Professional Documents

Culture Documents

Fuel System-Overflow Line: I Erco Part No. 415-48J62)

Uploaded by

Shyamshesha GiriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel System-Overflow Line: I Erco Part No. 415-48J62)

Uploaded by

Shyamshesha GiriCopyright:

Available Formats

ERCOUPE

SERVICE

BULLETIN

No. J5 Fuel System-overflow Line

I Erco part No. 415-48J62)

This bulletin affects Ercoupes serial number 2623 d. Disconnect overflow line at elbow on frame

to 2994 inclusive, with the exception of the Ercoupes "B" and at the forward opening of the mount-

on which the change was effected prior to delivery. ing flange on bottom of fuselage gas tank.

The exceptions are listed as an appendix to this

bulletin. e. Remove the overflow line by moving the lower

end of the assembly to the rear of the airplane

The change is being made because a report has as the upper end is being withdrawn from the

reached us to the effect that the imperial brass com- tank through the fitting on the flange.

pression sleeve No. 60F, located on the fuselage gas

tank overflow line at the tank mounting flange, has 3, Install Overflow Line.

necked the line causing it to fail. This sleeve has

been changed to a rubber washer No. A594, Kohler a. Insert the upper end of the assembly into the

Company or A-64-3, Hayes Industries, Inc. As the tank through the fitting on the mounting flange,

brass . sleeve cannot be removed from the gas line reversing the order of removal.

once it has been compressed, a complete new line b. Assemble the union nut loosely on the lower

must be installed. The procedure for replacing the end of the overflow line to the elbow located on

fuselage gas tank overflow line is as follows: frame "B." Use Parker Sealube No. 6 P.E. or

I. Drain Fuselage Gas Tank. equivalent material when assembling the

a. Turn fuselage gas tank valve to "off" position. threaded fitting. Do not tighten this fitting until

the following operation is completed.

b. Open left side engine cowling.

c. Relocate the overflow line support clamp in·

c. Disconnect gas line at filter bowl (remove stallation by measuring 3" down on frame "B"

clamp from hose), from the old location and drilling a No. 27

d. Drain gas through hose into container by hole. Install location and secure the clamp.

opening gas valve. Tighten the nut on the overflow line at the

ell!> ow on frame "B," installed in the preced-

2. Provide Access and Remove Overflow Line. ing operation.

a. Remove oil pressure gauge line after discon- d. Assemble the union nut on the upper end of

necting the fitting from the pressure gauge on the overflow line assembly, being certain that

instrument panel and the bulkhead filling on there is a rubber washer within the nut. Use

the firewall. thread lubricant.

b. Remove main gas line after disconnecting the

filling on the shut-off valve and the bulkhead e. Replace the main gas line and oil pressure

fitting on the firewall. line reversing the order of removal. Use thread

lubricant on assembly and avoid excessive

c. Remove tubing clamp from overflow line, lo· lightening which will damage flared ends on

cated directly above the elbow on frame "B." tubing assemblies.

Page 2-IULLETIN No. 15

f. Check fuel level in fuselage gas tank by add- overllow line when strain in the assembly

ing fuel (tank valve closed) until the fuel flows lends to move the line.

through the overl!ow line to the left wing g. Connect gas line at filler bowl. If the bowl on

tank. At this time. the fuel level should be the fllter contains any air, it will be necessary

between %" and 1" below the bottom of the to loosen the bowl retainer and bleed the air

fuselage tank filler neck when measured from off with the fuselage gas tank valve in the

the rearmost part. The level may be corrected ..on" position.

by relocating the overllow line alter loosening

the union nut on the mounting flange and Overllow line assemblies are being shipped. to

moving the line up or down as required to each distributor, on a no-charge basis, in sufficient

obtain the proper level. The overllow line quantities to correct the alfected Ercoupes immedi-

should be reformed when establishing a new ately.

level to prevent the level changing later by slip- The cooperation of the distributor /dealer organi-

ping through the fitting. Reforming is necessary zation in effecting this change immediately is im-

since the union nul and rubber washer will perative. A fmlure of the subject part would prob-

not satisfactorily retain the position of the ably result in an immediate forced landing.

