Professional Documents

Culture Documents

Starting System Starting System System Description: M/T Model

Uploaded by

Alexander El HierroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Starting System Starting System System Description: M/T Model

Uploaded by

Alexander El HierroCopyright:

Available Formats

STARTING SYSTEM

STARTING SYSTEM PFP:23300

A

System Description EKS0037Q

M/T MODEL

Power is supplied at all times: B

● through 40A fusible link (letter c , located in the fuse and fusible link box)

● to ignition switch terminal B.

With the ignition switch in the START position, power is supplied: C

● from ignition switch terminal St

● to clutch interlock relay terminal 5.

With the ignition switch in the ON or START position, power is supplied: D

● through 10A fuse [No. 20, located in the fuse block (J/B)]

● to clutch interlock relay terminal 1.

E

When the clutch pedal is depressed, ground is supplied to clutch interlock relay terminal 2 through the clutch

interlock switch and body grounds E7 and E37.

The clutch interlock relay is energized and power is supplied:

● from terminal 3 of the clutch interlock relay F

● to terminal S of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates. G

A/T MODEL

Power is supplied at all times: H

● through 40A fusible link (letter c , located in the fuse and fusible link box)

● to ignition switch terminal B.

With the ignition switch in the START position, power is supplied: I

● from ignition switch terminal St

● to park/neutral position relay terminal 5

J

With the ignition switch in the ON or START position, power is supplied:

● through 10A fuse [No. 20, located in the fuse block (J/B)]

● to park/neutral position relay terminal 1. SC

With the selector lever in the P or N position, ground is supplied:

● to park/neutral position relay terminal 2

● through park/neutral position switch. L

The park/neutral position relay is energized and power is supplied:

● from ignition switch terminal St

● through park/neutral position relay terminals 5 and 3 M

● to terminal S of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Revision: July 2004 SC-9 2005 Sentra

STARTING SYSTEM

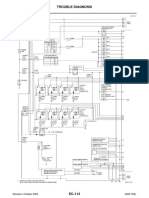

Wiring Diagram — START — EKS0037R

M/T MODEL

WKWA0644E

Revision: July 2004 SC-10 2005 Sentra

STARTING SYSTEM

A/T MODEL

A

SC

WKWA0160E

Revision: July 2004 SC-11 2005 Sentra

STARTING SYSTEM

WKWA0645E

Revision: July 2004 SC-12 2005 Sentra

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS0037S

A

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1. Turn off all loads on the vehicle electrical system. B

2. Perform battery test with Battery/Starting/Charging system

tester. Refer to SC-13, "Trouble Diagnoses with Battery/Starting/

Charging System Tester" . C

3. Press “ENTER” to begin the starting system test.

E

SEL408X

4. Start the engine.

F

SEL409X

I

5. Diagnosis result is displayed on the tester. Refer to SC-13,

"DIAGNOSTIC RESULT ITEM CHART" .

J

NOTE:

● If the starter performs normally but the engine does not start,

perform engine diagnosis.

SC

● For intermittent “NO CRANK” or “NO STARTER OPERA-

TION” incidents, refer to SC-17, "DIAGNOSTIC PROCE-

DURE 2" .

L

SEL410X

DIAGNOSTIC RESULT ITEM CHART M

Diagnostic item Service procedure

CRANKING VOLTAGE NORMAL Go to “WORK FLOW”, SC-14, "WORK FLOW" .

CRANKING VOLTAGE LOW Go to “WORK FLOW”, SC-14, "WORK FLOW" .

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Per-

CHARGE BATTERY form battery test again with Battery/Starting/Charging system tester. Refer to SC-13, "Trouble

Diagnoses with Battery/Starting/Charging System Tester" .

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

test again with Battery/Starting/Charging system tester. Refer to SC-13, "Trouble Diagnoses

REPLACE BATTERY

with Battery/Starting/Charging System Tester" . If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

Revision: July 2004 SC-13 2005 Sentra

STARTING SYSTEM

WORK FLOW

SEL411X

*1 SC-6 *2 SC-18 *3 SC-15

*4 SC-17

Revision: July 2004 SC-14 2005 Sentra

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit A

1. CHECK POWER SUPPLY FOR STARTER MOTOR “B” TERMINAL B

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

C

3. Turn the ignition switch OFF.

4. Check that the starter motor connector E202 terminal B (B/R) connection is clean and tight.

5. Check voltage between starter motor connector E202 terminal B (B/R) and ground using a digital circuit

D

tester.

