Professional Documents

Culture Documents

Sa564 PDF

Sa564 PDF

Uploaded by

Anonymous jefUrqfio0 ratings0% found this document useful (0 votes)

509 views11 pagesOriginal Title

SA564.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

509 views11 pagesSa564 PDF

Sa564 PDF

Uploaded by

Anonymous jefUrqfioCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

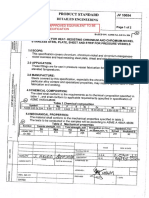

SA-564/SA-S64m,

ASME BPVCILA-2015,

SPECIFICATION FOR HOT-ROLLED

AND COLD-FINISHED AGE-HARDENING.

i STAINLESS STEEL BARS AND SHAPES I

SA-564/SA-564M.

[Identical with ASTM Specification A 568/A 564M. O4ROD)

1." Scope

1.1 This specification covers bars and shapes of age-

hardening stainless steels. Hot-inished or cold-finished

rounds, squares, hexagons, bar shapes, angles, tees, and.

channels are included; these shapes may be produced by

hot rolling, extruding, or forging. Billets or bars for reforg-

ing may be purchased to this specification,

1.2 These Steels are generally used for parts requiring

corrosion resistance and high strength at room temperature,

‘or at temperatures up to 600°F [315°C]; 700°F [370°C]

for Type 632; 840°F [450°C] for Type UNS $46910. They

are suitable for machining in the solution-annealed condi

tion after which they may be age-hardened to the mechani-

cal properties specified in Section 7 without danger of

cracking or distortion, Type XM-25 is machinable in the

as-received fully heat treated condition, Type UNS $46910

is suitable for machining in the solution-annealed, cold-

‘worked, and aged-hardened condition,

1.3. Types 631 and 632 contain a large amount of ferrite

inthe microstructure and can have low ductility in forgings,

and larger diameter bars. Applicatiohs should be limited

to small diameter bar.

14 The values stated in either inch-pound units or $1

(metric) units are to be regarded separately as standards;

within the text and tables, the ST units are shown in [brack-

ts]. The values stated in each system afe not exact equiva-

lents; therefore, each system must be used independent of

the other. Combining values from the two systems may

result in nonconfonmmance with the specification,

1.3. Unless the order specifies an “M” designation, the

‘material shall be furnished to inch-pound uni

[NOTE 1 — For forgings, se Speifstion A TDS/A TOSM,

[NOTE 2 — For billets and bars for forging se Specification A314

2. “Referenced Documents

21 ASTM Standards:

A314 Specification for Stainless Steet Billets and Bars for

Forging

A370 Test Methods and Definitions for Mechanical Tes

ing of Steel Products

AASA/A 484M Specification for General Requirements for

Stainless Steel Bars, Billets, and Forgings

‘A 70514 705M Specification for Age-Hardening, Stainless,

Steel Forgings

A751 Test Methods, Practices, and Terminology for

Chemical Analysis of Steel Products

£527 Practice for Numbering Metals and Alloys (UNS)

2.2 Other Documents:

SAE 51086 Recommended Practice for Numbering Metals

‘and Alloys (UNS)

3. Ordering Information

3.1 Its the responsibilty of the purchaser to specify

all requirements that are necessary for material ordered

under this specification. Such requirements may include

but are not limited to the following:

SAL Quantity (weight or number of pieoes),

341.2 Type or UNS designation (Table 1),

34.3. Specific melt type when required,

3.14 Heat treated condition (5.1)

3.5 Transverse properties when requited (7.6),

3.1.6 Finish (Specification A 484/4 484M),

3:17 Surface preparation of shapes (5.2.1),

3.18 Size, or applicable dimension including diame-

ter, thickness, width, length, etc.,

1042

ASME BPVGILA-2015,

3.1.9 Preparation for delivery (Specification

AABAIA 484M),

3.1.10 Special requirements (refer to 7.4 and 8.3),

3.11 Marking requirements (Specific

AABA/A 484M), and

3,112 ASTM designation and date of issue if other

‘than that currently published.

3.2 If possible, the intended use of the item should be

given on the purchase order especially when the item is

ordered for a specific end use or uses.

NOTE 3— A typical ordering description i as follows: 800016 (2270)

“Type 630, Sohtion-Anealed Cold Finished Cemgles Ground, 1 in

[50 ram] ound ba, 10 to 12 8 [3.00 3.6 em in Length, ASTM A $6

dat End se: valve salts

4. General Requirements

441 In addition tothe requirements of this specification,

all requirements of the current edition of Specifications

‘A-484/A 484M shall apply. Failure to comply with the

‘general requirements of Specification A 484/A 484M con-

stitutes nonconformance with this specification

5. Materials and Manufacture

S.A Heat Treatment and Condition

8.1.1 Material of types other than XM-16, XM25,

and Type 630 shall be furnished in the solution-anneated

‘condition, oF in the equalized and oven-tempered condition,

fas noted in Table 2, unless otherwise specified by the

purchaser.

