 3

▶ Robust bearing system absorbing the forces exerted by Design, classification 4

the rope pull Dimensions, Technical data 6

▶ Easy assembly Customer specification winch drive application 15

▶ Easy oil change Notes 18

▶ Integrated static multiple-disk parking brake Product range 20

▶ Low-noise operation

Additional informationen at:

www.boschrexroth.com/gears

RE 77502/02.2016, Bosch Rexroth AG

2/20 MOBILEX GFT-W | Winch drives

Functional description

Functional description Lubrication

The gears and bearings are splash-lubricated. The drive

Description units are maintenance-free save for periodic oil changes,

which are convenient to make. Only the oils specified in the

The hydrostatic Rexroth winch drives MOBILEX GFT-W

operating manual should be used in the gearboxes.

are the ideal drive components for winches. They have

The change intervals for different operating conditions are

proven their worth in the most arduous applications

also specified in the operating manual.

and under tough operating conditions. MOBILEX GFT-W

winch drives are used in all kinds of winches - mobile and

Spring pressure multiple-disk parking brake

crawler cranes, railroad cranes, shipboard, dockside and

In the standard version, one spring-loaded, hydraulic

container cranes. Due to their extremely compact design,

release spring pressure multiple-disk parking brake is

the gear units can be mounted inside the rope drum in

installed on the drive end.

a space-saving manner. They are designed for ease of

TBr. sta. min = 1,6 • T1 (Input torque)

installation and maintenance. High-quality manufacturing

processes and the use of case-hardened gearwheels as well

The spring pressure multiple-disk parking brake is not a

as quenched, tempered and surface-hardened ring gears

service brake, but a static parking brake, which must not

warrant outstanding load-carrying capacity, operational

be used for braking the load.

safety and low-noise running characteristics.

The device engineer/operator must provide a separate

service or emergency brake if necessary.

The teeth of the gearwheels are designed according to

The holding torque is multiplied according to the selected

standard specifications and our own strength calculations,

transmission.

which have been developed based on our comprehensive

konw-how and are optimally adapted to our manufacturing

processes. The drives provide optimum total efficiency due

Hydraulic motors

to the use of Rexroth hydraulic motors, among other things The gearbox is designed for direct flange-attachment of a

variable or fixed-displacement motor (preferably a Rexroth

hydraulic motor).

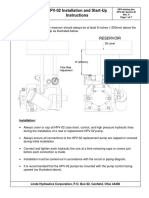

Three-stage hydrostatic Rexroth winch drive MOBILEX GFT-W

with static spring pressure multiple-disk parking brake and

connection for Rexroth hydraulic motor

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 3/20

Version, overview

Version, overview Options

Upon request, the drives can be supplied with the following

Explanation version accessories:

2000 = Oil inlet, oil outlet, oil level on the gear cover

4000 = Oil inlet, oil outlet, motor-side oil level

Counter bearing, hoisting drum, winch frame

6000 = Oil inlet, oil outlet, motor-side oil level In addition to the standard delivery scope, the winch drives

Installation of 2 gearboxes in a hoisting drum of series can also be delivered:

possible – with counter bearing

8000 = Optional with back stop – with counter bearing and hoisting drum

(built-in between gearbox and holding brake) – with counter bearing, hoisting drum and winch frame

9000 = Special version

Limit switches

Upon request, special counter bearings can be designed

with a connection option for specific gear cam limit

switches.

Overview of MOBILEX GFT-W Winch Drives

1)

Type/design Output torque Rope pull max. 2) Gear ratio

GFT-W T2 max from/to

Nm kN i

GFT 17 W2 14000 67 37,6 - 54

GFT 17 W3 14000 74 77,9 - 102,6

GFT 24 W3 19000 99 90,1 - 137,2

GFT 26 W2 18000 84 42,9 - 62

GFT 36 W3 26000 118 67 - 138,8

GFT 40 W2 27000 108 35,9 - 59,1

GFT 50 W3 37500 150 84,2 - 125,6

GFT 60 W3 42500 164 63,8 • 94,8

GFT 80 W3 67000 231 61,3 - 215

GFT 110 W3 100000 300 79,5 - 173,9

GFT 160 W3 140000 373 133 - 251

GFT 220 W3 200000 471 97,7 - 293

GFT 330 W3 275000 595 168,9 - 252

GFT 450 W4 325000 684 293,4 • 421,7

1)

Design according to FEM L2, T5, M5

2)

Based on a theoretical 1st layer winding diameter Dws

For our current range of

MOBILEX GFT-W winch drives, visit us at

www.boschrexroth.com/gears

RE 77502/02.2016, Bosch Rexroth AG

4/20 MOBILEX GFT-W | Winch drives

Design, classification

Design, classification Fleet Angle

Observing the admissible fleet angle ∝ is prerequisite for

Application Conditions proper cable winding.

The fleet angle ∝ should not be

The gearboxes have been designed for use at ambient

smaller than 0,5°, so that the rope

temperatures of between -20°C and +40°C. Environmental

does not ascend the drum flange

influences such as salt water, safety air, sand, dust,

and runs safely into the next layer.

overpressure, heavy vibrations, extreme shocks and

The fleet angle ∝ should not be

ambient temperatures, aggressive media, etc. will affect the

larger than 1,5°, so that the rope in

function of the product. Such influences must be specified

αmin. αmax. the first rope layer does not get

to ensure that the winch drive is designed to safety meet

pulled against the groove and by

the requirements.

several rope layers on the rope drum

are properly wound up to the drum

Gearbox design

flanges.

The gearbox design is based on many years of practical

experience. The maximum output torques T2 max indicated

Gearbox selection

under Technical Data relate to FEM Section I, 3rd issue

• T2 = output torque

and Section IX (FEM - Fédération Européene de la

F = rope pull in [N]

Manutention), as well as DIN 15020, collective load class

DW = relevant winding diameter in [m]

L2, service time category T5 corresponding to driver group

M5. The reference output speed is 25 revolutions per F • DW

T2 =

minute maximum. If the winch is classified into a different 2

driver group, the required output torque must be converted • T2K = corrected output torque

by applying factor K (see table). K factor according to the service time category and

This results in the maximum permissbile output torque collective group given in the table

for the new classification. Whether or not the selected T2K = T2 • K

overall classification is feasible, will be determined by the • T2K of the gearbox to be selected must be ≤ T2 max

specialists of Rexroth. (according to the bulletin).

