Professional Documents

Culture Documents

Pub 5125101 000 Apc Raw PDF

Pub 5125101 000 Apc Raw PDF

Uploaded by

Porden James JLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pub 5125101 000 Apc Raw PDF

Pub 5125101 000 Apc Raw PDF

Uploaded by

Porden James JLCopyright:

Available Formats

GX 120

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Manual de instrucciones es

Istruzioni d’uso it

Gebruiksaanwijzing nl

Brugsanvisning da

Bruksanvisning no

Bruksanvisning sv

Käyttöohje fi

Manual de instruções pt

Οδηγιες χρησεως el

Kulllanma Talimatı tr

Lietošanas pamācība lv

Instrukcija lt

Kasutusjuhend et

ko

zh

ar

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

1

5 2

+Ç

+≠ +# 7

9

+“

6

+±

+[

Gas

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

2 3

1 3

2 2

1

3

4 5

4 +[

1

2

3 GAS

6 7

6

4

5 2

1

3

8 9 1

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

10 11

+

-

1

12 13

2

2

1 3

14 15

1 3

+“

16 17

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

ORIGINAL OPERATING INSTRUCTIONS

GX 120 gas-driven fastening tool

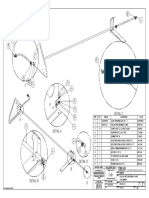

1 These numbers refer to the corresponding illustra-

It is essential that the operating instructions tions. The illustrations can be found on the fold-out cover

en are read before the tool is operated for the pages. Keep these pages open while studying the oper-

first time. ating instructions.

In these operating instructions, the designation “the tool”

Always keep these operating instructions to- always refers to the GX 120 gas-actuated fastening tool.

gether with the tool.

Parts, operating controls and indicators 1

Ensure that the operating instructions are

with the tool when it is given to other persons.

@ Grip

; Lockbutton and power regulator

Contents Page

= Nosepieces

1 General information 14 % Support leg

2 Description 15 & Magazine (40 nails or 20 nails)

3 Accessories, consumables 15 ( Type identification plate

4 Technical data 16 ) Gas can compartment

5 Safety instructions 17 + Gas can compartment cover

6 Before use 18 § Ventilation slots

7 Operation 19 / Locking lever

8 Care and maintenance 21 : Trigger

9 Troubleshooting 22 · Reset button

10 Disposal 24 $ Nail pusher

11 Manufacturer’s warranty - tools 25 £ Belt hook

12 EC declaration of conformity (original) 25 | Gas level indicator

13 Health and safety of the operator 25

1 General information

1.1 Safety notices and their meaning 1.2 Explanation of the pictograms and other

DANGER information

Draws attention to imminent danger that will lead to Warning signs

serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

General Warning: hot

warning surface

CAUTION

Draws attention to a potentially dangerous situation that Obligation signs

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful informa-

tion. Wear eye Wear a hard Wear ear Wear

protection. hat. protection. protective

gloves.

14

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

Symbols Location of identification data on the tool

The type designation and serial number can be found on

the type identification plate on the tool. Make a note of

this data in your operating instructions and always refer

to it when making an enquiry to your Hilti representative

or service department.

Read the

operating

instructions Type:

before use. en

Serial no.:

2 Description

2.1 Use of the product as directed with the Hilti fasteners and gas cans specially designed

and manufactured for it. The fastening and application

The tool is designed for driving specially manufactured

nails (fasteners) into concrete, steel and other materials recommendations given by Hilti apply only when these

conditions are observed.

suitable for the direct fastening technique (please refer to

the Fastening Technology Manual). The tool is for hand-held use only.

The tool is designed for professional use in fastening The tool may be operated, serviced and repaired only by

applications in the drywall installation trade and other trained personnel. This personnel must be informed of

building trades where fasteners are driven into concrete, any special hazards that may be encountered.

steel, sand-lime block, concrete block and rendered Modification of the tool is not permissible.

masonry. Observe the information printed in the operating instruc-

The tool, gas can and fasteners form a single technical tions concerning operation, care and maintenance.

unit. This means that the tool can achieve optimum The tool and its ancillary equipment may present hazards

fastening performance only when used in conjunction when used incorrectly by untrained personnel or when

used not as directed.

3 Accessories, consumables

Designation Description

Gas can GC 21/ GC 22

Nosepiece X‑120 TN

Additional nosepieces X‑120 WH (washers) / X‑120 PHD (Delta)/ X‑120 PHP

(Platon)

Magazine X‑120 GM 40/ X‑120 GM 20

Support leg X‑120 SL

Set of pin punches X‑120 NP set

Tool clip X‑120 TS

For use on (please

Nails Length In magazine strips of contact Hilti for de-

tailed information)

X‑EGN 14MX 14 mm (¹/₂") 10 Steel

X‑EGN 18MX 18 mm (¹¹/₁₆") 10 Hard concrete /

precast concrete /

steel

X‑EGN 20MX 20 mm (³/₄") 10 Hard concrete /

precast concrete /

steel

X‑EGN 24MX 24 mm (¹⁵/₁₆") 10 Hard concrete /

precast concrete /

steel

15

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

For use on (please

Nails Length In magazine strips of contact Hilti for de-

tailed information)

X‑GN 20 MX 20 mm (³/₄") 10 Concrete / rendered

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

en X‑GN 27 MX 27 mm (1") 10 Concrete / rendered

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

X‑GN 32 MX 32 mm (1 ¹/₄") 10 Concrete / rendered

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

X‑GN 39 MX 39 mm (1 ⁹/₁₆") 10 Concrete / rendered

masonry (1cm / ³/₈")

/ sand-lime block /

concrete block

X‑GPN 37 MX 37 mm (1¹/₂") 10 Sheet steel / thin steel

4 Technical data

Right of technical changes reserved.

