Professional Documents

Culture Documents

Asep-Steel-Handbook PDF

Asep-Steel-Handbook PDF

Uploaded by

Charlette Solano0 ratings0% found this document useful (0 votes)

15 views422 pagesOriginal Title

10. Asep-Steel-Handbook.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views422 pagesAsep-Steel-Handbook PDF

Asep-Steel-Handbook PDF

Uploaded by

Charlette SolanoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 422

ASEP

STEEL HANDBOOK

Association of Structural Engineers of the Philippines, Inc.

Unit T-10, New Manila Condominium

21 .N. Domingo St., Quezon City

The information included in this publication has been prepared

on generally accepted engineering principles and provisions of

applicable codes and standard specifications for steel

construction, While the information fourd herein is believed to

be accurate, the Association of Structural Engineers of the

Philippines, Inc, strongly recommends that competent

professional judgement and verification of the accuracy,

suitability and applicability of the given information for the

specific application shall be utilized. Anyone making use of this

information assumes all liability arising from such use.

ASEP STEEL HANDBOOK

Copyright @1994

by

Association of Structural Engineers of the Philippines, Inc. (ASEP}

Unit T-10, New Manila Condominium

21 N. Domingo St., Quezon City

All rights reserved. Printed in the Philippines. This book or any

part thereof must not be reproduced in any form without

written permission of the publisher.

ASEP Steel Handbook

wii =

PREFACE

The Association of Structural Engineers of the Philippines, Inc., (ASEP)

is a non-profit organization founded in 1961 with the primary objective of

upgrading the practice of structural engineering in the Philippines.

As part of its efforts to meet this objective, the association published the

Handbook of Steel Shapes and Sections in 1987. The main purpose of the

original publication was to provide local practitioners, suppliers, and fabricators

with a set of produced steel products. With the handbook, the need of

substitutions due to unavailability and its corresponding cost and delay can thus

be reduced or eliminated. Alternatively, it may be used to select substitute

sections designed using otf er design manuals and tables. A second purpose for

the publication was to provide the local practitioner with a design aid in

International System of Units (Sl) compatible with the National Structural Code

of the Philippines (NSCP}.

This publicatio 1, ASEP Stee! Handbook, represents the second edition of

the 1987 handbook. While its purpose and objectives are basically identical to

those of the original publication, changes in the local steel market conditions

as well as in design practices and technology necessitated revisions in the

shapes and sections.

Majov revisions include, for one, modification in the thickness of plates

and sheets used for the fabricated shapes to work towards the establishment

of a truly metric standard rather than a metricized equivalent of english unit

standards, Secondly, in an ffort to work towards compatibility to current

international standards and practices the rolled shape sections have been

considerably expanded to include locally available imported sections and metal

deck sections has been added. Thirdly, in an effort to increase the usefulness

of the handbook, design examples has been added while retaining the design

table and data in the original publication.

In the preparation of this second edition, both solicited and unsolicited

comments and suggestions coming from suppliers and fabricators, as well as

designers, were instrumental to some of the revisions presented. As future

periodic revisions of this Steel Handbook by a responsible technical committee

is expected, comments, corrections, recommendations, additions, deletions and

any other relevant information which may be used to improving this handbook

continue to be welcomed by the association. Such comments are assured to

receive the same careful consideration by the technical committee.

FIDEL R. SARAUSAD.

Overall Committee Chairman and Vice-President (1994-1995)

Association of Structural Engineers of the Philippines

ASEP Steel Handbook

iit.

ACKNOWLEDGEMENT

ASEP acknowledges all those who have contributed to the publication

of this ASEP STEEL HANDBOOK, which is actually an expanded version of the

ASEP HANDBOOK STRUCTURAL STEE!. SHAPES AND SECTIONS published

in 1987.

Special gratitude to Engr. Hermenegildo P. Manzano, Jr. who initiated the

project during his tenure as President (1993-1994) and who had been involved

ex-officio in the committee deliberations.

Sincere thanks to the Directors, incumbent and ex-officio, who read and

reviewed the manuscripts and who also offered many helpful suggestions.

Credit likewise goes to the following generous sponsors of the project,

through their representatives, for their financial assistance:

Sponsor Representative

Phil. Inst. of Steel Construction Engr. Samson P. Lazo, President

National Stee! Corporation Mr. Anthony S. Dizon, VP Marketing

Engineering Equipment, Inc. Engr. Rogelio M. Murga

PAG-ASA Steel Corporation Engr. Gabriel Y. Tong, General Manager

Capitol Stee! Corporation Mr. Alvin Cheng, General Manager

Philmetal Products, Inc. Mr. Bobby Valdez

Condeck International Mr. James Na

Finally, deep appreciation is due to the Overall Committee Chairman and

Vice President, Engr. Fidel R. Sarausad, for his coordination and supervision,

and to the various Technical Committee Chairmen, for their dedicated

professionalism, hard work, patience and persistence in pushing this project to

final fruition.

ROMER S. MONTOYA

Exec, Committee Chairman and President (1994 - 1995)

Association of Structural Engineers of the Philippines

ASEP Steel Handbook

“We

ACKNOWLEDGEMENT

In behalf of the Officers and Directors, we wish to express ASEP’s

sincere gratitude to all those who, one way or the other, made possible the

publication of this ASEP STEEL HANDBOOK seven years after the publication

of the ASEP HANDBOOK OF STRUCTURAL STEEL SHAPES AND SECTION in

1987.

Sincere gratitude goes to the committee that handled this project, chaired

by Engr. Fidel R. Sarausad, the ASEP Secretary {in concurrent capacity) and

assisted by hand-picked dedicated experts from among the Officers, Directors

and Members of the ASEP. The Committee did an outstanding job in finishing

the project according to schedule. It provided once more the adage: "If there

is a will, there is a way.”

Credit likewise goes to sponsors of the project: (1) Philippine Institute of

Steel Construction (PISC) through its President, Engr. Samson P. Lazo, (2)

National Steel Corporation (NSC) through its Marketing Vice President, Mr.

Anthony S., Dizon, (2) Engineering Equipment, Inc, (EEl) through its President,

Engr. Rogelio M. Murga, (4) PAG-ASA Steel Works, Inc. through its Sales

Manager, Mr. Robin Y. Tong, (5) Capitol Steel Corporation through its General

Manager, Mr. Alvin Cheng, (6) Philmetal Products, Inc. through its Vice

President for Marketing, Mr. Bobby Valdez, and (7) Condeck International

through its Vice President for Sales & Marketing, Mr. James Na, all of whom

provided the much-needed financial assistance that made possible this

handbook’s publication.

Finally, credit is likewise due to the ASEP Officers and Directors for their

patience in reviewing the manuscript, and the pieces of advice given especially

on new sections that were included to this handbook.

HERMENEGILDO P. MANZANO, JR.

Exec. Committee Chairman and President (1993 - 1994)

Association of Structural Engineers of the Philippines

ASEP Steel Handbook

nye

ASEP STEEL HANDBOOK COMMITTEE

Hermenegildo P. Manzano, Jr. Fidel R. Sarausad

Executive Committee Chairman Overall Committee Chairman

Members

Ernesto F. Cruz Romer S. Montoya

Ronaldo S. tson Hubert M. Palpal-latoc

Alfredo B. Juinio, Jr. Jobelito M, Sta. Ana

Arturo H. Libongco Mario D. Taruc

Enrique C, Medina

1993-94 ASEP OFFICERS and DIRECTORS

Hermenegildo P. Manzano, Jr.

President

Romer S. Montoya Fidel R. Sarausad Alfredo B, Juinio, Jr.

Vice President Secretary Treasurer

Directors

Jose S. Abad Octavio A, Kalalo

Antonio A, Abola Teodoro S, Legua

Rolando E. Cruz Jose F, Nabanta

Roberto P. Bernardo

Ex-Officio Director

ASEP Steel Handbook

-vie

CONTENTS.

ABBREVIATIONS

FOREWORD

PART 1

Built-Up Shapes

PART 2

Cold-Formec: Plate Shapes .. 0.0...

PART 3

Cold-Formed Light Gage Shapes ...........

PART 4

Rolled Shapes

PART 5

Metal Decks |

PART 6

Steel Flat Products

PART 7

Design Examples

PART 8

Welded Joints

PART 9

Miscellaneous Tables and Data .

ASEP Steel Handbook

vil -

1-1 to 1-52

cee tee 2-1 to 2-20

cee eee 3-1 to 3-40

4-1 to 4-80

5-1 to 5-22

6-1 to 6-48

7-1 to 7-42

8-1 to 8-26

9-1 to 9-60

ele

cm

cu.m.

excl.

incl.

kg/m

kN

max

min

mm

MPa

Pa

psi

tad

sq.m.

temp As

Typ

ACI

AISC

AISI

ASEP

ASTM

AWS

BS

JIS

NSCP

PNS

ABBREVIATIONS

center to center

centimeter

cubic meter

exclusive

inclusive

kilogram

kilogram per meter

kiloNewton

meter

maximum

minimum

millimeter

megaPascal

Newton

Pascal

pounds per square inch

radians

square meter

temperature steel

typical

weight

American Concrete Institute

American Institute of Stee! Construction

American Iron and Steel institute

Association of Structural Engineers of the Philippines

American Society for Testing and Materials

American Welding Society

British Standards

Japanese Industrial Standards, 1991

: National Structural Code of the Philippines, Vol. 1, Fourth

Edition, 1992

Philippine National Standards

ASEP Steel Handbook

= vill -

FOREWORD

GENERAL

This ASEP Steel Handbookis intended primarily to serve as a guide in the

selection and use of locally available structural steel products. These products

are divided into five classes based on the method of,manufacture and/or

maximum thickness of the section. The first five parts of this handbook

correspond to these classes as follows:

Part 1 - Built-Up Shapes

Part 2 - Cold-Formed Plate Shapes

Part 3 - Cold-Formed Light Gage Shapes

Part 4 - Rolled Shapes

Part 5 - Metal Decks

Each of these parts presents a series of tables of computed and/or

compiled data. These data consist of sectional dimensions and properties

chosen and arranged to enable rapid and convenient selection of structural steel

members. For increased usefulness, several other tables, formulas, and design

information are presented in Parts 6 to 9 of this handbook.

As an updated edition of the ASEP Handbook of Steel Shapes and

Sections, this handbook has considerably been expanded and contains several

major revisions, The major revisions include the following:

1. The thickness of steel plates for the built-up and bent plate have

been modified. The thickness adopted corresponds to the bar

sizes of reinforcing steel bars primarily to facilitate recollection.

This adaptation eliminates thickness with fractions of millimeters.

The maximum thickness adopted for built-up sections was also

increased from 44 to 45 millimeters. The maximum thickness used

for bent shapes has been reduced from 25 to 20 millimeters.

2. The thickness of steel sheets for light gage sections have been

modified. The edopted thickness range from 2.0 to 6.0 millimeters

in increments of 0.5 millimeter. This compares with the thickness

used in the first edition which range from 1.2 to 4.7 millimeters

with varying increments of 0.2 or 0.3 millimeter.

ASEP Steel Handbook

vix-

Foreword

3.

a

The range of overall depths of built-up BW and BH sections has

been modified. The overall depths of BW sections adopted range

from 200 to 1,000 millimeters in increments of 50 or 100

millimeters from the previous range of 100 to 920 millimeters

with variable increments. The overall depths of BH sections

adopted from 200 to 700 millimeters compared to the previous

195 to 425 millimeters.

Built-up wide flange Tee, BWT, section properties has been added.

The rolled shapes and sections has considerably been expanded

with the adoption of sections from the AISC Manual of Steel

Construction, 9th edition, except for the angle sections. Although

the standard AISC designations were adopted, the tabulated

section properties are in SI units.