SLA Types 630, XM-16, and XM-25 may be

fumished in the solution-annealed or age-hardened con-

dition.

5.1.2. Type UNS $46910 shall be funished in solu-

tion-annealed condition per Table 2, oF solution-annealed

‘and cold-worked condition per Table 3, or aged-hardened

condition per Table 4.

5.1.3. Reforging stock shall be supplied in a condition

of heat treatment to be selected by the forging manufac:

rer,

5.2. Shapes may be subjected to either Class A or

Class C preparation as specified on the purchase order.

5.2.1. Class A consists of preparation by grinding for

the removal of imperfections of a hazardous nature such

as fins, tears, and jagged edges provided the underweight

tolerance is nt exceeded andthe maximum depth of grind-

ing at any one point does not exceed 10% of the thickness

ofthe section

52.2 Class C consists of preparation by grinding for

the removal of all visible surface imperfections provided

SA564/SA-564M

the underweight tolerance is not exceeded andthe pax

imum depth of grinding at any one point does not expeed

TOF ofthe thickness of the section ;

6. Chemical Composition

6.1 Each alloy covered by this specification shall con-

form to the chemical requirements specified in Table 1

6.2 Methods and practices relating to chemical analysis

‘required by this specification shall be in accordance ‘with

‘Test Methods, Practices, and Terminology A751

7. Mechanical Properties Requirements

7A ‘The material, as represented by mechanical test

specimens, shall conform to the mechanical property

requirements specified in Table 2 or Table 3 and shall be

‘capable of developing the properties in Table 4 when heat

treated as specified in 5.1.

7.2. Samples cut from bars for forging stock shall con-

form to the mechanical properties of Table 2 and Table 4

‘when heat treated as specified in Table 2 and Table 4

7.3. The yield strength shall be determined by the offset

‘method as described in the current edition of Test Methods

tnd Definitions A 370, The limiting permanent offset shall

be 0.2% of the gage length of the specimen.

7A The impact requirement shall apply only when

specified in the purchase order. When specified, the mate-

rial, as represented by impact test specimens, shall be capa.

ble of developing the impact property requirements

specified in Table 4 when heat treated in accordance

with 5.1.

7S Longitudinal impact requirements are not applica

‘ble to bars less than % in. (16.9 mm) diameter or size oF

flats less than % in. (16.9 mm) thick

746 Tensile and impact requirements in the transverse

(@hrough thickness) direction are not applicable to bars less

than 3 in, {75 mm] diameter in size or fats less than 3 in.

[75 mm) thick.

7:7 Material tensile tested and, when specitied, impact

tested in the transverse (through thickness) direction and

‘meeting the requirements shown in Table 4 need not be

tested in the longitudinal direction,

8 Number of Tests

8.1 At least one room temperature tension test and one

‘or more hardness tests shall be made on each lot.

8.2. One or more hardness tests and at least one tension.

test shall be made from each Tot on test samples heat

1043

5A-564/SA-564m,

trgited as required in 5.1. Unless otherwise specified in

the purchase order, the condition of hardening heat treat-

ment shall be atthe option of the producer. The tests shall

meet the requirements of Table 4

83. When specified in the purchase order, the impact

test shall consist of testing three Charpy V-notch Type A

specimens in accordance with Methods and Definitions

A370. The specimens shall be heat treated in accordance

with 5.1, Unless otherwise specitied inthe purchase order,

the condition of hardening heat treatment shall be atthe

ASME BPVCILA-2015

option of the producer and testing sll be done at 70 ta

‘80°F (20 to-25°C]. The tests shall meet the requirements

of Table 4. When tested at temperatures cer than 70 to

8D°F, [20 o 25°C} the impact test requirements wil be as

agree upon by purchaser and produce.

Keywords t

9.1 age-hardening stainless steel; precipitation harden,

ing stainless steel: stainless steel bars; stainless steel shapes

1044

sor

® New designation established in accordance with Practice E 527 and SAE J1086,

© Columbium pls tantalum 0.15-0.8

nitrogen 0.07-0.13.

nitrogen 0.01.

* Columibium plus tantalum 0.10-0.5.

© Columbium 8 times carton minimum.

