Professional Documents

Culture Documents

Service Flash Will Not Spin Above 400 RPM & Direct Drive Motor Hall Sensor...

Service Flash Will Not Spin Above 400 RPM & Direct Drive Motor Hall Sensor...

Uploaded by

rafa_tibiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Flash Will Not Spin Above 400 RPM & Direct Drive Motor Hall Sensor...

Service Flash Will Not Spin Above 400 RPM & Direct Drive Motor Hall Sensor...

Uploaded by

rafa_tibiCopyright:

Available Formats

Models: WF218ANB, WF218ANW

Symptom: Will not spin above 400 RPM

Solution: Verify the drum motor Hall Sensor is mounted properly. Incorrect mounting will cause the micro to

incorrectly detect the imbalance.

Models:

WF203ANS/XAA,WF337AAL/XAA,WF337AAR/XAA,WF337AAW/XAA,WF328AAW/XAA,WF326LAS/XAA,WF326LA

W/XAA,WF328AAG/XAA,WF209ANW/XAA,WF328AAR/XAA,WF203ANW/XAA,WF338AAW/XAA,WF206ANS/XAA,W

F206BNW/XAA,WF306BHW/XAA,WF306LAW/XAA,WF316BAC/XAA,WF316BAW/XAA,WF316LAS/XAA,WF316LAW

/XAA,WF317AAG/XAA,WF317AAS/XAA,WF317AAW/XAA,WF337AAG/XAA,WF218ANB/XAA,WF218ANW/XAA,WF4

48AAW/XAA,WF438AAR/XAA,WF448AAP/XAA,WF338AAB/XAA

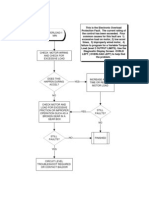

Symptom: Checking the front load washer Direct Drive Motor “Hall” sensor

Solution:

The drum motor has a sensor which is a part of the system that will determine if the drum is out of balance by the

MICOM on the main PCB. As the drum begins to spin, the MICOM looks for an indication if the motor is spinning and

how fast it is spinning.

If the drum rotation starts to vary; speeding up and slowing down rapidly, the Washer may show an error “DC”. This

might be related to the Hall Sensor which provides the drum rotation information to the Main PCB.

The wiring diagram for the drum motor shows that the HALL sensor is supplied with +5VDC from the main PCB (pink

wire). There is also a ground connection from the sensor to the board (orange wire). The other connections are signal

wires (red and blue) that the MICOM uses to determine speed and rotation of the motor.

Hall Sensor Check –

The hall sensor measures rotation speed by reading the magnetic field created by the magnets on the rotor.

Power the washer on and verify that +5VDC is being supplied to the sensor by measuring the pink wire at the sensor.

Be sure to use the orange wire as your ground reference, not chassis ground. If the +5VDC is not present, check the

connectors at the Main PCB and the continuity of the wiring.

1. Connect your DVM to the orange and red wires, you should measure 0VDC or 3.75VDC, manually rotate the

drum and verify that the voltage value changes up and down. If the voltage value does not change the hall

sensor is suspected to be defective.

If you have a DVM with frequency capability you will see the rotation speed or frequency by monitoring the orange and

red wires or the orange and blue wires.

• For full details on these tips, consult the GSPN website at http://service.samsungportal.com

Samsung Tech Talk 8

You might also like

- Kawa Ninja 650-Charging SystemDocument20 pagesKawa Ninja 650-Charging SystemFrancisco Alberto Comas Garcia100% (2)

- Mam Ky02sDocument34 pagesMam Ky02sTaufan Justvands67% (3)

- Maf Map EnhancerDocument4 pagesMaf Map Enhancerlucian_vNo ratings yet

- Troubleshooting A 4-20ma LoopDocument4 pagesTroubleshooting A 4-20ma LoopRizky MuhammadNo ratings yet

- VAJ ManualDocument6 pagesVAJ Manualshailesh28467% (3)

- 2 Disconnect The Yellow WiresDocument1 page2 Disconnect The Yellow Wiresanderson valerioNo ratings yet

- Milti TesterDocument5 pagesMilti Testerkdm004xxNo ratings yet

- Wire Length Calculator: Quick OverviewDocument2 pagesWire Length Calculator: Quick Overviewnazar750No ratings yet

- AR 1215 ManualDocument8 pagesAR 1215 ManualInsam FernandoNo ratings yet

- SGDO-FSU Troubleshooting ProcedureDocument2 pagesSGDO-FSU Troubleshooting ProcedurePeter SnellNo ratings yet

- Digital Multimeter: Owner'S ManualDocument21 pagesDigital Multimeter: Owner'S ManualUjjwal Kr. AcharyyaNo ratings yet

- Bird Site 3600-SA-XTDocument112 pagesBird Site 3600-SA-XTarsenaldoNo ratings yet

- Clamp ALS-1 MeasuringPowerDocument2 pagesClamp ALS-1 MeasuringPowerSubhrajyoti SilNo ratings yet

- Control Panel With Time Switch For Indoor/Outdoor Use: DangerDocument4 pagesControl Panel With Time Switch For Indoor/Outdoor Use: DangerOlga Joy Labajo GerastaNo ratings yet

- Bird Site Master 920-SA-XTDocument112 pagesBird Site Master 920-SA-XTengg.aliNo ratings yet

