Professional Documents

Culture Documents

Insights

Uploaded by

Arunkumar DurairajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insights

Uploaded by

Arunkumar DurairajCopyright:

Available Formats

EDITORIAL

Chief Editor

Rakesh Dubey, Tel: +91 91633 48159, E-mail: rakesh.dubey@mjunction.in

Executive Editor Dear Readers,

Tamajit Pain, Tel: +91 91633 48065, E-mail: tamajit.pain@mjunction.in

The year began on a positive note for the Indian

Editorial Board steel industry. India’s rank in the world order of

Dr Abhirup Sirkar, Professor Economics, Indian Statistial Institute (ISI)

steel production remained unchanged at fourth

Dr Amit Chatterjee, Consultant and former Advisor to MD, Tata Steel Ltd

Jayant Acharya, Director (Commercial & Marketing), JSW Steel Ltd with an output of 76.7 million tons, despite logging

K Ranganath, former CMD, KIOCL the highest growth of 4.2 percent among major

Vikram Amin, ED (Strategy and Business Development), Essar Steel Ltd producing nations in 2012. There was no change in the top three slots

Rana Som, Former CMD, NMDC Ltd with China, Japan and the US retaining their positions in respective

Advertising order. India was the world’s fourth largest steel maker in 2011 and 2010

Soumitra Bose, Tel: +91 92310 00232, Email: soumitra.bose@mjunction.in as well with a total production of 73.6 mt steel and 69 mt respectively.

Sumit Jalan, Tel: +91 91633 48243, Email: sumit.jalan@mjunction.in The country had clinched the third spot in 2009, but lost out to the

Subscription US since 2010.

Rachita Das, Tel: +91 91633 48045, Email: rachita.das@mjunction.in Does this signal anything for the industry? It surely does. It shows

Toll Free No.: 1800 4192 000 1. Press 8 for publication that even though India’s steel industry is faced with numerous hurdles

Email: publication.tbss@mjunction.in such as sluggish demand, raw material shortages, inflow of capital,

Design infrastructure and land acquisition, it is set to become a powerhouse.

Debal Ray, Sobhan Jas The pattern of steel demand would continue to change and

For suggestions, feedback and queries, please write to manufacturers who are able to roll out value-added products could see

steelinsights@mjunction.in their revenues improving. For instance, the product mix demand from

different sectors such as automobiles or real estate would vary. New

grades of steel and customised products would see more takers.

According to analysts, though there could be supply constraints in

India in 2013, steel prices are likely to remain under pressure due to a

steady stream of imports. Currently, India imports nearly 7-10 million

tons of finished steel. Meanwhile, the green field projects in the

country continue to encounter obstacles. Therefore, steel companies

are looking into brown field expansion. The global capacity utilisation

for steel mills is below 80 percent. However, it is more than 90 percent

Registered Office for India.

mjunction services limited, Tata Centre, 43 J L Nehru Rd, Kolkata 700 071 The big news is that India is set to get a new steel policy in a

Website: www.mjunction.in month. The policy is expected to iron out issues related to foreign direct

Corporate Head Quarters: Godrej Waterside, 3rd Floor, Tower 1, Plot V, Block DP, Sector investments, land acquisitions and environment clearances. The draft

V, Salt Lake, Kolkata 700091, Tel: +91 33 6610 6100, Fax: +91 33 6610 6187 Bhilai: Room

321, 3rd Floor, Ispat Bhavan, Bhilai Steel Plant, Bhilai 490001, Tel: +91 788 6451066, Tele/

has been circulated for final comments and it would be announced

Fax: +91 788 2221071 Bokaro: Room 19, Old Admin Bldg., Bokaro Steel Plant, Bokaro soon. The policy is also trusted to throw light on solutions to problems

827001, Tel/Fax: +91 654 2226132 Burnpur: SAIL - IISCO Steel Plant, Materials Building, plaguing the sector.

Order Department, Ground Floor, Burnpur 713325, Telfax: +91 341 2240107 Chennai:

Basement, Begum Ispahani Complex, New No 91, Old No 44, Armenian Street, Chennai

While dwelling on these various developments, in this edition

600 001, Tel: +91 44 64624733-35, Fax: +91 44 25216536 Durgapur: Room 618, Ispat of Steel Insights, we particularly focus on the foundry industry and

Bhavan, Durgapur Steel Plant, Durgapur 713203, Tel: +91 343 6510185, Tele/Fax: +91 343 examine how it is gearing up to meet challenges. Also, there is a

2586946 Jamshedpur: Kashi Kunj, Ground Floor, Road No. 02, Contractors Area, Bistupur,

Jamshedpur 831001, Tel: +91 657 6519985/86/90/91, Fax: +91 657 2230040 Mumbai: special feature on coking coal and met coke which delves on India’s

Jolly Bhavan II, 403, 4th Floor, 7 New Marine Lines, Mumbai 400020, Tel: +91 22 66510663, requirement for the key inputs and supply constraints going forward.

Tele/Fax: +91 22 66510662 New Delhi: C127, 2nd Floor, A One Plaza, Naraina Industrial

Area, Phase I, New Delhi 110028, Tel: +91 11 65661774/65413288, Tele/Fax: +91 11 Happy reading!

25897000 Noamundi: C/o TATA Steel Limited, Mines Purchase Cell, PO: Noamundi,

Singbhum (West), Jharkhand 833 217, Tel: +91 9204791638/9234368606 Rourkela:

Administrative Bldg., Room 624, 6th Flr, Rourkela Steel Plant, Rourkela 769011, Tel: +91

661 6514142/6511412

mjunction believes that all junctionites, customers, suppliers, partners,

etc should practice the highest ethical standards in their daily operations. (Rakesh Dubey)

Report a concern to ethics@mjunction.in

Letter to

the Edito

Dear Mr Rakesh r

Copyright: All rights reserved. No part of Steel Insights can be reproduced or copied in Thanks for your continuous updation of Steel World through your

any form or by any means without the prior permission of mjunction services limited. Please magazine Steel Insights. The Magazine has helped us to take informed

inform us if any copyright has been inadvertently infringed. decisions & improve our knowledge. I am delighted to receive your

Disclaimer: This document is for information purpose only. Certain information herein has magazine regularly.

been acquired from various external sources believed to be reliable. While we have taken

reasonable care to compile this report, we in no way assume any responsibility for any error Regards

or discrepancy in regards to information contained herein. Readers are requested to make Sushanta Ganguli

appropriate judgment without any prejudice or compulsion. Chief Sales Manager ( East), Tata Steel Ltd

Steel Insights, February 2013 3

Contents

6 | Cover Story

2 0 Green energy solutions need of the hour

34 Steel consuming sectors maintain

sluggish growth Foundry sector needs to focus on

36 Indian iron ore imports set to rise over sustainable growth

time India can tap global casting demand

39 Auto industry posts marginal growth in estimated at 110 mt and growing at 5-10%.

December

40 India ranks top in production growth

42 JSW expects steel demand to grow in

26 | INTERVIEW

2013-14 Tech upgradation need of the hour

44 Mining impasse hits Sesa Goa profits at HEC: Misra

HEC is planning to invest `750 crore for

45 Gujarat NRE reports higher Q3 profit

next four years on upgradation process.

despite sharp fall in met coke prices

29 | INTERVIEW

47 SAIL April-Dec steel production rise

marginally

48 Tata Steel annualized crude steel

production likely at 8.35 mt in 2012-13

Iron ore an area of concern: Sandvik

In India, revenue is approx. 20 percent below

49 RINL lights up ignition furnace at Sinter target on iron ore mining ban, lack of new

Plant No 3 projects.