TABLE 1

CHEMICAL REQUIREMENTS*

Composition,

UNS Other

Designation® | Type | carbon | Manganese | Phosphorus | Suir | sition | Chromium | Nickel | Aluminum | Molybdenum | Titanium | Copper | Elements

suraoo | 630° | 007 1.00 2.08 | 0.030 | 1.00 | 25.00-2750 | 5.00-5.00 soosoo] §

siroo fen | 009 100 e020 | 0.030 | 100 | 1600-2800 | 650-7.75 | 075-2.50

sis7oo | exe | 009 100 0.020 | 0.030 | 1.00 | 14.00-26.00 | 650-775 | 075150 | 2.00-3.00

sasso0 | 628 | oro-a1s | oso-125 | os | 0.030 | 0.50 | 15.00-26.00 | 4.00-5.00 250-325 0

sizeo0 | 635 | o.08 1.00 cas | 0.030 | 1.00 | 1600-1750 | 600-7.50 | oo 0.40.20

15500. | xttaz | 007 1.00 oer | 0.030 | 1.00 | 1400-2550 | 550-550 20450] =

suse00 | xitas | 005 020 ‘ooo | oo | o10 | 1225-2325 | 750-850 | os-135 | 2.00250 é

45500. | xitae | 0.03 050 a.o15 | aors | 050 | 11.00-12.50 | 750-950 0.50 ose-120 |rse250] *

sass |... [oor | aso 0.010 | aor | 020 | 1100-1250 | 750-950 | « 0.50 1og-ass | 1so2s0] ¢

45000 | x25 | 0.0 1.00 0.030 | 0030 | 1.00 | 1400-1600 | 5.00-7.00, 9.50-1.00 rasa | ©

10.75-

sisson]... | 0.02 025 oars | oor | 025 | 1100-1250 | 1.25 o7si25 | 150-180 .

steno |.) fooso | 1.00 0.030 | oors | 070 |r10-130 |eor00 [orsoso| 3050 | osorzo | 15-35

4 Limits are in percent maximum unless shown as @ range or tated otherwise

stoz-vtroaaa ansv

vgs-ys/t95-¥s

vor

ee Nei

TABLE 2

: SOLUTION TREATMENT rote ae

Mechanical Test Requirements in Solution Treated Condon”

Tensile Strength, Yield Strength, Elongation ares

‘ain in in2in. Reduction

uns ———— + ism or af Area, Rockwell C, Brin

Designation Type Contin Solution Treatment sia tsi Pat 40, mi, 9G 96 ax max

siv4o0 630 Aa 3900.2 25°F £1040 # 15°C) (coo! 38 263

3s required to below 90°F

Gren

ur ar a 1900 25°F O40 215°C water HRev ay

‘uenchd

Sisr00 eae a 19002 25°F howd 1=°CI water wReIO0 268

wench

Seo (aa a 3900 = 25°F [2080 # 15°07 3a

‘quench old nat ess than 3h at

ris 100°F oF lower

sare a a0 = 2sF How sisi 220 teas) 7S CISD Ww eS @ 302,

ool)

Sassoon a 3900 = 25°F (1040 = 15°C) (cool : 38 363

as required to below 90°F

Geen

S00 17002 75°F (9252 15°C Cools - . 38 305

required to below 60°F 16°C)

Sasso0 (XNA a 1525 2 25°F (650 = IC (cool = 36 3

ravi)

Sasooo=xM2S A 3900+ 25°F (10402150) cool azs Kaos CSB 0 wo 3 a2

ravi)

Sasso a 1525 + 25°F (630 > 15°C) (cao! 36 2

api)

Saesoo a 3600 + 25°F 1980 2 15°C Coll 36 3

‘ater queen) old fr min. 6h

at miaus100°F (73°0), airwarm

Suen a 1830 2050°F ooo 120°C) 7 —=«6OO)=«SBSSC« ODT 10 3 35

(cool rapa

45ee7.1

See 7.3

© Either Rock C hardness or Grivel! s permissible On sizes % In (22.70 mm) and smaller, Rechwal Cf prefered

321 BH for rounds cold drawn after solution treat.

* Equalzalion and over tempering treatment 1425 = 50°F (775 = 30°C] for not less than 3h, col ta room terparaure, Hest to 1075 + 25°F {580 + 25YC1 for not es than 3h

" Maxima 165 si (2140 MPa tele strenth only fr sits up 40 % i. (23 mm.

