Professional Documents

Culture Documents

Airfield and Highway Pavements 2019

Uploaded by

MEHDI FARROKHIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Airfield and Highway Pavements 2019

Uploaded by

MEHDI FARROKHICopyright:

Available Formats

Airfield and Highway Pavements 2019 11

Assessment of the 1993 AASHTO Structural Number as a Tool for Performance

Evaluation of Asphalt Pavements Using Falling Weight Deflectometer Data from LTPP

M. Elshaer1; M. Oshone2; E. Dave3; J. E. Sias4 ; Y. Mehta5; and A. Ali6

1

Center for Research and Education in Advanced Transportation Engineering Systems

(CREATEs), Rowan Univ., Mullica Hill, NJ 08062. E-mails: elshaer@rowan.edu

2

Dept. of Civil and Environmental Engineering, Univ. of New Hampshire, Durham, NH 03824.

E-mails: mto1@wildcats.unh.edu

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

3

Dept. of Civil and Environmental Engineering, Univ. of New Hampshire, Durham, NH 03824.

E-mails: eshan.dave@unh.edu

4

Dept. of Civil and Environmental Engineering, Univ. of New Hampshire, Durham, NH 03824.

E-mails: jo.sias@unh.edu

5

Center for Research and Education in Advanced Transportation Engineering Systems

(CREATEs), Rowan Univ., Mullica Hill, NJ 08062. E-mails: Mehta@rowan.edu

6

Center for Research and Education in Advanced Transportation Engineering Systems

(CREATEs), Rowan Univ., Mullica Hill, NJ 08062. E-mails: alia@rowan.edu

ABSTRACT

Since its first development in 1960, the AASHTO design guide for flexible pavements design

has been widely used by many agencies for the design of a pavement structure. The guide was

substantially modified in 1986 to incorporate nationwide requirements and climatic conditions.

However, with significant changes in asphalt technology such as the addition of recycled asphalt,

modifiers, and change in traffic and climatic condition, the reliability of the empirical equation to

predict the performance of flexible pavements has been put into question. However, even with

such concerns, it still remains the most prevalent design method used for the design of a

pavement structure by many agencies. One of the most significant breakthroughs of the 1993

design guide was the introduction of the concept of structural number (SN). This study

investigates the capability of 1993 AASHTO SN to monitor the changes in pavement

performance as it relates to roughness (IRI), rutting, and fatigue cracking using measured field

data of four sections from the long-term pavement performance (LTPP) database. The

backcalculated moduli values from FWD tests corrected at mid-depth reference temperature are

used to determine the layer coefficients. Then, the structural strength of the overall pavement

(i.e. SN) for the course of a pavement life is compared to the change in pavement performance

(i.e. IRI, rutting, and fatigue cracking). The results showed a significant relationship between the

change in SN and a change in pavement performance as it relates to rutting and roughness index

where with a decrease in SN, the IRI and rut depth increases. The SN assessment also showed

that the LTPP database can be used as a valuable source to calibrate the 1993 AASHTO SN

equation based on measured field data from LTPP.

Keywords: 1993 AASHTO Design, Structural Number (SN), LTPP, FWD, IRI, Rut depth

INTRODUCTION AND BACKGROUND

The AASHO road test in the late 1950s and early 1960s near Ottawa, Illinois resulted in the

development of a guide for flexible pavement design. The guide was first introduced in 1961 as

the “AASHO Interim Guide for the design of Rigid and Flexible Pavements”. Since its first

introduction, the guide has been significantly modified in 1986 to incorporate nationwide

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 12

requirements and climatic conditions. The road test was performed on pavements that have a

wide range of variation in surface mixture type, axle configuration, and layer thickness. Based on

a two-year performance data from AASHTO road test in 1958-1960, an empirical equation that

relates pavement layer thickness to total traffic load projected for the pavement life in terms of

Equivalent Axle Load (ESAL) is developed (HRB, 1962). Currently, due to a significant change

in asphalt technology such as the addition of RAP, modifiers, and increase in traffic loading and

change in climate, there is an ongoing regional effort by agencies to calibrate the Mechanistic-

Empirical Pavement Design Guide (Pavement ME) and subsequently transition to a mechanistic

pavement design. However, regardless of such effort, the AASHTO 1993 guide still remains the

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

most common method that is employed by agencies for the design of a pavement structure due to

its simplicity and agencies confidence in the method.

One of the most significant advances of the 1986 design guide was the introduction of the

concept of structural number (SN). The SN considers material property, thickness, and drainage

capability of each layer in a pavement structure as indicated in Equation 1 (AASHTO, 1993;

Pologruto, 2001). The layer coefficients (a1, a2, a3) are indicative of the relative strength of

different layers whereas the drainage coefficients (m2 and m3) account for moisture condition in

the unbound layers. The SN determines the design thickness of the pavement layers.

Consequently, the layer thickness determines the total number of designs ESAL the pavement

can carry without causing damage to the subgrade which is the primary goal of pavement design.

The SN concept follows the notion that the condition of the subgrade is protected by providing

sufficient structural strength and good drainage capacity for all pavement layers. Meaning, for a

stronger subgrade condition a lower SN is required as compared to a weaker subgrade condition

assuming the pavements are exposed to the same climatic and loading conditions.