50 Wining combination in flat products

equipment

55 BSP gets new Skin Pass Mill 30 | SPECIAL FEATURE

56 Industry pins hopes on steel demand India examines options as Chinese

growth demand chart coking, coke trend

57 Iron ore handling by major ports down By 2016-17, coking coal demand is

expected at around 90.2 mt and import

54.5% y-o-y in Apr-Dec

would more than double.

58 Railways iron ore handling up 13%

38 | FEATURE

m-o-m in Dec

59 Macroeconomic indicators of India

60 Global crude steel production rises y-o-y Proactive budget needed to solve

in 2012 issues: Nerurkar

61 Domestic flat & long markets Duty on steel grade limestone, dolomite and

iron ore should be reduced to zero

62 Domestic raw materials

Call 9163348243 for

more details

4 Steel Insights, February 2013

Cover Story

T

he Indian foundry industry has indeed come a long

way since the time metal castings as an industry started

in the later part of 19th century. Since then, the Indian

foundry industry has been successfully facing the challenges of

producing high precision and high quality castings conforming

to international standards. In spite of that, experts feel that the

industry has a long way to go in order to establish itself as

the best castings producer in the world in terms of quality,

quantity, delivery and price.

Foundry sector

needs to focus on

sustainable growth

Tamajit Pain

6 Steel Insights, February 2013

Cover Story

World foundry industry World casting production, product-wise (million tons)

The Census 2011-12 conducted by Modern Year Grey Iron Ductile Iron Malleable Iron Steel Non-Ferrous Total

Casting, USA, reported that the global casting 2009-10 37.62 19.94 1.04 9.03 12.71 80.34

production in the year is 98.59 million tons 2010-11 43.26 23.45 1.1 10.22 13.64 91.67

(mt) of iron, steel and non-ferrous castings.

2011-12 45.87 24.78 1.38 10.34 16.22 98.59

The output has been contributed by nearly

49,391 foundries from 33 countries. Source: The Institute of Indian Foundrymen

However, considering the unlisted

foundries, the number of operating foundries five years, while USA’s and Japan’s annual The present employment in Indian

globally will be approximately 55,000 production have come down by 15 percent foundries is approximately 2 million people

and world casting production would be and 6 percent respectively in the last five directly and indirectly and additional

approximately 105 mt. On examining the years. manpower needed for every million ton of

nature of castings produced the world over, it This shows that Germany with 8,933 production is approximately 2 lakh, directly

can be seen that approximately 48 percent of tons production during 2011-12 is on the and indirectly.

the total casting production consists of grey top and China with 1,375 tons production is An analysis of the Indian casting

cast iron products, 25 percent ductile iron, at the bottom, while India with 2,221 tons production shows that in the last seven years,

1 percent malleable iron, 10 percent steel production is in between in the production production has doubled. However, because

castings and 16 percent non-ferrous castings. curve. of recession, the production had dropped by

Out of the total production, China 11.98 percent in 2008-09 compared to the

produced 41.26 mt in 2011-12, while India Indian foundry industry previous year. But the situation has reversed.

produced 9.99 mt of castings. Therefore, the India has over 4,500 foundries and several In 2011-12, production has increased by

countries ahead of India are China and USA others in the small and medium and large 10.43 percent compared to the previous year.

(10.00 mt). According to industry experts, scale sector. A number of modern foundries

Asia’s casting production is approximately with state-of-the-art facilities have come up Strong points

67.5 percent of the world casting production. in recent times. The strengths of the Indian foundry industry

The Asian countries primarily under According to industry estimates, the lie in the fact that it has a large base which

consideration are China, India, Japan, Korea, annual turnover in India of all the foundries is spread all over the country. India has

Taiwan, Pakistan, Malaysia and others. put together has reached a figure of around a traditional legacy of metal casting and

The new emerging castings producing `60,000 crore. The installed capacity is manpower is available at a reasonable cost.

countries are UAE, Saudi Arabia, Bahrain estimated to be 15 mt and capacity utilisation The industry is now making efforts to train

and Muscat. is approximately 60 percent. It is expected them and retain them, industry officials said.

An evaluation of the achievements shows that casting production in India will touch Another advantage is that of access to

that China and India have increased their 15 mt in the next three years and 20 mt in latest technology and support by various

production by nearly 30 percent in the last the subsequent five years. government bodies and availability of vast

natural resources. Indian foundries are

successfully facing the challenges of producing

high precision and high quality castings

conforming to international standards.

Moreover, the country has a large

transportation and railway network and there

is an expectation of 50 to 60 percent increase

in offloading of cast components by major

developed countries of the world.

Major constraints

The continued rise in prices of important

raw materials like pig iron, steel scrap, low

ash coke, ferro alloys and other material have

crippled the industry. The foundry industry

is under tremendous pressure but seem to be

working individually to face the situation. In

the last seven years, the price of major raw

materials started increasing substantially

from November 2007 and reached a peak in

September 2008.

8 Steel Insights, February 2013

Cover Story

Production highlights of world’s 10

top casting producing nations

Country 2010-11 2011-12

China 39.6 41.26

USA 8.24 10

India 9.05 9.99

Japan 4.76 5.47

Germany 4.79 5.46

Russia 4.2 4.3

Brazil 3.24 3.34

Korea 2.23 2.34

Italy 1.97 2.21

France 1.96 2.05

Rest countries 11.63 12.17

Total 91.67 98.59

Source: The Institute of Indian Foundrymen

From then it came down substantially

under the influence of recession and currently

prices are on an increasing trend.

