Professional Documents

Culture Documents

MBBR Veolia Calculation PDF

Uploaded by

n_zeinoun100%(1)100% found this document useful (1 vote)

315 views14 pagesOriginal Title

76216463-Mbbr-Veolia-Calculation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

315 views14 pagesMBBR Veolia Calculation PDF

Uploaded by

n_zeinounCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

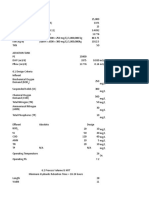

DESIGN PARAMETERS

INELUENT To meBR

zion Anal Average Flow (SAF) 9.0 mco

‘sing water

Design MBER Infuent BOD, = Smt, 7B rat

‘Design MABR influent CBO, = Samo S4mel 47 mot

‘Design MBBR Inluent S800, 30 mat 2omot 40 mot

Desigh MEER intuent TSS = SompL 100mg TO mL 68 ma

Design MBBR influent NA, 28 mg (al saasons)

Design Minimum Cel 8" Extvent Temperature ss:c sec sco arc

Design Maximum Cal"B EMluentTemperaure = 244°C 306°C 81°C 170"

DESIGN EFFLUENT PARAMETERS (ALL SEASONS)

Design fluent C500, = 20m,

Design Eten TSS = omet

Design Emuent Ny

5 mo

KRUGER

Kruger, Inc.

DESIGN MEMO

Submitted To:

McGoodwin Williams & Yates

For a Kaldnes Moving Bed™ biofilm technology

ANOXKALDNES

LagoonGuard™ Treatment System at:

Batesville WWTP

Batesville, AR

Revision 2

26 May, 2010

PROPRIETARY INFORMATION

TiS DOCUMENT CONTAINS ANOXKALDNES! /-VEOLIA PROPRIETARY INFORMATION AND

NEITHER THIS DOCUMENT NOR SAID PROPRIETARY INFORMATION SHALL BE PUBLISHED,

REPRODUCED, OF COPIED, DISCLOSED, OF USED FOR ANY PURPOSE OTHER THAN

CONSIDERATION OF THIS PROPOSAL, WITHOUT THE WRITTEN APPROVAL OF ANOXKALDNES

i

Qveoua

KRUGER

Our rot. Date

42040801 26 May, 2010

Ms. Jessica Keahey, P.E.

MeGoodwin Willams & Yates

302 E. Milsap

Fayettevile, AR 72703

Re: AnoxKaldnes Kaldnes MBBR technology

Batesville, AR LagoonGuard™ Design Memo

Ms. Keahey,

Below are our revised detailed design calculations for the Batesville WWTP application for

our Moving Bed™ Biofim Reactor (MBBR) process for BOD removal and nitification of

In general, the existing lagoons will provide adequate removal of large particulate matter

‘and no additional fine screening ahead of the MBBR is required. Facies that lack primary

treatment will require screening with a maximum of 6 mm (1/4 inch) openings for removal of

this particulate matter (rags, debris, etc) prior to entering the AnoxKaldnes LagoonGuard™

roactors.

‘The proposed design wil incorporate the AnoxKaldnes MBBR process for helping to

maintain an effluent quality of < 10 mg/L Soluble BOD and < 8 mg/L NHyN at 5“

PROPRIETARY INFORMATION

‘ poousey conan unaaLones /TEOUA PROPAETARY BEORMATON AND NEITHER THS DOCUMENT NOR SAD

PROPRIETARY nrcrwATION SHAL 8 PUBLISHED, AEPROCUGED, OF COPIED, DiSCOSED, OF USED FON ANY PURFESE

‘OTHER THN CONSDEFATION OF THs PROPOSAL, WITHOUT TM WITTEN APPROVAL OF ANORKALDNES/VEOUA

QOveoua

KRUGER

A. Design Basis

‘Below are the design conditions that the MBBA™ biological treatment system was designed around