SN a1D1 a2 D2 m2 a3 D3m3 anth Dnth mnth (1)

where

SN = Structural Number; a1, a2, a3 = layer coefficients of the surface, base, and subbase

layers, respectively; D1, D2 and D3 = layer thicknesses in inches of the surface, base, and subbase

layers, respectively; m2 and m3 = layer drainage coefficients of the base, and subbase layers,

respectively;

The AASHTO design guide suggests the use of backcalulated moduli from Falling weight

deflectometer (FWD) to determine the layer coefficients. This method was found to be more

accurate because it accounts for actual field conditions by measuring the deflection of

constructed pavement. On the other hand, the use of lab measured stiffness values might cause

bias in the estimated layer coefficient values due to deviations of material properties of lab-

produced samples from mixtures placed in the field. Moreover, the FWD test provides a closer

representation of the wide range of loading condition as well as the dynamic nature of the

moving vehicle load. The Long-Term Pavement Performance (LTPP) program launched the

Seasonal Monitoring Program (SMP) to monitor the pavement response at 64 sites by measuring

the FWD deflection, pavement profiles, daily and annual temperature, moisture content, and

frost/thaw on pavement structure (Elkins et al. 2003). The backcalculated moduli of pavement

layers available in LTPP are calculated from the FWD deflection measurements using three

programs: EVERCALC, MODTAG, and Modulus (Von Quintus et al. 2015).

Pavement smoothness (i.e. roughness) is one of the most important indicators of pavement

performance associated with pavement serviceability. It affects ride quality and accelerates the

occurrence of other pavement distresses (i.e. fatigue cracking and rutting) (Mubaraki, 2016). In

turn, any pavement distresses will also accelerate the deterioration of the pavement roughness

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 13

value (i.e. International Roughness Index (IRI)). As a result, there is a relationship between

pavement distresses and pavement roughness showing dependence of one on the other. Hence,

pavement performance should be assessed based on both IRI and pavement distress types to

make a better decision for pavement maintenance and rehabilitation.

A large amount of roughness, fatigue cracking, and rutting data has been collected as part of

the LTPP studies. However, the analysis of these extensive data to determine the relationship

between the change in the SN of overall pavement structure and the corresponding changes in

pavement roughness and distress are not well documented. In addition, limited studies have

evaluated the use of the 1993 AASHTO SN equation (Equation 1) to determine the SN of overall

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

pavement structure based on FWD test (Abd El-Raof et al. 2018). Therefore, there is a need to

investigate the ability of Equation 1 to track the changes in pavement cracking, rutting, and

roughness to accurately design a pavement structure. This can be achieved using historical

backcalculated modulus from FWD measurements, temperature profile, fatigue cracking, rutting,

and IRI measurements from the LTPP database to better understand the effect of change in

pavement strength on pavement performance.

GOAL AND OBJECTIVES

The goal of this study is to investigate the relationship between structural number and

pavement performance. The specific objectives of this paper to achieve the above goal include:

(a) assessment of the 1993 AASHTO SN equation to track the change in pavement strength as it

relates to pavement distresses and roughness; and (b) evaluation of the impact of pavement

maintenance and rehabilitation (M&R) on pavement strength and performance. The proposed

study is based on historical LTPP field data measurements in one climatic zone; wet-freeze (i.e.,

FWD backcalculated moduli, temperature profile, rutting, fatigue cracking, and IRI).

COLLECTED LTPP DATA DESCRIPTION AND ANALYSIS APPROACH

This section provides a discussion of the collected LTPP sections to investigate the capability

of 1993 AASHTO SN equation to track the changes in pavement performance over the course of

pavement service life. This section also provides the details of SN analysis using the collected

field data.

LTPP Data Collection

The data used in this study was obtained from the LTPP from Standard Data Release (SDR

32- July 2018) made available by the Federal Highway Administration's (FHWA). The selected

data was collected from four LTPP-SMP sections located in the New England region

(Connecticut (CT), Massachusetts (MA), Maine (ME), and Vermont (VT)). The selected sections

covered the wet-freeze climatic zone. Table 1 shows the information of the selected LTPP test

sections. The criteria for selecting the sections considered in this study was based on the

availability of a significant number of backcalculated modulus from FWD measurements,

temperature profile, fatigue cracking, rutting, and IRI measurements. This selection process was

important to ensure correlating realistic field-determined moduli values to the actual strength of

overall pavement section and therefore capturing the impact on their field distress and roughness.

Temperature profiles for each section were utilized to ensure the bound and unbound material

layers are not frozen during the time of FWD testing. This was done to exclude the

unrealistically high backcalculated modulus data of pavement layers from the analysis during

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 14

winter time which is due to frozen pavement layers (i.e., pavement structure temperatures < 0oC).

Consequently, field measurements of IRI, fatigue cracking, rutting and FWD collected for three

seasons (summer, fall, and spring seasons where the pavement structure temperatures > 0oC)

were considered in this study.

The average backcalculated moduli values obtained from FWD measurements when the test

was conducted in the outer wheel path at a load of 40 kN were used for SN analysis. These

backcalculated moduli values in the outer wheel path were selected because the pavement

distress usually occurs in the wheel path. In addition, the IRI profile data at LTPP test sections

were collected along the wheel path thus, capturing a realistic behavior of pavements. It is also

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

noted that the profile testing, fatigue cracking and rutting measurements and FWD testing were

not performed on the same day at LTPP test sections. Therefore, IRI, fatigue cracking, rutting

and FWD data collected on dates close to each other were selected from the LTPP database for

SN analysis.