However, the industry had fixed price

long term contracts without any escalation India’s casting production, product-wise (million tons)

clause. Added to this is the problem of old

Year Grey iron Ductile iron Malleable iron Steel Non-ferrous Total

equipment and technology, especially in the

small scale sector. 2009-10 5.05 0.8 0.06 0.88 0.653 7.44

Industry experts say the Indian foundry 2010-11 6.18 0.984 0.069 1.07 0.75 9.05

industry is a case of inverse relationship 2011-12 6.79 1.09 0.06 1.14 0.9 9.99

between technological sophistication in

Source: The Institute of Indian Foundrymen

terms of scientific inputs in molding, melting,

and mechanisation and the number of firms

adopting such systems. In the last decade, The ferrous foundry industry is highly ♦♦ People switching over to other industries

a lot of work has been done on introducing energy intensive. Energy cost is almost 15-20 due to favourable working conditions

new processes and using them to the percent of the manufacturing cost and cost of ♦♦ Physical work causing health hazards to

maximum possible advantage. However, the energy in India is very high in comparison workforce

corresponding growth in the production and to other countries. This factor wipes out

supply of critical equipment has not taken competitiveness of the sector not only in the Thus more and more foundries are using

place internally. It is essential to encourage export front but also in the domestic front. robots for material handling. It is predicted

manufacturers of critical equipment to locate that in future robotics based work would

their units in India to tap the huge export Automation be created to add content and value to the

market that is building up. Information technology and automation are product.

It is to be noted that despite the playing an increasingly important role in

introduction of new processes, over 90 growth of the industry currently and have Green foundry

percent of the world’s casting production is found a wider range of acceptance in foundry Foundry operations have significant

through green route. industry to tackle technical problems. environmental impacts both within and

The other ailments of the industry are Automation is required because of the beyond foundry plant. While the primary

low production per unit, shortage of skilled following factors: focus of metal casting technology is

manpower, insufficient research, delay in ♦♦ Increasing labour cost production of sound casting economically, it

payment by customers, inability to ensure ♦♦ More process variation due to more is increasingly necessary to take into account

prompt delivery at short notice, shortage human involvement which leads to heavy the effect of the process on the environment

of power, high energy cost and higher rejection and its communities.

import duties of raw materials compared to ♦♦ Customer requirement on quality and The key to foundry pollution prevention

competing countries. delivery is going up is to undertake comprehensive examination

10 Steel Insights, February 2013

Cover Story

of the operations in the facility with a goal

of minimising the creation of all types of

61st Indian foundry waste products. Foundry industry

depends on a range of natural resources which

Foundry Congress are consumed during production. Some of

this can be re-circulated within the foundry

Steel Insights Bureau plant but portion is lost in the surroundings

both within the plant and outside.

Environment impact caused by the foundry

size and 5 percent are large-scale industry due to emission of air, release of

units. The industry is labour- water, contamination of land and other local

intensive, employing 500,000 environmental and community issues need to

people directly and 150,000 be analyzed thoroughly and preventive action

K

olkata hosted the 61st Indian people indirectly.” The smaller units are needs to be taken in this regard.

Foundry Congress (IFC), an annual dependent on manual labour but most All foundries should work for a

flagship event of the Institute of medium and large units are partly or fully ‘green foundry’ concept. Minimization of

Indian Foundrymen (IIF) between January mechanized and many larger foundries emissions, efficient use of raw materials

27-29, on the theme “Building Brand India meet world-class standards. and energy, optimum utilisation of the

- The Casting Edge”. The event was held Major foundry clusters include process, recovering and recycling of the

concurrent with the International Foundry Jalandhar, Ludhiana, Batala, Agra, waste materials and substitution of harmful

Exhibition (IFEX 2013). Howrah, Pune, Mumbai, Belgaum, material are important facets of adopting

With over 800 delegates and 250 Kolhapur, Solapur, Rajkot, Chennai, green foundry techniques.

exhibiting companies, the 61st Indian Hyderabad, and Coimbatore. Ravi For foundries, focal points are air

Foundry Congress and IFEX 2013 Sehgal, chairman of the 61st IFC said: emissions, efficient use of raw materials

foundry exhibition drew over 4,000 “Castings produced include ferrous, non- and energy, waste reduction along with any

trade visitors. In addition to technical ferrous, aluminium alloy, graded cast recycling and re-use options.

presentations by Indian and international iron, ductile iron and steel for application The best available technique needs to be

authors, the IFC featured an Energy in automobiles, railways, power sector, used in order to optimise the management

and Environment Forum, Student pumps, compressors, valves, diesel engines, and control of internal flaws to prevent

Forum, Cast Source buyer-seller meet, cement, electricals, textile machinery, pollution. Also there is need to create better

prominent industry speakers and a host of sanitary pipes and fittings, engineering and better techniques for environment

international participants from Germany, industries, machine tools and special protection.

Italy, China, Japan, UK and USA. applications. Grey iron castings form the

Founded in 1950, IIF is an all-India majority at 68 percent of total castings Castings demand

industry association representing the produced.” Demand for castings is ever increasing. The

foundry sector and comprises foundries, “The theme for this year’s meet is present day demand for castings globally is

foundrymen, professors, academicians, ‘Building Brand India - The Casting estimated to be about 110 mt with product

foundry equipment vendors and foundry Edge’. Foundrymen must thus make value of over $150 billion. With 5-10 percent

input suppliers, with a current strength an effort to offer the right product mix, of expected growth, the demand for castings

of over 3000 members. Headquartered quality and price in order to reach out will increase substantially over a period of

in Kolkata, with four regional offices in to the world. Eastern India has taken up time.

Kolkata, Delhi, Chennai and Mumbai and the challenge to set up new foundries, The wind energy sector is expected

27 chapters across India, IIF is a member and with this the industry is once again to grow at 25-30 percent in the coming

of the World Foundry Organization growing in strength in India,” Sehgal said. years. The additional requirement for

(WFO), UK and of the Confederation of Anil Vaswani, joint secretary and ductile iron castings in the sector alone will

Indian Industry (CII). treasurer of the 61st IFC said: “The be approximately 1 mt of which India’s

Speaking on behalf of the domestic mission and vision of IIF is to make requirement will be 0.08 mt.

foundry sector, Harsh K. Jha, president, the foundry industry an attractive India has a stable domestic demand,

IIF said: “The Indian foundry industry proposition for all stakeholders, with which has helped the foundries to survive

is the second largest producer of castings government support, through technology the recent global meltdown. The order book

in the world with a production of 8 mt upgrades, competitiveness, enhancement position of most of the foundries who are

annually, behind China, which is far ahead of operational efficiency and capital equipped to produce quality castings is very

at 35 mt. There are more than 4,500 infusion. The focus is on development of good. India remains a high growth region for

foundries in India of which 85 percent are foundry clusters and common facilities for small cars, tractors and two wheelers. Demand

small-scale units, 10 percent are medium- foundries.” for castings in the domestic market is over 6

million tons per annum (mtpa) at present.

12 Steel Insights, February 2013

Cover Story

Industry experts feel that the world is looking With every supply the buyers give a list Benchmarking

at India as a source for their cast components of improvement expected in the next supply According to experts in the industry, there

and India can tap this opportunity. and current supply may be either rejected or is an imperative need for benchmarking

At present, the total casting export from accepted as a special case. Variable schedules of products to improve competitiveness.