APPENDIX NO. J

ERCOUPf SERVICE DEPARTMENT BULLETIN

Number 15

List of Ercoupes between serial numbers 2623 and

2994 on which the subject change has been com-

pleted prior to delivery.

2649 2810 2884 2928

2686 28!l 2885 2929

2690 2814 2887 2932

2693 2815 2888 2933

2706 2825 2889 2935

2707 2832 2891 2936

2709 2833 2893 2939

2710 2835 2895 2941

2745 2837 2897 2943

2749 2841 2899 2944

2750 2843 2900 2947

2754 2848 2901 2952

2759 2851 2903 2953

2770 2857 2905 2955

2774 2869 2907 2959

2783 2872 2908 2963

2797 2873 2912 2968

2801 2876 2913 2969

2802 2877 2915 297l

2803 2880 2920 2975

2805 2881 2921 2977

2806 2883 2924 2981

2845

2863

You might also like

- Ss AFFECTED PRODUCT 3508BDocument13 pagesSs AFFECTED PRODUCT 3508Bjoalca31No ratings yet

- Hanomag Hanomag Built Terex 55c PM 3091151m1 Parts BookDocument20 pagesHanomag Hanomag Built Terex 55c PM 3091151m1 Parts Bookthomas100% (45)

- MT4400 Exhaust Assembly - Heated BodyDocument5 pagesMT4400 Exhaust Assembly - Heated BodyBrian CareelNo ratings yet

- PCF Valve Guide Inspection GuideDocument13 pagesPCF Valve Guide Inspection GuideoscarNo ratings yet

- Cummins Serie K Calibracion de ValvulasDocument63 pagesCummins Serie K Calibracion de Valvulasfrank_16100% (1)

- Llave Hidraulica RodDocument29 pagesLlave Hidraulica RodCarlos TorradoNo ratings yet

- NA-R4B InstructionsDocument8 pagesNA-R4B Instructionsone-eyed fat manNo ratings yet

- Dimensions and Ratings: Watertube BoilerDocument10 pagesDimensions and Ratings: Watertube Boilerfauzi endraNo ratings yet

- Instrumentation Vacuum Gauge InstructionsDocument11 pagesInstrumentation Vacuum Gauge InstructionsEzsilvasilva SilvaNo ratings yet

- CATALOGO DE PARTES MOTOR DK51278Document91 pagesCATALOGO DE PARTES MOTOR DK51278Samuel Solorzano100% (1)

- Accelerator Control, Fuel & Exhaust System: Zd30Ddti Td27TiDocument12 pagesAccelerator Control, Fuel & Exhaust System: Zd30Ddti Td27TiHéctorHernándezDíazNo ratings yet

- Parts and Technical Service Guide Guía de Servicio Técnico y Recambio Guide D'instructions Et Pièces de Rechange Technische BedienungsanleitungDocument14 pagesParts and Technical Service Guide Guía de Servicio Técnico y Recambio Guide D'instructions Et Pièces de Rechange Technische BedienungsanleitungAlex Molina100% (2)

- Transfer PumpDocument3 pagesTransfer Pumpemad aminNo ratings yet

- 6AKM157WH2 Ver857115753050Document9 pages6AKM157WH2 Ver857115753050Sergio OlivieriNo ratings yet

- Air Dryer - Maint - Manual - Rev - 1 PDFDocument34 pagesAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuNo ratings yet

- MODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Document4 pagesMODEL 84980 Hydraulic Vent Valve Series "B": Section Form 402085 DEC - 2005Putro 10100% (1)

- Spare parts list and fitting instructionsDocument4 pagesSpare parts list and fitting instructionsRoberto RossiNo ratings yet

- Applying mass conservation to optimize ASU distillation column performanceDocument8 pagesApplying mass conservation to optimize ASU distillation column performanceSiti Hajar Mohd PodziNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Perkins engine spare parts for Massey Ferguson tractorsDocument68 pagesPerkins engine spare parts for Massey Ferguson tractorsDaniel Eduardo Damas Ysla100% (1)

- QC Installation GuideDocument25 pagesQC Installation GuideSinan AslanNo ratings yet