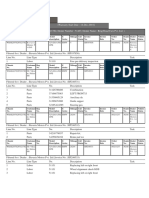

Table 1. Selected LTPP Sites

1 2 3 4

LTPP Sites

09-1803 25-1002 23-1026 50-1002

Connecticut Massachusetts Maine

Location Vermont (VT)

(CT) (MA) (ME)

AC (183

Surface type AC (180 mm) AC (198 mm) AC (216 mm)

mm)

Uncrushed Uncrushed

Crushed gravel Crushed gravel

Base type gravel (300 gravel

(102 mm) (655 mm)

mm) (447 mm)

Coarse- Coarse-

Coarse-Grained Coarse-Grained

Grained Soils: Grained

Soils: Poorly Soil: Poorly

Subgrade type Well-graded Soils: silty

graded sand with graded gravel

sand with silt sand with

silt with silt and sand

and gravel gravel

FWD deflection,

IRI, rutting and

fatigue cracking 1989-2010 1989-2004 1989-2001 1989-2003

data measurements

(year)

Crack sealing

Crack sealing

(Jan1995 & Asphalt

(Oct 1992 & Nov

Maintenance and Jul 1996) Overlay –

1994) Patch Pot

Rehabilitation Asphalt 67 mm _________

Holes (Sep 199,

(M&R) Overlay- 70 (Sep

May 1997 May

mm (Jun 1996)

2000, Apr 2003)

2000)

ANALYSIS APPROACH

Temperature is the most critical factor affecting surface deflection and AC modulus.

Therefore, the backcalculated AC modulus from FWD test should be adjusted to a reference

temperature. The measured mid-depth temperature of the AC layer was considered as the

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 15

effective temperature to represent the AC layer temperature at the time of FWD measurement

(Chen et al. 2000). The backcalculated AC moduli were corrected to the standard temperature of

68 F (20°C) using the Asphalt Temperature Adjustment Factor (ATAF) presented in Equation

(2) and Equation (3) was used to adjust the backcalculated moduli (Lukanen et al. 2000). Then,

the layer coefficient values for AC layer (a1) were determined using the corrected backcalculated

asphalt moduli at 20oC using the Equation in the AASHTO 1993. In addition, the impact of

environmental conditions such as moisture content on the stiffness of unbound material is

essential for determining the SN values where the stiffness increases as the moisture content

decrease and vice versa. Therefore, the backcalculated base moduli from FWD test was used as a

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

good indicator of the influence of environmental factors on unbound material. Consequently, the

structural layer coefficients of the unbound granular base (a 2) were calculated as a function of the

backcalculated moduli of base layer every time of measurements using the Equation in the

AASHTO 1993.

ATAF 10slope(Tr Tm ) (2)

ECorrected at reference temp ATAF Ebackcalculated at measured temp (3)

where,

ATAF=Asphalt Temperature Adjustment Factir; Slope = Log (Mr)=intercept+slope T=-

0.021 for mid-lane and −0.0195 for wheel-path; Tr = reference mid-depth AC layer temperature

o

𝐶; 𝑇𝑚 = mid-depth AC layer temperature at the time of FWD testing, o𝐶; E corrected at

reference temp = corrected AC layer modulus to a reference temperature; Ebackcalculated =

backcalculated AC modulus at temperature of FWD testing;

A drainage coefficient value of 0.4 was extracted from the LTPP database based upon the

climate zone of four LTPP sections and used in this analysis for all the unbound materials. Then,

the SN for each of the four LTPP pavement sections was calculated using Equation 1 with layer

and drainage coefficient values for the AC and base layers. Finally, the SN values computed

from FWD data were compared to average IRI, rutting, and fatigue cracking to examine the

relationship between change in IRI, rutting, and fatigue cracking to change in SN.

RESULTS AND DISCUSSION

Figures 1-4 show the change in IRI, fatigue cracking, and rutting with the change in SN for

the course of pavement life for each of the four LTPP sections. Figure 1 is for CT section, Figure

2 is for ME section, Figure 3 is for VT section, and Figure 4 is for MA section. As shown in

Figures 1a and 1b, when the SN decreases the rut depth, fatigue cracking and IRI increase.

Generally, the peak in SN occurred in the summer time due to the higher stiffness of base and

subgrade layers. The increase in stiffness is anticipated in the unbound layers during the summer

season due to the lower moisture content as compared to the spring season. In other words, the

measured moisture content of the unbound layers is expected to be at the optimum moisture

content or below the optimum value. To validate this assumption, the soil moisture profile was

extracted from the LTPP database and is used to evaluate if the moisture content of the unbound

materials is the reason for the observed high moduli value during summer seasons. The result

depicts that the SN increases by 17% in the summer season (e.g. August 1994) due to stiffer

unbound materials. There is a slight decrease in the rut depth (i.e. decrease of 1-2 mm) in some

years regardless of the maintenance and rehabilitation done. This decrease in rut depth could be

because of the volume change in the unbound materials during freeze-thaw cycles and/or the

variability in the rut depth measurements. The results also show that the crack sealing

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 16

maintenance improved the fatigue cracking while the AC overlay increased the structural

strength of the overall pavement (i.e. SN) and decreased IRI, rutting, and fatigue cracking.