NOTE

The tool is equipped with a transmitter module.

Tool with magazine

Weight 3.8 kg (8.41 lbs)

Dimensions (L x W x H) 431 mm X 134 mm X 392 mm (17" x 5 ¼" x 15 ½")

Nail length Max. 39 mm (max. 1 ⁹/₁₆")

Nail diameter ∅ 3 mm (∅ 0.118 in) / ∅ 2.6 mm (∅ 0.102 in)

Magazine capacity 40 + 2 nails or 20 + 2 nails

Contact movement 40 mm (1 ⁹/₁₆")

Operating temperature / ambient temperature with -5…+45°C (23 °F to 113 °F)

GC 21 gas can

Operating temperature / ambient temperature with -10…+45°C (14°F to 113°F)

GC 22 gas can

Maximum fastener driving rate 1,200/h

Energy-equivalent acceleration, ahw, RMS(3) Recoil: Applicable to 1 mm sheet metal on B45 con-

crete: 4.04 m/s²

Gas can

Capacity 1 can for 750 nails

Recommended transport and storage temperature +5…+25°C (41°F to 77°F)

Substances contained Isobutane, propene

Gas can Not refillable

The gas can is pressurized. Protect the gas can from Never expose the gas can to temperatures over 50°C

the heat of the sun. (122°F).

16

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

5 Safety instructions

5.1 Basic information concerning safety k) Never redrive a fastener. This may cause the

fastener to break and the tool may jam.

In addition to the information relevant to safety given

in each of the sections of these operating instructions, l) Never drive fasteners into existing holes unless

the following points must be strictly observed at all this is recommended by Hilti.

times. m) Always observe the application guidelines.

5.1.1 Personal safety

5.1.3 Work area safety en

a) Stay alert, watch what you are doing and use

common sense when operating a direct fastening

tool. Do not use a tool while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating tools may

result in serious personal injury. a) Ensure that the workplace is well lit.

b) Operate the tool only in well-ventilated working

b) Avoid unfavorable body positions. Make sure you

work from a safe stance and stay in balance at all areas.

times. c) Do not attempt to drive fasteners into unsuitable

c) Never point the tool toward yourself or other per- materials. Materials that are too hard, e.g. welded

steel and cast iron. Materials that are too soft, e.g.

sons.

wood and drywall panel (gypsum board). Materials

d) Never press the nosepiece of the tool against your

that are too brittle, e.g. glass and ceramic tiles.

hand or against any other part of your body (or

Driving a fastener into these materials may cause

other person’s hand or part of their body).

the fastener to break, shatter or to be driven right

e) Keep other persons, especially children, away

through.

from the area in which the work is being carried

d) Before driving fasteners, check that no one is

out.

present immediately behind or below the working

5.1.2 Fastening tool use and care surface.

e) Keep the workplace tidy. Objects which could

a) Use the right tool for the job. Do not use the tool cause injury should be removed from the work-

for purposes for which it was not intended. Use it ing area. Untidiness at the workplace can lead to

only as directed and when in faultless condition. accidents.

b) Press the tool against the working surface at right f) Keep the grips dry, clean and free from oil and

angles. grease.

c) Never leave a loaded tool unattended. g) Wear non-skid shoes.

d) Remove the gas can from the tool before trans- h) Take the influences of the surrounding area into

porting the tool. account. Do not expose the tool to rain or snow

e) Always unload the tool (remove the gas can and and do not use it in damp or wet conditions. Do

fasteners) before cleaning, before carrying out not use the tool where there is a risk of fire or

care and maintenance, before work breaks and explosion.

before storing the tool.

f) When not in use, tools must be unloaded and 5.1.4 Mechanical hazards

stored in a dry place, locked up or out of reach of

children.

g) Check the tool or machine and its accessories for

damage and ensure that they function faultlessly

and as intended. Check that moving parts function

correctly without sticking and that no parts are

a) Select the correct fastener guide and fastener

damaged. All parts must be fitted correctly and

combination for the job on hand. Failure to use

fulfill all conditions necessary for correct opera-

the correct combination of these items may result in

tion of the tool. Damaged guards, safety devices

damage to the tool and/or unsatisfactory fastening

and other parts must be repaired or replaced

quality.

properly at a Hilti service center unless otherwise

b) Use only fasteners of a type approved for use with

indicated in the operating instructions.

the tool.

h) Keep the arms slightly bent while operating the

c) Never fill the magazine with fasteners unless it is

tool (do not straighten the arms).

correctly fitted to the tool. The fasteners could be

i) Pull the trigger only when the tool is pressed

ejected uncontrollably.

against the working surface at right angles.

j) Always hold the tool securely and at right angles

to the working surface when driving a fastener.

This will help to prevent fasteners being deflected

by the working surface.

17

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

5.1.5 Thermal hazards 5.1.6.1 Storage

a) Do not store gas cans in inhabited rooms or in

rooms connected to inhabited rooms.

b) Store the gas cans in a dry, well-ventilated place.

c) Store the gas cans out of reach of children.

d) Do not expose gas cans to direct sunlight or

a) If the tool has overheated, allow it to cool down. temperatures above 50°C (122°F).

Do not exceed the recommended fastener driving e) Recommended storage temperature: 5°C to 25°C

en rate. (41°F to 77°F).

b) Always wear gloves if the tool has to be dis-

mantled for cleaning or maintenance before it 5.1.6.2 First aid

has been allowed to cool down. Read the material safety data sheet for information

about use, care and maintenance and first-aid meas-

5.1.6 Gasses ures.

Liquid gas under pressure:

Observe the hazard warnings and first-aid instruc- a) Direct skin contact with the liquid gas may cause

tions printed on the gas can and in the instructions frostbite or a serious freezing injury similar to a

for use. burn.