Paaor 1] ana [Spang Sune [Lea [We

Flow, Amualave | wed | 00 [| 20 [00 | 0

Flow, Max.0ay | wad | 100 | 100 [100 | 100

00, eign | mgt |e | | se | 70

©00,,Devan | mot | se | os | a | a7

2800, desin | mot | 20] se] 90 ao

738,088 | mot | 60] 100 70] os

Tee, Desn | not [ss] 33 as

Anmaria, Ossi | not [28 | 28 [8 | as

wax Tempers | _o| 204 | moe [25a | 170

vin-Tenporauro | “© [ee | 180 [08 [a7

“Tis asad 100s of oF CBE WTO} THD on AORN

‘AnoxKaldnes MBBR Biolosical Treatment System Proposed desian

+ Toll ark volun re.768 i

+ Number of process trains

+ Number of reactors per train

+ Overall Tank dimensions ftlong x62 ft wide x 18 side water depth

‘+ Flocommended freeboard 3. minimum

+ Design fil of bot carrer elements = 569%

+ Design air requirement 919 SOM,

+ Maximum fillofbifim cartier laments = 67%

+ Flow at max. il

Aa at max. fl

+ Aeration system = AnoxKaldnes Medium Bubble

+ Residual 0.0. evel 2.8.6 mglL depending on wastewater temp

+ sonar daageesvestiietse =81 530

Bearers er sce nee Sa Se te

Qveoua

KRUGER

Surface Area Loading Rate Calculations

The following loading rate is for BOD removal in aerobic MBBR's only. The percent

reduction is expressed as the ratio of the difference between the total BOD in the influent to

the MBBR and the soluble fraction of BOD in the MBBR outlet to the total BOD in the

influent to the reactor. Based upon AnoxKaldnes’ experience with organic removal and

ritification at over 100 facilities, the BOD: and Nitrification design surface area loading rate

(SALR) in order to meet < 10 mglL of soluble CBODs and < @ mglL ammonia at 4.7 °C is

2.86 g Total BOD/m?-day and a removal rate for nitsfication of 0.6155 g NHy-Nimday.

‘A major factor in the nitfcation design is the net nitrification rate, This rate decreases as

the effluent NHN concentration from the reactor decreases from 3 mall down to 0.5 magi.

As this system is targeting an effluent ammonia concentration of < 8 mgiL, this application

vil fallin the non-limiting range of process design.

‘As the base nitrification rate equations from AnoxKaldnes are based on 10 °C and the

process design is at 4.7 °C, the ammonia-niogen removal rate does need to be corrected

{or temperature thus the calculated removal rate below will be used for the process design

“The nitrification rate is also documented to have a relationship to the bulk tluid dissolved

‘oxygen concentration inthe reactor.

‘The calculation for the amount of media required is based upon the SALR selected & the

cffoctive surface area of the media in the basin. The effective surface area of AnoxKaldnes’

KS biomedia available for biomass growth is 500 m’/m® (152.4 f/f’). ‘The total effective

surface area of an MBBR is calculated by multiplying the effective surface area of the

biomedia by the MBBR reactor volume and the volumetric fil fraction of the blomedia in the

reactor. The process design uses a percent fil of 56% in all reactors, so the total effective

surface area (SA) of the reactors, when the volume of each reactor is 1,959 m° (69,192 ft?)

is:

[PROPRIETARY INFORMATION

Tis pocunen conan ANOKKALDNES / DUK PROPRIETEY NFOHUATON AND NETHER 148 DOCUMENT NOR SAD

PACeRETARY INCOMUATION SAL Be PUBLIED, REPrODUCED, OF COPIER ILOSED. ON USED FOR Ay PURPERE

‘OINER HAN CONSOEAATONGF TH PROPOSAL WITHOUT THE ATTEN APPHOVALOF ANERKALONES VEGUA

Qveoua

KRUGER

EACH REACTOR

SNe “(S289 asm sions,

B. Aeration Caloulations

‘Aeration calculations based on pollutant removal have been performed using the following

Standard aeration equation

sor=

en =a Cg"

(C.*D.)