See also gearbox design

See page 15 for a data sheet relating to the winch drive

design.

Driver Groups and Service Time Categories to FEM, section I, 3rd edition 1987

(FEM: Fédération Européene de la Manutention)

Service time category T2 T3 T4 T5 T6 T7 T8

Assumed average service time per day in hours 0,25 - 0,5 0,5 - 1 1-2 2-4 4-8 8 - 16 > 16

400 - 800 - 1600 - 3200 - 6300 - 12500 - 25000 -

Theoretical service life in hours

800 1800 3200 6300 12500 25000 50000

Load spectrum Drive group with K factor

Maximum loads occuring in

M1 M2 M3 M4 M5 M6 M7

L1 light exceptional cases only, side

0,90 0,90 0,90 0,90 0,95 1,05 1,2

loads constantly

Collective Groups

small, medium and maximum M2 M3 M4 M5 M6 M7 M8

L2 medium loads about equally distributed 0,90 0,95 0,95 1 1,15 1,30 1,50

over service time

M3 M4 M5 M6 M7 M8 M8

L3 heavy loads always near maximum

1,05 1,05 1,10 1,25 1,40 1,60 1,80

very M4 M5 M6 M7 M8 M8 M8

L4 Always maximum load

heavy 1,25 1,30 1,45 1,65 1,85 2,10 2,40

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 5/20

Design, classification

Classification examples (see FEM section I, 3rd edition, table T.2.1.3.5.)

Type of crane Component Type of Driver

(Designation) operated 1)

Hoisting Swinging Level Trolley Crane

luffing travelling travelling

Erection cranes M2-M3 M2-M3 M1-M2 M1-M2 M2-M3

Loading bridges Hooks M5-M6 M4 - M4-M5 M5-M6

Loading bridges Grab or magnet M7-M8 M6 - M6-M7 M7-M8

Workshop cranes M6 M4 - M4 M5

Overhead travelling cranes, ram cranes,

Grab or magnet M8 M6 - M6-M7 M7-M8

Scrapyard cranes

Unloading bridges, container gantry

Hooks or spreaders M6-M7 M5-M6 M3-M4 M6-M7 M4-M5

cranes

Other portal cranes

hooks M4-M5 M4-M5 - M4-M5 M4-M5

(with trolley and/or slewing ring)

Unloading bridges, container gantry

Grab or magnet M8 M5-M6 M3-M4 M7-M8 M4-M5

cranes (with trolley and/or slewing ring)

Berth cranes, shipyard cranes,

Hooks M5-M6 M4-M5 M4-M5 M4-M5 M5-M6

Dismantling cranes

Dockside cranes (slewable, gantry type, . .

Hooks M6-M7 M5-M6 M5-M6 - M3-M4

.), floating cranes, floating sheerlegs

Dockside cranes (slewable, gantry type, . .

Grab or magnet M7-M8 M6-M7 M6-M7 - M4-M5

.), floating cranes, floating sheerlegs

Floating cranes and floating sheerlegs for

M3-M4 M3-M4 M3-M4 - -

very high loads (normally above 100 t)

Shipboard cranes Hooks M4 M3-M4 M3-M4 M2 M3

Shipboard cranes Grab or magnet M5-M6 M3-M4 M3-M4 M4-M5 M3-M4

Tower cranes for construction sites M4 M5 M4 M3 M3

Derrick tower gantry M2-M3 M1-M2 M1-M2 - -

Railway cranes approv. or service in trains M3-M4 M2-M3 M2-M3 - -

Vehicle-mounted cranes Hooks M3-M4 M2-M3 M2-M3 - -

1)

The column only shows some typical areas of winch use for informative purposes.

RE 77502/02.2016, Bosch Rexroth AG

6/20 MOBILEX GFT-W | Winch drives

Dimensions, Technical data

Dimensions, Technical data

Dimensions

Dimensions of the

counter bearing

see page 14

Optional (only in connection

with version ≥ 4000)

Technical data

Type/design Output Rope Transmission ratio Holding Hydraulic motor

GFT-W torque pull torque

T2 max max. TBr max

Nm kN i Nm

GFT 17 W2 2000 14000 67 37,6 • 45,4 • 54 460 A6VE 55 / A2FE 45 • 56 • 63

GFT 17 W2 4000 14000 67 37,6 • 45,4 • 54 460 A6VE 55 / A2FE 45 • 56 • 63

GFT 17 W3 2000 14000 74 77,9 • 88,2 • 102,6 460 A6VE 55 / A2FE 45 • 56 • 63

GFT 17 W3 4000 14000 74 77,9 • 88,2 • 102,6 460 A6VE 55 / A2FE 45 • 56 • 63

GFT 24 W3 2000 19000 99 90,1 • 102,6 • 120,5 • 137,2 460 A6VE 55 / A2FE 45 • 56 • 63

GFT 24 W3 4000 19000 99 90,1 • 102,6 • 120,5 • 137,2 460 A6VE 55 / A2FE 45 • 56 • 63

GFT 26 W2 2000 18000 84 42,9 • 50,5 • 62 710 A6VE 80 / A2FE 80 • 90

GFT 26 W2 4000 18000 84 42,9 • 50,5 • 62 710 A6VE 80 / A2FE 80 • 90

GFT 36 W3 2000/1 26000 118 67 • 79,4 • 99,1 • 115 • 138,8 680 A6VE 55 / A2FE 45 • 56 • 63

GFT 36 W3 2000/2 26000 118 67 • 79,4 • 99,1 • 115 • 138,8 680 A6VE 80 • 107 / A2FE 80 • 90

GFT 36 W3 4000/1 26000 118 67 • 79,4 • 99,1 • 115 • 138,8 680 A6VE 55 / A2FE 45 • 90

GFT 36 W3 4000/2 26000 118 67 • 79,4 • 99,1 • 115 • 138,8 680 A6VE 80 • 107 / A2FE 80 • 90

GFT 36 W3 4000/2 = index no. for different structural lengths, diameter or motor attachment