India is over 1 percent of the total world are also a factor affecting foundries. Following are the areas where benchmarking

requirement. If all the foundries put their might, is required:

this share could go up to 10 percent providing Foundry cluster ♦♦ Rejection level

immense opportunity to our foundries. In both industrialised and developing ♦♦ Yield

countries, there is increasing evidence that ♦♦ Energy consumption

Rise in buyer expectation clustering and networking can help small ♦♦ Productivity

The foundry industry is facing challenges and medium enterprises to boost their ♦♦ Effective floor utilization

from industries all over the world. In this confidence. ♦♦ Raw material consumption

global competition the rule of survival of the Small scale enterprise clusters are ♦♦ Inventory level management

fittest will apply and only the best and the tools to effectively implement and support ♦♦ Delivery period

competent will survive the race. initiatives aimed at enlarging the production ♦♦ Development of lead time

According to industry experts, the only base, conquering market niches, accessing ♦♦ Emission level of dust and fumes

criterion for survival is quality, quantity, export markets, triggering growth, offering ♦♦ Generation of wastes

delivery and price. For the manufacturers the employment opportunities and redressing ♦♦ Manufacturing costs

message is to tighten their belts and fall in regional economic imbalances.

line quickly or be ready for the fallout. There are several successful clusters Future

In the global arena, the buyers’ functioning in India at Agra, Batala, The Indian foundry industry is expected to

expectations have also soared sky high and Belgaum, Chennai, Coimbatore, Howrah, grow at 10-20 percent per year for the next five

buyers just expect excellent quality of castings Jalandhar, Kolhapur, Ludhiana, Pune and to seven years provided proper government

as and when they need at a lower price. Buyers Rajkot. Foundry clusters and national policies are in place. Domestic and export

also expect continuous improvement. The cluster for export promotion of cast products demand and increased manufacturing and

castings which were declared ‘ok’ till now are together can bring a lot of comfort to the outsourcing activities could also take the

now being declared substandard and rejected. industry in coming years. industry forward.

A foundry unit in operation

14 Steel Insights, February 2013

Cover Story

Foundry-men engaged in casting operation

Many industry players believe that based manufacturing base in India with 100 percent that export of poor quality castings by

on the present growth pattern, India will buyback arrangement. some of the smaller manufacturers would

advance her position shortly as the second The technology transfers and absorption result in poor image of Indian foundries

largest casting producer in the world, leaving in such cases would mean transfer of in export markets.

behind the USA which is presently in the knowhow, equipment and training of Indian • Capacity building among smaller

second position. foundrymen. These alliances would, however, foundries and the ability to meet customer

As the demand for good quality castings help abolish middlemen and trading houses requirements of machined castings

increase over time, foundries capable of who otherwise import castings at a minimal • Reducing long investment lead times and

producing and supplying castings as per price and supply directly to the foreign buyers. delays in environment clearances which

customer requirement will have a bright It will help the foundry operators to gain result in project uncertainty.

future. However, Indian foundries have to access to foreign markets with higher margins. • Meet cost challenges like increasing cost

convince the foreign buyers about their ability The industry feels that the following of raw materials, power, manpower etc

to produce cast products of global standards. goals need to be taken up by the Indian • To develop competitive overseas market

Moreover, to be globally competitive, foundries to improve their performance:

Indian foundries have to urgently upgrade • To establish India as the Asian hub for For achieving the above goals the

themselves technologically, train manpower cast components industry needs to take into consideration the

continuously and benchmark with global

• To implement schemes to attract and following initiatives:

standards to produce quality castings and to

retain the best manpower available in the • Indian foundries need to invest more

create a brand image.

country and abroad on R&D on various fields to reduce

It is expected that there will be ample

scope for Indian foundry operators to forge • To accept the challenge of greening the production costs and for producing high

alliance with their counterparts in the foundry industry quality castings consistently.

developed countries. A feasible approach is • To attract latest technologies from all • Reduce rejection of castings by mapping

through technology transfer by the foreign over the world best casting production processing

foundry to its Indian counterpart with equity • To adhere to delivery standards – quality, and refrain from adjusting production

participation with a view to establishing a quantity, delivery and price – it is feared processes without thorough study.

16 Steel Insights, February 2013

Cover Story

the foundry industry will be very crucial to

support the manufacturing and engineering

IIF signs MoU with Japan Foundry Society industry in the coming years, according to

A.K. Anand, director, The Institute of Indian

Steel Insights Bureau Foundrymen – FIC, New Delhi.

T

The industry will have to focus on

he Indian Institute of Foundrymen (IIF) a pan-India body representing the

sustainable growth and take steps to achieve

foundry sector, has entered into a MoU with the Japan Foundry Society, the

the following targets by 2020 in a phased

largest organization of foundrymen in the world, for Green Business Foundry.

manner:

The MoU was signed at the 61st Indian Foundry Congress which got underway in

♦♦ Production to go up to 25-30 million

Kolkata on January 27. The move will help implement cost-effective and eco-sensitive

tons per annum

‘green’ manufacturing standards across the country’s $12-billion foundry industry.

♦♦ The productivity per unit to go up to

“This comes at a time when a whopping `600 crore worth of investment is expected

4500 tons per annum

to be invested in the foundry industry in West Bengal and the rest of eastern India,” said

♦♦ Productivity per man to go up to 40 tons

Ravi Sehgal, chairman, organising committee of 61st IFC and IFEX 2013.

per annum

The three-day meet, being organised by IIF will have two concurrent events – IFEX

♦♦ Specific energy consumption to go down

2013 and Cast India Expo. It is being attended by over 800 delegates from China,

by 10 percent

Germany, Italy and Japan, which are major hubs of the global foundry industry.

♦♦ Increase share of aluminium casting to 15

“The 61st IFC has a range of programs and informative technical seminars

percent

addressed by reputed speakers, and an internationally attended exhibition of the latest

machines and technology. Also, cast buyers of repute will be visiting to source their

This is possible only by creating additional

annual requirements, and industry representatives will be discussing their perceptions

capacity by improved productivity by using

of the current scenario of the industry,” Harsh K. Jha, president, IIF said.

modern design and manufacturing tools,

With 9.9 mt cast components, India is ranked among the top three globally with

technology and processes and by promoting

annual exports of around $2 billion. However, its share in the global market is below 2

investments in modern plants, according to

percent.

Anand.