Ns9S-vS/95-VS

stoz-viroaaa aKsv

coor

TABLE 3

SOLUTION-ANNEALED AND COLD-WORKED CONDITION

Mechanical Test Requirements in Solvtion Annealed and Cold-Worked Condition

Tensile Swenath, Yield Suensth, Elongation Wardness

min in in2in Reduction of

uns ———__ omni or Area, min, Briel,

Designation Type Condition isi Mats Pal_——_—4D, min, % max

S690 cw %rard 131900710975) 8 40 380

OWiulharé 1893007 7S 200) 3 55 300

WH9S-YS/F9S-¥S.

stoz-viroAad ansy

SA-564/SA-564M ASME BPVCILA2015 }

i +

¥ TABLE 4 {

MECHANICAL TEST REQUIREMENTS AFTER AGE HARDENING HEAT TREATMENT* f

* viele Troost

ee i a

= ss :

Se te ow ts

See ——eo

ESE

i ‘THLO50 Alternative treatment: 1400°F

i (reer bois 90, cot 85

thar too Oe Wad wo un ws ne eat

oases hl ort

Tao wwsotses) 08 vee ee we Gone

1048

coor

‘SOLUTION-ANNEALED AND COLD-WORKED CONDITION

Mechanical Test Requirements in Solution Annealed and Cold-Worked Condition

Reduction of

‘Tensile Stenath,

kita

a1 t9001

1903003

Hardness

‘Area, min, Rockwell, Brin,

40 380

35 380

stoz-viroaad ansv

Wrs-vs/ros-vs

ae

Ase sevenaanis sxseustfoon

i

mates

MECHANICAL TEST REQUIREMENTS AFTER AGE HARDENING HEAT TREATMENT“ (CONT'D)

=n = . =

Ssaaae eie S meeE

eo et

1049

5A.564/SA-564M, ASME BPVGHA-2015

rate 4

MECHANICAL TEST REQUIREMENTS AFTER AGE HARDENING HEAT TREATMENT“ (CONT'D) i

“TEE coment. ERS wee! OY

i a es ee Rate wane eae

1050

i

ASME BPVCILA-2015, 5A564/SA-564M

i TABLE 4 }

y MECHANICAL TEST REQUIREMENTS AFTER AGE HARDENING HEAT TREATMENT (CONT'D)

Te Ta

sures nas og Tenie seep Eton Om

wo oe enease sevice Sina, te =

Teapots, Tie ‘any nas Te 80, alae skal Bi

se _conmer RCC Hane Drecnt _rat t ah aig mm

3 se ee Ee Ta a

See 72.

Time refers to minimum tine material Is at temperature and may be extended to obtain requited ductility properties.

we Unies etherwce noted, temperatures shown are suggested teiperaturs ard maybe vared to obtaln required tensile properties,

# 2 tnermedite temperatures must mest de cctlity requtements ofthe next highest suggested hardening or aging temperature, ar bth.

Example: Type 630 at 1050°F (565°C! must have 13% elongation ard 45% reduction, same as far age hardening at 1079°F (580°C)

(L) — Longitudinal axis of specimen parallel to direction of grain flew during rolling or forging. (1) — Transverse axis of specimen per

pendiclar to direction of galn fow during rolling or forging.

PS 73,

5 Either Rockwal G hardness or Briel s permissible, On sles % In (42.70 ram) and smaller, Rockwell Cs preferred,

hen aie cooling Is specifies, gases other tran alr may be used.

"Refer to Table 2 for details on equalize and over temper heat treatment

ost

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Check List For Argon GasDocument1 pageCheck List For Argon GasAnonymous jefUrqfio0% (1)

- 1.0 Table of ContentDocument2 pages1.0 Table of ContentAnonymous jefUrqfioNo ratings yet

- For Export Orders Only Approved Equivalent To Be Procured Against This SpecificationDocument5 pagesFor Export Orders Only Approved Equivalent To Be Procured Against This SpecificationAnonymous jefUrqfioNo ratings yet

- JV 10054 Spec PDFDocument2 pagesJV 10054 Spec PDFAnonymous jefUrqfioNo ratings yet

- Sans - 282 - 2004bending PDFDocument27 pagesSans - 282 - 2004bending PDFAnonymous jefUrqfioNo ratings yet

- Audit Report: Veer Steel MillsDocument8 pagesAudit Report: Veer Steel MillsAnonymous jefUrqfioNo ratings yet

- For Export Orders Only Approved Equivalent To Be Procured Against This SpecificationDocument2 pagesFor Export Orders Only Approved Equivalent To Be Procured Against This SpecificationAnonymous jefUrqfioNo ratings yet

- JV 10054 Spec PDFDocument2 pagesJV 10054 Spec PDFAnonymous jefUrqfioNo ratings yet

- For Export Orders Only Approved Equivalent To Be Procured Against This SpecificationDocument2 pagesFor Export Orders Only Approved Equivalent To Be Procured Against This SpecificationAnonymous jefUrqfioNo ratings yet

- (JV10057) Carbon Steel Pipes For High Temperature Service (STPT370) PDFDocument10 pages(JV10057) Carbon Steel Pipes For High Temperature Service (STPT370) PDFAnonymous jefUrqfioNo ratings yet