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 7/20

Dimensions, Technical data

Dimensions, masses

Type/design D1 D2 D3 D4 D5 D6 D7 D8 DWS

GFT-W

mm

GFT 17 W2 2000 250 290 320 16x M20 280 305 330 16x M16 380

GFT 17 W2 4000 250 290 320 14x M20 280 305 330 16x 17,5 380

GFT 17 W3 2000 250 290 320 16x M20 280 305 330 16x M16 380

GFT 17 W3 4000 250 290 320 14x M20 280 305 330 16x 17,5 380

GFT 24 W3 2000 240 285 320 20x M20 280 305 330 20x M16 385

GFT 24 W3 4000 250 290 320 20x M20 280 305 330 20x 18 385

GFT 26 W2 2000 270 310 350 16x M20 320 350 380 20x M16 430

GFT 26 W2 4000 270 310 350 14x M20 320 350 380 20x 18 430

GFT 36 W3 2000/1 270 310 350 16x M20 320 350 380 20x M16x1,5 440

GFT 36 W3 2000/2 270 310 350 16x M20 320 350 380 20x M16x1,5 440

GFT 36 W3 4000/1 270 310 350 16x M20 320 350 380 20x 18 440

GFT 36 W3 4000/2 270 310 350 16x M20 320 350 380 20x 18 440

Type/design L1 L2 L3 L4 L5 L6 L7 A+B Mass

GFT-W C Co

mm kN kg

GFT 17 W2 2000 16 82 152 264 18 56 47 108 142 105

GFT 17 W2 4000 16 82 152 264 18 56 47 108 142 105

GFT 17 W3 2000 16 82 174 286 18 56 47 140 290 115

GFT 17 W3 4000 16 82 174 286 18 56 47 140 290 115

GFT 24 W3 2000 16 82 189,5 301,5 18 56 47 140 290 130

GFT 24 W3 4000 16 82 189,5 301,5 18 56 47 140 290 130

GFT 26 W2 2000 20 90 220 340 25 58 50 186 400 136

GFT 26 W2 4000 20 90 220 340 25 58 50 186 400 136

GFT 36 W3 2000/1 20 90 210 343 25 56,5 56,5 170 405 155

GFT 36 W3 2000/2 10 90 200 300 25 56,5 56,5 170 405 155

GFT 36 W3 4000/1 20 90 210 343 25 56,5 56,5 170 405 155

GFT 36 W3 4000/2 10 90 200 300 25 56,5 56,5 170 405 155

RE 77502/02.2016, Bosch Rexroth AG

8/20 MOBILEX GFT-W | Winch drives

Dimensions, Technical data

Dimensions

Dimensions of the

counter bearing

see page 14

Optional (only in connection

with version ≥ 4000)

Technical data

Type/design Output Rope Transmission ratio Holding Hydraulic motor

GFT-W torque pull torque

T2 max max. TBr max

Nm kN i Nm

GFT 40 W2 4000/1 27000 108 35,9 • 41 • 48,3 • 59,1 1080 A6VE 80 • 107 / A2FE 80 • 90

GFT 40 W2 4000/2 27000 108 35,9 • 41 • 48,3 • 59,1 1080 A6VE 107 • 160 / A2FE 107 • 125

GFT 50 W3 2000 37500 150 84,2 • 91,1 • 125,6 800 A6VE 80 • 107 / A2FE 80 • 90

GFT 50 W3 4000 37500 150 84,2 • 91,1 • 125,6 800 A6VE 80 • 107 / A2FE 80 • 90

GFT 60 W3 4000 42500 164 63,8 • 94,8 • 105,5 • 119,8 • 139,9 • 169,9 720 A6VE 80 • 107 / A2FE 80 • 90

A6VM 107 • 160 • 200 • 250 /

GFT 60 W3 6000 42500 164 63,8 • 94,8 1620

A2FM 107 • 125 • 160 • 180 • 200

A6VM 107 • 160 • 200 • 250 /

GFT 60 W3 8000 42500 164 63,8 • 94,8 1620

A2FM 107 • 125 • 160 • 180 • 200

GFT 80 W3 6000/1 67000 231 61,3 • 79,1 • 99 • 126,9 • 149,5 • 215 1890 A6VM 160 / A2FM 160 • 180

GFT 80 W3 6000/2 67000 231 61,3 • 79,1 • 99 • 126,9 • 149,5 • 215 1890 A6VM 200 • 250 / A2FM 200

GFT 80 W3 8000/1 67000 231 61,3 • 79,1 • 99 • 126,9 • 149,5 • 215 1890 A6VM 160 / A2FM 160 • 180

GFT 80 W3 8000/2 67000 231 61,3 • 79,1 • 99 • 126,9 • 149,5 • 215 1890 A6VM 200 • 250 / A2FM 200

GFT 80 W3 8000/3 67000 231 61,3 • 79,1 • 99 • 126,9 • 149,5 • 215 1890 A6VM 107 / A2FM 107 • 125

GFT 80 W3 8000/2 = index no. for different structural lengths, diameter or motor attachment

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 9/20

Dimensions, Technical data

Dimensions, masses

Type/design D1 D2 D3 D4 D5 D6 D7 D8 DWS

GFT-W

mm

GFT 40 W2 4000/1 270 310 350 17x M20x1,5 350 400 440 16x 22 500

GFT 40 W2 4000/2 330 370 410 18x M20 350 400 440 16x 22 500

GFT 50 W3 2000 270 310 350 20x M20x1,5 350 400 430 16x M20x1,5 500

GFT 50 W3 4000 270 310 350 18x M20x1,5 350 400 430 16x 22 500

GFT 60 W3 4000 330 370 410 20x M20x1,5 370 410 450 20x 22 520

GFT 60 W3 6000 360 405 440 12x M24 370 405 440 16x 22 520

GFT 60 W3 8000 360 405 440 12x M24 370 405 440 16x 22 520

GFT 80 W3 6000/1 380 430 470 28x M24 430 460 495 24x 22 580

GFT 80 W3 6000/2 380 430 470 28x M24 430 460 495 24x 22 580

GFT 80 W3 8000/1 380 430 470 28x M24 430 460 495 24x 22 580

GFT 80 W3 8000/2 380 430 470 28x M24 430 460 495 24x 22 580

GFT 80 W3 8000/3 380 430 470 28x M24 430 460 495 24x 22 580

Type/design L1 L2 L3 L4 L5 L6 L7 A+B Mass

GFT-W C Co

mm kN kg

GFT 40 W2 4000/1 25 82 243 364,5 30 57 54 212 425 192

GFT 40 W2 4000/2 25 108,5 243 376,5 30 56,5 54 212 425 219

GFT 50 W3 2000 25 82 281,5 403 30 62 48 212 425 212

GFT 50 W3 4000 25 82 281,5 403 30 56,5 54 212 425 212

GFT 60 W3 4000 25 114 284 423 30 79 38 250 520 230

GFT 60 W3 6000 6 115 271 434,5 16 84 25 250 520 230

GFT 60 W3 8000 6 115 271 434,5 16 84 25 250 520 230

GFT 80 W3 6000/1 10 120 295 484 30 76 19 212 425 430

GFT 80 W3 6000/2 10 120 295 484 30 76 19 212 425 430

GFT 80 W3 8000/1 10 120 295 604 30 76 19 212 425 430

GFT 80 W3 8000/2 10 120 295 604 30 76 19 212 425 430

GFT 80 W3 8000/3 10 120 295 583 30 76 19 212 425 430

RE 77502/02.2016, Bosch Rexroth AG

10/20 MOBILEX GFT-W | Winch drives

Dimensions, Technical data

Dimensions

Dimensions of the

counter bearing

see page 14

Optional (only in connection

with version ≥ 4000)