The gas is extremely flammable (contains: isobutane, b) In case of inhalation of the gas: The person af-

propene). fected should be taken into the open air and

Refilling the gas can is not permissible. brought into a comfortable position.

c) In case of unconsciousness: Bring the person af-

a) Do not use damaged gas cans. fected into a secure recovery position. Should the

b) Do not attempt to force the gas can open. Do not person stop breathing, apply artificial respiration

incinerate or crush the can and do not attempt to and supply oxygen if necessary.

reuse it for any other purpose. d) In case of gas contact with the eyes: Rinse the

c) Never spray the gas toward persons or other living open eyes under running water for one minute.

beings. e) In case of gas contact with the skin: Wash the

d) Keep the gas away from all sources of ignition contact surface carefully with warm water and

such as naked flames, sparks, pilot lights, static soap. Subsequently apply a skin cream.

discharge and very warm surfaces. f) Consult a doctor if necessary.

e) Do not smoke while using the tool.

5.1.7 Protective device

Never use the tool if the applicable safety devices

have been damaged or removed.

6 Before use

3. Release the nail pusher and allow it to slide forward

slowly.

6.2 Inserting the gas can 3

1. Open the cover.

NOTE

2. Push the gas can into the gas can compartment,

Read the operating instructions before using the tool.

valve first, until the clip engages.

3. Close the cover.

6.1 Inserting nails 2 4. Press the tool against the working surface 3 times

1. Pull the nail pusher back until it engages. without pulling the trigger.

NOTE The nail pusher must engage in this position.

2. Slide the nails into the magazine (maximum of 4 6.3 Removing the gas can 4

strips of 10 nails).

1. Open the cover of the gas can compartment.

2. Press the can retaining clip.

3. Remove the gas can.

4. Close the cover of the gas can compartment.

18

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

6.4 Checking the gas can 5

NOTE

- To check the gas level in the can, press the button marked GAS. When doing so, take care to ensure that the tool is

not pressed against the working surface.

- Even when the indicator shows “empty”, a small quantity of gas, for technical reasons, still remains in the can.

4 LEDs light green constantly. The gas can is full.

2 LEDs light green constantly. The gas can is half full. en

1 LED blinks green. The gas can is almost empty. The gas can should be changed.

1 LED lights red constantly. The gas can is empty, no gas can fitted or wrong gas can fitted.

7 Operation

WARNING

The tool must always be unloaded before changing

the magazine and before carrying out cleaning or

maintenance (see section “Unloading the tool”).

WARNING

Parts of the tool outside the grip area may get hot when

fasteners are driven at a rapid rate over a long period of

time. Wear protective gloves.

NOTE 7.1 Operation 6

When holding the tool steady with the second hand, the

NOTE

hand must be positioned in such a way that no ventilation

It is possible to drive a fastener only when more than 3

slots or openings are covered.

nails are in the magazine.

CAUTION

1. Position the nose of the tool at right angles to

Never redrive a fastener. This may cause the fastener

the working surface and then press it against the

to break and the tool may jam.

working surface as far as it will go.

WARNING 2. Drive the fastener by pulling the trigger.

Material may splinter when the fastener is driven or frag- 3. After driving the fastener, lift the tool away com-

ments of the magazine strip may fly off. Splintering ma- pletely from the working surface.

terial presents a risk of injury to the eyes and body. The

user of the tool and all persons in the vicinity must 7.2 Gas level indicator 5

wear eye protection and a hard hat. Please refer to section 6.4 “Checking the gas can (for 2

seconds)”.

CAUTION

The fastener is driven by the energy released on ignition of

7.3 Fitting and removing the magazine

a gas-air mixture. Exposure to noise can cause hearing

loss. The operator and bystanders must wear ear 7.3.1 Removing the magazine 7

protectors. 1. Pull the nail pusher back until it engages.

NOTE The nail pusher must engage in this position.

WARNING 2. Remove all fasteners from the magazine.

Never make the tool ready to fire by pressing it against a 3. Release the nail pusher and allow it to slide forward

part of the body (e.g. the hand). When the tool is ready slowly.

to fire, fasteners could be driven inadvertently into parts 4. Push the locking lever down toward the magazine.

of the body. Never press the tool against parts of the 5. Pivot the magazine forward away from the tool.

body. 6. Disengage the magazine from the tool.

WARNING

Never pull the tool nosepiece back by the fastening

component inserted in it (e.g. soft washer, pipe ring

or clip etc.). This presents an increased risk of accident.

19

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

7.3.2 Fitting the magazine 8 1. Align the nosepiece with the slot in the tool.

1. Engage the magazine with the tool. 2. Push the nosepiece onto the tool.

NOTE The locking lever must be in the open posi- 3. While holding the nosepiece with the hand, press the

tion. tool against the working surface until the nosepiece

engages in position.

2. Guide the magazine toward the tool until the shaped

parts fit together.

3. Close the locking lever and check that it engages. 7.5 Support leg

7.5.1 Fitting the support leg 12

en 7.4 Nosepiece 1. Push the support leg into the slot in the magazine at

7.4.1 Removing the nosepiece 9 right angles.

1. Set the power regulator to “Eject”. 2. Turn the support leg through 90° and engage it in

position.

2. Remove the nosepiece.

7.5.2 Removing the support leg 13

7.4.2 Settings at the nosepiece

1. Release the support leg by pressing the spring

NOTE

catch.

When the power regulator is set to “+”, the nosepiece is

2. Turn the support leg through 90°.

set to the standard fastener driving depth.

3. Pull the support leg away from the magazine at right

NOTE angles.

When the power regulator is set to “-”, the nosepiece is

set to the reduced fastener driving depth. 7.6 Bringing the piston into the correct position 14

NOTE

NOTE The piston is incorrectly positioned when the tool

If the nail is still driven too deeply when the power nosepiece has not extended to its original position after

regulator is set to “-”, it may be necessary to use a longer the tool is lifted away from the working surface and the

nail. reset button is projecting.