- Haskel SKIS 001Document1 pageHaskel SKIS 001Agung Eko PurnomoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- TM 5-4000 Pneumatic Chain Saw, Timberhog 24-Inch, Reed-Prentice Corp 1942Document31 pagesTM 5-4000 Pneumatic Chain Saw, Timberhog 24-Inch, Reed-Prentice Corp 1942Sheri Canham100% (1)

- Manitowoc Crane Component IndexDocument1,263 pagesManitowoc Crane Component IndexMardianNo ratings yet

- Land Rover Series I 1954-1958 Parts Catalogue COMPLETEDocument443 pagesLand Rover Series I 1954-1958 Parts Catalogue COMPLETEJames67% (3)

- Delay in Opening of LP Bypass ValveDocument94 pagesDelay in Opening of LP Bypass ValveCharu ChhabraNo ratings yet

- Parts Book 1306Document5 pagesParts Book 1306Noor Sa'adahNo ratings yet

- B7 Fuel System: To IndexDocument25 pagesB7 Fuel System: To IndexKwun Hok ChongNo ratings yet

- Section 90: Pedal and Pedal Switch AdjustmentsDocument24 pagesSection 90: Pedal and Pedal Switch Adjustmentsjeffrey pelletierNo ratings yet

- SL97-345 B&W Service LetterDocument5 pagesSL97-345 B&W Service Letterkamal100% (1)

- MBE4000 EGR Connector Pipe InstallationDocument6 pagesMBE4000 EGR Connector Pipe InstallationАндрейNo ratings yet

- Thermostat 8212-5-0l Removal and InstallationDocument2 pagesThermostat 8212-5-0l Removal and InstallationMichael HernandezNo ratings yet

- Rubber Union from Power Unit to F1 Oil Tank Campaign 161Document17 pagesRubber Union from Power Unit to F1 Oil Tank Campaign 161WyattNo ratings yet

- Summer - Training - ONGC - Report - Naresh BishnoiDocument32 pagesSummer - Training - ONGC - Report - Naresh BishnoiNaresh BishnoiNo ratings yet

- lt3 00032 2 A p24 p30sDocument67 pageslt3 00032 2 A p24 p30sBruno SamaeianNo ratings yet

- Attachments: Attachments Kit Fitting InstructionsDocument43 pagesAttachments: Attachments Kit Fitting InstructionsMichael DavenportNo ratings yet

- 18SP664 Cambio Actuador TurboDocument6 pages18SP664 Cambio Actuador TurboAngel DlsgNo ratings yet

- Flow MeasurementDocument16 pagesFlow MeasurementMahela WeerakoonNo ratings yet

- CVS Series 50 Chemical Injection Pump ManualDocument12 pagesCVS Series 50 Chemical Injection Pump Manualiqmpslab0% (1)

- Solex InfoDocument0 pagesSolex Infocolas001No ratings yet

- Fordson Major Systeme HydrauliqueDocument23 pagesFordson Major Systeme HydrauliqueNicolas100% (1)

- Intake Pressure Tester For 2.7T Engine: Parts List: Tool ListDocument2 pagesIntake Pressure Tester For 2.7T Engine: Parts List: Tool ListrobNo ratings yet

- 18 Ah41d1 2 - 1206Document8 pages18 Ah41d1 2 - 1206scribdquyNo ratings yet

- Regulador EQA-99-17Document2 pagesRegulador EQA-99-17Ronan CristhiamNo ratings yet

- Exhaust System: Section 7C - Exhaust CollectorsDocument8 pagesExhaust System: Section 7C - Exhaust CollectorsJorge SoberanoNo ratings yet

- Fa2A Winch Control Valve Retrofit Instructions: Material HandlingDocument4 pagesFa2A Winch Control Valve Retrofit Instructions: Material HandlingMauricio GarciaNo ratings yet

- VSP 267Document11 pagesVSP 267JS VivasNo ratings yet

- Equipment and PipingDocument49 pagesEquipment and Pipingnuruddin2409No ratings yet

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- Econominder Remote Reset Meters: 2750RM, 2850RM, 3100RM & 3900RMDocument32 pagesEconominder Remote Reset Meters: 2750RM, 2850RM, 3100RM & 3900RMGreg ReynekeNo ratings yet