Technical data

Type/design Output Rope Transmission ratio Holding Hydraulic motor

GFT-W torque pull torque

T2 max max. TBr max

Nm kN i Nm

A6VE 107 • 160 /

GFT 110 W3 4000 100000 300 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1100

A2FE 107 • 125 • 160 • 180

GFT 110 W3 6000/1 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890 A6VM 200 • 250 / A2FM 200

GFT 110 W3 6000/2 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890 A2FM 250

GFT 110 W3 6000/3 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890 A6VM 160 / A2FM 160 • 180

A6VM 107 • 250 /

GFT 110 W3 6000/4 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890

A2FM 107 • 125 • 200

GFT 110 W3 8000/1 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890 A6VM 200 • 250 / A2FM 200

GFT 110 W3 8000/2 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890 A6VM 160 / A2FM 160 • 180

GFT 110 W3 8000/3 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1890 A6VM 107 / A2FM 107 • 125

A6VM 160 • 200 • 250 / A6VE 160 /

GFT 110 W3 9000 100000 300 79,5 • 95,8 • 114,8 • 128,6 • 147,2 • 173,9 1500

A2FM 107 • 125 • 160 • 180

GFT 110 W3 6000/4 = index no. for different structural lengths, diameter or motor attachment

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 11/20

Dimensions, Technical data

Dimensions, masses

Type/design D1 D2 D3 D4 D5 D6 D7 D8 DWS

GFT-W

mm

GFT 110 W3 4000 420 460 500 24x M24 460 500 540 36x 20 640

GFT 110 W3 6000/1 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 6000/2 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 6000/3 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 6000/4 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 8000/1 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 8000/2 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 8000/3 380 430 470 28x M24 490 530 567 24x 26 650

GFT 110 W3 9000 380 430 470 28x M24 490 530 567 24x 26 650

Type/design L1 L2 L3 L4 L5 L6 L7 A+B Mass

GFT-W C Co

mm kN kg

A 509 A 1080

GFT 110 W3 4000 21,5 165 305 491,5 30 107 25 440

B 480 B 950

GFT 110 W3 6000/1 10 140 280 489 15 96 -2 212 425 460

GFT 110 W3 6000/2 10 140 280 489 15 96 -2 212 425 406

GFT 110 W3 6000/3 10 140 280 489 15 96 -2 212 425 515

GFT 110 W3 6000/4 10 140 280 481 15 96 -2 212 425 460

GFT 110 W3 8000/1 10 140 280 598 15 96 -2 212 425 460

GFT 110 W3 8000/2 10 140 280 598 15 96 -2 212 425 460

GFT 110 W3 8000/3 10 140 280 598 15 96 -2 212 425 460

GFT 110 W3 9000 10 140 290 498 15 94 0 212 425 515

RE 77502/02.2016, Bosch Rexroth AG

12/20 MOBILEX GFT-W | Winch drives

Dimensions, Technical data

Dimensions

Dimensions of the

counter bearing

see page 14

Optional (only in connection

with version ≥ 4000)

Technical data

Type/design Output Rope Transmission ratio Holding Hydraulic motor

GFT-W torque pull torque

T2 max max. TBr max

Nm kN i Nm

A6VM 200 / A6VE 107 • 160 /

GFT 160 W3 4000 140000 373 133 • 210,8 • 251 1360

A2FE 107 • 125 • 160 • 180

97,7 • 105,9 • 143,3 • 155,4 • A6VE 107 • 160 /

GFT 220 W3 4000/1 200000 471 1360

188,9 • 246,1 • 293 A2FE 107 • 125 • 160 • 180

GFT 220 W3 4000/2 200000 471 97,7 • 105,9 • 143,3 • 155,4 • 188,9 1360 A6VM 200 • 250 / A2FM 200

A6VE 107 • 160 /

GFT 220 W3 6000/1 200000 471 188,9 • 246,1 • 293 1360

A2FE 107 • 125 • 160 • 180

GFT 220 W3 6000/2 200000 471 97,7 • 105,9 • 143,3 • 155,4 • 188,9 2200 A6VM 200 • 250 / A2FM 200

GFT 330 W3 9000/1 275000 595 209,8 • 252 2860 A6VE 250 / A2FE 250

GFT 330 W3 9000/2 275000 595 168,9 • 181,7 2x 1700 2x A6VM 160

GFT 450 W4 6000 325000 684 293,4 • 421,7 2300 A6VE 250 / A2FE 250

GFT 220 W3 4000/2 = index no. for different structural lengths, diameter or motor attachment