- Xantrex Trace Inverter ManualDocument70 pagesXantrex Trace Inverter ManualKasNo ratings yet

- Model 160A: Compressor LimiterDocument20 pagesModel 160A: Compressor Limiterbbrbbr123No ratings yet

- Johnson/Evinrude 60° 4 Cylinder Optical Ignition (OIS 2000) Carbureted 1995-2006 Model YearsDocument4 pagesJohnson/Evinrude 60° 4 Cylinder Optical Ignition (OIS 2000) Carbureted 1995-2006 Model YearsАлександр КачеишвилиNo ratings yet

- Bike Battery Charging CKTDocument3 pagesBike Battery Charging CKTseshubabu_999No ratings yet

- Electrex Troubleshooting 3P PMG & RRDocument3 pagesElectrex Troubleshooting 3P PMG & RRazuertohbshhhNo ratings yet

- TMA Installlation TrainingDocument21 pagesTMA Installlation Trainingdungnt84No ratings yet

- MANUALrev Fviewing 1Document12 pagesMANUALrev Fviewing 1saleossNo ratings yet

- Build A Basic Capacitance BridgeDocument5 pagesBuild A Basic Capacitance BridgeSiew Jen YihNo ratings yet

- 15h BALDORDocument24 pages15h BALDORford4funNo ratings yet

- High Speed Tripping Relays VAJH, VAJS and VAJHMDocument6 pagesHigh Speed Tripping Relays VAJH, VAJS and VAJHMvikash sharmaNo ratings yet

- RJSINGLEDocument88 pagesRJSINGLEAbhishek TiwariNo ratings yet

- DeviceNet TroubleshootingDocument15 pagesDeviceNet TroubleshootingBocefaloNo ratings yet

- Testing Teccor Semiconductor Devices Using Curve TracersDocument20 pagesTesting Teccor Semiconductor Devices Using Curve TracersSajjad4434100% (1)

- AC Current TransducerDocument5 pagesAC Current TransducerOrlando MelipillanNo ratings yet

- Nick RF MV ProjectDocument8 pagesNick RF MV Projectag1tatorNo ratings yet

- 01 Vajhm23Document6 pages01 Vajhm23jigyeshNo ratings yet

- CorePower AVR Users Guide July 2013Document2 pagesCorePower AVR Users Guide July 2013Wilbert T. LimNo ratings yet

- Ea16 Manual enDocument6 pagesEa16 Manual enabuzer1981No ratings yet

- Yamaha O1vDocument315 pagesYamaha O1vOscar PachecoNo ratings yet

- Micronta 22-204A Range Doubler Multimeter InstructionsDocument7 pagesMicronta 22-204A Range Doubler Multimeter InstructionsJunior100% (1)

- 10,000 Watt Ac Inverter: ProlineDocument11 pages10,000 Watt Ac Inverter: ProlineSalahuddin MughalNo ratings yet

- FP Troubleshooting HP1 WindingsDocument8 pagesFP Troubleshooting HP1 WindingsjengandxbNo ratings yet

- Wiring Diagram Magnetic Particles InspecionDocument7 pagesWiring Diagram Magnetic Particles InspecionAlan GodoyNo ratings yet

- v3 Voltage CalibrationDocument2 pagesv3 Voltage CalibrationAwraq Al-MualimNo ratings yet

- IMS150/300/600/1000/1500/2500 (12/24V) : Modified Sine Wave Inverter User ManualDocument11 pagesIMS150/300/600/1000/1500/2500 (12/24V) : Modified Sine Wave Inverter User ManualProbal SinhaNo ratings yet

- A 1179 - A 1257 - A 1395 Flex Current Clamps - ANGDocument15 pagesA 1179 - A 1257 - A 1395 Flex Current Clamps - ANGruben condeNo ratings yet

- Digital Multimeter: User's GuideDocument15 pagesDigital Multimeter: User's GuidePablo VélizNo ratings yet

- Sony Kdl-40r474a Chassis Rb1fkDocument76 pagesSony Kdl-40r474a Chassis Rb1fkManuelDaríoCadavidValderramaNo ratings yet

- AW900i User ManualDocument8 pagesAW900i User ManualJose Raul Reyes GarciaNo ratings yet

- Panasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38Document110 pagesPanasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38drunk65100% (1)

- Sanyo DS13204 - NTSC - ChareDocument30 pagesSanyo DS13204 - NTSC - Charelondon335No ratings yet

- Drive Troule ShootingDocument23 pagesDrive Troule ShootingArvind NangareNo ratings yet

- Manual KW903 SP Iss 04Document21 pagesManual KW903 SP Iss 04Ranjeet singhNo ratings yet

- Advr 16 Manual enDocument6 pagesAdvr 16 Manual enabuzer1981No ratings yet

- VFD Installation GuideDocument2 pagesVFD Installation Guidemujassam noorNo ratings yet

- Parker DA1500Document8 pagesParker DA1500Megh Prasad UpadhyayNo ratings yet

- Danger Warning Caution: Safety InformationDocument7 pagesDanger Warning Caution: Safety InformationcombaheeNo ratings yet

- AVEOX 260upcontrollerDocument3 pagesAVEOX 260upcontrollerfortescribd1No ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)