Part 5, presenting two metal deck shapes has been added to the

handbook. Metal decks are cold-formed light gage shapes and

normally vary with the manufacturer. The handbook limited the

shapes to those shapes locally available.

The discussion on steel flat products, originally incorporated

within the rolled shapes, has been considerably expanded to

include excerpts from standard specifications. This expansion

merited the separation of the discussion to a new Part 6 of the

handbook.

Design examples has been added in the new Part 7 of the

handbook. Each of the five design examples include detailed

discussions and references to the different parts of this handbook

as well as the NSCP.

The discussion on welded joints, previously presented with the

miscellaneous tables and data, is presented in a separated Part 8

of this handbook. An expanded miscellaneous tables and data is

presented in Part 9.

ASEP Stee! Handbook

xe

CLASSIFICATION AND DESIGNATIONS

Foreword

The following classifications and designations are used for the different

structural shapes presented in this handbook.

Class Shape Designation

Built-Up | Wide-Flange BW Hx W

Heavy Column BH Hx W

Wide Flange Tee BWT Hx W

Cold-Formed Plate Angle BA HxBxt

Channel BC HxBxt

Cold-Formed Light Stiffened Cee Lc HxBxCxt

Gage

Stiffened Zee LZ HxBxCxt

Rectangular Tube LR HxBxt

Square Tube LS HxBxt

Rolled Wide Flange WwW oidxw

S-Shape S ‘dxw

Channel dxw

Structural Tee WT dxw

Angle Ll HxBxt

Pipe - standard Psd

Pipe - Extra Strong PE d

Pipe - Double-Extra pp d

Metal Deck sD SD Nxt

cD cD Nxt

ASEP Steel Handbook

oxi

Foreword

Where: B - is the flange width of the section; shorter leg

of angles; shorter side of tubular sections, in

mm.

cc - is the overall depth of lip of light gacie

sections, in mm.

a is the depth of rolled sections, in inches.

is the depth of the section; longer leg of

angles; longer side of tubular section, in mm.

is the overall widths of metal decks, in mm.

is the base metal thickness of the section, in

mm.

the nominal weight per unit length, in kg/m.

- is the nominal weight per unit length of rolled

sections, in Ibs/ft.

xe

-z2

FABRICATED SHAPES

The sections and shapes presented in the first three parts of this

handbook may be referred to as fabricated shapes as they are made from rolled

flat products. These sections are limited therefore by the availability of these

flat products, and the availability and limitations of the equipment required in

the fabrication of these shapes and sections.

There are two general metliods of producing structural shapes from flat

steel products. One is by welding together plates into the desired shape, and

the other is by cold-forming plates, coils sheets, or strips.

Shapes produced by weldments are referred here as ‘Built-Up’ shapes

and are limited to the use of plates having a thickness greater than or equal to

6.0 millimeters.

Shapes may also be cold-formed by passing the flat steel products in rolls

until the desired shape is attained, or by press brake bending. For consistency

with common practice, however, these shapes are divided into two classes

depending on the thickness of the base metal used. Cold-formed plate shapes

are produced from plates with thickness greater than or equal to 6.0 millimeter.

Cold-formed light gage shapes, on the other hand, are produced from coils,

sheets, or strips with thickness less than or equal to 6.0 millimeter.

ASEP Steel Handbook

= xii -

Foreword

For plates, the following thickness, in millimeters, were adopted: 6, 8, 10, 12,

16, 20, 25, 28, 32, 40, 45. For light gage sections the following thickness, in

millimeters, were adopted: 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0.

Because of the general flexibility of the fabrication methods, an infinite

variation of shapes and sections can be produced. The shapes presented have

been limited to those commonly used for each classification.

For the sections, the dimensions were chosen such that the optimum

utilization of the available flat products is attained. Furthermore, the dimensions

were chosen such that certain limits given in the provisions of applicable codes

and specifications are not exceeded. These limits are discussed more fully in

the text accompanying each part of this handbook.

Note that the fabricated sections presented are not standard stock

sections. The designer is also in no way limited to the tabulated shapes and

sections. Use of special shapes and sections may be advantageous in some

cases where substantial economy may be derived from its use. Furthermore,

special shapes and sections may also be required to meet requirements

particular to a given protlem.

ROLLED SHAPES

Rolled shapes are defined here as those produced by passing red-hot

blooms or billet steel through rolls until the desired shape is attained. Except for

the angles, the shapes and sections adopted are those from the Sth edition of

the AISC Manual of Steel Construction. The AISC sections adopted include the

W, S, C, WT and pipe sections.

As stated above, the designation used in this handbook is identical to

those used in the AISC Manual, although the section dimensions and properties

are presented in the SI units.

SECTION AND PROPERTIES

‘The sectional properties tabulated were calculated based on generally

accepted engineering princisles and were generated using micro-computers.

Simplifications and/or assumptions particular for each class of shapes are

discussed in the descriptive material preceeding each part of this handbook.

ASEP Steel Handbook

+ xii =

Foreword

( Iwcalculating the theoretical weight of the steu! sections, a mass density

of 7850 kg/m® was used.

WORKMANSHIP AND TOLERANCES

The dimensions and properties shown on the tables are theoretical values

and those of the finished products will be subjected to the usual variations.

Tolerances not covered shall be based on applicable specifications relating to

each class and. shall be specified by the designer with proper regard to

fabrication and érection requirements.

STEEL FLAT PRODUCTS

Flat structural steel products are locally available as hot-rolled plates,

Coils and sheets. In addition, cold-rolled coils and sheets a’e also manufactured

locally. The detailed discussion on flat products and available sizes can be

found in Part 6. The fabricated shapes are based on these products.

ASEP Steol Handbook

+ xiv =

Built-Up Shapesl-1A

PART 1

BUILT-UP SHAPES

ASEP Steel Handbook

aA

1-1B Built-Up Shapes

NOTES

ASEP Steel Handbook

“2

Built-Up Shapes 1-1

CONTENTS

Scope and Classification.

Materials...

Sectional Dimensions.

Sectional Properties.

Welds... 6 ee eee e ee eee ee eee eee eee eee ee bebe tee e eee 1-8

Comments on the Design Tables..... bebe beet eee eee see e ee eee Ld

Dimensional Tolerances.........-.-+ cree 1-10

Tables of Dimensions and Properties

BW ~ Shapes. 2... eee eee ee eee eee eee wee1-14

BH ~ Shapes...... 0. eee eee cece eee eee e eee cence seen ee LH24

BWT- Shapes... 2.6... cece eee eee ee eee eee eee eee eee eee 1-34

Beam Selection Table.........esee eee ee eee

Values of C, Table....

Allowable Compress:.ve Stress Table

ASEP Steel Handbook

“Be

1-2 Built-Up Shapes

NOMENCLATURE

Symbol Definition

Cross-sectional area

Area of compression flange

Flange width

Slenderness ratio of compression elements as

defined in Appendix A of 1992 NSCP, Chapter 4.

Axial compressive stress permitted in a prismatic

member in the absence of bending moment

Specified minimum yield stress of structural steel

Depth of the section

Clear distance between flanges

Moment of inertia about the X-X axis

Moment of inertia about the Y-Y axis

Effective length factor for prismatic member

Actual unbraced length of compression member

Maximum unbraced length of the compression flange

at which the allowable bending stress may be taken

as 0.66F, based on NSCP Sect. 4.5.1.4.1

Maximum unbraced length of the compression flange

at which the allowable bending stress may be taken

as 0.60F,

Beam resisting moment

Ratio of effective profile area of an axially

loaded member to its total profile area,

Appendix A, 1992 NSCP

First moment of area of the beam flange about

the neutral axis

Axial stress reduction factor where width-

thickness ratio of unstiffened elements exceeds

limiting value given in Sect. 4.9.12,

Appendix A of 1992 NSCP

Radius of gyration of a section comprising the

compression flange plus 1/3 of the compression

web area, taken about an axis in the plane of

the web

Radius of gyration about the X-X axis

Radius of gyration about the Y-Y axis

Elastic section modulus about X-X axis

ASEP Steel Handbook

4

Units

why

N-m

BaSs

3D

te

Zee

NN

Py

Built-Up Shapes 1-3

Elastic section modulus about Y-Y axis

Neight of web excluding weld thickness

Flange thickness

Web thickness

Minimum fillet weld size

Weight of the section per unit length

Plastic section modulus about the X-k axis

Plastic section modulus about the Y-Y axis

ASEP Steel Handbook

Be

BBs 8

gaa

F

1-4 Built-Up Shapes

r-

NOTES

ASEP Steel Handbook

6

Built-Up Shapes 1~5

BUILT-UP SHAPES

General

Built-up shapes are herein defined as structural steel

sections made up of steel plates with thickness ranging from 5.0

mm to 45.0 mm, welded together to form structural shapes.

Considering that locally produced rolled shapes are normally

limited to depths of about 200 mm, built-up sections are fre-

quently used as a substitute for rolled sections.

Some fabricators use modern equipuent, such as multiple head

gas cutting machines and automatic welding machines, needed in

the production of built-up shapes. These modern equipment have

considerably increased the economy and efficiency of production

of built-up sections. With the tables presented in this Part 1

of the Steel Handbook, designers may directly select and specify

a built-up section. Alternatively, the tables may be used to

facilitate the substitution of built-up sections for rolled

sections.

Scope and Classification

As defined above, there is an infinite number of possible

shapes which could be presented. For simplicity, however, this

Steel Handbook is limited to the most commonly used built-up

shapes, i.e. the bi-symmetric I shape and the wide flange Tee

shape.

Three specific built-up shapes are presented in this Steel

Handbook, the BW, BH, and BWI shapes. The BW sections are in-

tended primarily for use as beam members, while the BH sections

are normally intended for use as columns, The BWT sections are

intended for use as truss top and bottom chord elements. ‘The

classification and designation relating to these shapes are given

below.

ASEP Steel Handbook

“Te

1-6 Built-Up Shapes

r 1

| Class Shape Designation |

I i

E 1

| Built-Up Wide Flange BW HxW |

i Heavy Column BH HxW |

| Wide Flange Tee BWT HxW |

L i

The designation of built-up sections are based on outside

depth and weight per meter length rather than on all dimensions

of the built-up section as is used in other standards. The adopt-

ed form is simpler and is one which is familiar to local design-

ers.

The BW and BH sections are distinguished by the ratio,

x,/ty, of the radius of gyration about the X-K and Y-Y axes,

respectively. BW sections have r,/r, ratios greater than or

equal to 3.0, while BH sections have r,/r, ratios less than 3.0.

The grouping, however, does not imply that the BW sections

are to be used only as beams, and BH sections as columns. Par-

ticular loading or lateral support conditions or other require~

ments may dictate the shape of a given member.

The built-up tee (BWT) sections presented are assumed to be

obtained by cutting BW sections similar to rolled tee sections.

The depth of BWI sections are therefore half of those correspond-

ing BW sections.

A total of 255 built-up sections are presented in this Steel |

Handbook. Of these, 68 are BW sections with depths ranging from |

200 mm to 1000 mm. There are 81 BH sections with depths rang-

ing from 200 mm to 700 mm. There are 86 BWT-sections with depths

ranging from 100 mm to 500 mm.

Materials

The minimum quality requirement for built-up shape fabrica-

tion is structural steel conforming to ASTM A36 and/or JIS 63101

SS 400 (formerly JIS G3101 SS 41).

ASEP Steel Handbook

8.

Built-Up Shapes 1-7

Locally rolled plates are available for these grades of

structural steel which have minimum specified yield stresses, Fy,

of 248 MPa and 245 MPa, respectively. The sectional properties

and limits of built-up shapes and sections are based on these

values. Further information regarding materials for built-up

shapes is given in Part 6.

Sectional Dimensions

A major consideration in the choice of dimensions of the

sections is the optimum utilization of locally available plates.