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 13/20

Dimensions, Technical data

Dimensions, masses

Type/design D1 D2 D3 D4 D5 D6 D7 D8 DWS

GFT-W

mm

GFT 160 W3 4000 450 510 560 30x M24x2 535 600 650 30x 30 750

GFT 220 W3 4000/1 460 600 650 30x M30 610 680 735 24x 33 850

GFT 220 W3 4000/2 460 600 650 30x M30 610 680 735 24x 33 850

GFT 220 W3 6000/1 460 600 650 30x M30 610 680 735 24x 33 850

GFT 220 W3 6000/2 460 600 650 30x M30 610 680 735 24x 33 850

GFT 330 W3 9000/1 580 680 735 28x M24 660 730 785 30x 33 925

GFT 330 W3 9000/2 580 680 735 28x M24 660 730 785 30x 33 925

GFT 450 W4 6000 580 680 735 36x M30 670 750 810 36x 33 -

Type/design L1 L2 L3 L4 L5 L6 L7 A+B Mass

GFT-W C Co

mm kN kg

GFT 160 W3 4000 30 168 340 538 65 131,7 20,2 783 1557 680

GFT 220 W3 4000/1 25 170 350 565 60 155 35 710 1560 820

GFT 220 W3 4000/2 21 170 350 560 60 155 35 710 1560 820

GFT 220 W3 6000/1 25 170 350 565 60 155 35 710 1560 820

GFT 220 W3 6000/2 25 170 350 560 60 155 35 710 1560 820

GFT 330 W3 9000/1 87 188 430 705 80 190 25 1040 2450 1380

GFT 330 W3 9000/2 20 188 430 705 70 190 25 1040 2450 1380

GFT 450 W4 6000 87 156 532 775 37 155 39 1040 2450 1460

RE 77502/02.2016, Bosch Rexroth AG

14/20 MOBILEX GFT-W | Winch drives

Dimensions, Technical data

Standard counter bearing

Gearbox size D1 D2 D3 D4 D5

H7/j6 H7/j6

mm

GFT 17 W 140 115 90 157 12x ø14

GFT 24 W 175 145 115 198 12x ø18

GFT 26 W 175 145 115 198 12x ø18

GFT 36 W 200 170 140 230 12x ø18

GFT 40 W 200 170 140 230 12x ø18

GFT 50 W 225 190 150 260 12x ø22

GFT 60 W 225 190 150 260 12x ø22

GFT 80 W 225 190 150 260 12x ø22

GFT 110 W 260 220 180 295 12x ø22

GFT 160 W 260 220 180 295 12x ø22

GFT 220 W 260 220 180 295 12x ø22

GFT 330 W Dimensions upon request

Gearbox size D6 L1 L2 L3 Mass

approx.

mm kg

GFT 17 W 6x ø9 76 13 10 9

GFT 24 W 6x ø11 76 20 15 15

GFT 26 W 6x ø11 76 20 15 15

GFT 36 W 6x ø14 77 20 15 21

GFT 40 W 6x ø14 77 20 15 21

GFT 50 W 6x ø18 91 25 17 30

GFT 60 W 6x ø18 91 25 17 30

GFT 80 W 6x ø18 91 25 17 30

GFT 110 W 8x ø18 102 25 20 30

GFT 160 W 8x ø18 102 25 20 30

GFT 220 W 8x ø18 102 25 20 30

GFT 330 W Dimensions upon request

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 15/20

Customer specification winch drive application

Customer specification

winch drive application

You wish to receive an offer for Company: _________________________________________________

the winch drives MOBILEX GFT-W Name/Dept: _________________________________________________

To process your request Place: _________________________________________________

we need the following data: Phone: _________________________________________________

E-mail: info.gears@boschrexroth.de E-mail: _________________________________________________

Date: _________________________________________________

Please enclose existing drawings, diagrams,

comments and the like.

Page 1/3

Operating data / design Type of device

(all values based on the 1. rope layer)

Hoisting winch Boom hoist winch Auxiliary winch

It is mandatory to fill out all fields!

For exceptions see footnotes. Pulling winch Other: ___________________________

Rating acc. to FEM section I T ___________ L ___________ M ___________

or alternative load spectrum ___________________

Ambient temperature from/to ___________________ °C

1)

Operating machine weight ___________________ t

1)

Lifting capacity, max. ___________________ t

2)

Rope pull (top rope layer) F ___________________ N

2)

Rope speed (1. rope layer) V1 ___________________ m/min

2)

Rope speed (top rope layer) V2 ___________________ m/min

Rope diameter d ___________________ mm

3)

Type of rope groove grooveless DIN Lebus

3)

Rope groove pitch p ___________________ mm

3)

Drum lead right left

Standard scope of supply Number of rope layers, max.

2)

___________________

Transmission unit Winding diam. (1. rope layer)

2)

DWS ___________________ mm

2)

Winding diam. (top rope layer) DWx ___________________ mm

Optional scope of supply Diameter of drum flanges

3)

D2 ___________________ mm

Counter bearing Length between drum flanges

3)

L ___________________ mm

3)

Rope drum Rope drum capacity

3)

Winch frame incl. 3 safety turns ___________________ m

Techn. data gearbox

Selected gearbox type GFT-W ________________

2)

Max. output torque T2 max ___________________ kNm

2)

Max. drive speed n2 ___________________ rpm

1)

Ratio i ___________________

Multiple-disk parking brake yes no

Min. park. torque

multiple-disk parking brake ___________________ Nm

Release pressure, max. Pmax ___________________ bar

1)

Release pressure, min Pmin ___________________ bar

Top coat specific yes no

1)

Optional entry Color RAL ___________________

2)

Mandatory field T2 max is not specified

3)

Mandatory field in case of delivery with rope drum

RE 77502/02.2016, Bosch Rexroth AG

16/20 MOBILEX GFT-W | Winch drives

Customer specification winch drive application

You wish to receive an offer for Company: _________________________________________________

the winch drives MOBILEX GFT-W Name/Dept: _________________________________________________

To process your request Place: _________________________________________________

we need the following data: Phone: _________________________________________________

E-mail: info.gears@boschrexroth.de E-mail: _________________________________________________

Please enclose existing drawings, diagrams, Date: _________________________________________________

comments and the like.

Page 2/3

Dimensions of gearbox

• Please fill out the table with the available standard dimensions from valid

“Technical data sheet“, or if possible the SAP material number of a reference

gearbox.

• Please mark the deviating requirements/dimensionsin the table.

Material no. reference ______________________

D1 ______________________ mm

D2 ______________________ mm

D3 ______________________ mm

D4 No. of threads ____ pcs. ______________

D5 ______________________ mm

D6 ______________________ mm

D7 ______________________ mm

D8 No. of threads ____ pcs. ______________

L2 ______________________ mm

Technical basic data hydraulic motor

Hydraulic circuit open closed

Motor type code ___________________________

Displacement Vg min _______________ cm3

Displacement Vg max _______________ cm3

Flushing valve yes no

Speed sensor, if yes: type yes, type ________ no

Counter balance valve yes no

Pressure relief valve yes no

Pressure relief valve setting ______________________ bar

Working pressure Δp ________________ bar

Input flow, max. qv max ________________ l/min

1)

Estimated number of transmission units per year ___________________

1)

Price range ___________________

1)

Requested ship date RSD ___________________

Special application conditions ____________________________________________________

Further customer-specific requirements ____________________________________________________

Are there any legal requirements and/or other standards to be considered?

yes no if yes, please specify ________________________________________________

1)

Optional entry

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 17/20

Customer specification winch drive application

You wish to receive an offer for Company: _________________________________________________

the winch drives MOBILEX GFT-W Name/Dept: _________________________________________________

To process your request Place: _________________________________________________

we need the following data: Phone: _________________________________________________

E-mail: info.gears@boschrexroth.de E-mail: _________________________________________________

Please enclose existing drawings, diagrams, Date: _________________________________________________

comments and the like..