Where

SOR = Standard Oxygen Requirement (th)

AOR = Actual (Process) Oxygen Recuirement (ty)

= Ratoofongen transfer coefcient (ofthe wastewater to that of an

water

Ratio of oxygen saturation of the wastewater to that of clean water

‘Surface saturation dissolved oxygen concentration in clean water at the

influent design temperature (Tj) and basin elevation (mglL)

Depth Correction Factor = (Diffuser Depth’ 100)+4

Residual Dissolved Oxygen concentration in the reactor (mg/L)

= Surface saturation DO cone. in clean water at 20 °C and 760 mm Hg

9.09 mgl (per ASCE)

‘Temperature correction coefficient = 1.024

Wastewater Temperature (°C)

‘PROPRIETARY INFORMATION

Qveoua

KRUGER

Air Required For BOD and Ammonia Removal

Winter BOD; Removed = 5,564 Ibsiday (79 mg/L down to 5 mglL at 9.0 mgd)

Winter AOR =|

[5.5541 BOD gan ]q_1-OlDO ras [22] 231.4160,

aay TBODypvon0 | [24n5 |" br

‘Spring BODs Removed = 5,855 lbs/day (&3 mg/L down to S mglL at 9.0 mgd)

Spring BOD; AOR = 243.9 Ib Oyhhr

‘Summer BODs Removed = 3,608 lbs/day (53 mgiL down to 5 mg/L at 8.0 mgd)

‘Summer BODs AOR = 150.1 lb Oyhhr

Fall BOD; Removed = 3,528 lbs/day (52 mg'L down to § mg/L at 8.0 mgd)

Fall BOD; AOR = 147.0 ll Oxihr

Given:

a = 09

B= as

Cwatt = 12.792 mglL @ 4:7 °C, 300 feet Elevation (Winter

= 12.039 mg @ 6.9°C, 300 feet Elevation (Spring)

= 10.219 mg @ 13.9°C, 900 feet Elevation (Summer)

= 11.095 mglL @ 10.5 °C, 300 feet Elevation (Fall)

(17/100) +1=1.17

3.0 mg

8.09 mg (per ASCE)

1.024

Tw = 47°C (Winter)

6.9 °C (Spring)

= 139°C (Summer)

“es pou covTas aNoMKALDNES

PROPRIETAHY REORWATION SHALL Be PususeeD, RePROCUGED, OR COMED biscLoseD, On USED Fon AY PURPOSE

‘GINGA THAN CONSOEAATION OF THs PROPOSAL WITHOUT THE WHITTEN APPROVAL OF ABONKALENES/VECUA

Qveoua

KRUGER

= 105°C (Fal)

Winter BOD, SOR =

Spring BOD; SOR = 3788 Ib Ozhr

‘Summer BOD; SOR = 245.4 lb Ohr

Fall BOD; SOR = 234.9 lb Oyhr

NHs-N Removed = Infiuent Load ~ Assimilation ~ Effluent Load

Winter NHs-N Removed =2,477 — (0.04°5,554) ~ 563

6921 Ne. ]q 45710 Osu],

‘ay TNF,

= 1,692 Ibid

322.21b0,

hr

Winter NH, AOR

Spring NHN Removed =2,477 ~ (0.045.855) ~ 563 = 1,680 Ibid

Spring NHN AOR =319.9 bb Ozhr

Summer NH-N Removed =2,477 ~ (0.04"3,603) ~ 563

Summer NH-N AOR = 337.0 b Oyhr

Fall NHN Removed = 2,477 ~ (0,043,528) ~ 563

Fall NHN AOR = 997.6 lb Ouhr

770 Ibid

773 bid

Given:

a = 09

B 0.95

Cwatt = 12732 mgl @ 4.7°C, 300 feet Elevation (Winter)