LSC037

OK or NG H

OK >> GO TO 2.

NG >> Check harness between the battery and the starter motor for open circuit.

2. CHECK BATTERY CABLE CONNECTION QUALITY (VOLTAGE DROP TEST) I

1. Check voltage between starter motor connector E202 terminal B (B/R) and battery positive terminal using

a digital circuit tester. J

SC

M

LSC038

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

Revision: July 2004 SC-15 2005 Sentra

STARTING SYSTEM

3. CHECK STARTER MOTOR GROUND CIRCUIT (VOLTAGE DROP TEST)

1. Check voltage between starter motor case and battery negative terminal using a digital circuit tester.

LSC039

OK or NG

OK >> Starter motor “B” terminal circuit is OK. Further inspection is necessary. Refer to SC-14, "WORK

FLOW" .

NG >> Check the starter motor case and ground for poor continuity.

Revision: July 2004 SC-16 2005 Sentra

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 2

Check “S” Terminal Circuit A

1. CHECK POWER SUPPLY FOR STARTER MOTOR “S” TERMINAL B

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

C

3. Turn the ignition switch OFF.

4. Disconnect starter motor connector F53 (QG18DE), F32 (QR25DE) terminal S (B/Y) connector.

5. Check voltage between starter motor connector F53 (QG18DE),

D

F32 (QR25DE) terminal S (B/Y) and ground using a digital cir-

cuit tester.

With the ignition switch : Battery voltage should

E

ON exist

OK or NG

OK >> GO TO 2. F

NG >> Check the following.

● 40A fusible link (letter c , located in fuse and fusible

link box) WKWA0096E

G

● Clutch interlock relay

● Park/neutral position relay

● Harness for open or short H

2. CHECK “S” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

I

1. Connect starter motor connector F53 (QG18DE), F32 (QR25DE) terminal S (B/Y) connector.

2. Check voltage between starter motor connector F53 (QG18DE),

F32 (QR25DE) terminal S (B/Y) and battery positive terminal

using a digital tester. J

With the ignition switch in : Voltage less than 1V

START SC

OK or NG

OK >> Starter motor “S” terminal circuit is OK. Further inspec-

tion is necessary. Refer to SC-14, "WORK FLOW" . L

NG >> Check harness between the battery and the starter

motor “S” terminal for poor continuity. WKWA0097E

Revision: July 2004 SC-17 2005 Sentra

STARTING SYSTEM

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Voltage V

Engine coolant temperature

QG18DE QR25DE

−30°C to −20°C (−22°F to −4°F) 7.4 8.7

−19°C to −10°C (−2°F to 14°F) 8.2 9.2

−9°C to 0°C (16°F to 32°F) 9.3 9.6

More than 1°C (More than 34°F) 9.5 10.0

Construction EKS0037T

WKIA0287E

1. Solenoid through bolts 2. Drive end shield 3. Retainers

4. Pinion assembly 5. Fork lever 6. Bearing pedestal

7. Solenoid switch assembly 8. Seal 9. Locking washers

10. Intermediate bearing 11. Internal gear 12. Cover disc

13. Drive shaft 14. Planetary gears 15. Yoke assembly

16. Armature assembly 17. Brush holder 18. Commutator end shield

19. Closure cap 20. Starter through bolts 21. Closure cap screws

Revision: July 2004 SC-18 2005 Sentra

STARTING SYSTEM

WKWA0066E

1. Gear case 2. Shift lever 3. Plate

I

4. Packing 5. Adjusting plate 6. Magnetic switch assembly

7. Pinion stopper set 8. Pinion assembly 9. Internal gear

J

10. Pinion shaft 11. Planetary gear 12. Packing

13. Yoke 14. Armature 15. Brush holder assembly

16. Rear cover

SC

Revision: July 2004 SC-19 2005 Sentra

STARTING SYSTEM

WKWA0067E

1. Pinion stopper set 2. Pinion assembly 3. Front bracket

4. Shift lever 5. Plate 6. Packing

7. Adjusting plate 8. Magnetic switch assembly 9. Clutch gear

10. Internal gear 11. Gear shaft 12. Planetary gears

13. Ball 14. Center bracket 15. Yoke assembly

16. Armature 17. Brush assembly 18. Rear bracket

Removal and Installation EKS0037U

QG18DE

Removal

1. Disconnect the negative battery terminal.

2. Remove the upper starter mounting bolt.

3. Remove the harness protector from the starter engine room har-

ness.