Page 3/3

Other (e.g. load spectra, application-relevant data, customer drawings, nameplate):

RE 77502/02.2016, Bosch Rexroth AG

18/20 MOBILEX GFT-W | Winch drives

Notes

Notes

Bosch Rexroth AG, RE 77502/02.2016

Winch drives | MOBILEX GFT-W 19/20

Notes

Notes

RE 77502/02.2016, Bosch Rexroth AG

20/20 MOBILEX GFT-W for mobile applications | Winch drives

Product range

Product range Planetary gearboxes for mobile units

Hydrostatic travel drives

• HYDROTRAC GFT

For fixed- or variable-displacement motors

Output torques between 9,5 and 580 kNm

Data sheet RE 77110

• HYDROTRAC GFT 2000

Series 30

Output torques between 13,5 and 42,5 kNm

Data sheet RE 77116

• HYDROTRAC GFT 8000

Series 30

Output torques between 20 and 30 kNm

Data sheet RE 77128

• HYDROTRAC GFT 8000

Series 40

Output torques between 10 and 130 kNm

Data sheet RE 77117

• HYDROTRAC GFT 45 T2/T3

Output torques max. 45 kNm

Data sheet RE 77115

Hydrostatic swing drives

• MOBILEX GFB

For fixed- or variable-displacement motors

Output torques between 4 and 68,3 kNm

Data sheet RE 77201

• MOBILEX GFB 2000

Series 20

Output torques between 4 and 14,5 kNm

Data sheet RE 77206

Hydrostatic winch gears

• MOBILEX GFT-W

For fixed- or variable-displacement motors

Output torques between 14 and 325 kNm

Data sheet RE 77502

Bosch Rexroth AG © All rights reserved by Bosch Rexroth AG, including in relation to filing of

Transmission Unit industrial property rights. Any and all rights of disposal such as the right to

copy or disclose the information shall remain with us. The data specified

Nortkirchenstr. 53

are intended solely for product description. The information provided by

44263 Dortmund, Germany us must not be construed as a warranty of a specific property or fitness for

Phone +49 231 22819-5 a particular purpose. The information given does not relieve the user from

info.gears@boschrexroth.de making his own assessments and tests. Note that our products are subject

www.boschrexroth.com/gears to normal wear and ageing.

Bosch Rexroth AG, RE 77502/02.2016

You might also like

- Book1 PDFDocument47 pagesBook1 PDFArbainn Al-RantawiNo ratings yet

- Rexroth Axial Piston A2FO Hydraulic Pump & A2FM Motor: Open and Closed CircuitsDocument11 pagesRexroth Axial Piston A2FO Hydraulic Pump & A2FM Motor: Open and Closed CircuitsKaian OliveiraNo ratings yet

- A10VO 52 Series Re-A92703Document68 pagesA10VO 52 Series Re-A92703Agus YulfizarNo ratings yet

- Service Manual PVG32 - 16Document28 pagesService Manual PVG32 - 16PitupyNo ratings yet

- Hydraulic Variable Motor SpecsDocument18 pagesHydraulic Variable Motor SpecsTimuçin KARABULUTLAR100% (3)

- Variable displacement pump technical dataDocument20 pagesVariable displacement pump technical dataadelmomouraNo ratings yet

- Service - Service Manual Code 950 - 994 - 653Document49 pagesService - Service Manual Code 950 - 994 - 653CristianNo ratings yet

- Overview Eng CD PDFDocument20 pagesOverview Eng CD PDFRafael Cortes100% (1)

- Englisch LAGZ 11868 - 2003-07Document10 pagesEnglisch LAGZ 11868 - 2003-07HERNANDO A BECERRANo ratings yet

- Mobile Division Service Parts List A10VO Series 31 Size 28Document52 pagesMobile Division Service Parts List A10VO Series 31 Size 28Samy SamNo ratings yet

- Kobelco Construction Machinery Hydraulic Motors GuideDocument26 pagesKobelco Construction Machinery Hydraulic Motors GuideHai VanNo ratings yet

- K3VL Controls 2010 MDDocument55 pagesK3VL Controls 2010 MDHamza Lashin100% (1)

- Manual Service Danfoss Motor OMTDocument26 pagesManual Service Danfoss Motor OMTsergio blandon l100% (2)

- CraneDocument3 pagesCraneNgọc Đức ĐoànNo ratings yet

- A10vo GBDocument19 pagesA10vo GBEdgar HuimanNo ratings yet

- Variable displacement pump technical data sheetDocument48 pagesVariable displacement pump technical data sheetEVCY100% (1)

- Series: K5V 200 DT H 100 R 9N 01Document1 pageSeries: K5V 200 DT H 100 R 9N 01Stelian Crisan100% (1)

- Section A: Transmission Familiarization: Allison Off-Highway TransmissionsDocument8 pagesSection A: Transmission Familiarization: Allison Off-Highway Transmissionsamin chaabenNo ratings yet

- A11vlo 200-250 DRLDocument1 pageA11vlo 200-250 DRLxxsh100% (1)

- Rexroth A10vso Variable Axial Piston Pump PDFDocument18 pagesRexroth A10vso Variable Axial Piston Pump PDFAkbarmoradi100% (1)

- Hägglunds - Choice of Hydraulic Fluid PDFDocument2 pagesHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosNo ratings yet

- Re92004 PDFDocument72 pagesRe92004 PDFsuriantoNo ratings yet

- Hawe PDFDocument262 pagesHawe PDFmadan mohan katta0% (1)

- A11vlo 130 HD2DDocument1 pageA11vlo 130 HD2DxxshNo ratings yet

- Pumps Motors and Transmission Units For Mobile Application BRDocument2 pagesPumps Motors and Transmission Units For Mobile Application BRbee140676No ratings yet