- Safety Relief Valves For Steam, Air, Gas and Vapors: F-SSRV - QXD 4/11/08 2:18 PM Page 1Document12 pagesSafety Relief Valves For Steam, Air, Gas and Vapors: F-SSRV - QXD 4/11/08 2:18 PM Page 1sathiya narayananNo ratings yet

- Mig Manual RX 250 & RX 400Document18 pagesMig Manual RX 250 & RX 400Madhavesh KulkarniNo ratings yet

- Valve Lash G3408Document9 pagesValve Lash G3408Djebali MouradNo ratings yet

- Series FV-4M1 Specification SheetDocument2 pagesSeries FV-4M1 Specification SheetWattsNo ratings yet

- b30a-oil-burnerDocument20 pagesb30a-oil-burnerPiyush DhimanNo ratings yet

- Application Equipment Part4Document66 pagesApplication Equipment Part4gguadian21No ratings yet

- Air in Fuel - TestDocument4 pagesAir in Fuel - TestKopyuk Kopyuk Kopyuk KopyukNo ratings yet

- RI Cassette Toilets C200 enDocument27 pagesRI Cassette Toilets C200 enOriol PrietoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Meebhoomi - Ap.gov - in ViewMap PDFDocument1 pageMeebhoomi - Ap.gov - in ViewMap PDFShyamshesha GiriNo ratings yet

- Different Models of Royal Enfield Decoded PDFDocument2 pagesDifferent Models of Royal Enfield Decoded PDFShyamshesha GiriNo ratings yet

- Note For BookingDocument1 pageNote For BookingShyamshesha GiriNo ratings yet

- Mtech Naval Architecture Andhra UniversityDocument13 pagesMtech Naval Architecture Andhra UniversityShyamshesha GiriNo ratings yet

- B.E. NAME 4th YearDocument16 pagesB.E. NAME 4th YearShyamshesha GiriNo ratings yet

- About Investing1Document67 pagesAbout Investing1kirthikodaiNo ratings yet

- Home Adangal 1-B Aadhar Linking F. M. B. Village Map Complaints Contact Department Login Photo Gallery OtherDocument1 pageHome Adangal 1-B Aadhar Linking F. M. B. Village Map Complaints Contact Department Login Photo Gallery OtherShyamshesha GiriNo ratings yet

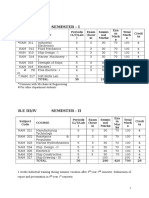

- B.E. NAME 2nd YearDocument19 pagesB.E. NAME 2nd YearShyamshesha GiriNo ratings yet

- B.E. NAME 2nd YearDocument22 pagesB.E. NAME 2nd YearShyamshesha GiriNo ratings yet

- Naval Architecture Questions PDFDocument42 pagesNaval Architecture Questions PDFShyamshesha Giri100% (1)

- B.E. NAME 2nd YearDocument19 pagesB.E. NAME 2nd YearShyamshesha GiriNo ratings yet

- Vol09 Pt04 Issue 01 Submarine Hydrodynamics, Manoeuvring and Control PDFDocument33 pagesVol09 Pt04 Issue 01 Submarine Hydrodynamics, Manoeuvring and Control PDFShyamshesha GiriNo ratings yet

- B.E. NAME 2nd YearDocument19 pagesB.E. NAME 2nd YearShyamshesha GiriNo ratings yet

- B.E. NAME 4th YearDocument16 pagesB.E. NAME 4th YearShyamshesha GiriNo ratings yet

- Submarine StructuresDocument39 pagesSubmarine StructuresShyamshesha GiriNo ratings yet

- Mery PDFDocument7 pagesMery PDFShyamshesha GiriNo ratings yet

- Scantling Calculation Design CheckDocument6 pagesScantling Calculation Design CheckShyamshesha GiriNo ratings yet

- BB Shooting Book PDF 2Document97 pagesBB Shooting Book PDF 2Arpith KumarNo ratings yet

- 142809-Bobcat 331 331E 334 PDFDocument953 pages142809-Bobcat 331 331E 334 PDFKevin Cederquist100% (1)