4. Disconnect the starter harness connectors.

5. Remove the lower starter mounting bolt.

6. Remove the starter.

LSC024

Revision: July 2004 SC-20 2005 Sentra

STARTING SYSTEM

Installation

To install, reverse the removal procedure. A

WSC016

D

QR25DE

Removal E

1. Disconnect the negative and positive battery cables.

2. Remove the engine undercover (M/T) or the air duct, fresh air

intake hose, and air cleaner lid (A/T). F

3. Disconnect the starter harness connectors.

4. Remove the two starter mounting bolts.

5. Remove the starter. G

H

WKWA0065E

Installation

To install, reverse the removal procedure. I

SC

L

WKWA0064E

Pinion/Clutch Check EKS0037V

1. Inspect pinion assembly teeth. M

● Replace pinion assembly if teeth are worn or damaged. (Also check condition of ring gear teeth.)

2. Inspect planetary gears/planetary gear teeth.

● Replace planetary gears if teeth are worn or damaged. (Also check condition of pinion shaft/drive shaft

gear teeth.)

3. Check to see if pinion assembly locks in one direction and rotates smoothly in the opposite direction.

● If it locks or rotates in both directions, or unusual resistance is evident, replace.

Revision: July 2004 SC-21 2005 Sentra

You might also like

- Yd AcceleratorDocument5 pagesYd AcceleratorRomeo HinogNo ratings yet

- Remover Tapa Altima 2005Document5 pagesRemover Tapa Altima 2005JorgeHernandezNo ratings yet

- ST PDFDocument23 pagesST PDFzeroNo ratings yet

- Charging PDFDocument16 pagesCharging PDFred eagle winsNo ratings yet

- Power Outlet: SectionDocument7 pagesPower Outlet: SectionMaiChiVuNo ratings yet

- Trouble Diagnosis Circuit Diagram: Revision: October 2004 2005 TitanDocument10 pagesTrouble Diagnosis Circuit Diagram: Revision: October 2004 2005 TitanDavid QuispeNo ratings yet

- Trouble Diagnosis Circuit Diagram: (QR25 (WITH EURO-OBD) )Document10 pagesTrouble Diagnosis Circuit Diagram: (QR25 (WITH EURO-OBD) )Xavier AlvarezNo ratings yet

- Direct On Line Starter Princeple (Important)Document4 pagesDirect On Line Starter Princeple (Important)Dom PouchNo ratings yet

- Phason MTC 4c User ManualDocument8 pagesPhason MTC 4c User Manuale-ComfortUSANo ratings yet

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Starting System PDFDocument23 pagesDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Starting System PDFMozes SimataaNo ratings yet

- Praher Superstar E-6000 - F2 PDFDocument12 pagesPraher Superstar E-6000 - F2 PDFForxánNo ratings yet

- Revisión Circuito Sensor LevaDocument5 pagesRevisión Circuito Sensor LevaDariolesly bustamanteleinsNo ratings yet

- Power Outlet: SectionDocument7 pagesPower Outlet: SectionMaiChiVuNo ratings yet

- Dinli ATV Electrical System ManualDocument15 pagesDinli ATV Electrical System ManualgryzzlyNo ratings yet

- CS-130 ManualDocument6 pagesCS-130 Manualluis leonNo ratings yet

- Acc PDFDocument4 pagesAcc PDFEvan VlogzNo ratings yet

- Key Interlock Cable: Removal and InstallationDocument3 pagesKey Interlock Cable: Removal and InstallationGilberto Ulisses Leon CarballoNo ratings yet

- Exp6.Single Phase Bridge Inverter Using PWMDocument6 pagesExp6.Single Phase Bridge Inverter Using PWMAbdullah MohammedNo ratings yet

- Iql Electric Linear Actuator Installation and Maintenance ManualDocument7 pagesIql Electric Linear Actuator Installation and Maintenance ManualretrogradesNo ratings yet

- Electrical Connections: Section F - TransmissionDocument1 pageElectrical Connections: Section F - TransmissionvasconyNo ratings yet

- ACC-2 - Accelrator Control SystemDocument4 pagesACC-2 - Accelrator Control SystemjteamNo ratings yet

- DTC P1777 Step Motor - Circuit DTC P1777 Step Motor - Circuit DescriptionDocument4 pagesDTC P1777 Step Motor - Circuit DTC P1777 Step Motor - Circuit DescriptionRaul Rodriguez JuarezNo ratings yet