- BARDEN Parts ListDocument20 pagesBARDEN Parts ListDwiki RamadhaniNo ratings yet

- Spare Parts List: For Prop. Directional Spool Valves Type PSL, PSV and PSM Size 3Document42 pagesSpare Parts List: For Prop. Directional Spool Valves Type PSL, PSV and PSM Size 3words2zhigang_612545100% (2)

- W Olsbergs DLHV enDocument2 pagesW Olsbergs DLHV enMike Guerreros0% (1)

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- Rexroth A6VM Variable MotorDocument3 pagesRexroth A6VM Variable MotorSathish KumarNo ratings yet

- Sistemas Hidrostáticos para Rodillos VibratoriosDocument12 pagesSistemas Hidrostáticos para Rodillos VibratoriosJheins GupeNo ratings yet

- ICVD 01 GB 0319 - WebDocument20 pagesICVD 01 GB 0319 - WebintecelNo ratings yet

- Hight Quality Spare Parts: Bosch Rexroth (Rexroth Build) Series A4VGDocument1 pageHight Quality Spare Parts: Bosch Rexroth (Rexroth Build) Series A4VGINVESTIGACION Y DESARROLLONo ratings yet

- Hiab XS 144 CLX Capacity 14 TM: Basic DataDocument2 pagesHiab XS 144 CLX Capacity 14 TM: Basic DataFabian RamirezNo ratings yet

- H1B 110 PartsDocument110 pagesH1B 110 Parts16712No ratings yet

- Linde HPV 02 Datasheet PDFDocument36 pagesLinde HPV 02 Datasheet PDFFilipposNo ratings yet

- Type OSPB, OSPC and OSPF PDFDocument32 pagesType OSPB, OSPC and OSPF PDFmusafirNo ratings yet

- Allied ManualDocument36 pagesAllied ManualNatalia LunaNo ratings yet

- Field Testing of A Closed Loop PumpDocument4 pagesField Testing of A Closed Loop Pumpmagarmat1980No ratings yet

- D155E 10.02 (DOWMAX English)Document50 pagesD155E 10.02 (DOWMAX English)Nastase Dan NicusorNo ratings yet

- Ra 92003 PDFDocument35 pagesRa 92003 PDFAgus Yulfizar100% (1)

- Workshop Manual: Training CenterDocument9 pagesWorkshop Manual: Training CenterStas100% (1)

- L20 Series: Service and Repair ManualDocument28 pagesL20 Series: Service and Repair ManualJoe CorreaNo ratings yet

- 77019634-Tram PumpDocument22 pages77019634-Tram PumpEduardo Brayan Melchor Briceno100% (1)

- Introduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Document20 pagesIntroduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Narasimha DNo ratings yet

- A2fm 70Document24 pagesA2fm 70SunilNo ratings yet

- Sauer Danfoss H1B Bent Axis Motor Service ManualDocument64 pagesSauer Danfoss H1B Bent Axis Motor Service ManualJustin100% (2)

- M-LDocument68 pagesM-LSamuel Lopez BenitesNo ratings yet

- Ra92100 1997-10Document48 pagesRa92100 1997-10mmaldonado10No ratings yet

- Compact Mini Spider Crane Specs and FeaturesDocument1 pageCompact Mini Spider Crane Specs and FeaturesMário BernardoNo ratings yet

- Sauer DanfossDocument88 pagesSauer DanfossThanh CongNo ratings yet

- HPV02 Installation and Start-Up Instructions PDFDocument7 pagesHPV02 Installation and Start-Up Instructions PDFxxshNo ratings yet

- LUDV Control Block of Mono and Sandwich Plate Design Type M7-22Document16 pagesLUDV Control Block of Mono and Sandwich Plate Design Type M7-22W Morales100% (2)

- Regulating Motor: With: - Hydraulic Maximum Displacement Override - Counterbalance ValveDocument10 pagesRegulating Motor: With: - Hydraulic Maximum Displacement Override - Counterbalance ValveSarra ChoucheneNo ratings yet

- Hydraulic Hammer Service Manual: GH Series HammersDocument121 pagesHydraulic Hammer Service Manual: GH Series HammersomarxicotepecNo ratings yet

- Variable displacement pump technical data sheetDocument19 pagesVariable displacement pump technical data sheetJose Maria CuencaNo ratings yet

- Winch Gearboxes GPT-W enDocument16 pagesWinch Gearboxes GPT-W enPaulNo ratings yet

- Slewing Drives by LiebherrDocument8 pagesSlewing Drives by LiebherrKaromah SembodoNo ratings yet

- Slewing Drives by Liebherr: Series-ProductionDocument10 pagesSlewing Drives by Liebherr: Series-ProductionAgung Tri HatmokoNo ratings yet

- Planetary Plug-In Gearboxes by LiebherrDocument12 pagesPlanetary Plug-In Gearboxes by LiebherrRachid Smaili100% (1)

- Actuators: Haldex Life Seal Actuators Vocational Truck ApplicationsDocument4 pagesActuators: Haldex Life Seal Actuators Vocational Truck ApplicationsorlandolanchipaNo ratings yet

- GPM HarrierDocument10 pagesGPM HarrierorlandolanchipaNo ratings yet

- Track Roller SF Part DatasheetDocument3 pagesTrack Roller SF Part DatasheetorlandolanchipaNo ratings yet

- HEMS Prensas Hidraìulicas PortaìtilesDocument2 pagesHEMS Prensas Hidraìulicas PortaìtilescesarasmNo ratings yet

- Repuestos J. DeereDocument1 pageRepuestos J. DeereorlandolanchipaNo ratings yet

- Backhoe LoaderDocument43 pagesBackhoe Loadertarsono sonoNo ratings yet

- Actuator: Quick Reference GuideDocument4 pagesActuator: Quick Reference GuideorlandolanchipaNo ratings yet

- LucasElektrik A.S. PNEWS 12-08 STARTER MOTOR LES0257Document1 pageLucasElektrik A.S. PNEWS 12-08 STARTER MOTOR LES0257orlandolanchipaNo ratings yet

- Transmission Parts List and Cross Reference GuideDocument550 pagesTransmission Parts List and Cross Reference GuideorlandolanchipaNo ratings yet

- Gear Pump PDFDocument6 pagesGear Pump PDForlandolanchipaNo ratings yet

- ZF Is Efficiency IAC 14 EN PDFDocument23 pagesZF Is Efficiency IAC 14 EN PDForlandolanchipaNo ratings yet