PROPRIETARY INFORMATION

Poem AY INFORIATON SHALL GE PuSED,REPHOOUCED, OR COPIED, ISLOSED, OR USED FoR ANY PURPOSE

Qveoua

KRUGER

12,039 mg/L @ 69°C, 300 feet Elevation (Spring)

= 10213 mg/L @ 13.9 °C, 300 feet Elevation (Summer)

= 11.085 mg/L @ 10.5 °C, 300 feet Elevation (Fall)

De = (17/100) 4121.17

C= 86 mg/l. Winter)

74 malt (Spring)

= 67 mg (Summer)

= 7.0 mgt (Fall

Ca = 9,09 mglL (per ASCE)

1.024

Tw = 47°C Winter)

6.9 °C (Spring)

= 139°C (Summer)

= 105°C (Fall

Winter NH, SOR =

LE

‘Spring NH-N SOR = 862.3 lb Oy/hr

‘Summer NH¢-N SOR = 989.4 b Oyfnr

Fall NHs-N SOR = 948.1 lb Oyhr

PROPRIETARY INFORMATION

‘Tg ocamen covrans avoxauones / YEOLIA rhe TAY NIOMUATION AND NEITHER TS DOCUMENT NOR SAD

PRopmiraey nrormATioN SHALL Be PUBLISHED, ReenOQUGED, Oh COME, ISCIOSCD OR USED FOR ANY PURPOSE

‘Otres Tae CONSDEFATION OF Tas PROPOSAL, WTHOUT THE WAI TEN APPROVAL OF ANDRXALONES ECU.

Qveoua

KRUGER

Biological Air Requirement = Fre OTE en

Given:

‘SOR = Standard Oxygen Requirement (bh)

Ps Densiy of ar air at 70 °F and 14.696 psia = 0.075 ft

Wo = Mase fraction of oxygen in dry air= 0.232 fo Ox air

> Diflusr depth = 17

OTE = Onygen transfor efficiency = 1.1% per foot SWD

352.54.985.8100:

WinterBiological AirRequiremer et

023200; eras

70.2327 178

100

6,855sefim

‘Spring Biological Air Requirement = 6,357 scfm

‘Summer Biological Air Requirement = 6,325 scfm

Fall Biological Air Requirement = 6,085 scfm

In addition tothe biological ar requirement, the system also has an air requirement,

associated with keeping the media well mixed. This equates to roughly 0.45 sci? of

‘basin area or 6,919 scfm of total mixing air.

When the mixing ir requirement is greater than the biological air requirement (as is the

‘case for this design), the system is referred to as being “mixing limited. This is generally the

‘case for most LagoonGuard applications.

‘The blower discharge pressure is estimated at 8.1 psig from the top ofthe basins.

spornmenceronynay

TEE Ee a ne

Qveoua

KRUGER

D. Mass Balance Calculations

Basod on the Batesvile WWTP average influent characteristics and effluent requirements,

the AnoxKaldnes MBBR process conditions are presented below fora falty designed to

meet an effluent NHN of < 8 mglL ata design temperature of 4.7 °C.

ag00n MBER for NEBR for

‘BOOINAton Nitfeaton

‘Winter Influent Parameters to MBBR:

Flow = 9,000,000 gpd

BOD; = 5,990 Ib/day (79 mg)

TKN =2,477 bb/day (83 mg/L)

We assume 100% of the organic nitrogen is going to hydrolyze into ammonia-ritrogen. If

the wastewater has some non-degradable organic nitrogen in the wastewater the resulting

system design is then conservative, The higher D.O. concentration allows for the use of

increased nitrification rates.