- 5.electrical System of B160Document19 pages5.electrical System of B160Dedi rahmat100% (1)

- Audio Visual, Navigation and Telephone SystemDocument14 pagesAudio Visual, Navigation and Telephone SystemKanzaNo ratings yet

- Codigo de FallaDocument5 pagesCodigo de FallaMarco Yarasca RomeroNo ratings yet

- Cs 663e Electrical DagDocument2 pagesCs 663e Electrical Dagqwureyquwery0% (1)

- Daewoo Lanos T-195 Electrical WiringDocument283 pagesDaewoo Lanos T-195 Electrical Wiringca3accoNo ratings yet

- Parking Brake System: SectionDocument4 pagesParking Brake System: SectionAldo ApazzaNo ratings yet

- Ee 591 Machine 2 PDFDocument39 pagesEe 591 Machine 2 PDFPrabhat Kumar SahuNo ratings yet

- HV1Document20 pagesHV1Izwan AzrinNo ratings yet

- 24072001Document3 pages24072001Kanishka PrasadNo ratings yet

- Data SheetDocument227 pagesData Sheetjulio797No ratings yet

- tm1606 TXTX178649Document10 pagestm1606 TXTX178649Ber HonzaNo ratings yet

- STC - Steering Control SystemDocument6 pagesSTC - Steering Control SystemBRILLIANCE AUTO LIFENo ratings yet

- Throttle Switch Circuit - Test: C18 Engine For PM-200, PM-201, and PM200 Cold PlanersDocument5 pagesThrottle Switch Circuit - Test: C18 Engine For PM-200, PM-201, and PM200 Cold Planersbasem elhosanyNo ratings yet

- Acc PDFDocument4 pagesAcc PDFFabrizio JesúsNo ratings yet

- TestDocument2 pagesTestsalusfrankNo ratings yet

- Acc PDFDocument4 pagesAcc PDFColton MurphyNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionPete PitchfordNo ratings yet

- Trouble Diagnosis Circuit Diagram: (QG (With Euro-Obd) )Document18 pagesTrouble Diagnosis Circuit Diagram: (QG (With Euro-Obd) )Electronicdeivi DeiviNo ratings yet

- Manual Ducati Home 812-300 - Board CH44Document84 pagesManual Ducati Home 812-300 - Board CH44Vasco CarrilhoNo ratings yet

- Phason VTC1D User ManualDocument12 pagesPhason VTC1D User Manuale-ComfortUSANo ratings yet

- Brake Test DC Shunt MotorDocument3 pagesBrake Test DC Shunt MotorVARAPRASADNo ratings yet

- Charger M HDocument4 pagesCharger M HgeorgeNo ratings yet

- Accelerator Control SystemDocument4 pagesAccelerator Control Systemاحمد عصام المغربيNo ratings yet

- Tacuma Electric PDFDocument169 pagesTacuma Electric PDFАлександр КваченкоNo ratings yet

- Power Outlet: SectionDocument5 pagesPower Outlet: SectionNestor RosalesNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionWilberAlmanzaMitaNo ratings yet

- Service Manual Delco-Remy CS-130Document10 pagesService Manual Delco-Remy CS-130api-2614064475% (4)

- Parking Brake System: SectionDocument4 pagesParking Brake System: SectionTuralNo ratings yet

- Electro Hid Raul I CADocument69 pagesElectro Hid Raul I CAJulio WilliamsNo ratings yet

- 2002-Nissan-Altima-Fuel SystemDocument10 pages2002-Nissan-Altima-Fuel SystemSergio Robles CastroNo ratings yet

- Acc PDFDocument4 pagesAcc PDFAldo ApazzaNo ratings yet

- Matrix 2003 2zz 6Document4 pagesMatrix 2003 2zz 6alan lantiguaNo ratings yet

- Allison Wtec IIIDocument2 pagesAllison Wtec IIIChris100% (3)

- Audio, Visual & Telephone System: SectionDocument18 pagesAudio, Visual & Telephone System: SectionMohamed HarbNo ratings yet

- S7200 ManualDocument12 pagesS7200 ManualethioelectricianNo ratings yet

- Accelerator Control SystemDocument6 pagesAccelerator Control SystemGenaro AgustinesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- VCT-2000 Service ManualDocument28 pagesVCT-2000 Service ManualSalvador Nelson0% (1)