Again, to facilitate easy recall in detailing and design and to

simplify splices between connections, out-to-out" depth at pre~

dictable increments is adopted in this Steel Handbook.

With the "out-to-cut" depth, the clear distance between

flanges will vary depending on the flange thickness resulting in

a lower yield of the web plates. This situation is unlike the

case of rolled wide-flange and S-shapes whose clear distances

between flanges are kept constant for each family of the nominal

depths. The constant clear distance between flanges of rolled

sections is due to che rolling equipment used in its manufacture

where sectional differences within a family are achieved by

modifying the flange dimensions and the web thicknesses.

Built-up sections, however, are not subject to these limi-

tations. It is believed that the use of a constant “out-to-out"

depth would provide greater ease in detailing, fabrication and

erection. Furthermore, it is believed that the cited utilization

of plates could still be improved by choosing a proper cutting

layout or by using the remaining plate materials for secondary

structural elements such as gussets and stiffeners.

Aside from the utilization of available plates, the dimen-

sions of the flanges of both BW and BH sections were proportioned

to satisfy the limit on the width to thickness ratio for unstiff-

ened elements of the compression flange according to NSCP Sect.

4.5.1.4.1. This limiting ratio, of 170//F,, equals to 10.8 for

structural steel conforming to ASTM A36.

ASEP Steel Handbook

1-8 Built-Up Shapes

For the web dimensions of BW sections, the thicknesses were

limited such that the allowable shear stress may be taken as

0.40F, without the use of stiffeners. The maximum ratio of the

clear distance between flanges to web thickness h/t, equal to

1000//F,. For a yield stress of 248 MPa, this ratio has a value

of 63.5. Note that stiffeners should still be provided as re-

quired by other provisions of the code, particularly NSCP Sects.

4.10.5 and 4.10.10.

For the web dimensions of BH sections, the thicknesses were

limited so that the depth to thickness ratio of the web, h/t,

does not exceed the value specified by NSCP formula 4.5-4b. This

limiting ratio, 675//F,, has a value of 42.8 for Fy equal to 248

MPa.

Sectional Properties

The properties, ratios, and weights of the sections were

computed considering the dimensions of the flange and web plates

only, The weld material was excluded. In a competitive design

and construction environment, some designers would include the

capacity of the weld material,

For built-up tees, values of Q, and C', for steel with mini~

mum yield stress, F, equal to 248 MPa are also tabulated. For

sections with width to thickness ratio of unstiffened projecting

elements of compression flange exceeds 330//Fy as specified in

NSCP Sect. 4.9.1.2, the allowable stress is governed by the

Provisions of Appendix A, Section A2, AS and A6 of Chapter 4,

Part 2 of the NSCP. Where no values of Q, and C', are shown, the

built-up tee conforms to NSCP Sect. 4.9.1.2 and i$ considered as

fully effective.

Welds

The dimension "w" given in the tables of dimensions and

Properties is the minimum leg size of fillet welds as specified

in NSCP Table 4.17.2A. The actual size of fillet welds must be

specified by the designer. To facilitate this calculation, the

quantity Q¢/1, are tabulated for each BW and BH sections. Q, is

ASEP Steel Handbook

-10-

Built-Up Shapes 1-9

the first moment of area of a flange about the X-X axis.

Groove welds may also be used to connect the flanges to the

web plate. I£ required, groove welds shall be as specified by

the designer.

Comments on the Design Tables

Aside from the tables of dimensions and properties, a Beam

Selection Table for the BW sections is included to facilitate the

selection of flexural members designed on the basis of NSCP Sect.

4.5.1.4.1. For ease of use, the quantities required to check the

compact section criteria are included, together with the limit-

ing values of the unbraced lengths.

For the design of compression members, a table of the allow-

able stress as a functior. with the slenderness ratio, Kl/r, is

also included.

ASEP Steel Handbook

ie

1-10 Built-Up Shapes

DIMENSIONAL TOLERANCES

Built-Up Shapes

A. CROSS-SECTIONAL TOLERANCES

Variation from Specified Dimensions

r

H,* Depth, mm | B,Flange Width, mm E,

i

less than 6 mm

Web |F,° Combined

Over Under| Over Under off Center| Tilt and

mm | mn mm | Warpage, mm

I

I

|

3 3 | 6 3 6 B/100, but not

|

1

a

H is measured parallel to the web at the web center line.

> pis the maximum offset at the toe of the flange from a

line normal to the plane of the web through the intersec-

tion of the web center line and the outside face of the

flange.

ASEP Steel Handbook

Az

Built-Up Shapes 1-11

B. STRAIGHTNESS TOLERANCE

[Member | Length | Permissible Variations in |

I | mm | Straightness, mm |

I | I \

Jcolumns | Less than 9,100 | 1 mm x (total length in m) |

| | 9,100 to 13,700 | 10 mm I

| | Over 13,700 | 10 mm + 1 mmx (total length = |

| | | in m - 13.7 m) |

| I | |

[Beams w/o | \ |

[specified | | |

|Camber or | i |

[| al | 1 mm x (total length in m) |

L 4 i

|Sweep

t

C. CAMBER AND SWEEP TOLERANCES

I 7 7 1

[Variable | Member [Permissible Variations from Specified |

| | { Camber or Sweep, mm i

I I \ |

I I I 1

{Camber |Beams except | 2 mm x (test length in m), but not |

| [below # | less than 6 mm |

| I | |

| [Beams with = | {

| [top flange | |

| embedded in | 0.5 mm x (total length in m), but |

| [concrete > | not less than 6 mm |

| | | |

[Sweep | Beams | 1 mm x (total length in m) |

i 1 i

3 Tolerance over specified camber of beams need not exceed

the greater of 1 mm x (length to the nearest end in m) or

19 mm. The tolerznce under the specified camber is O mm,

> must not have a designed cohcrete haunch. Specified

tolerance is for over and under specified camber.

ASEP Steel Handbook

“13-

1-12 Built-Up Shapes

NOTES

ASEP Steel Handbook

-14-

Built-Up Shapes 1-13

TABLES

OF

DIMENSIONS AND PROPERTIES

ASEP Steel Handbook

1-14 Built-Up Shapes

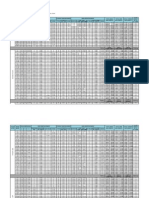

BW SHAPES

Dimensions

Properties

Weight} Area Web Flaiige Distances

Designation | W A Hi] 8B] fh | 7 | w {Bey} wit, | HA,

HxwW kgim | mm? | mm fmm] mm jmm] mm | mm | nm timm

BW 1000x 518/517.94} 65,980 |1,000} 28} 450) 46} 910} @94| 6) &00| 85,71] 0.049

x 497 /496.51 | 63,250 ]1,000) 25] 450] 45) 910, 804} 8] 5.00} 40.00} 0.049

x 463/463.15] 59,000 1,000) 25} 480) 40) 920) 904] 6} 5.63] 40.00} 0,056

x 3931490.29) 60,100 |1,000) 20! 480) 95] 930) 914] 6} 643] 50.00] 0.063

x 973|379,03] 47,520|1,000] 20) 460] G2} $36) 920) 8} 7,08} 60.00] 0.080

BW 800 x 496/495.96) 63,180) $00) 28; 450) 4%} 810) 794; 8) 5.00] 214] 0.044

X 464 /443.58) 86,500) 900) 26) 450} 40} G20) 604) 8] 8.63) 96.00} 0.080

x 410/410.16] $2,280) 900) 28) 460) 33] 60) B14! 6] 643) 36.00) 0.087

x $78/877.59) 48,100} S00} 20) 480} 96} 830} 814) 8] 6.43) 45.00! 0.087

x 987 |957.33| 45,520) 900) 20) 450! 32] 895) G20) 8] 7.03} 48.00; 0.060

x 330/930.83} 42,060) 900) 20) 450) 28) 844; 828) | 8.04} 45.00) 0.071

x 904/303.83} 98,704/ 900] 16) 450) 26) 844) @28) 8] 8.04) 56.25) 0.071

x 283/263.99) 96,100) 900) 16) 450) 25) 850) 634) 6) 9.00) 66.25! 0.060

BW 800 x 947)347.28] 44,240| 900! 28) 300! 35) 8%] 814) 8! 429) 9214) 0.068

x 315 }314.78} 40,100} 900) 25] 300) 32) 636] 620; 8] 469) 36.00) 0.094

X 264 |264.99} 93,680} 900) 20; 900) 26/ 644] 828} 8) $98) 45.00) 0107

x 298 /237.89} 90,904/ $00) 16] 300) 28) 644] 626] 8) 598/ 56.25) 0.107

x 225 1224.51 | 28,600} $00} 16] 300) 25) 850] 834} 8) 600! 56.25) 0.120

X 202 |202.22| 25,760} 900} 16] 300) 20) 960] 844] 8) 7.50| 56.25] 0.150

ASEP Steel Handbook

Built-Up Shapes 1-15

BW SHAPES

Dimensions.

Properties

Elastic Properties Plastio Modulus

Axis X-X Axis Y-Y

|] on 7 8 TT] s Designation

ae mm | xio® | xi? |r | xtof) aio? |r ae ae HXW

[mm mm* | mm? | mm _|mm*| mm? | mm | mm? | mm?

0.88] 118.1/10,9¢8) 21,99] 408.3] 685) 9.045) 101.9] 26,195} 4,785] BW 1000x 518

089) 119.2/10.811 | 21,622) 419.4) 688) 9.043] 104.0) 24.514] 4608 x 7

0.87) 118.0) 9921| 19,843) 410.1] 609] 2.705) 101.6] 22,570] 4,194 x 463

0.88) 118.7) 8677| 17,954] 416.2) 892] 2965! 108.1] 19,523] 9.697 x 33

0.86) 117.8) 6116) 16,231] 419.3/ 487) 2163! 101.2] 18,920) 3934 x 373

1,00) 119.2] 6,648) 19,219| 970.0) 685} 3,044] 1041] 21,906] 4715|BW 900x 496

0.89) 119.1) 7,810] 17,955) 971.8) 609] 2705! 103.8] 19.683] 4178 x 444

0.96) 117.6) 7,087; 15,748] 968.9] 533/ 2967| 101.0) 17,929] 3673 x 410

O99) 119.8) 6848] 15.219] 377.9) 532| 2965) 105.2) 17,068] 9.627 x 878

0.98} 1189} 6.401} 14,224 378.0) 487) 2162) 1084] 16,904] 3.924 x 37

O95) 117.8) 8794) 12,876) 974.1] 426] 1,60) 100.6] 14,849] 2919 x 390

0.98) 119.7) 5,594] 12,490] 360.2) 426] 1,891/ 104.9| 19.697/ 2669 x 904

0.98} 1185/ 8127] 11,908) 976.8} 960| 1,689) 1026) 12,734] 2566 x 283

0.86} 74.0) 5,264) 11,699) 945.0) 189] 1,060) 60.0] 13,905] 1,798|BW 900x 947

0.88} 74.2} 4,695) 10,745) 947.2) 145) 967} $0.2] 12,701} 1,871 x 315

0.87] 75.0) 4,197) 9926) 953.0) 127] 944] 61.9) 10,686] 1,944 x 284

0.82) 769) 3996} 6881! 3631] 126} 842} 646! 10,174) 1,014 x 238

089) 759) 4691/ 9202) o59.2) 113] 752] e28! 9463] 1,179 x 226

0.83) 737) 3172) 7,048] 350.9; 90) 602] 592) e238 985 x 22

ASEP Stee] Handbook

AT

1-16 Built-Up Shapes

Y

Ty

|

x--- dhe tn

fh BW SHAPES

“pe Dimensions

__ ” Properties,

[a]