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

Figure 1. Change in (a) SN vs fatigue cracking and rutting data (b) SN vs IRI data for CT

section

Figure 2. Change in SN vs rutting and IRI data for ME section

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 17

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

Figure 3. Change in (a) SN vs fatigue cracking and rutting data (b) SN vs IRI data for VT

section

In the case of ME section (Figure 2), the SN and rutting depth follow the same pattern as CT

section, where SN decreases, rut depth and IRI increase. However, the IRI profile showed some

mixed results where the trend between SN and IRI fluctuates. These mixed results could be the

impact of inherent error in backcalculation process. The fatigue cracking data was not plotted

because the measurements were zero for all investigated years. It is also noted that thin overlays

have resulted in large reductions in IRI and rut depth. For example, the IRI value was reduced

from 1.4 m/km to 0.9 m/km after resurfacing with a 67-mm thick AC overlay. In addition, the rut

depth values after the resurfaced section decreased from 16 mm to 5 mm in a 5-year period.

However, in the last five years, the rut depth shows some mixed results where SN increase rut

depth increase as well. One potential reason explaining these mixed rut depth results is the

domination of base layer modulus (i.e. higher stiffness) due to lower moisture content).

Similar to CT and ME sections, when the SN decreases IRI, rut depth and fatigue cracking

increase as shown in Figure 3a and 3b. However, there are few mixed results where SN

increased, the rut depth, fatigue cracking, and IRI increased as well. These mixed results could

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 18

be a result of 1) inconsistency in field measurements, 2) volume change in unbound materials

due to freeze-thaw cycles, 3) variability in the backcalculation analysis 4) lower subgrade

modulus due to high moisture content. As shown in Figures 4a and 4b, when the SN decreases,

IRI and rut depth increased. On the other hand, fatigue cracking does not follow similar trend to

SN. The plots show that the M&R (potholes) improved the strength of overall pavement, IRI,

fatigue cracking, and rutting potential (i.e. fatigue cracking, IRI and rut depth decreased).

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

Figure 4. Change in (a) SN vs fatigue cracking and rutting data (b) SN vs IRI data for MA

section

Table 2. Significance and Correlation of SN to Different Performance Measurements

Performance R2 p-values

Measurements CT ME VT MA CT ME VT MA

IRI 0.59 0.83 0.59 0.02 0.0002 0.0001 0.0057 0.7224

Rutting 0.51 0.79 0.51 0.16 0.0043 0.0001 0.0231 0.1701

Fatigue Cracking 0.01 0.14 0.07 0.004 0.8534 0.0381 0.2214 0.9146

A statistical analysis was performed to determine the significance and correlation of SN to

different pavement performance measurements. The p-values between SN and IRI, rut depth, and

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 19

fatigue cracking were determined from a stepwise regression analysis are shown in Table 2. The

common practice of using p-value of 0.05 as a threshold is adopted. The pavement performance

measurements where SN is found significant are shown in Bold. The results indicated that SN

has a significant effect on the IRI and rutting performance of pavements with the exception of

MA section. The coefficient of determination (R2) values between SN and the different

performance measurements are also shown in Table 2. In general, the results from CT, ME and

VT show that more than 50% of the variation in SN is explained by change in IRI and rutting

whereas the contribution of fatigue cracking to the observed change in SN was found minimal.

Overall, the analysis presented in this study showed the existence of a statistically significant

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

relationship (at 95% confidence interval) between SN and roughness (IRI) and rutting over the

pavement service life for three of the four LTPP sections.

CONCLUSIONS

The study presented in this paper investigated the capability of the 1993 AASHTO SN model

(Equation 1) to monitor the changes in pavement performance as it relates to fatigue cracking,

rutting, and roughness of a pavement. Four LTPP pavement sections located in Connecticut,

Massachusetts, Maine, and Vermont were used to assess the SN equation using FWD test data.

The backcalculated moduli of AC layer were adjusted to a reference mid-depth temperature of

20C to predict the layer coefficient of AC layer. A comparison between the change in SN

predicted from the 1993 AASHTO SN equation after temperature correction and change in

pavement roughness (i.e. IRI) and pavement distress (i.e. fatigue cracking and rutting) was

conducted. The following conclusions can be drawn based on the observation:

There is a statistically significant relationship between SN calculated from 1993

AASHTO equation and pavement performance (i.e. Rutting and IRI) for the majority of

the selected LTPP sections.

LTPP database can be used to calibrate 1993 AASHTO SN equation based on FWD

testing and pavement performance measurements.

This study was limited to assessing the 1993 AASHTO SN equation to monitor the changes

in pavement performance based on FWD testing for four sections in the wet-freeze climatic

zone. Further studies are needed to investigate other pavement structures from different locations

in the four climatic zones to accurately calibrate the SN equation. Despite this limitation, this

study has preliminary showed that the use of this information can be adapted to calibrate the SN

equation regionally based on measured field data from LTPP. This will lead to increase in

pavement service life, and decrease the interventions (preservation, rehabilitation, and

maintenance).

REFERENCES

Abd El-Raof, H. S., Abd El-Hakim, R. T., El-Badawy, S. M., & Afify, H. A. (2018). Structural

number prediction for flexible pavements using the long-term pavement performance data.

International Journal of Pavement Engineering, 1-15.

Chen, D. H., Bilyeu, J., Lin, H. H., & Murphy, M. (2000). Temperature correction on falling

weight deflectometer measurements. Transportation Research Record: Journal of the

Transportation Research Board, (1716), 30-39.

Elkins, G. E., Schmalzer, P., Thompson, T., & Simpson, A. (2003). Introduction to the LTPP

information management system (IMS) (Rep. No. FHWA-RD-03-088). Washington, DC:

© ASCE

Airfield and Highway Pavements 2019

Airfield and Highway Pavements 2019 20

Federal Highway Administration, U.S. Department of Transportation.