‘The required amount of biomedla surface area for organic removal is obtained by dividing

the organic load by the organic SALR while the surface area fornitfication is obtained by

dividing the ammonia-nirogen required to be nitiied by the nitfication SALR. The total

media volume is obtained by dividing the biomedia surface area requirement by the

effective surface area of the biomedia,

BOD + Nitrification (4.7 °C)

2,6358800/

Se eee

a fa? day

orgie Load Mea Votame =| 8049" nets. 1965238)

Sam neil.

‘nus ooc.MEetCONTANS ANOALONES / EOLA PROPRIETARY REOTMATOW AND NETHER T48 OOCUMENT NOR SAD

rors orunrion Sc Be PURE, REPRODUCED Gr COMED, MSELOSED OLED FON i PRP

Qveoua

KRUGER

- 7677488 NAY)

ifn mei) =| 7 eons

‘m?day

Niwifying Load Media Volume =| 1246918 m* media_|_ > 494 m? (98,0698)

Oe mesg? media.

The total media volume is 4,375 m° (184,492 ft), This equates to 2,187.5 m° (77,471

ft) per reactor.

{As the first reactor is designed for both BOD and partial nitifcation and the second reactor

's designed for nitification, the total media volume is 4,375 m’, Knowing the basin volume is

1,959 m' for each reactor, the media fil percentage equates to a percent fil of 56% for each

reactor.

Pmopmerany!

‘as oocawent covranysAuonaupnes / YEON POPRE TAFY REOFAATION AND NEITHER THS DOCUMENT NOR SAD

PROPMIETAW NEORUATIN SVU Be PUBLISHED, RESRODUCED, OF COPED, USG.OSED, OF USED FOR ANY PURPOSE

‘Stren re CONSOETATIONOF THiS PROPOSAL, WITHOUT He WITTEN APPROVAL OF ANDRKA.DNES/VEOUA

Qveoua

E Desi

In using the design requirements of soluble BOD < 10 mg and NHs-N < 8 mg/L while

maintaining an equal basin size, a reactor volume chosen for this design is 62 ft long x 62 ft

wide x 18 ft side water depth. This provides for a total reactor volume of 276,768 ff within a

stem of (2) pronase tae of two (3) rendre sais Eee reetor fue hes

volume of 69, 192 ft and a percent fil of media of 56% in each reactor.

‘+ Number of Basins 4 (2 Trains of 2 Basins in Series)

‘Basin Dimensions 62 ft wide x 62 ft long x 18 ft SWO

Aeration Type ‘AnoxKakines Mediurn Bubble aeration system

© Design Flow =9MGD — Dally Average

oak Hydraulic Flow = 10.8 MGD — for sieve design only

= Infuent BOD, =79 mall (6,990 Ibiday)

+ Infuent TKN = 38 mglL (2.477 Ibday)

* Infuent TSS = 68 mg/L (6,104 ibay)

+ Temperature =47-80.6°C

© Media Fill = 56%

Design Air Requirements =6.919 SCFM

© Max. Media Fill =67%

Flow at Max. Fill =10.8MGD

+ AirRequirement at Max. Fil -=8,475 SCFM

‘+ Blower Pressure Required = 8.1 psig

‘Should you have any questions relating to this design memo please feel free to contact us.

Regards,

David Foster

Process Manager - Kruger

CC: Brain Jones, Glenn Thesing, Fle

Tapeuran cranny

ameter cues martes Bet eet trees Set ene eng Mae

Qveoua

Solutions for Process and Wastewater Treatment

DATE: January 6, 2010

To: Glenn Thesing, Susan Roszko, Kruger

FROM: Greg Parks, World Water Werks, Inc.

co! Mark Fosshage, Kyle Booth, John Schnecker WWW

RE: WWW Design Calculations for Batesville, AR Project

‘Frease find te attached Preliminary Design Calculations for the quoted WWW DAF syaiom for

Batesvile, AR. Please note that all system sizing is subject to final system review and design,

“The solids removal calculations would be as follows:

1) DAF influent Flow: “11 MGD (To be split between Two (2) DAF Units)