- Electronic Pressure Transducers: Upa2 Upa2Document2 pagesElectronic Pressure Transducers: Upa2 Upa2Qatar home RentNo ratings yet

- Motherboard Manual Ga z77 (h77) d3hDocument104 pagesMotherboard Manual Ga z77 (h77) d3hmeatsauceNo ratings yet

- Manual DVC2Document42 pagesManual DVC2Tenchiu AndreeaNo ratings yet

- Installation and Operation Manual - Growatt - MOD 3 15KTL3 X - Inverters - 2021 - ENGDocument30 pagesInstallation and Operation Manual - Growatt - MOD 3 15KTL3 X - Inverters - 2021 - ENGMarius Constantin VochinNo ratings yet

- Ut511 enDocument31 pagesUt511 enarc10No ratings yet

- 0617 ModuflexDocument61 pages0617 Moduflexasphalto87No ratings yet

- Product CAT BLMT - DatasheetDocument8 pagesProduct CAT BLMT - DatasheetiamlpNo ratings yet

- QSFP (Quad Small Form-Factor Pluggable) ConnectorsDocument17 pagesQSFP (Quad Small Form-Factor Pluggable) ConnectorsAbdallah Ben HamidaNo ratings yet

- Bow Thruster Installation InstructionsDocument9 pagesBow Thruster Installation InstructionsRovert AlonzoNo ratings yet

- (A) The Diagram Shows The Inside of A Three-Pin Plug.: Leave BlankDocument2 pages(A) The Diagram Shows The Inside of A Three-Pin Plug.: Leave BlankYu SunNo ratings yet

- Chapter 2 PDFDocument52 pagesChapter 2 PDFoscar trujilloNo ratings yet

- LV Insulated Overhead LinesDocument59 pagesLV Insulated Overhead Linesyavuz772No ratings yet

- Electrical 336el 03Document48 pagesElectrical 336el 03rjan7pe100% (1)

- Chapter 3 - Wiring System and DistributionDocument65 pagesChapter 3 - Wiring System and DistributionMohamad Syahmi100% (1)

- Mecair lct4 Sequencer 826974 PDFDocument24 pagesMecair lct4 Sequencer 826974 PDFAugusto LimaNo ratings yet

- Inner Finisher H1 PCDocument51 pagesInner Finisher H1 PCAnh TienNo ratings yet

- Piezomechanik Product Range Low 2013-12-05 RedDocument26 pagesPiezomechanik Product Range Low 2013-12-05 Redalich500No ratings yet

- XAD 100 110 Product GuideDocument37 pagesXAD 100 110 Product Guidematt12many100% (1)

- Quick LubDocument40 pagesQuick LubMohamed RashedNo ratings yet

- 1832 Multimauspro enDocument49 pages1832 Multimauspro enjmmfonsecaNo ratings yet

- RV-2F-D Series Standard Specifications Manual: Mitsubishi Industrial RobotDocument162 pagesRV-2F-D Series Standard Specifications Manual: Mitsubishi Industrial RobotAyoubNo ratings yet

- Ir1430 - 1435 SM E PDFDocument355 pagesIr1430 - 1435 SM E PDFPierre Chirac92% (12)

- RS520-E6/ERS8: 2U Rackmount Server User GuideDocument146 pagesRS520-E6/ERS8: 2U Rackmount Server User GuideMarian CatanoiuNo ratings yet

- ZM-MFC1 Combo: To Ensure Safe and Easy Installation, Please Read The Following PrecautionsDocument7 pagesZM-MFC1 Combo: To Ensure Safe and Easy Installation, Please Read The Following PrecautionsnegatronnNo ratings yet

- Diagnostico Freios Abs MK Ii PDFDocument17 pagesDiagnostico Freios Abs MK Ii PDFtadeuNo ratings yet

- Samsung-Lcd-510 710 910 912 913 915n t-mj15 17 19 - ChassisDocument43 pagesSamsung-Lcd-510 710 910 912 913 915n t-mj15 17 19 - ChassismosavlaNo ratings yet

- JHA Welding Arc and Cutting (Hotwork)Document2 pagesJHA Welding Arc and Cutting (Hotwork)Popo EaldamaNo ratings yet

- Micom E124: Capacitor Trip UnitDocument80 pagesMicom E124: Capacitor Trip Unitmaria kamylaNo ratings yet

- Product Catalogue 2014/2015Document56 pagesProduct Catalogue 2014/2015RICARDO ALEXIS LARA GALLEGO STORKNo ratings yet