Weight} Area |_ Web | Flange | _Distanogs

Designation | W | A | H]| Bi] t | A w | B/2t,| Hit, | HA,

Hxw kgim | mm? | mm |mm| mm |mm| mm | mm |mm 4/mm

BW 800x 296/296.42| 97,780) 800] 20| 960| S2| 795| 720| 8| 5.63) 40,00) 0.069

x 275|275.06| 38,040| @00| 20| 960) 28] 744| 728) 8) 6.43) 40.00) 0.079

x 252/251.70! 92,084) 900} 16) 960] 26) 744] 728) 8) 643) 50.00 0,078

x 296 /288,50! 90,000] 800} 16] 360} 25) 750} 734; 8| 7.20] 60.00) 0.089

x 212|211.95] 27,000} @00| 12] 380) 25} 780) 794) 8] 7.20) 6867) 0.089

BW 60x 212/211.95| 27,000} B00] 16) 900] 25] 750] 784) 8| 6.00] 60.00) 0107

x 190/169.68} 24,180| @00| 16] 300] 20) 760| 744) 6} 7.50) 60.00] 0193

BW 700x 281/280.72| 96,780) 700) 20] 960 92) 698) 620| 8| 5.63) 95.00] 0.081

x 261 260.75] 93,216] 700| 16] 960] @2] 696) 620] 8) 5.63) 49.75] 0.081

x 209|236,14] 90,484) 700) 16| 960| 26} 644] 626) 8) 6.49) 42.75) 0.069

x 219|216.92| 27,688| 700] 12} 960] 28) 644] 628} 6| 6.43) $8.93) 0.080

x 209|202.53| 28,800) 700] 12) 960] 28) 680} 634] 8] 7.20] $8.93] 0.078

BW 600x 244)/243,66] 91,040) 600| 20) 960] 20) S44) S28) 8) 643/ 30.00/ 0.080

x 227/228.58} 28,884] 600| 16, 360] 28 644] 528} 8) 643) 97.50] 0,080

x 210/210.88| 26,800} 600] 16} 960] 25) 860] S34) 8] 7.20] 97.50| 0.087

x 193]193.11] 24600} 600] 12} 960] 25) 850] §34} 8} 7.20) 50.00) 0.087

x 166|165.73| 21,120] 600) 12] 980) 20) 560) 544) @} 9.00) 50.00) 0.083

vy \ 1 oi |

LL ‘ t

ASEP Steel Hancbook

“48.

Built-Up Shapes 1-17

BW SHAPES

Dimensions

Properties

Elastic Properties, Plastic Modulus

ay AxiaX-X Axis Y-Y

M0 | I 8 i 8 x 4% Designation

fmm | mm | xi0& | x10% | or | xto%) xto® | or | xto? | x10? HxwW

mm? | _omm? | _omm_| meat} mm? | mm | mm? | mm?

4,08} 94.4] 4084] 10,160) 928.1] 249] 1,965] 81.3] 11,858) 2147) BW 800x 206

1.05] 93.1] 9691) 9,229] 9246] 2ie| 1,212| 7e9) 10,549) 1,889 x 278

1,08] 95.0] 3.884} 9985) 232.9) 218] 1,211| 925) 9996] 1,862 x 282

1.07] 94.0] 9,266) 9168] 930.0! 195] 1,081} 908) 9.205] 1,668 x 26

442| 96,2} 8126] 7,814) 340.2| 195] 1,081) 949/ 9.663) 1,647 x 212

1,03} 769) 2816) 7,039) 3229] 113) 752] 646! 8083! 1,173; BW 6800x 212

097} 749) 2411) 6027) 3169) 90) 602) 61.1) 6900 949 x 190

1,28] 95.5) 9001; 6574) 289.7) 249] 1,985/ 635) 9718] 2197|/BW 700x 261

1,92) 97.0) 2915| 6,29] 206.3) 249) 1,964) 866) 9913) 2114 x 264

1,29} 96.1] 2633] 7,824] 204.0) 216] 1,211) 84.6) 6.433) 1,856 x 239

1,33] 97.9] 2844) 7,270; 3021) 218) 1,210/ 684} 8018; 1,608 x 219

4.81] 97.1 | 2326) 6645) 300.9) 194] 1,081) 666, 7,943) 1,643 x 208

1,50] 95,7! 1,919] 6006) 248.6) 218] 1,212) 63.8} 7,245) 1,669! BW 600x 244

1,55] 97.2] 1,885] 6217) 254.2| 218| 1,211] 869] 6980] 1,849 x 227

151} 96.4) 4,711] §,702} 2626| 196] 1,081} 882] 6985) 1,655 x 210

1,56; 98.1} 1,655; §,517| 269.4} 194) 1,080| 889) 6083; 1,640 x 193

151) 96,7) 1,987! 4,624) 265.9) 166) 664) 858] 5117) 1,316 x 166

ASEP Steel Handbook

-19-

1-18 Built-Up Shapes

BW SHAPES:

Dimensions

Properties:

Weight] Area Web Flange Distances

Designation | W | A [AH ]t)B]% | m | T [w [Bie] HR, | HA

HXxW kgim | mm? | mm [mm] mm |mm| mm | mm {mm t(mm

BW 600x 186/166.44| 23,750! 600] 20] 285) 28] 850} 834) 8] 5.10) 30,00] 0.094

x 169]169.17 21,580} 600] 16] 288] 25] S60] S34] 8] 5.10) 97,80} 0.004

x 150/180.41) 19,160} 600! 16] 285} 20] S60| S44] 8) 698) 37.50) 0118

x 198/192.82| 16,920} 600] 12) 265} 20] S60) 544] 8) 699/ 50.00] 0.118

x 118]117,56| 14,976] 600] 12) 268} 16] 868) 554] 7) 7.97) 50.00) 0147

BW 600x 157/157.39/ 20,050] 600] 16] 226/ 25) 560] 534) @| 4.60) 97.50) 0.107

x 140/140.12] 17,850| 600| 12) 225! 25) StO| §34) 8) 4.50) 50.00; 0.107

x 123|123.40] 18,720} 600! 12) 225) 20) 860) 544] 8) 5.63) 60.00) 0.193

x 101|104.11) 12,880} 600] 10} 226] 16] Sea} S84] 7! 7.03) 60.00) 0.167

BW 800x 90] 89.80] 11,440} 600] 10) 160) 16} S88] 554) 7) 5.63) 60.00) 0.208

x 79| 70.18] 10,080| 600] 10) 180] 12] 576) S68} 5) 7.60] 60,00] O276

BW 450x 161/181.97| 23,104] 480} 16) 300] 28) So.) 978) 8) 5.96) 28.13) 0.054

x 168/167.99| 21,400] 450} 16] 00) 26) 400) 984) 8) 600; 28.13) 0.080

x 165|185.43| 19,800] 480} 12) 300) 25} 400} 984) 8] 6.00) 97.50) 0,060

x 193]182,82| 16,920] 450) 12} 900) 20] 410] 964) @| 7.50} 97.80) 0.075

x 108}108.17] 19,780] 460| 10} 900/ 18) 418] 404) 7) 9.8) 48.00) 0.084

BW 450 x 101}101.42} 12,920} 450| 12] 200] 20) 410) 394} 8} 5.00} 97.50) 0.119

x 95] 94.99) 12,100) 480) 10) 200]. 20) 410) 304) 8) 5.00) 45.00) 0113

x 3} 63,05] 10,880} 460) 10| 200) 18] 416) 404) 7| 628} 48.00] O141

ASEP Steel Handbook

-20-

Built-Up Shapes 1-19

BW SHAPES:

Dimensions

Properties

Elastic Properties Plastic Modulus

ay AXEX-X Axe y-Y

de} or T 8 ry s zu Z Designation

fmm | mm | xi0® | xio? rt xto®) x10? ' x109 | x10? HxW

mm* |_omm? | mm [mmt| mm? | mm | mm? | mm?

1,88) 649) 1,932] 4,499) 238.8] 69) S45) 541) 5178 868| BW 600x 186

1.44; 66.4) 1,276) 4255) 243.4) 69) §43/ 56.7) 4876 848 x 169

1,95) 647) 1,082} 9641} 2608] 88) 495) S38) 4212 686 x 160

1.43} 66.7) 1,084] 9446) 247.2; SS] 494] 57.2) 93.699 870 x 183

196) 651) 879) 2931] 2429) 44) 347) S44) 3.081 541 x 118

1.40} §7.8) 1,152) 9841} 200.7) 48) 424) 48,7) 4,444 668/BW 60x 157

1.47) 69.4) 1,007) 9656] 247.9) 48) 423) 51.6) 4142 653 x 140

1.40} 68.1} 933] 3109) 243.6) 38) 938) 49.2) 3,551 $26 x 123

1.87] 57.8) 767) 2558) 244.0) 30} 270| 48.6) 2909 419 x 101

1,91) 451) 644) 2147) 237.3) 16} 173) 969) 2498 273/BW 600x 90

419) 432) 833) 1,776) 226.9; 12] 180) 941] 2100 208 x 79

219) 816) 631) 9692) 180.6) 126] 841) 739) 4168) 1,265) BW 450x 161

209; 81.0} 763) 9903) 1889) 113) 761) 725] 3628) 1,151 x4

215) 623) 742) 9208) 183.6] 113! 750) 76.4) 9668) 1,190 x 135

207) 81.2) 624) 2773| 192.0] 90) 600) 73.0) 3,084 91S x 18

203; 80.9; 813) 2261| 193.0} 72! 480) 723) 2520 73 x 108

1,98) 526) 439! 1,951) 1843/27) 267) 455) 2224 415( BW 450x 104

201) 534) 428) 1,900) 1680) 27) 267) 47.0) 2140 410 x 9

402) 623) 962) 1,611) 1831) 21) 214) 449) 1,626 380 x 8

ASEP Steel Handbook

“21

1-20 Built-Up Shapes

BW SHAPES

Dimensions

Properties

Weight) Area Web Flange Distances

Designation | W | A [A ]t |S Te) A | Tt lw fae,

Hew kgm | mm? | mm mem} mm | mm} mm | mm |mn

+}.

BW 480x 70] 70.49) 6980) 450} 10} 180! 16) 418) 404] 7) 469

x 55} 95.01] 7,008) 480) 8] 180) 12] 426) 416; §| 625

x 51] 50.55] 6,440| 450) 8] 480] 10) 490) 420) 5) 7.80

BW 80x 78] 78.20) 9880] 980) 10) 200/ 16) 316} 304) 7) 6.25

x 70| 7021] 8944} 360; 8} 200) 16) 218) 304; 7] 626

x 58) 5815) 7,408} 360} 6] 200! 12] 326) 316] 5] 893

BW 850x 54) 5498) 6928; 360} 8) 160] 12} 926] 916) §| 7.50

x 49) 48.98; 6240/ 950) 6] 180) 10) 330] 920) 5/ 900

xX 44) 43.60) §,580) 950) 6] 160) 10) 330) 920) 5} 9.00

BW 50x 34] 34.38; 4,380| 980) 6] 120] 10) 990) 929} §] B00

x $1} 90.80] $924) 380] 6) 120) @] 34) 924) 5] 7.60

BW 900x §1| 51.24] 6628) 300) 68) 180) 12] 276) 266 §| 7.60

x 47/ 4691) §976| 900] 6] 180) 12) 278) 286) 5} 7.60

x 41) 41.45) 6,280) 300) 6] 180] 10] 280) 270) 5} 900

BW 00x 20) 26.89} 9680} 900) 6) 100] 10) 280) 270] §/ 6.00

x 26) 25.94) 3904) 300] 6] 100; 8) 284) 274) 8) 625

x 23! 2298) 2928) 300; 6 100; 6) 268) 278) 5/ ac

“22.