Highway Research Board (1962), The AASHO Road Test, Special Reports Nos. 61A-61G and

73, Washington, D. C.

Lukanen, E. O., Stubstad, R., & Briggs, R. 2000. Temperature Predictions and Adjustment

Factors for Asphalt Pavement.

Mubaraki, M. (2016). Highway subsurface assessment using pavement surface distress and

roughness data. International Journal of Pavement Research and Technology, 9(5), 393-402.

Pologruto, M. (2001). Procedure for use of falling weight deflectometer to determine AASHTO

layer coefficients. Transportation Research Record: Journal of the Transportation Research

Downloaded from ascelibrary.org by Mohamed Elshaer on 08/02/19. Copyright ASCE. For personal use only; all rights reserved.

Board, (1764), 11-19.

Transportation Officials. (1993). AASHTO guide for design of pavement structures, 1993 (Vol.

1). AASHTO.

Von Quintus, H. L., Rao, C., & Irwin, L. (2015). Long-Term Pavement Performance Program

Determination of In-Place Elastic Layer Modulus: Backcalculation Methodology and

Procedures (No. FHWA-HRT-15-036).

© ASCE

Airfield and Highway Pavements 2019

You might also like

- Rear Disk ConversionDocument5 pagesRear Disk Conversionphil_moody46No ratings yet

- Flags and Pennants MarcomDocument145 pagesFlags and Pennants MarcomJeus Bencio100% (1)

- Example Case Study-Milwaukee Art MuseumDocument26 pagesExample Case Study-Milwaukee Art MuseumZhihui HuangNo ratings yet

- 2nd Mate Oral Exam Questions ListDocument2 pages2nd Mate Oral Exam Questions ListKumaaran AchuthanNo ratings yet

- 08 Star Trek Comic Strip US - Its A LivingDocument27 pages08 Star Trek Comic Strip US - Its A LivingColin NaturmanNo ratings yet

- Contents.: The New BMW M4 GTSDocument31 pagesContents.: The New BMW M4 GTSturbojloNo ratings yet

- LNGC Golar Frost - IMO 9253284 - Cargo Operating ManualDocument347 pagesLNGC Golar Frost - IMO 9253284 - Cargo Operating Manualseawolf50No ratings yet

- Shore Protection Manual Vol 2Document652 pagesShore Protection Manual Vol 2Jonathan Alberto EscobarNo ratings yet

- Military Modelling Volume 47 Issue 2 2017 PDFDocument76 pagesMilitary Modelling Volume 47 Issue 2 2017 PDFFrankie Mundens100% (1)

- Gandeza Practical Exercise 2 Criminal ComplaintDocument13 pagesGandeza Practical Exercise 2 Criminal ComplaintRoss AnasarioNo ratings yet

- Amphibious VehiclesDocument11 pagesAmphibious Vehiclesk2gadu7457No ratings yet

- Pulsation Free (Piston Pump)Document18 pagesPulsation Free (Piston Pump)Fanny Fabiola YupanquiNo ratings yet

- Incorporating Highway Capacity Software in Undergraduate Teaching of Transportation CoursesDocument14 pagesIncorporating Highway Capacity Software in Undergraduate Teaching of Transportation CoursesdarcinaNo ratings yet

- East Campus Urban Design Study: Final Report: Massachusetts Institute of TechnologyDocument22 pagesEast Campus Urban Design Study: Final Report: Massachusetts Institute of Technologysyedaurooj818No ratings yet

- Group 06 FinalDocument16 pagesGroup 06 Finalmahmudhasanmasuk6No ratings yet

- 18 Understanding The SubContractual Relationship For Proper Management of ConstructionDocument10 pages18 Understanding The SubContractual Relationship For Proper Management of ConstructionDhika AdhityaNo ratings yet

- 97807844127872e132 2 PDFDocument11 pages97807844127872e132 2 PDFTanmoy DasNo ratings yet

- Stability Analysis of Seismically Loaded Slopes Using Finite Element TechniquesDocument11 pagesStability Analysis of Seismically Loaded Slopes Using Finite Element TechniquesTanmoy DasNo ratings yet

- Impact of Training Methods On Hazard Recognition and Risk Perception inDocument11 pagesImpact of Training Methods On Hazard Recognition and Risk Perception inMoumin AsmaNo ratings yet

- Music Market AnalysisDocument17 pagesMusic Market AnalysiskhalsaamanNo ratings yet

- Pre ProofDocument39 pagesPre ProofDo Hoang LanNo ratings yet

- The National Academies PressDocument289 pagesThe National Academies PressAlejandro RuizNo ratings yet

- Turn Pocket Blockage and Spillback Models: ArticleDocument21 pagesTurn Pocket Blockage and Spillback Models: ArticleDevaki sitoulaNo ratings yet

- Diseño Ecológico de Caminos de MontañaDocument6 pagesDiseño Ecológico de Caminos de MontañaWilliam TamayoNo ratings yet

- Comparison of Life Cycle Carbon Footprints of Steel and Concrete Pressure PipesDocument11 pagesComparison of Life Cycle Carbon Footprints of Steel and Concrete Pressure PipesAndresNo ratings yet

- Team-CVs (1) - 1-10Document10 pagesTeam-CVs (1) - 1-10Nitin RautNo ratings yet

- OutputDocument71 pagesOutputNitin RautNo ratings yet

- Pdf24 MergedDocument29 pagesPdf24 MergedNitin RautNo ratings yet

- Team CVsDocument60 pagesTeam CVsNitin RautNo ratings yet

- Ecological Indicators: Anh Kim Nguyen, Yuei-An Liou, Ming-Hsu Li, Tuan Anh TranDocument18 pagesEcological Indicators: Anh Kim Nguyen, Yuei-An Liou, Ming-Hsu Li, Tuan Anh TranRidho Al-fatah MaulanaNo ratings yet