- De Servicio Freightliner fl70 Service Manual PDFDocument5 pagesDe Servicio Freightliner fl70 Service Manual PDForlandolanchipa67% (3)

- SP18117 Axles EuropeDocument8 pagesSP18117 Axles EuropeTeddy KhantNo ratings yet

- Axip 0089Document33 pagesAxip 0089orlandolanchipaNo ratings yet

- Euroricambi Delekatalog PDFDocument271 pagesEuroricambi Delekatalog PDForlandolanchipa33% (3)

- 24-CL Coils Catalog PDFDocument40 pages24-CL Coils Catalog PDForlandolanchipaNo ratings yet

- Orox Flexo Tailor IngleseDocument2 pagesOrox Flexo Tailor Ingleseorlandolanchipa100% (1)

- Redutores Planetarios gft45Document4 pagesRedutores Planetarios gft45orlandolanchipaNo ratings yet

- Oilgear Pump PVG100-130 - Control V-SDocument3 pagesOilgear Pump PVG100-130 - Control V-SorlandolanchipaNo ratings yet

- Bombas DanfossDocument44 pagesBombas DanfossalfborbrNo ratings yet

- FLDocument5 pagesFLorlandolanchipaNo ratings yet

- Concrete Forming Accessories HBDocument108 pagesConcrete Forming Accessories HBorlandolanchipaNo ratings yet

- Gear Pump ParkerDocument28 pagesGear Pump ParkerorlandolanchipaNo ratings yet

- Bostrom SeatingDocument36 pagesBostrom SeatingorlandolanchipaNo ratings yet

- Operation and Maintenance Manual Bulletin Nh220Document4 pagesOperation and Maintenance Manual Bulletin Nh220Cordova MarcosNo ratings yet

- ZF Servo MackDocument2 pagesZF Servo MackorlandolanchipaNo ratings yet

- MinnPar Seats Catalog 0620Document43 pagesMinnPar Seats Catalog 0620orlandolanchipaNo ratings yet

- Sheppard M100 - MP8 - 163Document70 pagesSheppard M100 - MP8 - 163orlandolanchipaNo ratings yet

- Micom p343Document66 pagesMicom p343kjfenNo ratings yet

- Software Testing Types, Levels, Roles & Best PracticesDocument3 pagesSoftware Testing Types, Levels, Roles & Best PracticesAbhinav DakshaNo ratings yet

- ANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemDocument42 pagesANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemArzu AkarNo ratings yet

- Xtrons - TD609 User ManualDocument16 pagesXtrons - TD609 User ManualadrianNo ratings yet

- Technical Reference Guide On Steam DistributionDocument66 pagesTechnical Reference Guide On Steam DistributionDainycious KibiwottNo ratings yet

- Combination Woodworking Machine Quotation PDFDocument2 pagesCombination Woodworking Machine Quotation PDFAlunel TapuNo ratings yet

- PLKKKDocument36 pagesPLKKKelecompinnNo ratings yet

- Stray Current CorrosionDocument21 pagesStray Current CorrosionPaolo Mogollon AcostaNo ratings yet

- Tank Size CalculatorDocument6 pagesTank Size CalculatorVijayakumar Chandrasekaran100% (2)

- ManualDocument14 pagesManualnas_hoNo ratings yet

- Preparatory Year Program Computer Science (PYP 002)Document34 pagesPreparatory Year Program Computer Science (PYP 002)Hassan AlfarisNo ratings yet

- Colorado Passenger Tramway Safety Board Adam Lee Accident ReportDocument28 pagesColorado Passenger Tramway Safety Board Adam Lee Accident ReportMichael_Lee_RobertsNo ratings yet

- S Parameter Theory of Lossless BlockDocument14 pagesS Parameter Theory of Lossless BlockthgnguyenNo ratings yet

- 7 Inch Liner Cementing ProgramDocument44 pages7 Inch Liner Cementing ProgramMarvin OmañaNo ratings yet

- Xiv 11.5.1 XcliDocument704 pagesXiv 11.5.1 XcliMuthu LNo ratings yet

- Active Front EndDocument5 pagesActive Front EndDaleel LillaNo ratings yet

- Fico Exam GuideDocument2 pagesFico Exam GuideDANIELNo ratings yet

- BYG Опросный лист на режущую кромкуDocument51 pagesBYG Опросный лист на режущую кромкуMMM-MMMNo ratings yet

- Aerodrome Controller (ADC) ExamDocument5 pagesAerodrome Controller (ADC) ExamaxnpicturesNo ratings yet

- Civil-Vii-Air Pollution and Control (10cv765) - Question PaperDocument4 pagesCivil-Vii-Air Pollution and Control (10cv765) - Question PaperSathya MurthyNo ratings yet

- NOx Control of Kiln and Preheater Complete AnalysisDocument129 pagesNOx Control of Kiln and Preheater Complete AnalysisAnonymous sfY8T3q0100% (2)

- M103C 10/11 Meter Maximum Beam AntennaDocument9 pagesM103C 10/11 Meter Maximum Beam AntennaRádio Técnica AuroraNo ratings yet

- Mechanical Analysis Software of Downhole Operation Pipe Strings and Its ApplicationDocument4 pagesMechanical Analysis Software of Downhole Operation Pipe Strings and Its ApplicationDarya Khan BhuttoNo ratings yet

- Military Standard for Circular Connector Insert ArrangementsDocument59 pagesMilitary Standard for Circular Connector Insert ArrangementsVadim RiabovNo ratings yet

- A967517734 - 24017 - 22 - 2018 - 10. Header Linked List (2 Files Merged) PDFDocument25 pagesA967517734 - 24017 - 22 - 2018 - 10. Header Linked List (2 Files Merged) PDFKiran KumarNo ratings yet

- Haffmans DPT: Dew Point TesterDocument2 pagesHaffmans DPT: Dew Point TesterLaura Elianne QuirogaNo ratings yet

- Finite Element Analysis of The In-Service-Welding of T Joint Pipe ConnectionDocument12 pagesFinite Element Analysis of The In-Service-Welding of T Joint Pipe ConnectionMohamed SamyNo ratings yet

- HYDRO VesselsDocument5 pagesHYDRO VesselsMarvinPatricioNarca0% (1)

- Cisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5Document60 pagesCisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5JodieNo ratings yet

- f094 PDFDocument4 pagesf094 PDFAnshuman SinghNo ratings yet