ASEP Steel Handbook

Built-Up Shapes 1-21

BW SHAPES

Dimensions

Properties

Elastic Properties Plastic Modulus,

oft AxieX-X Axis Y-Y

M0} T 8 ry 8 Zz Designation

frm | mm | xio®} xi0® | or | xt08) xto® | or | xt0® | x10? HxW

3 3

mm_|_ moi °

mm? _|_mm_|mm*| mm’ mm

4.81] 961) 287.0) 1,276) 1788) 90) 120) 31.7) 1,478 190} BW 480x 70

1.76} 37.8) 224.2 997! 1789; 68 90; Sit) 4154 142 x 5

1.68) 968) 198.2 681) 176.4) 56 75| 29.6) 1,080 119 x 5

260) $3.5! 205.4) 1,174) 146.4) 21.4! 214) 47.2) 1,922 $28) BW 850x 75

267) 84.3) 200.1! 1,143) 149.6] 21.3) 213) 489) 1,271 825 x 70

263) 63.1! 160.2 918| 147.1] 16.0! 160) 485) 1,024 245 x §8

249) 47.4) 1465 637) 146.4] 11.7) 190) 41.4 943, 200) BW 350x 54

299) 46.6! 128.0 782| 1432) 97) 108) 99.5 830 167 x 4

281; 47.8) 1220 697) 1479) 9.7) 108) 41.7 75 165 x 44

234| 30,7) 873 499! 144.2) 29 48, 267 S71 75|BW 60x 34

220; 298) 748 427| 193.0) 29 991 243 496 61 x

8.00} 48.0) 103.6 691) 126.0] 11.7) 130) 423 774 199; BW 900x 51

B14] 48.9) 100.1 668/ 129.5) 11.7; 180) 442 736 197 x 47

301) 483) 867 678) 128.1/ 97) 108) 429 840 166 x 4

278] 26.5; 53.0 984) 1201) 1,7 8) 218 408 53/ BW 300x 29

256) 248) 456 Ha) 117.4) 1.3 27) 20.1 35 a x 2%

293! 23.7; 937.9 283) 113.7) 1.0 20; 185 301 33 x 2

ASEP Steel Handbook

-23-

1-22 Built-Up Shapes

BW SHAPES:

Dimensions

Properties:

Weight| Area Web__| Flange Distances

Designation Ww A Hye P ea Tey ph [Tt Tw [eyet,| HA, | HA,

Hxw kg/m | mm? | mm fmm} mm fmm] mm | min fin 1mm

BW 280x 42] 42.45; 5408] 260) 8) 160] 12) 226) 216) 5) 625} 31.25} 0130

x 99] 98,90) 4956| 250) 6] 180] 12] 226] 216] 5| 6.28) 41.67/ 0.199

x $4) 34.98] 4,960) 250) 6) 150} 10! 280} 220) 8) 7.60) 41.67] 0.167

BW 280x 27] 26.53) 3.960) 260] 8} 100) 10) 290} 220] §} 5.00] 41.67] 0.280

x 24) 23.68} 9,004) 250] 6] 100) 8) 234} 224) 5] 625) 41.67| 0.319

x 21) 20,63) 2628} 260) 6] 100] 6| 208) 228) 5) 893) 41.67) O417

BW 20x 89; 99.31/ 6008) 200) 8) 150} 12) 178} 166] 5) 625] 26.00] 0111

x $2) 2.03) 4080) 200] 6] 150} 10) 180; 170; §| 7.60} 93.93) 0103

BW 20x 31] 30.90] 3938) 200) 6] 120) 12) 176] 166} 5] 5.00] $3.93) 0,139)

x 27] 27.82) 3480) 200) 6) 120] 10) 160) 170] §) 600] $3.33] 0.167

x 24) 23.74) 3024; 200] 6] 120| 8] 164) 174] §

BW 20x 27) 27.00} 9440] 200] 8) 100] 10] 160] 170) 5

x 24) 2418) 3080] 200] 6] 100] 40) 180] 170/ 5

x 21} 21.28) 2704) 200) 6] 100} 8] 164) 174) 5

ASEP Steel Handbook

Built-Up Shapes 1-23

BW SHAPES

Dimensions

Properties

Elastic Properties Plastic Modulus

ay Ala X-X Axe Y—-¥

10} T s j s % Designation

Imm} mm | xto& | xto® | or | xto®] xt0% | or | xt0% | x108 HxW

mm* | mm? | mm [mm] mm? | mm | mm? | mm?®

365} 40.1) §87 470| 104.2) 68 90) 35.4 831 180) BW 280x 42)

377) 40.8) 568 454) 107.1) 68. 90) 36.9 50S 187 x %

365) 40.3) 49.3 904) 1061) 56 7§| 36 439 445 x 34)

$44) 26.0) 34.9 279| 101.6) 1,7 33) 222 318 52; BW 250x 27

824) 25.4; 29.8 209) 98.7) 1.3 ar) ati 276 42 x 24

298) 24.4) 246 197) 96.8} 1.0 20; 195 231 82 x 2

477| 40.7) 96.6 835] 84.2) 68 90) 367 400 188; BW 200x oo

475) 40.9} 90.0 300] 858) 66 75| 37.4 334 114 x 32

480) 927) 282 3. 84.7) 35 §8} 29.6 7 ee) BW 200x 31

463) S23) 246 246) 841) 29 46/ 288 277 74 x 27

4.43) 31.7) 208 208; 83.0} 29 36) 27.6 235 59 x 24

483) 26.9) 220 220) 705) 1.7 33] 221 265 §3) BW 200x 27

453) 26.6) 21.0 210) 826) 1.7 33) 239 239 52 x 24

490) 26.0) 179] 179) 61.3) 1.8) 27); 222) 204 42 x 2t

ASEP Steel Handbook

25:

1-24 Built-Up Shapes

BH SHAPES

Dimensions

Properties

Weight) Area Wed Flange Distances

Designation | Wo) A [HA ]TR) BTR) A | T | w/e] Hit, | HA

HxW kgim | mm? | mm |mm} mm |mm] mm | mm jmm 4/mmn

BH 700x 700)/700,22/ 89,200} 700] 32] 700] S0| 600) Sé4) 8/ 7.00) 21.68) 0.020)

x 681 /681.98} 86,800} 700} 28| 700) $0) 600; S84) 8} 7.00| 28.00) 0,020]

xX 626 |628.63/ 60,080} 700} 28) 700) 45) 610) S94 7.78) 25.00) 0,022

x 614/614.26/ 76,250} 700) 265) 700; 45] 610/ 584) 8) 7.78] 28,00) 0.022

x §08/508.29! 64,750] 700} 25) 700) 35] 830! 614) 8/1000) 28.00) 0.029

X 484/483.66| 61,600] 700! 20) 700} 95) 830) 614) 6/10.00} 96.00) 0.c29)

BH 00x 536/596,00] 68,280} 600] 28) 600) 45] S10} 494) @/ 667) 21.43) 0.022

xX 624/629,99) 66,750) 600) 25) 600| 45] 510; 484) 6) 6.67] 24.00] 0.022)

x 479/478.88| 61,000] 800) 26) 600} 40] 820) 504] 8] 7.60} 24.00) 0.026

x 488/458,44) $6,400) 600} 20) 600) 40] 820} 504) 8) 7.60| 90.00] 0.028

Xx 413/412,91 | $2,600] 600) 20) 600] 95] 890) Ji) 6] 857] 90.00) 0.029

X 986 /985.59} 49,120] 600) 20) 600} 92) $36) S20} 8/ 9.98) 90.00| 0.001

BH 480 x 428)429.27) §3,920] 480) 16) 600) 40] 370) 954) @| 7.80] 28.13) 0.019

x 412/411.85| 52,440} 480) 12) 600] 40] 970) 354] 8) 7.50) 97.50) 0.019

x 965}965.50) 46,560} 450) 12) 600} 95] 380] 364; 8} 357) 97.50) 0.021

ASEP Steel Handbook

-26-

Built-Up Shapes 1-25

BH SHAPES

Dimensions

Properties

Elastic Properties Plastic Modulus

ay! Riis X-X Axe y-Y

MO} I 8 1 8 % 4% Designation

fmm} mm | xto® | x10? | rj x08 | xto® | or | xto® | x10? HxW

mm* mm? mm_| mm mm? _| mm mm? mm?

1.42} 198.4] 7,984] 22,812] 209.2) 2860) 171| 179.1) 25,890) 12,404; BH 700x 700

4.441 194.4] 7,912] 22,607] 901.9] 2.859} 8170) 181.5) 26,270] 12,968 x 681

1.41} 199.5) 7,287] 20,850) 901.9) 2674) 7,963) 178.3] 23,237) 11,145 x 623

1,42] 194.4] 7,241] 20,688) 904.2) 2973} 7.982) 181.9) 22,956) 11,120 x 614

1.87} 192.0] §,943| 16,981 | 203.0) 2,002] 5,719] 175.8) 16,773) 8673 x 508

4,401 193.9] 5,899} 16,683; 07.9| 2001) 5718) 180.2| 16.277) 8638 x 484

a7

4

.87| 168.0) 4,477) 14,923) 258.1) 1,621] 5,403] 1541] 16,806/ 8,200) BH 600x 598

69

CJ

1

1.69] 166.8| 4,444| 14,813) 258.0! 1,621] 5402) 1558] 16,611 6,160 x §24

4.65] 166.9| 4,063/ 13,542) 268.1] 1,441] 4,802/ 1537] 15,130) 7,261 x 479

4,68) 187.3| 4,004] 18,046) 261.8] 1,440) 4,801) 157.0] 14,792) 7,262 x 458

4.65} 166.9] 3.604] 12,014) 261.8] 1,260] 4201] 184.8] 13,270) 6,353 x 413

4,62) 165,7| 9,987] 11,199] 261.4] 1,152] 9841) 1682] 12,942) 5,814 x 386

295] 160.8| 2.001) 9,204] 196.9] 1,440] 4,800} 163.4) 10,988] 7,224) BH 450x 423

287] 170.6] 2.074] 9.219] 198.9] 1,440] 4600) 166.7/ 10,251) 7,219 x 412

283] 170.2| 1,888) 900) 200.3} 1,260] 4200; 1645] 9148) 6314 x 965

ASEP Steel Handbook

27-

1-26 Built-Up Shapes

BH SHAPES

Dimensions

Propertes

T

Weight! A Web | Flange | Distances

Designation | w | xo? [A Tt] 8 RTT | w {B/2t,| Hit, | HA,

HxW kgim | mm? | mm [mm] mm jram) mm | mm jmm 4mm

BH 480x 441/441.17| $6,200] 480] 92} 450| 69) 960] 34) 8) 4.50 14,08) 0.020

x 430|490,18] 84,600} 450] 28] 450) 50] 350) 334) 8) 4.50 16.07| 0,020

x 397 |397,05| 80,860} 480! 26] 480) 45] 960} 944) 8 6,00) 16.07) 0.022

x 969 /988.88) 49,800| 480} 25} 450] 45] 380] 44) 8} 5.00) 16.00] 0.022

x 922|921.85| 41,000] 480) 25) 480] 95} 980} 964) 8} 6.43) 18.00 0,029)

x 907 /308,04} 99,100] 450) 20] 450] 35) 980} 964) 8 643} 22.50] 0.020

x 907 906.94] 9,100} 450} 20] 460] 95} 980] 964) 6) 643) 22.50 0.028)

x -260|269,68| 93,080} 450} 20) 450} 28] 994) 978} 8) B04) 22.50 0,096

BH 950x 237/296.99| 90,190) 950] 25] 960] 92/ 288| 270| 8| 5.63] 14.00 0,080)