- Expanding The Technology Acceptance Model (Tam) To Examine Faculty Use of Learning Management Systems (LMSS) in Higher Education InstitutionsDocument23 pagesExpanding The Technology Acceptance Model (Tam) To Examine Faculty Use of Learning Management Systems (LMSS) in Higher Education InstitutionsFritz FerranNo ratings yet

- Advancing Understanding of Natural Resource Governance: A Post-Ostrom Research AgendaDocument9 pagesAdvancing Understanding of Natural Resource Governance: A Post-Ostrom Research AgendaRakha GurandNo ratings yet

- Green PlanningDocument14 pagesGreen Planningcaroline murugiNo ratings yet

- GIS BasedLandSuitabilityAnalysistoSupportTransit OrientedDevelopmentTODMasterPlanACaseStudyoftheCampusStationofThammasatUniversityandItsSurroundingCommunitiesDocument13 pagesGIS BasedLandSuitabilityAnalysistoSupportTransit OrientedDevelopmentTODMasterPlanACaseStudyoftheCampusStationofThammasatUniversityandItsSurroundingCommunitiesAzka RamadhanNo ratings yet

- CE744 Syllabus - Fall 2017-2018 PDFDocument2 pagesCE744 Syllabus - Fall 2017-2018 PDFesraaalhajNo ratings yet

- CE744 Syllabus - Fall 2017-2018Document2 pagesCE744 Syllabus - Fall 2017-2018esraaalhajNo ratings yet

- A Novel Artificial Intelligence Technique To Predict Compressive Strength of Recycled Aggregate Concrete Using Ica Xgboost ModelDocument18 pagesA Novel Artificial Intelligence Technique To Predict Compressive Strength of Recycled Aggregate Concrete Using Ica Xgboost ModelLusman SulaimanNo ratings yet

- Modeling of Prestressed Concrete Bridge GirdersDocument18 pagesModeling of Prestressed Concrete Bridge GirdersPhạm Tiến ĐạtNo ratings yet

- The National Academies PressDocument88 pagesThe National Academies PressAdan ReyesNo ratings yet

- President Ramon Magsaysay State University: Telefax: 047-8111683/email Address: Prmsu - Edu.phDocument16 pagesPresident Ramon Magsaysay State University: Telefax: 047-8111683/email Address: Prmsu - Edu.phshan kelly marillaNo ratings yet

- GIS-based Land Suitability Analysis To Support Transit-Oriented Development (TOD) Master Plan: A Case Study of The Campus Station of Thammasat University and Its Surrounding Commun..Document13 pagesGIS-based Land Suitability Analysis To Support Transit-Oriented Development (TOD) Master Plan: A Case Study of The Campus Station of Thammasat University and Its Surrounding Commun..Dillan SatyagamaNo ratings yet

- First Year SyllabusDocument66 pagesFirst Year Syllabusgvraju123No ratings yet

- Gurjar CV 2015 IITRDocument25 pagesGurjar CV 2015 IITRexecutive engineerNo ratings yet

- Annurev Environ 050120 113117Document43 pagesAnnurev Environ 050120 113117Rafsan Al- AminNo ratings yet

- Accident Analysis and Hazard Analysis For Human and Organizational FactorsDocument283 pagesAccident Analysis and Hazard Analysis For Human and Organizational FactorsRdhn fingerstyleNo ratings yet

- BSME - People and The Earths Ecosystem - 22 23Document15 pagesBSME - People and The Earths Ecosystem - 22 23Ganyu AyakaNo ratings yet

- Traffic Impact Analysis of Existing Road at Jalan Berapit (State Route P131) Bukit Mertajam, Pulau Pinang Based On Road Safety Audit (Stage 5) GuidelinesDocument9 pagesTraffic Impact Analysis of Existing Road at Jalan Berapit (State Route P131) Bukit Mertajam, Pulau Pinang Based On Road Safety Audit (Stage 5) Guidelinesamelinda jocelinNo ratings yet

- Peer Team Report On Institutional AssessmentDocument14 pagesPeer Team Report On Institutional Assessmentthunderaviation88No ratings yet

- ADS Workshop LeafletDocument2 pagesADS Workshop LeafletShivam AgarwalNo ratings yet

- Cognitive Vs Hierarchical TADocument30 pagesCognitive Vs Hierarchical TAReshmi VarmaNo ratings yet

- Predictive Equation For Estimating Lateral Deformation of GRS AbutmentsDocument12 pagesPredictive Equation For Estimating Lateral Deformation of GRS AbutmentsTruc PhanNo ratings yet

- President Ramon Magsaysay State University: Telefax: 047-8111683/email Address: Prmsu - Edu.phDocument16 pagesPresident Ramon Magsaysay State University: Telefax: 047-8111683/email Address: Prmsu - Edu.phDarwin Salinas LubongNo ratings yet

- Arizona Graduate Study RequirementDocument4 pagesArizona Graduate Study Requirementحسين الشهريNo ratings yet

- Innovation in Utility Locating and Mapping Technologies: 793 ICPTT 2009 © 2009 ASCEDocument10 pagesInnovation in Utility Locating and Mapping Technologies: 793 ICPTT 2009 © 2009 ASCEaneethavilsNo ratings yet