For example, for increasing the scale

of operations the model of China can be

• B enchmark all process parameters based manufacturing in GDP to 25 percent from

taken into consideration. China has 30,000

on best practices in similar units which present 15 percent and to create additional

foundries with average production per unit of

are performing well. 100 million jobs by 2022. 1,400 tons per annum. As per reports, they

• Benchmark pollution norms of the The other significant features are single plan to reduce the number of foundries to

developed countries to ensure minimum window clearance mechanism to cut red tape 10,000 and increase the per unit production

damage to environment and the high priority for skill development. to 5,000 tons per annum, thus closing down

• R&D to target for producing high quality The private sector will be given standard inefficient units.

strategic castings which command high deduction of 150 percent of expenditure for The Indian industry will need to invest

selling prices skill development institutes. an estimated $9-10 billion by 2020 in the

The government has notified 10 National next 10 years for capacity expansion and

• Improve manpower efficiency and

Manufacturing Investment Zones, which are upgradation to support manufacturing.

capabilities and providing education and

mega integrated townships with world class Thus although the foundry industry

training of foundry personnel at all levels

infrastructure. Moreover, the government is is successfully facing the challenges of

• Provide continuous training in modern offering a host of incentives like exemption

technologies producing high precision and quality castings

from capital gains tax and liberalised labour conforming to international standards, it

• There is a need for centralised R&D and environment norms to promote these has a long way to go to achieve the status

centres for foundry clusters with zones. of the best castings producer in the world.

necessary testing facilities and effective Also, the government is closer to Actions taken by the industry has been

participation of foundry experts. implementing the goods and service tax and showing positive results but there is a need

• Increased mechanization, monitoring has set ambitious power generation capacities to pay attention to R&D activities to reduce

and controls for improved productivity in the Twelfth Plan and plans to invest $1 production costs and for producing high

• Value addition by producing ready to use trillion during the Plan period (2012-17) in quality castings consistently.

components/sub-assemblies power and infrastructure. With 9.99 mt of casting production in

2011-12, India has become the third largest

Growth drivers Focus areas castings producer in the world. It is expected

The new National Manufacturing Policy The Indian foundry industry currently that shortly India will become the second

of the government of India approved generates revenue of $12.5 billion and exports largest casting producer in the world next

recently, envisages to increase the share of worth $2 billion. In this context, the role of only to China.

18 Steel Insights, February 2013

Cover Story

development of technology and process in

Green energy solutions making effective solutions to the problem

including development of renewable energy

sources for various technical purposes,

need of the hour

efficient technology to have less energy use

and techniques to recover waste heat etc.

Efforts should be made to minimise use

of fossil energy, which is the basic cause of

environmental problems or find out the

possibility of an alternative energy use.

The world metal production and energy

requirements reveal that steel industry

alone requires 8.1 percent share of the total

world energy. The energy use share by five

major metal industries is nearly 10 percent

indicating that metallurgical industries are

the major energy consumers in the world.

Industry sources opine that energy

audit should necessarily be carried out in

metallurgical plants including iron and steel

and aluminium industries to identify quality,

quantity and cost of various energy input

sources, assessment of the current pattern

of energy consumption, identification of

potential areas of energy economy, the energy

waste in the system, fixing targets for energy

saving potential and implementation of

measures for energy conservation.

Energy use

Steel can be produced by using four different

routes and their energy requirements are also

different:

♦♦ B

last furnace – basic oxygen furnace –

continuous casting (BF – BOF – CC)

route

Tamajit Pain 1.4 kg per ton while NOX generation is

♦♦ D

irect reduction of iron ore - electric

approximately 1.8-2 kg per ton of crude

arc furnace – continuous casting (DRI –

I

ndia is emerging as an industrial nation steel. Slag and flue dusts are generated as

EAF – CC) route

in the world with significant economic solid waste which is about 1-1.4 ton per ton

of finished product. Fugitive dust emissions, ♦♦ S

melting reduction – basic oxygen

growth. Metallurgical industries are also furnace – continuous casting (SR – BOF

expanding rapidly particularly in primary ground water contamination and solid waste

disposal are the main problems, according to – CC) route

metal production providing growth in

economy, needed for a prosperous nation. industry experts. ♦♦ E

lectric arc furnace – continuous casting

Metallurgical industries are known as This not only affects the flora, fauna, (EAF – CC) route

hazardous and polluting industries since terrestrial and aquatic ecology but also

BF-BOF-CC route is the oldest method

they generate huge amount of solid wastes health of the population in the vicinity of the

of making steel and is dependent on a

like slag, tailings, red mud, heavy metals, plant. The environmental problems can be

particular energy source (metallurgical coke)

anode slimes etc toxic effluents, flue gases, minimized by decreasing the energy use by

which has limited supply in the world. 31.1

discharges of thermal emissions and noise are undertaking short and long term goals. The

GJ energy is needed for steel making by the

common with the process. short term goals include conducting energy

primary route starting from iron ore. The

For example, steel production process audit to know the energy use or loss pattern,

actual value of energy consumption can

(BF-BOF) is highly energy intensive and avoiding and reuse of waste energy and

vary from the best available technique in the

releases about 2.3-3 tons of CO2 per ton adopting energy efficient technology.

world to 16.7 GJ per ton. The blast furnaces

of crude steel. SO2 emission ranges 1.2- The long term project should involve

consume maximum energy (54 percent) of

20 Steel Insights, February 2013

Cover Story

the total requirement of the process, which to cause combustion and minimize the

nearly 31 GJ per ton of steel. nitrogen content in the gas. A typical unit

Since 1970, efforts are being made to requires 36.9 GJ energy by consuming 1 ton

minimise the coke rate and replace it as far of coal and 700 m3 of oxygen to produce 1 ton

as possible by other energy sources such as of steel and 4700 kWh power. This process

oil and coal, depending on the availability produces two products (steel and power) with

and economics and had been decreasing as a nearly equal energy intensity share. This is

result of substitution by oil and non-coking the reason why such plants are called steel

coal injections. and power plants. The power generated in

To find an alternative for metallurgical excess of its own need is exported to national

coke, the DRI-EAF-CC route was developed grid. The plant technology involves coal

in 1970s that used non-coking coal or gasification and its use for reducing iron

natural gas as the main energy source for iron ore. In this process the excess reducing gas

making. The iron thus made was converted consisting carbon monoxide is utilized to

into steel using electric arc furnace. The non- generate power.

availability of such large quantity of electrical The fourth route (EAF – CC) is a very

energy was restricting the growth of the steel old method of steel making which has gained

sector. Both coal and natural gas can also be importance in the recent times in view of

used as the primary energy source to produce the energy crisis. This method involves the

DRI using two different technologies. The

melting and casting of steel which requires

coal based DRI plants use 12.6 GJ per ton

less energy. Typical EAF steel melting uses

energy, while has based plants need only 9.5

2.44 GJ of energy to produce 1 ton of steel.

GJ per ton for producing sponge iron as the sector (power plants) the third route (SR-

This energy is derived from 410 kWh per

product. BOF-CC) was evolved in 1980. This is the

ton electrical power (1.47 GJ) and heat

In case of coal based plants, the unused most recent method of steel making using

of oxidation of Carbon (0.56 GJ), silicon,

energy is more than 70 percent mainly in the non-coking coal and oxygen as the main

manganese etc. In addition, 0.16 GJ of

form of waste char and hot gases. The waste energy sources. Many processes under this

energy is provided by burning some fuel to

char and hot gases are exploited for power group have been developed but only two

generation to avoid wastage. The char is preheat the scrap.

technologies (COREX and FINEX) have

pulverized and fired in boiler to raise steam Thus energy requirement is different for

reached the commercial stage. The COREX

to generate power. In case of gas based plants, four different routes of steel making and use

plant, first in India and third in the world,

the heat loss is much less and further effort is was initiated in 1999 at Bellary by JSW. The of energy is different due to technological

needed to recover heat from flue gases. The commercial FINEX plant is planned to be set changes. However, efforts have been taken

spent gas is recycled in the system thus reducing up in India for the first time by Posco near reduce energy consumption in every process.

the demand for the fresh energy source. Paradip in Odisha.