X 226|205,77} 28,760] 950] 20} 960) 92] 206} 270) 8} 6.63) 17.50 0.080

x: 204]204.41 | 28,040] 950] 20) 960] 28) 204] 276] 8) G49) 17,50) 00%)

x 204 [204.41 | 26,040} 980] 20] 960) 26] 204] 276] 8| 6.43) 17.50] 0.0%)

x 188|188.40] 24,000} 960} 20) 960] 28] 900) 284) 8] 7.20] 17.50) 0.03)

x 17917898] 22,000) $60| 16] 960) 25) 300] 264) @) 7.20) 21.68 0.039)

x 170|169.58| 21,600] 950) 12] 960] 25| 900] 284] 8) 7.20) 29.17 0.088)

x 142|142.24] 18,120) 980) 12) 360] 20) 410) 264) 8] 9.00) 20.17} 004

x 197]187.98| 17,800} 960] 10] 980} 20] 910) 204} 8) 9.00) 85.00) 0.049

BH 950x 149/149.02] 10,964/ 960] 18) 265) 28) 204) 278) 8) 4.85) 21.68) 0.049

x 140|199,79| 17,908] 960] 12] 256] 28] 204) 278) 8) 455) 29.17) 0.04)

x 128/128.95) 16,950) 960] 12) 288) 25} 900] 284) 6] 510) 29.17) O08

x 124112364] 18,780] 950} 10) 285) 25) 900] 284/ 8] 5.10) 95.00} 0.085

x 104|104.41 | 13,900} 980] 10) 288] 20) 910] 294) 8) 698) 95.00} 0.08)

ASEP

Steel Handbook

-28-

Built-Up Shapes 1-27

BH SHAPES

Dimensions

Properties

| 6 |

df

Elastic Properties Plastic Modulus

yt CL ‘Axis X-X Axis Y-Y

jie} os i 8 ry s z% Z Designation

fmm | mm | xto® | xt0® | or fxto®} xo? ] or | xtO® | xt? HxW

4

mm? |_mm®_| mm |mint| mm? | mm | mm? | _mm®

2.84) 124.8] 1,924) 850) 185.0) 760) 9.379| 116.8) 9980) 5162) BH 40x 444

296! 125.4] 1,009| 9,496] 1887) 760) 3378] 117.8) 9,858) 5131 x

281] 1248! 1,778| 7,695) 187.4) 684) 3040] 116.3] 9108) 4,627 x 37

232| 125.3) 1,765] 7,844] 188.8] 684/ 3040) 117.5) 9.011) 4613 x 369

222! 1280! 1.474} 6850| 189.6) 832) 2965! 1139) 7,430) 3608 x 822

225| 126.0) 1.151) 6.440! 192.6) 892] 2,964) 116.6) 7,268) 3,582 x 907

225! 126.0) 1,451) 6449) 1926] S32! 2964] 116.6) 7,258 3,682 x 807

217) 128.6| 1,228| 5,447| 1925) 426] 1.691) 1194) 6093) 2874 x 260

200] 989} 633] 9618) 146.9) 249] 1,064) 909) 4176) 2118) BH 950x 237

294) 989/ 623) 95862] 147.2! 249| 1,963) 931] 4072) 2102 x 226

287) 992] 585) 3,296] 147.5] 218] 1211) 91.5) 9676) 1,844 x 204

287) 99.2| §66/ 3,286) 147.5} 218) 1.211) 91.5! 3676) 1,844 x 204

281} 986) S21} 2979) 147.4] 195] 1,081) 90,0} 3975) 1,650 x 188

286) 996) S12} 2927| 1499) 195] 1,081; 924) 3285 1,689 x 179

291| 1006} S03} 2876] 1626] 194) 1,080] 94¢) 3195) 1,631 x 170

201! 9a7| 422; 2413| 1627| 166] 864] 92.7) 2664) 1,907 x 142

205; 100.4| 417| 2,985] 1544) 166} 864} 943] 2816) 1,904 x 197

284} 699} 405} 2314] 146.1] 77] 608} 63.9; 2645 920) BH 360x 149)

290, 708| 306! 2266) 148.2) 77) 607) 659) 2558 gat x 140

284) 70.4/ 364) 2082 1499) 69] 542) 65.0) 2942 824 x 128

268) 70.9| 960) 2,056) 151.2; 69) 542) 66.2] 2.297 820 x 124

278| 70.1; 303) 1,731| 150.9} 55) 404] 645) 1,928 858 x 104

ASEP Steel Handbook

29-

1-28 Built-Up Shapes

BH SHAPES

Dimensions

Properties

Weight) Area Web Flange Distances

Designation | Ww] A [Ht] 8 | t T | w |B/2t,| Hit, | HIA,

HxW kgm | mm? | mm fmm] mm mm) mm | mm bmn mm

BH 90x 933/932.84) 42,400} 00| $2) 360] SO} 200) 184) 8) 360] 9.98! 0.017

X 327/326.56} 41,600} 300) 28) 360) 50) 200; 184) 8) 360| 10.71) 0.017

X 900}300.50} 98,280) 300) 28) 360] 45) 210) 194) 8) 400] 10.71) 0.019

X 296) 295,55} 97,650) G00) 25} 360} 45; 210) 194] 8] 4.00) 12,00} Qo19

X 259/256.74] 92,960) 300) 25} 960] 8] 224) 208) 8) 474) 12.00) 0.022

x 250/249.94) 31,840) 300/ 20) 360} 38] 224) 208) 8| 474] 15.00) 0.022

x 218/217.92) 27,760) 300) 20) 360} 32} 236) 220) 8| 5.63) 15.00) 0,026

x 197/196.58| 25,040} 300} 20) 360] 28] 244) 228) 8] 843] 15.00) 0.030

x 181}180.55) 23,000} 300} 20) 960] 26! 260; 234) 8) 7.20) 15.00] 0.033

BH 900x 170)170.19! 21,680) 300! 20) 300} 26| 244! 226] 6) 536| 15,00] 0.006

x 183/16253| 20,704) 300) 16) 900) 28| 244; 226} 6] 596| 18.75| 0.036

X 149/149,15} 19,000] 900} 16) 900) 28) 280] 234) 8| 6.00] 18,75) 0,040:

x 144/141.90} 18,000} 300) 12] 900] 28) 250] 284) 8/ 600 25.00) 0.040;

x 119]118.69] 15,120} 900) 12) 900) 20] 260) 244) 8) 7.50) 25.00! 0.080!

x 118]114.61] 14,600) 900! 10} 300! 20] 260) 244) 8) 7.60] 30.00} 0.050

x 9B) 96.40} 12,280) 300) 10] 300! 16] 268) 264| 7/ 9.98] 90.00) 0.083

x 92) 92.19] 11,744) 300} 8) 300; 18] 268) 264, 7) 9.98) 37.50) 0.083

BH 300x 85| 85,08] 10,840] 300} 10) 265) 16] 2B) 284) 7) 7.97] 90.00] 0.074)

x 81) 80.89] 10,504} 300) 8) 265; 16] 268] 284, 7| 7.97) 37.50! 0.074)

BH 00x 78) 77.56] 9,880) 300) 10] 225} 16} 268) 254 7) 7.0%} 30,00] 0,083

x 64) 64.06] 8160; 900) 10) 225) 12) 276] 268) §| 9.8) 90.00] Of1t

x60) 59.72] 7,608] 900| 8) 225) 12] 276; 266; 5] 9.96) 97.50) 0411

ASEP Steel Handbook

-30-

4

Built-Up Shapes 1-29

BH SHAPES

Dimensions

Properties

Elastic Properties Plastic Modulus

ay! Arish-X Bie YY

xe] i 8 T § & % Designation

fmm | mm | xt0& | xto? | or | xto&} x10? } or | xt0® | xi0% KxW

tmmt mm? mm_imm* | mm? | mm mm? mm?

8@0| 101.0] S81} 3942] 118.1) S80) 2163) 966] 4620) 3.201/ BH 00x 333

362} 101.3] 588} 3924] 118.0) 369] 2162] 967] 4,780) 3279 x 927

371} 100.8] 548) 3843] 120.5) 943] 1,908) 95.4] 4370) 2,693 x 286

878) 101.1] S44! 3627) 121.8) 942] 1,902] 962] 4,996) 2,694 x 280

361} 100.5] 486} 3308] 122.7) 206] 1,643) 94.7] 998] 2,497 x 289

265] 101.2} 492) 277] 124.9) 296] 1,642) 984) 9635) 2.495 x 260

453] 1005} 438} 2917) 1266) 249] 1,983) 947/ 9966! 2,097 x 218

844) 100.0} 968} 2658] 126.1! 218/ 1,211] 99.9) 9099) 1,690 x 197

ag7| 93.4} 967} 2449| 126.4) 1965) 1,081] 920] 2788) 1,645 x 181

340] €27| 936/ 2240| 1245) 126) 841) 763! 2582) 1,284) BH 300x 170

345] 83.4) 931} 2208) 1265) 126] 941) 79.0] 2523] 1,276 x 163

age] 3.0} 305] 2035] 1267) 113) 781) 77.0) 2919) 1,141 x 149

344] €3.9/ 9300} 2000} 120.1) 113] 760) 79.1] 2260) 1,194 x 141

492) 931/ 253] 1,686) 1204) 90/ 600] 77.2) 1,883) 09 x 118

496} e386! 260] 1,868) 190.9) 90/ 600) 785) 1,849/ 907 x 115

425) 628); 210) 1,990] 190.7/ 72) 480) 766] 1,543/ 727 x 6

390) 935! 207] 1,977) 1926| 72} 480) 789] 1,807; 724 x @

a2i| 699) 181) 1,208] 1201] 44) 347] 639) 1,998) 827) BH 900x 85

926| 70.6; 178} 1,164) 191.9) 44] 947) 688) 1,902) S24 x 6

@17| 619] 161] 1,076) 127.98) 90/ 270) 585] 1,202] 412/ BH 900x 78

300] 60.0] 130} 964] 126.0) 23) 203) S29] 968) 311 x 64

3.08} 60.9) 126 840; 1287) 23| 203) 54,7 930 308 x_ 60

ASEP Steel Handbook

“31

1-30 Built-Up Shapes

BH SHAPES

Dimensions

Properties

Weight! Area Web Flange Distances

Designetion | W | A | H|t) BY thy] Tt | w |B} Hy | HA

Hxw kgim | mm? | mm [mm] mm | mm) mm | mm (mm 1mm

BH 280x 157|187.31} 20,040] 260] 20) 265) G2) 186) 170} 8] 398) 12.50) 0.031

x 143/142.56| 18,160) 280] 20] 285] 28) 194] 178) 8] 455) 12.60) 0.085

x 125]125.21 | 18,950) 280] 16] 285} 25) 200] 184) 8} 6.10) 15.63) 0.039

x 119]118.93] 18,180] 260] 12} 285] 28] 200] 184) 6) 810} 20.83/ 0.000

x 100] 99.65] 12,720] 250] 12] 265) 20] 210) 194) 8] 698} 20.83) 0.049

x 81} 81.17] 10,340} 260) 10] 265] 16] 218] 204) 7) 7.97] 25.00] 0.081

x 78! 77.75| 9,904) 260) 8] 266] 16) 218) 204) 7) 7.97) 31.25] 0.061

BH 260x 67| 67.95) 9580} 260) 10! 200) 16] 216] 204) 7| 625) 26.00) 0.078)

x 62] 51.67} 6,608! 250) 8) 200) 12| 226) 216) 5} 833) 91.25) 0.104

x 46] 48.84} 5,840! 260) @! 200] 10) 290) 220) 5/10.00} 91.25) 0.125

BH 200x 97) 97.94] 12,400} 200] 16) 200! 25) 150} 14) @) 4,00] 12.560) 0.040

x @3| 82.90] 10,560] 200] 16] 200) 20] 160) 144) 8} 5.00) 12,50) 0.050

x 78)'77.87| 9,920) 200] 12) 200) 20} 160) 144) 8| $00) 16.67) 0,080

x 75] 76.98] 9,600] 200) 10] 200) 20; 160] 144) 8} 5.00) 20.00) 0.08

x 63} 63.48] 8.080} 200/ 10] 200] 18} 168) 184/ 7| 6.25) 20,00/ 0.063

x §1] 61.50] 6,660) 200} 10} 200] 12} 176) 168) $§| 8.93) 20.00) 0.083

x 49| 48,78; 6208] 200] | 200] 12] 176] 168] | 893) 26.00) 0.083

BH 20x 39{ 99.91] 5,008) 200) @] 180] 12] 176} 168) S| 6.25} 25.00) 0111

x 97] 96.85] 4,658| 200) 6) 180] 12) 176] 166] §| 625] 93.93) Q111

x 92} 92,03} 4,080| 200] 6| 150] 10] 180} 170) 5) 7.50] 99.63) 0.183

ASEP Steel Handbook

-32-

Built-Up Shapes 1-31

BH SHAPES

Dimensions

Properties

Elastic Properties Plaste Modulus

ay! Axis X-X Riis y-Y

mer; oy I $s ry s Zz | 2, Designation

fmm} mm | xto® | xto* | or | xto} xt0% ] or | xto® | x10? HxW

mm* mm? mm_|mm*| mm? | mm mm? mr?