7.4.2.1 Setting the standard fastener driving The piston can be returned to the correct position by

depth 10 pressing the reset button. Fasteners can then be driven.

Set the power regulator to “+”. In exceptional cases, the tool may fire without driving a

fastener when the tool is operated for the first time after

7.4.2.2 Setting the reduced fastener driving resetting the piston.

depth 10 Press the reset button.

NOTE

This setting is suitable for fastening thin sheet metal to 7.7 Removing a jammed fastener 15

soft materials (e.g. young / green concrete). 1. Remove the magazine.

2. Remove the nosepiece.

Set the power regulator to “-”. 3. Fit the nosepiece into the support supplied.

4. Use the pin punch to remove the fastener.

7.4.3 Fitting the tool nosepiece 11

WARNING 7.8 Unloading the tool

Check to ensure that the tool is not loaded. The tool

1. Open the cover of the gas can compartment.

could be made ready to fire inadvertently by pressing the

nosepiece in by hand. 2. Press the can retaining clip and remove the gas can.

3. Close the cover of the gas can compartment.

4. Pull the nail pusher back until it engages.

NOTE The nail pusher must engage in this position.

5. Remove the fasteners from the magazine.

6. Release the nail pusher in the magazine and allow it

to slide forward slowly.

7.9 Application guidelines

NOTE

For detailed information, please ask the Hilti marketing organization in your country for a copy of the Hilti Fastening

Technology Manual or the applicable national regulations.

Concrete

A = min. distance from edge = 70 mm (2¾")

B = min. fastener center spacing = 80 mm (3¹/₈")

20

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

C = min. base material thickness = 100 mm (4")

B A

ET C

en

Steel

A = min. distance from edge = 15 mm (⁵/₈")

B = min. fastener center spacing = 20 mm (¾")

C = min. base material thickness = 4 mm (⁵/32")

B A

7.10 Belt hook 16

The belt hook can be used to attach the tool in position

1 to a belt or in position 2 to a ladder or scaffold.

8 Care and maintenance

2. Never operate the tool when the ventilation slots are

blocked. Clean the ventilation slots carefully using a

dry brush.

3. Do not permit foreign objects to enter the interior of

the tool.

WARNING 4. Clean the outside of the tool at regular intervals with

The tool must be unloaded (gas can and fasteners a slightly damp cloth.

removed from the tool) before carrying out cleaning 5. Do not use a spray, steam pressure cleaning equip-

or maintenance. ment or running water for cleaning.

6. Always keep the grip surfaces of the tool free from

CAUTION oil and grease.

The tool may get hot during use. You could burn your 7. Do not use cleaning agents which contain silicone.

hands. Wear protective gloves before carrying out 8. Do not use Hilti spray or similar lubricants or cleaning

care and maintenance. Allow the tool to cool down. agents.

8.1 Care of the tool 17 8.2 Maintenance

CAUTION Check all external parts of the tool for damage at regular

Take care not to damage the piston detector, nail intervals and check that all controls operate faultlessly.

detector and magazine detector. Do not operate the tool if parts are damaged or when

the controls do not function faultlessly. Have the tool

1. Remove plastic debris from the nosepiece at regular repaired by Hilti Service.

intervals.

8.3 Checking the tool after care and maintenance

After cleaning or servicing, check that the power regulator

is correctly set (standard setting “+”) before inserting the

gas can.

21

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

9 Troubleshooting

WARNING

The tool must be unloaded (gas can and fasteners removed from the tool) before carrying out cleaning or maintenance.

Fault Possible cause Remedy

Fastener head stand-off is fre- The power regulator is set to “-”. Set the power regulator to “+”.

en quently too high.

The fastener used is too long. Use a shorter fastener.

The base material is too hard. Use a DX fastening tool.

The intake/exhaust valve is dirty or Clean the tool and pay attention to

covered over. the hand position.

Contact Hilti if the problem persists.

Fastener frequently driven too Driving power is too high. Set the power regulator to “-”.

deeply (punches through).

The fastener is too short. Use a longer fastener.

Fastener breakage. The power regulator is set to “-”. Set the power regulator to “+”.

The fastener used is too long. Use a shorter fastener.

The base material is too hard. Use a DX fastening tool.

The tool is pressed against the sur- Hold the tool at right angles to the

face at an angle. working surface. Use the support leg.

See section: 7.5 Support leg

Fasteners are bent. The power regulator is set to “-”. Set the power regulator to “+”.

The fastener used is too long. Use a shorter fastener.

The tool is pressed against the sur- Hold the tool at right angles to the

face at an angle. working surface. Use the support leg.

See section: 7.5 Support leg

Fastener doesn’t hold in steel. The base material is not thick enough Use a different fastening technique.

(less than 4 mm).

Gas can doesn’t last for the Frequently pressing the tool against Avoid pressing the tool against the

whole box of fasteners. the working surface without pulling working surface without pulling the

the trigger causes increased gas con- trigger.

sumption.

22

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

Fault Possible cause Remedy

The tool remains compressed The piston is incorrectly positioned. Press the reset button.

(does not extend when pressure See section: 7.6 Bringing the piston

is released). into the correct position 14

The nail detector is jammed; The re- Remove the gas can and the

set button still projects after it has magazine from the tool and remove

been pressed (white edge still visible). any dirt or debris from the nail

detector. en

A fastener is jammed in the tool. Remove the magazine and the tool

nosepiece. Fit the tool nosepiece into

the support supplied and use the pin

punch to remove the fastener.

CAUTION

Do not damage the tool nosepiece.

See section: 7.7 Removing a jammed

fastener 15

See section: 7.3.1 Removing the

magazine 7

See section: 7.4.1 Removing the

nosepiece 9

See section: 7.8 Unloading the tool

Contact Hilti if the problem persists.