- Lam Derek ResumeDocument1 pageLam Derek Resumeapi-319165781No ratings yet

- Workshop BrouDocument2 pagesWorkshop BrouSooraj ShenoyNo ratings yet

- Intro To Ecosystem AssessmentDocument6 pagesIntro To Ecosystem AssessmentDstormNo ratings yet

- Converting Paved Roads To Unpaved (2015)Document97 pagesConverting Paved Roads To Unpaved (2015)prmraoNo ratings yet

- The State Level Online Quiz Competition: Government Polytechnic WashimDocument1 pageThe State Level Online Quiz Competition: Government Polytechnic WashimKunal AhiwaleNo ratings yet

- Development of Artificial Neural Networks Based Predictive Models For Dynamic Modulus of Airfield Pavement Asphalt MixturesDocument7 pagesDevelopment of Artificial Neural Networks Based Predictive Models For Dynamic Modulus of Airfield Pavement Asphalt Mixturesmohammad faresNo ratings yet

- Importance of Preserving The Natural Environment in The Design Schools in MalaysiaDocument10 pagesImportance of Preserving The Natural Environment in The Design Schools in MalaysiaMercil Pasco BancairenNo ratings yet

- A Study On School Location Suitability Using AHP in GIS ApproachDocument7 pagesA Study On School Location Suitability Using AHP in GIS ApproachAsep Deden Rahmat SNo ratings yet

- NCHRP RPT 646Document139 pagesNCHRP RPT 646juan camilo chivata alvaradoNo ratings yet

- Instant Download Ebook PDF Bounded Rational Choice Behaviour Applications in Transport PDF ScribdDocument41 pagesInstant Download Ebook PDF Bounded Rational Choice Behaviour Applications in Transport PDF Scribdmyrtis.donaldson459100% (41)

- Bhagya Coordinator Resume FinalDocument3 pagesBhagya Coordinator Resume FinalBhagya RamalingamNo ratings yet

- Procedia 13yearolds NorainiDocument12 pagesProcedia 13yearolds NorainiRayner TangkuiNo ratings yet

- ElkhouryDocument97 pagesElkhouryAbderrezak BlgNo ratings yet

- Guidelines For Design and Operation of U-turns-Safety Evaluation of U-Turn DesignDocument12 pagesGuidelines For Design and Operation of U-turns-Safety Evaluation of U-Turn Designdanang abdilahNo ratings yet

- David A. Paolella Et Al 2018 - MapsDocument6 pagesDavid A. Paolella Et Al 2018 - MapsAlejandro Lome HurtadoNo ratings yet

- Characterization of Freestream Disturbances in ConventionalHypersonic Wind TunnelsDocument12 pagesCharacterization of Freestream Disturbances in ConventionalHypersonic Wind TunnelsSohel MahmudNo ratings yet

- BrochureDocument2 pagesBrochurealex_moontv7497No ratings yet

- Interpretable Machine Learning for the Analysis, Design, Assessment, and Informed Decision Making for Civil InfrastructureFrom EverandInterpretable Machine Learning for the Analysis, Design, Assessment, and Informed Decision Making for Civil InfrastructureM. Z. NaserNo ratings yet

- No More Broken Pavement Around ManholesDocument5 pagesNo More Broken Pavement Around ManholesMEHDI FARROKHINo ratings yet

- Testresultat För DASAG TERAZZO PlattorDocument1 pageTestresultat För DASAG TERAZZO PlattorMEHDI FARROKHINo ratings yet

- 100128175847preview - SS 214-2009Document5 pages100128175847preview - SS 214-2009MEHDI FARROKHINo ratings yet

- Cooling Rates in Hot-Poured Bituminous Sealants: N R C C - 4 8 3 8 1 Collins, P. Masson, J-F. Al-Qadi, I.LDocument11 pagesCooling Rates in Hot-Poured Bituminous Sealants: N R C C - 4 8 3 8 1 Collins, P. Masson, J-F. Al-Qadi, I.LMEHDI FARROKHINo ratings yet

- 3bi - Terrazzo Tiles - Performance and TestingDocument1 page3bi - Terrazzo Tiles - Performance and TestingMEHDI FARROKHINo ratings yet

- Appendixes To TCRP Report 118:: Bus Rapid Transit Practitioner's GuideDocument51 pagesAppendixes To TCRP Report 118:: Bus Rapid Transit Practitioner's GuideMEHDI FARROKHINo ratings yet

- NH DOT Supplemental Design Criteria: Roundabouts: An Informational Guide (2000)Document5 pagesNH DOT Supplemental Design Criteria: Roundabouts: An Informational Guide (2000)MEHDI FARROKHINo ratings yet

- Uniform Standard Specifications For Public Works ConstructionDocument15 pagesUniform Standard Specifications For Public Works ConstructionMEHDI FARROKHINo ratings yet

- Empa - Road Engineering - Sealing Components - Innovative Manufacturing of Crumb Rubber Modified Asphalt ConcreteDocument2 pagesEmpa - Road Engineering - Sealing Components - Innovative Manufacturing of Crumb Rubber Modified Asphalt ConcreteMEHDI FARROKHINo ratings yet

- Vulcanization Characteristics of Asphalt/SBS Blends in The Presence of SulfurDocument8 pagesVulcanization Characteristics of Asphalt/SBS Blends in The Presence of SulfurMEHDI FARROKHINo ratings yet