492) 71.0] 2030} 1,648] 101.4) 66.6; 695) 665) 1,052) 1,089) BH 250x 157

419) 70.5! 138.0) 1,512] 1020) 775; 608] 653] 1,773 $30 x 143

445} 70.7) 172.7) 1,962) 104.1] 69.2} 542) 658} 1,594 826 x 125

422) 71.4] 170.0) 1,660] 1089] 69.1] 542] 67.5) 1,554 820 x 119

406) 70.8) 144.5} 1,186] 106.9] 66.3) 434) 665.9) 1,005 668 x 100

396) 70.5) 1205 964/ 108.0) 44.2) 347) 65.4) 1,074 526 x Bt

402} 71.1) 1188 960) 109.5! 44.2] 347) 66.8; 1,050 524 x 78

368) 547} 96.4 771 | 106.0) 21.4) 214) 49.9 868 925| BH 250x 67

877) 54.4) 767 608) 107.1] 16.0; 160, 49.2 673 244 x 52

365) $38) 657 $26; 106.1) 13.3] 133) 47.8 586 204 x 46

596] 65.6) 81.6 816) 611) S34} 934) 51.9 965 $10) BH 200x 97

510) 549) 70.5 708) 81.7] 26.7) 267; 503 822 410 x 8

S21} §5.6) 69.2 692) 83.5) 26.7) 267) S19 797 406 x 78

626) 559) 685 685) 84.6! 26.7} 267] 527 784 404 x 75

6.05) 56.4) 58.3 983; 849/213) 219) 814 659 324 x 63

460] 645) 47.0 470; 84,7) 16.0) 160) 48.4 52g 244 x 1

489) 56.1) 461 461) 862) 16.0} 160; S08 513 243 x 49

A477, 40.7) 365 385) 842) 68 90) 36.7 400 136) BH 200x %

489) 41.3) 34.6 346) 86.2) 68 OO} Bi 35 197 x 37

475) 40.9) 30.0 300; 85.8) $6 7) 374 334 414 x 32

ASEP Steel Handbook

33

1-32 Built-Up Shapes

BH SHAPES

Dimensions

Properties

Weight! Area |Web | Flange Distances

Designation Ww A HK

wt eth? A |] T |w/Bie,| Ht | HA

HxW kgm | mm? | mm |mm| mm |mm| mm | mm |mm t/mm

BH 200x 27) 27.82) 9,480) 200; 6) 120] 10] 180) 170] §| 6.00} 33.93] 0.167

x 24) 23.74) 3,024) 200; 6) 120] 8! 164) 174) 5] 7.80) 33.93/ o.208!

ASEP Steel Handbook

“34

Built-Up Shapes

“TT ml

(| i

y---

hy

BH SHAPES

Dimensions

Properties

Elastio Properties Plastic Modulus

ay. Axis X-X ie Y-Y

MP} oy T s T s % Designation

fmm} mm | x08} x0? | or jxto®] x08] or | xt? | x10? HxW

mm* mm? mm_| mm‘) mm? | mm mm? mm?

27 74) BH 200x 27

29 48) 28.8

23 98) 27.6 235 5¢ x 24

463} 923) 24.6 248) 84.1

443) 81.7! 208 208} 83,0

ASEP Steel Handbook

35+

1-34 Built-Up Shapes

BWT SHAPES:

Dimensions

Properties:

Weight | Area Stem Fang Distances

Designation | W A Ht, |ie@jAee | B14) veh] T fw

HxW kgm | mm? jm [mm] mm | mm? | mm jmm} mm j mm | mm [mm

BWT S00 x 248] 248.26, 31,625) 500} 25] 125|12,600) 450] 45) 225) 465) 447) 8

xX 290] 280.40) 29,950) $00! 20} 10.0|10,000/ 480) 48) 22.5] 408) 447| 8

x 214] 21352) 27,200! 500] 20| 10.0/10,000) 480} 40) 20.0) 460) 482) @

x 197] 196.64} 28,050| $00] 20] 10,0/10,000] 450) 95/ 17.5) 465) 487]

x 167] 186.52] 23,760| S00} 20} 10.0/10,000} 460) $2] 16.0) 46a] 460] @)

BWT 450x 288] 298.44) 90,975) 480/ 25] 125)11,250' 460) 45) 22.5) 405 997] |

x 222! 221,76) 26,260] 450] 26! 128|11,260| 480) 40) 20.0] 410; 402) 8}

x 208} 206.87] 26,200} 480) 20} 10.0] 9,000) 460} 40} 20.0! 410) 402) @

x 189] 168,79} 24,080} 450) 20] 10.0] 9,000] 480) 45] 17.5] 415) 407) @),

x 179] 178.67} 22,760) 480) 20! 10.0] 9,000] 480] 22] 16.0] 418) 410) @

x 165] 165.16| 21,040] 480 20| 10.0) 9,000) 480] 28] 14.0) 22) 414] @

x 182] 181.91} 19,852] 450] 16/ @0| 7,200] 480} 26] 14.0) 422) 414) |

x 142] 141.68} 18,050] 480) 16) 80} 7,200] 480] 25] 128) 425) 417) 81

WT 480 x 148] 147.68} 16,800| 450] 20) 10.0/ 9,000] 900) 95/ 17.5] 416] 407) &

x 141] 140.981 17,960] 450! 20) 10.0] 9,000) 900) 32| 16.0) 418] 410) 9

x 192] 192.19} 16,840] 450} 20! 10.0} 9,000) 900] 28/ 14.0) 422] 414] 8

x 118) 118.84) 15,152} 480/ 16} 6.0) 7,200) 800} 28; 14.0) 422] 414) @

x 142] 112,26] 14,900} 450) 16} 80} 7,200) 900) 26/125! 426) 417| @

x 101} 104.11) 12,880) 480] 18) @0! 7,200] 00] 20] 10.0) 490) 422) @

ASEP Steel Handbook

-36-

Built-Up Shapes 1-35

to

=

a f t

xeon dp net

BWT SHAPES ] 4

Dimensions sete

Properties i

4 _

Y

Elastic Properties 0, = 20

Axia X-X Axis Y-Y QaF,

Ht, | 1 | 8 i]s Q,=1.0 Designation

xto® y x10? | or y | xto® | xto% |r HxWw

mm* | mm? | mm | mm | mmt | mm? | mm | Q | cy

20,00] 9549] 1,690] 143.9] 112.4] 942.9} 1,521| 1040|~---|----| BWT 800x 248

25,00} 562.8) 1,982] 197.2] 100.0) 942.0] 1,520| 1080] o.e45| 197 x 230

25,00} 545.1] 1,973] 141.6) 104.6] 9041] 1,951| 108.7] 0.645) 197 x 214

26,00} 594.6] 1,972] 148.1] 110.9) 288.1] 1,193| 1031] 0.845) 197 x 197

25,00} 826.6] 1,965] 148.9] 1148) 243.3] 1,081/ 107.2] 0.845] 197 x 187

18.00) 463.5] 1,972) 126.2) 97.5] 3422} 1,521) 106.1 238

48,00] 476.6] 1,968] 128.9] 101.6) 304.3) 1,962| 1038 x 222

22,60] 4028] 1,119] 1239] 90.4) 304.0! 1,981] 107.7) 0.951} 129 x 208

22,80| 995.9] 1,116] 126.9] 95.2) 266.1) 1,182] 1052) 0.951) 120 x 188

22,60] 390.7| 1,112] 131.0) 98.6) 243.3) 1,081] 103.4! 0.961] 129 x 178

22,30| 982.0] 1,105] 134.7] 1048) 2129} 948| 1008] 0.951| 129 x 165

28.13] 9236) 905] 128.) 925) 2128] 948| 1049| 0.703] 180 x 182

28,13] 317.6] 900] 1926] 97.3) 190.0} a4] 102.6| 0.703) 180 x 142

22,60} 964.9] 1,065] 197.4] 116.8) 79.0} S27] 648] 0.951) 129) BWT 460x 148

22,50| 348.8) 1,059] 199.4] 170.7) 729) 482) 634] 0.951| 128 x 141

22,80] 398.9! 1,048} 141.9] 1268) 633) 422] 61.9] 0.951) 129 x 192

28,18] 290.2) 965] 198.4| 1149] 631) 421! 646] 0.703) 150 x 119

26.13] 263.9) 687] 140.8) 119.5) $6.4; 378) 62.8) 0.703} 150 x 112

28,18| 2685) 639] 1444] 1902) 451} 301] $9.2] 0.703| 150 x 101

Where no value of C', of G, le ahown, the aection compties with NSOP Section 4.9.1.2

ASEP Steel Handbook

O7-

1-36 Built-Up Shapes

BWT SHAPES

Area Stem Flange

Designation A ty [1/2 2

HxW mmé | mm jmm} mm mi mm

BWT 400 x 148 18,880| 400] 20| 10.0 %0| 32) 16.0 8

x 198 17,520) 400) 20! 10,0 960) 28) 14.0 8)

x 126 16,032} 400; 16] 80 960| 28) 14.0 9

x 118 18,000] 400] 16) 80 960) 25) 12.5 8

x 106 19,500) 400} 12) 60) 360) 25) 12.5 8)

BWT 400 x 108 18,600} 400} 16) 80 0) 25) 125 8

x 9 12,080] 400) 18] 80, 0] 20) 10.0 8

BWT 980 x 140 17,880 | 960] 20) 10.0 360| 92] 16.0

x 190 16,608) 360; 16; 80 360! 32) 16.0

x 120 18,282) 950) 16] 80 960} 28) 14.0

x 109 18,044) G60} 12) 60 960] 28} 14.0

x 101 12,800} 350) 12] 80 960) 26) 125

BWT 800 x 122 18,620| 900} 20} 10.0 960] 28} 14.0 8)

x 118 14,492} 300] 16] 60 60} 28) 14.0 8}

x 105 13,400} 30) 16] 80 360! 25) 12.5 8)

x ow 12,900] 00] 12) 60 960) 25) 125 8|

x & 10,560} 300! 12) 60 960] 20) 10.9 8

ASEP Steel Handbook

38-

Onnow

Built-Up Shapes 1-37

BWT SHAPES

Dimensions

Properties

Elastic Properties CO. sere

Axis X-X Axis Y-Y QaFy

Hy | 1] S$ i]s Q,=1.0 Designation

xio® | x0? | or y | xto® | x10? Jor Hxw

mmt | mm? | mm | mm | mmé | mm? | mm | a | C

20.00] 263.7) 862) 1182] 94.0) 124.7] 693] 61.0 BWT 400x 146)