Fastener driving failure rate too The tool is pressed against the sur- Hold the tool at right angles to the

high. face at an angle. working surface. Use the support leg.

See section: 7.5 Support leg

Wrong type of nail used. Use X-GHP nails if necessary.

The base material is too hard. Use a DX fastening tool.

The tool doesn’t fire. The nail pusher is in the rearmost po- Release the nail pusher.

sition. See section: 7.3 Fitting and removing

the magazine

Insufficient number of fasteners in the Reload fasteners.

magazine (2 or less).

Fastener feed malfunction. Use a different strip of fasteners (strip

is possibly damaged).

Clean the magazine.

The gas can is empty. Check the gas level by pressing the

button marked GAS.

If only 1 LED lights red constantly, the

gas can is empty. Fit a new gas can.

See section: 7.2 Gas level indicator.

No gas can fitted or wrong type of Open the gas can compartment cover

gas can fitted to the tool. and check the contents.

If a gas can is present in the tool,

press the button marked GAS.

If 1 LED lights red constantly, the

wrong type of gas can has been in-

serted in the tool. Insert the correct

type of gas can.

See section: 7.2 Gas level indicator.

New gas can fitted, but the tool has Press the tool against the working

not been pressed against the working surface 3 times without pulling the

surface 3 times without pulling the trigger.

trigger.

23

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

Fault Possible cause Remedy

The tool doesn’t fire. Foreign object in the tool nosepiece Remove the magazine and nosepiece

section. and then remove the foreign object

from the tool.

See section: 7.3.1 Removing the

magazine 7

See section: 7.4.1 Removing the

en nosepiece 9

The tool is too hot. Allow the tool to cool down.

Contact Hilti if the problem persists.

When hot, the tool doesn’t fire The fastener driving rate was consid- Remove the gas can and then refit it.

after a pause between use. erably higher than 1200 per hour and Then press the tool against the work-

the gas can is almost empty. ing surface 3 times without firing it.

Check the gas level indicator. If the

LED lights red constantly, the gas can

is empty. Fit a new gas can.

Allow the tool to cool down.

Observe the maximum fastener driv-

ing rate (1200 per hour).

Contact Hilti if the problem persists.

The tool doesn’t fire or fires Operation in ambient conditions out- If possible, take measures to ensure

sporadically. side the permissible limits. that the ambient conditions in the

working environment remain within

the permissible limits.

Use a different fastening technique.

The gas can is not at the operating Bring the gas can to the

temperature. operating temperature

(-5°C to 45°C with GC 21, -10°C to

45°C with GC 22).

Gas bubbles have formed in the gas Remove the gas can and then refit it.

injection system.

The tool is not lifted away completely Take care to ensure that the tool is lif-

from the working surface. ted away completely from the working

surface after driving each fastener.

Fastener cannot be removed A fastener is jammed in the tool Remove the tool nosepiece from the

from nosepiece. nosepiece. tool. Fit the tool nosepiece into the

support supplied and use the pin

punch to remove the fastener.

CAUTION

Do not damage the tool nosepiece.

See section: 7.4.1 Removing the

nosepiece 9

See section: 7.7 Removing a jammed

fastener 15

10 Disposal

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for

taking back old tools and appliances for recycling. Ask Hilti customer service or your Hilti representative for further

information. If you wish to bring the tool to a materials separation facility yourself: Regional and international directives

and regulations must be observed.

24

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

11 Manufacturer’s warranty - tools

Hilti warrants that the tool supplied is free of defects in sequential damages, losses or expenses in connec-

material and workmanship. This warranty is valid so long tion with, or by reason of, the use of, or inability to

as the tool is operated and handled correctly, cleaned use the tool for any purpose. Implied warranties of

and serviced properly and in accordance with the Hilti merchantability or fitness for a particular purpose are

Operating Instructions, and the technical system is main- specifically excluded.

tained. This means that only original Hilti consumables,

components and spare parts may be used in the tool. For repair or replacement, send the tool or related parts en

immediately upon discovery of the defect to the address

This warranty provides the free-of-charge repair or re- of the local Hilti marketing organization provided.

placement of defective parts only over the entire lifespan

of the tool. Parts requiring repair or replacement as a This constitutes Hilti’s entire obligation with regard to

result of normal wear and tear are not covered by this warranty and supersedes all prior or contemporaneous

warranty. comments and oral or written agreements concerning

warranties.

Additional claims are excluded, unless stringent na-

tional rules prohibit such exclusion. In particular, Hilti NOTE

is not obligated for direct, indirect, incidental or con- Observe the gas can expiry date printed on the edge of

the can.

12 EC declaration of conformity (original)

Designation: Gas-driven fastening tool Hilti Corporation, Feldkircherstrasse 100,

FL‑9494 Schaan

Type: GX 120

Year of design: 2007

We declare, on our sole responsibility, that this

product complies with the following directives and

standards: 75/324/EEC, 91/155/EEC, 64/548/EEC, Norbert Wohlwend Tassilo Deinzer

EN ISO 12100, EN 13752‑1:2008‑12, EN 50081‑2, Head of Quality & Processes Manage- Head of BU Direct Fastening

EN 1127‑1, EN 417, ISO 8662‑11 AMD 1:2001-12, ment

BU Direct Fastening BU Direct Fastening

EN 792‑13:A1:2008‑09, EN 60529:2000‑09, 09/2012 09/2012

64/548/EEC, EN 55011:1998+A1:1999, CISPR 11:2003,

A1:2004, IEC 61000‑6‑2:2005, EN 61000‑6‑2:2001, Technical documentation filed at:

IS1:2005, IEC 61000‑6‑3:1996, EN 61000‑6‑3:2001,

IEC 61000‑4‑2:1995, IEC 61000‑4‑3:2006, Hilti Entwicklungsgesellschaft mbH

IEC 61000‑4‑8:1993: A1:2000, 2006/42/EC, 2011/65/EU. Zulassung Elektrowerkzeuge

Hiltistrasse 6

86916 Kaufering

Deutschland

13 Health and safety of the operator

13.1 Noise information

Gas-actuated fastening tool

Type GX 120

Model Series

Caliber GC 22

Power regulation +

Application Fastening 1 mm metal sheet to concrete (C40) using

X-EGN14-MX

25

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

13. Health and safety of the operator

13.1 Noise information

Gas-actuated fastening tool

Type GX 120

Model Series

en Caliber GC 22

Power regulation +

Application Fastening 1 mm metal sheet to concrete (C40) us-

ing X-EGN14-MX

Declared measured values of noise characteristics according to 2006/42/EC Machinery Directive in

conjunction with DIN EN 15895

Noise (power) level, LWA, 1S 1 105 dB (A)

Emissionmeasured

Declared noise-pressure

values level in the

of noise characteristics 101 dB

work station,according (A)

to 2006/42/EC Machinery Directive in conjunction

with

LpA, DIN

1s

2 EN 15895

Noise (power) level, LWA, 1S 1 105 dB (A)

Peak sound pressure emission level, LpC, peak 3 137 dB (C)

Emission noise-pressure level in the work station, 101 dB (A)

1LpA, 2

± 2 dB

1s(A)

2 ± 2 dB (A)

Peak sound pressure emission level, LpC, peak 3 137 dB (C)

3 ± 2 dB (C)

en 1 ± 2 dB (A)

2± 2 dB (A)

Operation and set-up conditions: Set-up and operation of the pin driver in accordance with E DIN EN 15895-1

3 ± 2 dB (C)

in the semi-anechoic test room of Müller-BBM GmbH. The ambient conditions in the test room conform to

DIN EN ISO 3745.

Operation and set-up conditions: Set-up and operation of the pin driver in accordance with E DIN EN 15895-1 in the

Testing procedure:

semi-anechoic Enveloping

test room surfaceGmbH.

of Müller-BBM method Theinambient

anechoic room oninreflective

conditions surface

the test room area to

conform in DIN

accordance with

EN ISO 3745.

ETesting

DIN ENprocedure:

15895, DINEnveloping

EN ISO 3745 and method

surface DIN EN ISO 11201. room on reflective surface area in accordance with

in anechoic

E DIN EN

NOTE The15895,

noise DIN EN ISO measured

emissions 3745 and DINandENtheISO 11201. measurement uncertainty represent the upper limit

associated

NOTE

for theThe noise

noise emissions

values measuredduring

to be expected and the

theassociated measurement uncertainty represent the upper limit for the

measurements.

noise values to be expected during the measurements.

Variations in operating conditions may cause deviations from these emission values.

Variations in operating conditions may cause deviations from these emission values.

14. FCC statement

This device complies with Part 15 of the FCC Rules and to RSS-210 of Canada.

Operation is subject to the following two conditions

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

30

26

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

Hilti Corporation

LI-9494 Schaan

Tel.: +423 / 234 21 11

Fax:+423 / 234 29 65

www.hilti.com

*274633*

274633

Hilti = registered trademark of Hilti Corp., Schaan

W 3250 | 0612 | 4-Pos. 1 | 1

Printed in Germany © 2012

Right of technical and programme changes reserved S. E. & O. 274633 / A2

Printed: 07.07.2013 | Doc-Nr: PUB / 5125101 / 000 / 00

You might also like

- Selva Negra - TabsDocument3 pagesSelva Negra - TabsjamoncioNo ratings yet

- Macias Enrico-Adieu Mon Pays 1Document3 pagesMacias Enrico-Adieu Mon Pays 1mohnatiyNo ratings yet

- Example Srs Document For A Project PDFDocument2 pagesExample Srs Document For A Project PDFMichele0% (1)

- Operating Instruction VC 20 U Um VC 40 U Um 01 en Operating Instruction Pub 5129774 000Document20 pagesOperating Instruction VC 20 U Um VC 40 U Um 01 en Operating Instruction Pub 5129774 000pedjakgNo ratings yet

- Manual de UsuarioDocument122 pagesManual de UsuarioSabores del Guijo - Casa AlonsoNo ratings yet

- TE 50 / TE 50-AVR: Hilti CorporationDocument16 pagesTE 50 / TE 50-AVR: Hilti CorporationRendy FahleviNo ratings yet

- Bedienungsanleitung TE 7-A (en-US)Document19 pagesBedienungsanleitung TE 7-A (en-US)Ion AvramNo ratings yet

- 29 LVW HKT9 FZ XFix 2Document76 pages29 LVW HKT9 FZ XFix 2eduardo hernandezNo ratings yet

- Hilti TE2 A22 ManualDocument19 pagesHilti TE2 A22 Manualbailey.ceilingsNo ratings yet

- Padrao 1 Padrao 2 Padrao 3: Standard TuningDocument1 pagePadrao 1 Padrao 2 Padrao 3: Standard TuningGabriel de AndradeNo ratings yet

- Treino LigadosDocument1 pageTreino LigadoshugaoawayNo ratings yet

- Bosch GST 85 PbeDocument43 pagesBosch GST 85 Pbej_abendstern4688No ratings yet

- Granados, Enrique - Orientale Danse N 2 (Corretta) 10-11-2022Document4 pagesGranados, Enrique - Orientale Danse N 2 (Corretta) 10-11-2022Andrew FranticNo ratings yet

- Instrucciones Pasta MakerDocument106 pagesInstrucciones Pasta MakerMarc FerruzNo ratings yet