To become non-dependent on electrical Energy efficiency

The COREX plant uses non-coking coal

power which comes from a different industrial as the energy source along with pure oxygen Foundries are energy intensive production

22 Steel Insights, February 2013

Cover Story

units where adoption of the best energy ♦♦ O perate the furnace at its constant rated to solve the ecological problems rooted

solution provides great energy saving power with the use of fossil fuels. Therefore,

potential. ♦♦ Install an automatic power factor efforts should be made to find green energy

According to foundry industry officials, controller solutions through hydrogen as a renewable

♦♦ Cooling towers with change of blades reductant and energy source for the iron and

currently foundries are effectively recycling

from aluminium to FRP steel industry.

their materials. More than 90 percent of all

♦♦ Introduction of low wattage compressor According to experts in the field,

cast parts are made from re-melted scrap

♦♦ Replacement of partially loaded motors hydrogen is an ideal reductant for iron

metal.

with smaller capacity motors making since it can be produced without any

The costs for energy and materials in ♦♦ Use of natural light through the use of undesirable gases in it. The product of the

foundries are in average responsible for 40 transparent roofing sheets reduction reaction is water which would be

percent of all costs. Melting and solidifying ♦♦ Replacement of high speed diesel fired recycled in the nature without resulting in

metals require a high amount of energy. burners with furnace oil fired burners any environmental problem. The hydrogen

Physical laws determine an average energy ♦♦ Replacement of conventional copper has been used successfully to produce high

input of 2000 kWh per ton of final casting ballast with HF electronic ballast quality iron on a commercial basis in the

product. This adds up to a total energy ♦♦ Replacement of filament indication world by H-iron techniques.

consumption of 18 billion kWh. lamps in control panels with LED lamps This method is not used presently in

The foundry industry is energy intensive ♦♦ Use of 36 watt slim tubes instead of 40 the normal iron and steel production due

and has an important role to play from an watt conventional fluorescent tubes to economic reasons however this may be

environmental point of view while seeking ♦♦ Increase emissivity of heat treatment possible in future if hydrogen gas in available

to develop and play an important role in the furnaces by coating the hot face in abundance as a renewable energy. It may

development. also be possible to modify the currently

According to industry experts, some Green energy used gas based process for DRI production

energy efficient processes that need to be Although efforts have been made to reduce exploiting pellet or lumps in hydrogen,

followed include: energy consumption in the past, one has industry sources said.

24 Steel Insights, February 2013

interview

are expecting

Tech upgradation need of the the business

to improve

marginally in

hour at HEC: Misra

the coming

fiscal.

Our orders

are usually big

in nature, hence

Sanjukta Ganguly However, following the breaking up of both our business

the regions, the sourcing of these equipment is hit even if

H

eavy Engineering has become difficult. Technological we miss one of R Misra, Chairman & MD, HEC

upgradation, however, is now the biggest them.

Corporation Ltd (HEC), the

need. Without further investment on We are also in the business of turnkey

public sector integrated

upgradation, it is impossible to move projects from designing till commissioning

engineering complex based out of

forward. of projects. So orders also come in from

Ranchi, has been battling the odds

of technological obsolescence and there.

What is the proposed investment for this

lack of skilled manpower for some upgradation? What is the demand scenario at present?

time now. That has been adversely

We are currently planning to invest about As far as the demand scenario is concerned,

impacting the profitability of the

`750 crore for the next four years on this PSUs are delaying their orders. At the

company of late.

upgradation process. We are not planning same time, private sector customers want

In a free-wheeling conversation to build any new plant but we want to make

with Steel Insights, the chairman to procure the products at a lower cost as

our existing plants energy efficient. We are they are in a cost cutting mode. Hence,

and managing director of HEC, R. consuming about 750 Kilowatt of energy at it is getting difficult for us to match their

Misra, said that only a successful present. It can come down roughly to about requirements.

technological and infrastructural 600 Kilowatt once upgradation is done.

upgradation can boost the profit

Are you focusing on any particular industry

margins of the company. Plans are Are you collaborating with any other at present for business?

being chalked out accordingly, company for this technological

We are looking at the steel plants. The coke

he said. He also spoke about the upgradation?

oven batteries, especially, have become very

state of the mining industry and the Being a public sector company, we have to old and there is a need to change them.

present order book of the company. pass through a transparent tendering system Earlier they used the wet quenching system

at every stage. We will tie up with whichever but now they need to use dry quenching

Excerpts: company clears all requirements and comes system. Batteries also need to be changed.

through the process. These usually work for 15 years but they

What will be HEC’s focus area and plans in have already crossed 20 in most of the SAIL

the near future? What is your outstanding order book right plants. Hence, an immediate change is the

now? need of the hour.

We have been making profits for the last six

years, but even that has been very nominal. Our outstanding order book right now is

Turnover has increased by only one and `1,700 crore. However, as we are passing What are your offerings for the Indian

half times. Technological obsolescence and through a recession now, there is a delay in mining industry?

lack of trained manpower are some of the placing of new orders. Mainly we are in the In the lower range we have 5 m3 shovels and

main reasons for such low profits. We need business of supplying equipment to steel 10 m3 shovels all of which are electrically

younger people with new ideas to carry this plants and SAIL, for instance, has already operated. So, these require electrical lines

company forward. placed its orders for the modernisation and the cables should be drawn to such

Perfection is an important component process. points where these machines are being used.

of the foundry business. The slightest defect We are also supplying another big machine

in casting can get it rejected. That is why The pace of orders in the mining sector has called drag line for overburden removal in

it has now become imperative that the also slowed down. Are you expecting any opencast coal mines. The weight of the

old plants should be replaced as they have improvement in the scenario? machine is about 2,000 tons and the system

become obsolete. The machine building We have already submitted tenders against a costs about `150 crore.

tools and forging plants were set up in the lot of requirements by various companies. It We have received an order from Coal

early 1960s with equipment imported from is a fact that the orders are being hampered India Limited for three such walking drag

the erstwhile USSR and Czechoslovakia. owing to the current situation. However, we lines. We have already supplied one and

26 Steel Insights, February 2013

interview

Are you getting any orders from abroad?

Recently, we have got an order from

Bangladesh which is under execution at

present. The order is of supplying under

floor wheel lathe to the Bangladesh

Railways. The tool that we will provide is

very sophisticated and can automatically

detect what should be the optimum size of

the wheel plate and can change it once it

gets deformed.