20.00} 267.7) 886] 121.3] 98.9) 100.1 606} 78.9 x 198

25.00] 219.0) 702} 116.9] 66.3| 109.0} 606] 625) 0845) 197 x 126

26.00) 214.8) 698) 119.7/ 925) 97.3) 541] 80.6) 0.845) 197 x 118

93.93] 173.2} 540) 1189) 792) 97.8; 540] 49) 0801) 178 x 108

28.00} 204.0| 683} 122.9! 101.4 56.4) 376} 646] 0.645) 137/ BWT 400x 106

28.00} 194.2) 671) 126.8) 110.7) 454) 901) 61.1) 0845) 197 x

17.50] 180.1) 663} 100.4) 78.2| 1246) 692} @38|----|----|BWT 350x 140

21.88} 151.9) 542) 98.6) 696] 1245| 602) 666) 0.976) 128 x 180

21.88) 149.6) 540/ 994) 73.2] 108.0) 605) 846/ 0978) 128 x 120

29.17) 1196) 416) ¢26) 626! 1089) 605) 684) 0654) 156 x 109

29.17! 118.1) 415) 96.7} 65.4) 97.2} 540) 868) 0.654) 158 x 104

16.00) 113.7] 487} 85.6} 666) 109.0) 605 SOx 122

18,75} 96.9} 396) 81.5) 69.2) 109.0} 605 x 118

1675) 94.7) 397| 841) 61.8) 97.3) §41 x 105

28.00} 75.6} 308} 78.4) 527] 97.2) 540} 689) 0845) 137 x 97

26.00! 73.7; 904] 983.6] 57.7) 77.8) 482} 5.8) 0.845) 137 x 8

Where no value of C', of Q, ia chown, the section compliga with NSCP Sect, 4.9.1.2

ASEP Steel Handbook

39-

1-38 Built-Up Shapes

BWT SHAPES

Dimensions

Properties

Weight | Area Stem Flange: Distances

Designation | W A Hye, |iv2;Aea, B | | we) nh | tT lw

Hew kg/m mm? oj mm |mm| mm} mm?) mm |mm| mm | mm | mm jmm}

BWT 90x 93) 98.22) 11,878} 300 20| 10.0) 6000| 265] 28] 128) 275| 267! I

x G5) 64.68) 10,775 00) 16) 80] 4eco| 258] 25] 125! 275! 267] 4)

x 75] 78,20 9,880 900] 16] 80) 4800] 285] 20) 10.0) 280) 272) 8

x 66) 66.41 8460) $00| 12) 60] 3600) 288) 20] 100! 280) 272] 3B

x §8) $8.78 7,488 300| 12) 60} 3600; 255) 16| 980) 264) 277| 7|

BWT 300x 79) 7870} 10,025} 300) 16] 80] 4,800; 225] 28| 125) 275) 267| 9

x 65) 65.05 8.286 900; 12) 60! 3600] 225] 22] 11.0] 278) 270) @|

x 80) 60.03 7,847/ 900; 12] 6.0) 3800; 226] 19/ 95] 2e1| 274] 7]

x St) 60.55 8,440; 300} 10; 6.0} 3.000] 226] 16) 80! 264) 277) 7,

BWT 800x 48| 44.90 §,720| 00] 10| 60) 3,000; 180; 16] 90) 264) 277) 7)

x ©) 30.56 §,040} 300| 10) §0| 4000] 160] 12) 60) 268) ze3| §|

BWT 25x G1) 90.68) 11,552) 228! 16] @0/ 3,800] 00; 26] 14.0] 197] 169) a).

x 84| 84.00) 10,700! 225) 16) 80) 9,600] 900] 26] 125) 200] 192] 9)

x 78) 77,72 9,900] 225} 12] 60] 2700) 900) 25} 125) 200] 192] 4

x 86) 66.41 8,460) 225) 12) 60) 2700) 300} 20] 10.0; 206] 197] |

x 84) 54,09 6800) 225) 10} 60} 2250) G00] 16; 80) 20a] 202| 7]

BWT 25x 51} $0.71] 6460} 225] 12) 60/ 2700] 200} 20| 10.0| 208] 197] a

x 47) 47.49 6,080} 228] 10) §0) 2250) 200] 20] 10.0] 205] 197] |

x 42) 41.53 5,200) 225) 10) $0) 2260) 200; 16] 80) 209] 202] 7)

ASEP Steel Handbook

-40-

Built-Up Shapes 1-39

BWT SHAPES

Dimensions

Properties

Elastic Properties Ci =2n8

Axia X-X Axis Y-Y Q.aF,

Hit, | s I § Q,=1.0 Designation

xio® | x0? | or y | iO} xt? | or HxW

mm* jm? | mm | mm | mm | mm? | mm Q |

15.00) 101.4) 465, 92.4) @20) 947) 272) 54.1 BWT 300x 93

4875) 98.6) 963) 697) 738) 346) 272) 867 x

18.75; 83.1 978; $81} 80.1) 27.7) 217] 538 x 75

26.00) 67.7) 204) 896] 696! 27.7) 217) 57.2 x 66

25.00) 64.8) 290) 93.0) 763; 221) 174) 544| 0.845] 137 x 89

16.75) 836] 377) 91.3] 763) 238/ 212) 487/-~--|----|BWT 30x 79

25,00} 665) 201| 60.6) 71.4) 209] 188] 509] 0,845) 197 x 65

25.00) 647) 280) 920) 756] 181! 161; 466) 0645) 197 x 6

$0.00) 549] 243) 923] 741) 182) 195) 486) 618) 160 x S41

90.00) 51.3) 238} 947) 625 7.8 87, 6.9] 0618) 160} BWT 300x 4§

80.00) 47.7) 228) 97.3) 91.7 so 65/ 34.1) 0618) 160 x 40

14.08} 998) 220) 58.7) 447) 63.1) 420) 739 BWT 225x 91

14.08) 39.4) 221] 60,7] 461] S63) 975! 725 x 84

18.75; S14! 170) 56.3) 99.8) 563) 375| 754 x 78

18.75) 30.9) 169) 6.4) 42.7| 48.0) 300] 73.0)- x 66

2250) 264] 143) 61.6} 421] 96.0] 240) 723; 0951; 129 x §4

18.75] 28.0} 163) 659] 528) 184) 134) 4§5|/---~-|----| BWT 225x St

22.50) 245) 138) 636) 481) 194] 134] 47.0) 0981) 129 x 47

2260; 237) 187) 86.9] 524] 10.7] 107] 449] 0.981| 120 x 42

Where no value of C’, of Q, ia shown, the aaation complies with NSCP Sect, 4.9.1.2

ASEP Steel Handbook

“4

1-40 Built-Up Shapes

a

—{——

t vo

7]

pe BWT SHAPES

Sfletw Dimensions

| Pe Properties

Weight | Area Stem Flange Distances

Designation | W A [ATR] \e;ae lB) yep rn | Tt fw

HxwW kgm | mm? | mm [mm| mm | mm? | mm jmm} mm | mm | mm fmm H

BWT 225 x

x

x

96.25 4,490} 225) 10) $0) 2260) 180] 16) 80) 208) 202] 7

27.51 9,504) 228) 8) 40) 1,600; 180) 12) 60) 213} 208) 8

25,28 3,220| 225! 8} 40) 1,600} 160) 10) 50) 215) 210) §|

6

28

3

BWT175x 98) 97.60 4,790! 175) 10} $0) 1,780} 200] 16} 60] 189} 182) 7

3

2

8

x 95.11 4,472| 175) 8} 40) 1,400] 200) 16; 80) 159] 152) 7 1

x 29.08! 3704] 176] 8] 40] 1,400) 200) 12) 60] 163] 158, §) a

12

BWT178x 27| 27.19} 3.464) 175] 8} 40) 1,400] 1e0) 12| 60} 163) 158 | 21

x 24) 24.49 3120; 175] 8} 40) 1,400] 160) 10) 0] 165) 160) §| f

x 22] 21.80) 2,790] 178} 6| @0] 1,050) 180] 10) S0| 168) 160 a

;

BWT178x 17| 17.19] 2190] 175) 6] 30] 1,080) 120] 10} So] 165] 160 3,

x 18] 1840} 1,982] 175! 6] 30] 1,080] 120; 8] 40] 187! 162 lon

BWT 180x 28| 26.62] 9264] 160} 8] 40] 4,200! 160] 12) 60} 198 .

x 23] 2348) 2988) 150/ 6! 30) $00) 180] 12) 60] 198

x 21] 2072) 2640) 180] 6] 80) 900) 1@0| 10) 0] 140

BWT 160x 14) 14.44 1,840} 150) 6) 30; 900} 190) 10) 50] 140

x 13| 1297) 4,852] 180) 6] 30] 900| 100] 8] 40} 142

x 41} 11.49) 4,484] 180] 8) 0] $00] 100! 6) 30) 144

ASEP Steel Handbook

-42-

Built-Up Shapes 1-41

BWT SHAPES:

Dimensions

Properties

Elastic Properties

Axis X-X Axis Y-Y ,aF,

Hity | 1 s 1 8 Q,=1.0 Designation

xo | xt?) or y | x08} x10? | or Hxw

mm‘ | mm? | mm | mm | mm* | mm? | mm | | c!

22,50] 21.60) 1924) 89,7) 60.4) 452] 60.2] 31,7) 0.951) 129) BWT 225x 3

28,19] 17.64) 106.8) 70.8) 60.7] 998) 451] 31.1] 0.703] 150 x 2B

28.13} 1678) 104.9) 722] 651} 282) 97.6] 296) 0.703) 160 x

17.60} 11.85] 63.7] 49.1} 97.0] 10.68} 1088) 47.2)----|----| BWT 175x 98

2188) 972| 684) 48.6} 329] 10.67) 1067) 489) 0.976) 126 x

21.88} 9.96) 67.9) $03) 368) @O1) 801) 465) 0.978) 128 x 2

21.88) 814) 67.2) S14} 389) S84) 649) 41.1) 0978) 126/BWT {75x 27

21,08) 884) AES} 52.2) 420) 487) 841] 305] 0.978) 128 x 24

2,17) 7.18] &15] $0.6] 36.0) 488) 540] 41.7| 0684) 156 x 22

20.17] 641) 491) $4.1) 44.6] 1.44) 240) 25.7) 0.684) 188) BWT 175x 17

29.17| 609) 482! 65,7! 48.7) 1.16] 19.8) 243) 0.654) 166 x 15

18.75! 5.80) 496) 425) 314) 684) 649] 429/-~--|----) BWT 150x 26

00) 471| $82) 367) 26.8) S63) 648) 442) 0645) 187 x 23

2.00) 461} 980) 41.8) 28.9) 488) 540) 429] 0645) 197 x a

25.00] 395) 356) 463) 30.2) 084) 167) 21.3) 0848) 187) BWT 180x 14

25,00} 3.76) 35.0} 47.7) 42.7; 067| 18.4] 20.1) 0.845) 197 x 13

25.00 349] 999] 488) 473} 050] 101) 188] eds] 197 x tt

‘Where no value of C*, of Q, le chown, the section complies with NSCP Sect. 4.9.1.2

ASEP Steel Handbook

-43-

1-42 Built-Up Shapes

BWT SHAPES

Dimensions

Properties

Weight | Area Stem Flange Distances:

Designation | W A Wt, tye) Ama? B 1 t | te) h | Tt fw

HxWw kgim mm? | mmimmi mm | mm? | mm imm) mm | mm | mm jmm) Hy

BWT 125x 21) 21,23 2704) 125] 8] 40) 1,000} 180) 12} 60! 113) 103) $ -—

x 19) 19.45 2478| 125] 6] 90) 780) 180) 12| 60} 113) 108) § 1563

x 17) 17.19 2190) 125{ 6] 20) 780] 180) 10) 80} 115} 110) § 20.83

20.83

BWT 125x 13) 12.27 4,600; 125) 6] 0) 750} 100] 10) 50] 118] 110) §|