- A B J G H A B J G H: HR3651, HR3652, HR3653, HR3655, HR3656, HR3657, HR3658, HR3663, HR3664Document106 pagesA B J G H A B J G H: HR3651, HR3652, HR3653, HR3655, HR3656, HR3657, HR3658, HR3663, HR3664alllim88No ratings yet

- BN44 00359a PDFDocument4 pagesBN44 00359a PDFAlfredo Feres SchekaibanNo ratings yet

- FMC-420RW-GSGRD FMC-420RW-GSGBU FMC-420RW-GSGYE: Cs Da de en Es FR HR Hu It NL PL PT Ro Ru SL TRDocument32 pagesFMC-420RW-GSGRD FMC-420RW-GSGBU FMC-420RW-GSGYE: Cs Da de en Es FR HR Hu It NL PL PT Ro Ru SL TRSergioCaceresNo ratings yet

- Desbloqueie Seus DedosDocument1 pageDesbloqueie Seus Dedosedson TavaresNo ratings yet

- Desbloqueie Seus DedosDocument1 pageDesbloqueie Seus Dedosedson TavaresNo ratings yet

- Typhoon Preparedness Checklist Huni Lio May 25, 2023Document2 pagesTyphoon Preparedness Checklist Huni Lio May 25, 2023jordan calderonNo ratings yet

- SLASH Warm Up Exercise PDFDocument1 pageSLASH Warm Up Exercise PDFRonaldo OrtizNo ratings yet

- SLASH Warm Up ExerciseDocument1 pageSLASH Warm Up ExerciseIncredible MaxNo ratings yet

- Toyota 8FDF 18 20 25 8FGF18Document382 pagesToyota 8FDF 18 20 25 8FGF18SARAMQR100% (6)

- Operating Instructions DX 36 P2 ES-US PUBDocument23 pagesOperating Instructions DX 36 P2 ES-US PUBadderlyorgNo ratings yet

- Guia Instalacion FMC420RWSingleA - InstallationGuide - FMC-420RWDocument32 pagesGuia Instalacion FMC420RWSingleA - InstallationGuide - FMC-420RWfirenet colombiaNo ratings yet

- Putte På Taket BluesDocument1 pagePutte På Taket Bluesfastback999No ratings yet

- BG 2000 SFDocument43 pagesBG 2000 SFdbricchiNo ratings yet

- Pentatonicas 3nps: Standard TuningDocument1 pagePentatonicas 3nps: Standard TuningDamiano14sNo ratings yet

- Montaje de Bridas AGA A La ElectrovalvulaDocument1 pageMontaje de Bridas AGA A La Electrovalvulamanuelj.carreteroNo ratings yet

- Albeniz Isaac-TangoDocument4 pagesAlbeniz Isaac-Tangothierry sombardierNo ratings yet

- Angèle - Balance Ton Quoi (Guitar 1)Document1 pageAngèle - Balance Ton Quoi (Guitar 1)Leander LyonsNo ratings yet

- Dionisio Aguado-Andante - Op 2 Nro 2Document4 pagesDionisio Aguado-Andante - Op 2 Nro 2Vương Ngọc Trung DũngNo ratings yet

- Iron Steam Philips InstructionDocument170 pagesIron Steam Philips InstructionMamat XNo ratings yet

- GWS Professional: 22-180 H - 22-180 JH - 22-230 H - 22-230 JH - 24-180 JH - 24-230 H - 24-230 JH - 26-180 JH - 26-230 JHDocument13 pagesGWS Professional: 22-180 H - 22-180 JH - 22-230 H - 22-230 JH - 24-180 JH - 24-230 H - 24-230 JH - 26-180 JH - 26-230 JHاحمد النجارNo ratings yet

- SIDEL Peças Pasteruziador PDFDocument50 pagesSIDEL Peças Pasteruziador PDFEduarda PortellaNo ratings yet

- Angèle - Balance Ton Quoi (Guitar 1)Document1 pageAngèle - Balance Ton Quoi (Guitar 1)Leander LyonsNo ratings yet

- Arpegios BluesDocument1 pageArpegios BluesJordi ClarianaNo ratings yet

- Tiger 3 Review Test 3 STANDARDDocument3 pagesTiger 3 Review Test 3 STANDARDKarolinaNo ratings yet

- Soldador Inverter Mma A Stayer 10507651 Assemblysheet-2Document64 pagesSoldador Inverter Mma A Stayer 10507651 Assemblysheet-2miguelNo ratings yet

- Manual IO - Rexa PRODocument34 pagesManual IO - Rexa PROSilviu DochiaNo ratings yet

- Full Download Ati RN Proctored Leadership Form A 2016 PDF Full ChapterDocument35 pagesFull Download Ati RN Proctored Leadership Form A 2016 PDF Full Chapteroscines.filicide.qzie100% (20)

- Full Ati RN Proctored Leadership Form A 2016 PDF Docx Full Chapter ChapterDocument35 pagesFull Ati RN Proctored Leadership Form A 2016 PDF Docx Full Chapter Chapterprosaism.horologe.fuu88100% (22)

- Improv Intro Fusion Tk1: Cracking The Code: Oz Noy Interview 1Document3 pagesImprov Intro Fusion Tk1: Cracking The Code: Oz Noy Interview 1Carlos Iafelice Junior Musica e LazerNo ratings yet

- Improv Intro Fusion Tk1Document3 pagesImprov Intro Fusion Tk1Genaro OlivieriNo ratings yet

- Operating Instruction AG 500 A18 01 Operating Instruction PUB 5223807 000Document60 pagesOperating Instruction AG 500 A18 01 Operating Instruction PUB 5223807 000Nyein ZawNo ratings yet

- Endecha PDFDocument1 pageEndecha PDFScottNo ratings yet

- Type Model: Original InstructionsDocument22 pagesType Model: Original Instructionstugrul tanNo ratings yet