2) TSS In: 300 mai (Actual 76-151 mgt; 300 mil tobe used for

design)

3) Iss ou

‘a) With Chemistry <20 mo

b)With Out Chemisty TBD

4) Estimated Float,

‘a) With Chemistry

4, 36% TS

2. 1,288 to 102,575 GPO

2) With Out Chemistry

1. 24% TS

2. 71,7750 149,550 GPD

“The chemical calculations would be as follows:

1)DAFs influent Flow: 11 MGD (To be split between Two (2) DAF Units)

2) Estimated Polymer Usage:

2. 1-5 PPM

». Polymer Density: 9.5 Ibsigal

©, 104.510 522.5 Ibsiday Usage

Additional DAF Calculations:

1

‘8. 11 MGD Flow (To be spit between Two (2) DAF Units)

. Effective Surface Area: 2,566 12 Per DAF

300 mgf TSS influent

20 mgli TSS Effvent

©. 87 Dog F Max Wastewater Temp

2) AS Ratio: 0.0142

3) Hydrauiic Loading Rate: 1.49 GPM?

44) Solids Loading Rate: 5.04 IbsiDayit'2

5) Max Tum Down: 30-40% of Max Capacity; Proper Chemical mixing

‘would be the biggest concern at lower flow.

iv O4F Design Casts 05-10 56

You might also like

- Thrust Block Sizing 13feb14Document1 pageThrust Block Sizing 13feb14n_zeinounNo ratings yet

- Selection and Sizing of Air Release Valves PDFDocument22 pagesSelection and Sizing of Air Release Valves PDFMilenko TulencicNo ratings yet

- Thrust Block SizingDocument1 pageThrust Block Sizingn_zeinounNo ratings yet

- Massif de ButeeDocument4 pagesMassif de Buteen_zeinounNo ratings yet

- Thrust Block Sizing 13feb14Document1 pageThrust Block Sizing 13feb14n_zeinounNo ratings yet

- AnoxKaldnesBrochure2016Document6 pagesAnoxKaldnesBrochure2016n_zeinounNo ratings yet

- SBR Design CalculationsDocument9 pagesSBR Design Calculationsn_zeinounNo ratings yet

- SBR Design CalculationsDocument26 pagesSBR Design Calculationsn_zeinoun78% (9)

- Airrex Diesel HeaterDocument4 pagesAirrex Diesel Heatern_zeinounNo ratings yet

- Napoleon B36 Ascent 36 Direct Vent Gas Fireplace Manual PDFDocument144 pagesNapoleon B36 Ascent 36 Direct Vent Gas Fireplace Manual PDFn_zeinounNo ratings yet

- MC608 ManualDocument12 pagesMC608 Manualn_zeinounNo ratings yet

- 666 Digital Water Level Recorder (WMS-02)Document1 page666 Digital Water Level Recorder (WMS-02)n_zeinounNo ratings yet

- MC608 Manual PDFDocument68 pagesMC608 Manual PDFn_zeinounNo ratings yet

- Euromag Mut2200el SensorDocument12 pagesEuromag Mut2200el Sensorn_zeinoun100% (1)

- IBC Seismic For Abu DhabiDocument9 pagesIBC Seismic For Abu Dhabin_zeinounNo ratings yet

- MC608 ManualDocument12 pagesMC608 Manualn_zeinounNo ratings yet

- Specifications WWTP Parshall FlumeDocument572 pagesSpecifications WWTP Parshall Flumen_zeinounNo ratings yet

- Diagnostic Report 20140423 Final-Low2Document368 pagesDiagnostic Report 20140423 Final-Low2n_zeinounNo ratings yet

- Lebanon Figures 2008Document18 pagesLebanon Figures 2008n_zeinounNo ratings yet

- Centrifugation Des BouesDocument7 pagesCentrifugation Des Bouesn_zeinounNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)