- Evolution of The Model A 1930 - 31 Gas - TankDocument21 pagesEvolution of The Model A 1930 - 31 Gas - TankDavid RobinsonNo ratings yet

- T-SB-0163-08 Fuel TankDocument7 pagesT-SB-0163-08 Fuel TankdonotbugNo ratings yet

- Airtronic L: Technical Description, Installation, Operation and Maintenance InstructionsDocument52 pagesAirtronic L: Technical Description, Installation, Operation and Maintenance InstructionsevgenyNo ratings yet

- Grader ChecklistDocument16 pagesGrader ChecklistJhun Aquino100% (1)

- 5-650kva 60HZ en PDFDocument26 pages5-650kva 60HZ en PDFAndrésRozoNo ratings yet

- Cdcomplete PDFDocument164 pagesCdcomplete PDFMarian Placzek100% (2)

- PSL 8.8l Propane Service ManualDocument76 pagesPSL 8.8l Propane Service ManualUziel PavónNo ratings yet

- SP961 车辆保函Document2 pagesSP961 车辆保函1033699842No ratings yet

- Tohatsu MFS2.5-3.5B US en Web 1Document64 pagesTohatsu MFS2.5-3.5B US en Web 1tempxNo ratings yet

- Unmanned Refuelling Facilities / Above-Ground Storage: AS1940:2017 Now ReleasedDocument2 pagesUnmanned Refuelling Facilities / Above-Ground Storage: AS1940:2017 Now Releasedمحمود من فارس للبترولNo ratings yet

- 11 - Fuel PDFDocument33 pages11 - Fuel PDFJaya Kepalo LobuahNo ratings yet

- 500kW User ManualDocument83 pages500kW User ManualvanhoackdNo ratings yet

- Operation Manual 1760xl-OmDocument116 pagesOperation Manual 1760xl-Omrce.ramNo ratings yet

- Eco Fit RomDocument3 pagesEco Fit RomRobin AttallaNo ratings yet

- Submittal: Series: HSC, Diesel EngineDocument14 pagesSubmittal: Series: HSC, Diesel EngineOmar MuqtharNo ratings yet

- 73 (r00)Document120 pages73 (r00)Mhd100% (1)

- KR502 - Serial # 1128 - CE - R04Document33 pagesKR502 - Serial # 1128 - CE - R04GregNo ratings yet

- Fuel Containment System RequirementsDocument9 pagesFuel Containment System Requirementsnipper7No ratings yet

- Briggs Engine Owners Manual Model 12 277040tri - K - Hi1Document32 pagesBriggs Engine Owners Manual Model 12 277040tri - K - Hi1Willy Lozano GalindoNo ratings yet

- Mitfuso Owners Manual 2014 FefgDocument468 pagesMitfuso Owners Manual 2014 FefgSam ArevaloNo ratings yet

- Dyna PacDocument32 pagesDyna PacGianmarcosNo ratings yet

- Fuel SystemDocument7 pagesFuel SystemখালিদহাসানNo ratings yet

- Genie TrinityDocument214 pagesGenie TrinityMONTECARLO88No ratings yet

- E38 Fuel Supply SystemDocument4 pagesE38 Fuel Supply SystemNorizwad Shah NasharudinNo ratings yet

- 7745858w D2-55, D2-75 OPERATOR'S MANUALDocument64 pages7745858w D2-55, D2-75 OPERATOR'S MANUALm.kelleci72480% (1)

- TC 785 - Type Certification Data Sheet 28-5ACF (Army/Navy PBY-5A)Document6 pagesTC 785 - Type Certification Data Sheet 28-5ACF (Army/Navy PBY-5A)Mário MineiroNo ratings yet

- Aircraft Fuel SystemsDocument36 pagesAircraft Fuel SystemsShaddy Gitau100% (2)

- XRVS 1000 CD T4i HopDocument2 pagesXRVS 1000 CD T4i HopJose Cruz Martinez MedinaNo ratings yet

- QBDC - Season 5-RulebookDocument50 pagesQBDC - Season 5-RulebookHggvgNo ratings yet