We have the expertise to produce these

kind of machines but we are mainly an

India focused company. This order from

Bangladesh has been our first international

order.

Are you interested in acquiring more

international clients for your products?

Although we are already supplying machines

the rest of the order is being executed. One overhead cranes to SAIL which can operate to the Bangladesh Railways, at the moment

machine is about 4-5 storeys high and the at a very high temperature which can pour we are just keen on upgrading our plants and

erection of the machine takes about eight liquid pig iron, liquid steel on a 24-hour supplying primarily to Indian companies.

to 10 months. Its length is about 96 metres. basis. Recently we have supplied three such We are planning accordingly. But, if we

These machines will be deployed mainly in the cranes of 450-tons capacity to Bokaro Steel continue to get more orders from abroad,

northern coalfields in the Singrauli coal mines. Plant (BSL). Altogether, right now, we have we will definitely also look at supplying to

We also have the expertise in supplying orders for more than 100 such machines. them.

28 Steel Insights, February 2013

interview

and Chiplun.

Iron ore an area of concern: The company

has its

research and

Sandvik

development

centre in

Bangalore. Its

businesses in

India include

Steel Insights Bureau captive coal blocks. This had both positive materials

and negative effects. There were a lot on technology,

S

andvik Mining is a leading controversial things, but also some positives tooling, mining Soumitra Banerjee, President,

global supplier of equipment coming out of it. and construction Sandvik Mining India

and tools, service and technical Currently, iron ore is an area of concern equipment.

solutions for the mining industry, and for us. As I said, a sizeable chunk of our Overall, Sandvik has its presence in

their products span the entire range revenue comes from this segment. Goa has India for nearly 60 years now. Our total

including rock drilling, rock cutting, stopped exports altogether. Production has

turnover from the Indian operations is

rock crushing, loading, hauling and been affected substantially in Karnataka.

around `2,600 crore.

material handling. The progress of captive blocks is very slow.

Sandvik AB subsidiary Sandvik In Odisha, steel mills are affected due to

What is your current market share in India?

Asia Ltd has its headquarters in various government notifications restricting

mining of ore in the state. In India, competition is intense. There are

Pune and manufacturing units in five

Overall, the Indian government is a number of international players present

places. President of Sandvik Mining

working on various policy initiatives to in the mining equipment sector. Almost

India, Soumitra Banerjee, talks to

properly develop the mining sector. But the everybody is affected due to the slow

Steel Insights on the company’s

speed of such policymaking is very slow. progress in the country’s mining sector. This

focus areas in India, its current

includes Metso, Caterpillar and Terex. India

concerns as well as its outlook for

How has been the year 2012 for Sandvik accounts for around 2 percent of our global

the new year.

Mining, globally and in India? What is the turnover. The major markets are Australia,

outlook on 2013? South Africa and Canada. Russia and CIS

Excerpts:

countries are coming up and Sandvik is

In 2012, despite the economic uncertainties,

What are the focus areas for Sandvik in doing a lot of work in those countries.

Sandvik Mining globally achieved its

India? budgeted revenue targets. 2013 would be

What is the scenario in the Chinese market?

Our major strength in the Indian mineral even more challenging and if we can achieve

sector is on iron ore and underground hard 8 to 10 percent growth in topline, it will be In China, we are seeing a slowdown in both

rock. Thus, a lion’s share of our revenue is a very reasonable performance considering the segments of construction and mining

from underground hard rock and iron ore the outlook. equipment. Due to Chinese slowdown,

and the related after market. In India, the revenue performance is Australian miners supplying ore to that

In coal, we do not have any presence in approximately 20 percent below the target as country are facing problem. Also, coking

surface and load haul segments at present. the new mining projects did not come up as coal imports by the country was down in

Instead, our focus is on underground for per expectation. This is particularly true for 2012.

continuous mining in Bord and pillar coal and underground hard rock greenfield In our case, China’s share in our global

operations and development work in projects. Iron ore was also extremely weak turnover is around 7-8 percent. We have

Longwall mining. due to ban on mining in major states like a manufacturing set up in that country.

In the Indian mining sector, currently Orissa, Karanataka and Goa. Besides, Sandvik mining has manufacturing

we are not covering the entire segment. Our facilities in France, Sweden, Finland and

entire product range would come when the What is your level of presence and turnover Australia.

market opens up. As of now, imports are in India?

sourced from Finland and Sweden. We have Our mining equipment revenue from India Lastly, what was the impact of the recent

manufacturing plants in India for rock tools, is around `250 crore. Besides, Sandvik has split of Sandvik’s global mining and

but not for mining equipment as such. presence in materials technology, tubes used construction divisions?

in fertilizer, machining and tooling in India. The objective of this split was to gain

What is your reading of the current scenario For these we have five plants. Sandvik’s increased customer focus. Today,

of mining in the country? India subsidiary Sandvik Asia Ltd has its aftermarket demand from these two

There are mixed signals coming from India. headquarters in Pune and manufacturing divisions is entirely different and we are

Some people have invested heavily on units in Pune, Mehsana, Hosur, Hyderabad reaping benefits of increased focus.

Steel Insights, February 2013 29

SPECIAL feature

current lead runners China and Japan.

India examines options Among these two, China (despite importing

around 45 to 50 mt of coking coal in 2011)

is much more self-sufficient, producing the

as Chinese demand chart

vast majority (over 500 mt) of the dry fuel

from its own mines to feed its giant steel

plants. Japan, in contrast, is almost entirely

coking, coke trend

dependent on imports.

Between the two, India should find

greater resemblance to the island nation of

Far East Asia. As they grow their steel output,

the Indian steel mills would increasingly face

the problem of import dependence for coking

coal procurement. But whether they will take

a lesson from their Japanese counterparts –

the well-knit Japanese Steel Mills (JSM)

– in turning their weakness into strength,

and dictating terms in international price

benchmarking, is a matter to wonder about.

India’s coking coal procurement

As of today, all of the major Indian

steelmakers – SAIL, JSW, RINL, Tata

Steel, JSPL, Essar – procure some part

or their entire requirement of coking coal

from overseas miners. Only the integrated

steel plants – such as SAIL and RINL – get

some portion from Bharat Coking Coal Ltd

(BCCL), the only significant producer of

coking coal in India.