- Surf Rider LowerDocument5 pagesSurf Rider LowerFred StachowiakNo ratings yet

- Licks (Diminished Scale)Document1 pageLicks (Diminished Scale)MarioNo ratings yet

- 5 Swinging Blues Licks in G - TABDocument3 pages5 Swinging Blues Licks in G - TABcursos fenixNo ratings yet

- Alternate Picking ExerciseDocument1 pageAlternate Picking ExercisebiswajitNo ratings yet

- Final 'In Umba Marelui URSS'Document1 pageFinal 'In Umba Marelui URSS'Geo PuiuNo ratings yet

- Final 'In Umbra Marelui 1Document1 pageFinal 'In Umbra Marelui 1Geo PuiuNo ratings yet

- Operating Instruction DX 351 01 en Operating Instruction PUB 5126242 000Document21 pagesOperating Instruction DX 351 01 en Operating Instruction PUB 5126242 000jeffreyNo ratings yet

- Uf1007a02 1Document1 pageUf1007a02 1MARTIN GONZALEZNo ratings yet

- Fretboard Challenge! 12 Licks in A Single Position: Dm7 G7 Cmaj7Document3 pagesFretboard Challenge! 12 Licks in A Single Position: Dm7 G7 Cmaj7Blessing AsewejeNo ratings yet

- Piano Forte (Live Ver.)Document4 pagesPiano Forte (Live Ver.)bakcou100% (1)

- GCM 12 GDL Professional PDFDocument30 pagesGCM 12 GDL Professional PDFmijnmik jonesNo ratings yet

- Sales Performance Chart Analysis: Month Income Cost Profit Product 1 Product 2 Product 3 Product 1 Product 2 Product 3Document3 pagesSales Performance Chart Analysis: Month Income Cost Profit Product 1 Product 2 Product 3 Product 1 Product 2 Product 3Al kuyuudiNo ratings yet

- Implementation of Family-Centered Services: Perceptions of Families and ProfessionalsDocument17 pagesImplementation of Family-Centered Services: Perceptions of Families and Professionalsclaudiamsmonteiro-1No ratings yet

- Base Tables in APDocument6 pagesBase Tables in APdevender143No ratings yet

- Admission DocumentDocument6 pagesAdmission DocumentMichael SasiNo ratings yet

- Application Research On VSC-HVDC in Urban Power NetworkDocument5 pagesApplication Research On VSC-HVDC in Urban Power NetworkjorgeNo ratings yet

- Jones LXX Notes Feb06Document190 pagesJones LXX Notes Feb06FGNo ratings yet

- Unit 1. TimeDocument3 pagesUnit 1. TimeKDDKNo ratings yet

- Bahasa Inggris 50 Soal 2Document24 pagesBahasa Inggris 50 Soal 2poro poroNo ratings yet

- 3cd7b7dd-b842 Eu Marlipal o 13 89 En-IeDocument13 pages3cd7b7dd-b842 Eu Marlipal o 13 89 En-Iepkh29No ratings yet

- Cpar Week 9-15Document17 pagesCpar Week 9-15Aizeldy GuiribaNo ratings yet

- Data Sheet: MN2PS00003RFDocument43 pagesData Sheet: MN2PS00003RFSoni BhattaNo ratings yet

- Anti-Theft Alarm For Bikes: A Project Report OnDocument44 pagesAnti-Theft Alarm For Bikes: A Project Report OnSonia AgrawalNo ratings yet

- Testimony Workshop HandoutDocument7 pagesTestimony Workshop HandoutEquipping CoursesNo ratings yet

- 2020 Catalogue Diesel GeneratorDocument25 pages2020 Catalogue Diesel GeneratorRavikant SainiNo ratings yet

- Tharu Kirana - Sample (A4 Pages)Document8 pagesTharu Kirana - Sample (A4 Pages)Dasun Sameera WeerasingheNo ratings yet

- Vickers Pneumatic CylindersDocument48 pagesVickers Pneumatic CylindersHYDRAULICGURUNo ratings yet

- Note Casia Irisv4Document16 pagesNote Casia Irisv4Lãng Tử 白玉荣No ratings yet

- This Is Not A Frank Ocean Cover Album: Alan ChazaroDocument9 pagesThis Is Not A Frank Ocean Cover Album: Alan ChazaroStacy HardyNo ratings yet

- PoliteiaDocument115 pagesPoliteiaRandall HittNo ratings yet

- Sturt Stony DesertDocument4 pagesSturt Stony DesertJenushan JesuthasanNo ratings yet

- Snowball Fight ActivityDocument3 pagesSnowball Fight ActivityDaveNo ratings yet

- Spiritual Shouter Baptist Liberation Day Is Celebrated 30th MarchDocument1 pageSpiritual Shouter Baptist Liberation Day Is Celebrated 30th MarchKumarie PersadNo ratings yet

- Lesson Plan Grade 1Document4 pagesLesson Plan Grade 1Nhuquyen NguyenNo ratings yet

- Op-Com 2020 Gratuit Pour TousDocument2 pagesOp-Com 2020 Gratuit Pour TousAli El AsliNo ratings yet

- C Lab ProgrammingDocument47 pagesC Lab ProgrammingSandhya KandikatlaNo ratings yet

- Tab File: + Orange Gradient Data BarDocument10 pagesTab File: + Orange Gradient Data BarHuế LêNo ratings yet

- Opportunities and Barriers For Producing High Quality Fuels From The Pyrolysis of Scrap TiresDocument15 pagesOpportunities and Barriers For Producing High Quality Fuels From The Pyrolysis of Scrap TiresAbdisalamNo ratings yet

- Laboratory Exercise 1 Matlab Introducction: Name SectionDocument7 pagesLaboratory Exercise 1 Matlab Introducction: Name SectionDean16031997No ratings yet

- Is 1726 1991Document17 pagesIs 1726 1991RaykochiNo ratings yet