- Rheological Properties of The Polymer Modified Bitumen With Emphasis On SBS Polymer and Its MicrostructureDocument8 pagesRheological Properties of The Polymer Modified Bitumen With Emphasis On SBS Polymer and Its MicrostructureMEHDI FARROKHINo ratings yet

- Fundamental Characterization of SBS-Modified Asphalt Mixed With SulfurDocument9 pagesFundamental Characterization of SBS-Modified Asphalt Mixed With SulfurMEHDI FARROKHINo ratings yet

- (Paperhub Ir) 10 1016@j Jclepro 2020 120817Document52 pages(Paperhub Ir) 10 1016@j Jclepro 2020 120817MEHDI FARROKHINo ratings yet

- Commentary To Ag:Pt/T101 - Method of Sampling Polymer Modified Binders, Polymers and Crumb RubberDocument8 pagesCommentary To Ag:Pt/T101 - Method of Sampling Polymer Modified Binders, Polymers and Crumb RubberMEHDI FARROKHINo ratings yet

- 10-1. - Asphalt-Rubber Seal CoatDocument11 pages10-1. - Asphalt-Rubber Seal CoatMEHDI FARROKHINo ratings yet

- Compatibilizer Role of Styrene-Butadiene-Styrene Triblock Copolymer in AsphaltDocument6 pagesCompatibilizer Role of Styrene-Butadiene-Styrene Triblock Copolymer in AsphaltMEHDI FARROKHINo ratings yet

- Pavement Preservation Technology: in France, South Africa, and AustraliaDocument59 pagesPavement Preservation Technology: in France, South Africa, and AustraliaMEHDI FARROKHINo ratings yet

- Fuel Processing Technology: Maciej Sienkiewicz, Kaja Borz Ędowska-Labuda, Artur Wojtkiewicz, Helena JanikDocument8 pagesFuel Processing Technology: Maciej Sienkiewicz, Kaja Borz Ędowska-Labuda, Artur Wojtkiewicz, Helena JanikMEHDI FARROKHINo ratings yet

- NORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameDocument69 pagesNORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameMEHDI FARROKHINo ratings yet

- Ir Hp1300wcu SpecsDocument2 pagesIr Hp1300wcu SpecsMEHDI FARROKHINo ratings yet

- Defining Green Road Infrastructure Projects-A Critical ReviewDocument11 pagesDefining Green Road Infrastructure Projects-A Critical ReviewMEHDI FARROKHINo ratings yet

- AKCELIK - ROUaaSIDRA&AUSTR (CAITR 2004)Document25 pagesAKCELIK - ROUaaSIDRA&AUSTR (CAITR 2004)MEHDI FARROKHINo ratings yet

- F05 - Al Rashidiya Metro Station To Mizhar 1 Dubai Bus Service TimetableDocument4 pagesF05 - Al Rashidiya Metro Station To Mizhar 1 Dubai Bus Service TimetableDubai Q&ANo ratings yet

- HowStuffWorks - How Bridges WorkDocument6 pagesHowStuffWorks - How Bridges WorkomuletzzNo ratings yet

- New Caledonia Travel GuideDocument27 pagesNew Caledonia Travel GuideDreamsAvenue.com100% (1)

- The Global Maritime Partnership Initiative Mike MullenDocument93 pagesThe Global Maritime Partnership Initiative Mike MullenKim HedumNo ratings yet

- 9700 m17 Ms 42 PDFDocument16 pages9700 m17 Ms 42 PDFIG UnionNo ratings yet

- CP2 2000 Installation, Operation and Maintenance of Electric Passenger and Goads LiftsDocument52 pagesCP2 2000 Installation, Operation and Maintenance of Electric Passenger and Goads Liftskhant kyaw khaingNo ratings yet

- Planning of LIFTS in BuildingsDocument34 pagesPlanning of LIFTS in Buildingsnaman sharmaNo ratings yet

- Taurus X PTU Section ServmanDocument39 pagesTaurus X PTU Section ServmanBalsanjav MunkhbayarNo ratings yet

- B727 - 200 Load & Trim Sheet: For Exam Purposes Only!Document1 pageB727 - 200 Load & Trim Sheet: For Exam Purposes Only!AMOSNo ratings yet

- BIT - Integrated Time Ticket: How Much Does It Cost?Document2 pagesBIT - Integrated Time Ticket: How Much Does It Cost?FabianNo ratings yet

- ASF Act 1975 (Amd Dec 2012)Document10 pagesASF Act 1975 (Amd Dec 2012)yusha habibNo ratings yet

- The Suez Canal Blockage Is OverDocument3 pagesThe Suez Canal Blockage Is Overroberto becmanNo ratings yet

- Hylite, HyLED Installation Check List V1.0 enDocument1 pageHylite, HyLED Installation Check List V1.0 enAzzam SaputroNo ratings yet

- Find Your Car's Date of Manufacture (VIN) - Team-BHPDocument13 pagesFind Your Car's Date of Manufacture (VIN) - Team-BHPPatrick OttoNo ratings yet

- WBAKS4702J0Y21762 Service HistoryDocument30 pagesWBAKS4702J0Y21762 Service HistoryRahul DattoNo ratings yet

- P 10 eDocument1 pageP 10 eMuhdAisar96No ratings yet

- S1917301-Application of Colours and Safety ColoursDocument19 pagesS1917301-Application of Colours and Safety Coloursram27_rajiNo ratings yet

- Volkswagen TouranDocument13 pagesVolkswagen Tourantemujin93No ratings yet