Tata Steel is a notable exception, having

acquired coking coal mines (through joint

Steel Insights Bureau to jump. By 2016-17, coking coal demand by ventures) in Australia (Bowen Basin in

India’s expanding steel sector is expected to Central Queensland) and Mozambique

M

uch in contrast with iron ore, India be around 90.2 mt and import would more (Benga Coal Project). The company mostly

is critically short of coking coal as than double, according to an estimate by the sources the fuel from its own overseas

a natural resource. The proven working group on steel. operations for its steel plants in Europe,

reserve of coking coal is only 17.9 billion However, strangely enough, there is Asia and elsewhere. This, however, remains

tons, much less than the vast proven reserves hardly any concern about the increasing a rarity in the Indian steel vertical. Except for

of non-coking coal of 99 billion tons. Of the requirement of coking coal in the country. very few players – that includes coke maker

total proven coking coal reserves, deposit of With such high growth in imports, India Gujarat NRE Coke Ltd – acquisition of

prime coking coal is only 5.3 billion tons, would possibly become the largest importer coking coal mines have not been on the radar

official data shows. of coking coal a few years on, surpassing of the Indian corporate entities.

More importantly, the quality of coking Break-up of coking and non-coking reserves (in million tons)

coal available is quite inferior, so much so

Depth Coking Non-coking High Grand

that sometimes costlier imports prove more

Range (m) Prime Medium Semi coking Superior Inferior Ungraded Sulphur Total

economical.

As of 2011-12, India’s coking coal 0-300 0.00 11566.45 466.38 21585.76 129038.81 9894.48 1290.64 173842.52

consumption was around 50 million tons 0-600 4043.42 4067.00 0.00 202.42 5899.58 0.00 0.00 14212.42

(mt), of which around 33 mt was met by

300-600 0.00 5869.61 758.14 12362.80 49294.31 15436.32 202.00 83923.18

imports, 85 percent of which came from

600-1200 1269.64 5165.48 482.61 2505.12 7144.89 4951.29 0.00 21519.03

Australia.

With the growth in steel demand to 0-1200 5313.06 26668.54 1707.13 36656.10 191377.59 30282.09 1492.64 293497.15

113.3 mt by 2016-17 from 65.61 mt in 2011- Source: Geological Survey of India (GSI)

12, coking coal demand in the country is set

30 Steel Insights, February 2013

SPECIAL feature

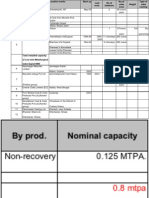

Estimated requirement of raw materials and other inputs by 2016-17 Massey, Banpu, Xstrata, Yanzhou, Glencore,

Anglo, Arch, Rio, James River. The major

Estimated Estimated Additional Requirement

Input Materials Unit

Consumption 2011-12 Consumption 2016-17 by 2016-17

supplier countries are Australia, US and

Canada.

Coking Coal Million Tons 43.2 90.2 47.0 The global trade of coking coal stood

Non-coking Coal Million Tons 35.3 28.4 - at around 260-280 mt in 2012. The big

three importers – China, Japan and India –

Iron Ore Million Tons 115.0 206.2 91.2

together accounted for around 155 mt of this

Natural Gas MMSCMD 7.2 13.541 6.341 market.

Ferro Alloys in ’000 tons 2152 3673 1521

As estimated by Merlintrade &

Consultancy, total seaborne trade would

Refractories Million Tons 1.29 1.97 0.69 increase to around 415 mt by 2020, of which

Source: Working group on Steel the top three importers – India, China and

Japan – would claim a share of 271 mt or 65

Nevertheless, almost all the major Indian imports will go up from current 30 mt to 90 percent. This, however, may be a conservative

steelmakers have embarked on very aggressive mt by 2015 surpassing Chinese coking coal estimate. If India can achieve its planned

expansion plans to increase installed capacity. imports. By comparison, China’s coking coal expansion, and Japan’s consumption does not

SAIL has aimed to increase its annual hot imports may be at most 70 mt by 2015. come down dramatically, the share of these

metal production capacity from the current “I think India will become a bigger three countries may go up further.

13.8 mt to 24 mt by FY13. importer than Japan and China, the current On the supply side, Australia would

Accordingly, the company’s coking coal leaders in importing coking coal,” Pervan was continue to dominate the market with

import could increase from current 13 to 14 quoted as saying. export of 255 mt in 2020, with a share of

mt to 21 mt by the next few years. Similarly, While ANZ estimate may seem to be a 61 percent, same as in 2010. While new

the annual coal consumption of JSW, the little on the higher side, another estimate by suppliers like Mongolia, which has started

country’s largest private sector steelmaker, Merlintrade & Consultancy Ltd put India’s feeding the Chinese market, would come up

will reportedly double from current 7.4 mt to coking coal imports at 90 mt in 2020. in due course, Australia’s domination would

14 mt by next two years. hardly wane. US, on the other hand, is likely

Even if the Indian steel sector fails to Global supply scenario to see a drop in exports; this however would

achieve the targeted 10 percent production Currently, the coking coal market is not impact the Indian companies which do

growth annually, coking coal consumption overwhelmingly dominated by mining giants not receive much of the material from that

by all the major steel companies would grow including BHP, Walter Resources, Peabody, country.

immensely by 2020. SAIL has targeted to

have a capacity of 60 mt by that year. RINL, Top met coal seaborne exporters (in mt)

another public sector unit, has chalked out

Country 2008 2009 2010 2020

an expansion from current 6.3 mtpa to 20

mtpa by 2020. JSW, on its part, has planned Australia 134.3 130.0 158.8 255.0

34 mtpa production by then, from 14.3 as US 35.3 29.9 47.8 25.0

of March 2011. Most of this expansion Canada 25.4 20.1 27.0 50.0

would be undertaken through Blast Furnace/

Others 25.6 22.5 30.5 85.0*

Basic Oxygen Furnace (BOF) route, which

require coking coal as primary raw material. Total 220.6 202.5 264.1 415.0

Attempts are being made by a few companies *Including: Colombia, Russia, Indonesia, Mongolia, New Zealand and Mozambique

to adopt the Corex/Finex technology,

whereby thermal coal can be directly used Top seaborne met coal importers (in mt)

for ore reduction and melting work. But the Country 2008 2009 2010 2020

initial investment requirement is substantial Japan 66.5 52.5 62.6 71.0

and there is significant technology barrier in China 6.9 37.0 53.0 110.0

terms of patent rights.

India 26.8 26.8 37.2 90.0

As a result, such prolific expansion in

India’s steel making capacity cannot but be South Korea 21.9 15.0 18.4 38.0

achieved without a huge surge in coking coal Brazil 17.9 15.0 18.4 38.0

imports. As estimated by Mark Pervan, Head Others 81.0 51.0 66.3 75.0

of commodity research at the Australia and Total 221.0 202.0 260.7 415.0

New Zealand Banking Group (ANZ), India

Source: Merlintrade & Consultancy Ltd

may triple coking coal imports as early as

2015. He estimates that India’s coking coal

Steel Insights, February 2013 31

SPECIAL feature

In coming years, experts say, the demand Tolgoi coal mine is a case in point. The Annual production capacity of

boom from China and India would lead to a aggressive bidding for properties coupled some players in India

demand-supply gap in global trade of coking with growing supply gap would invariably Annual production

Company

coal. This is particularly feared for premium lead to pricing pressure for this vital raw capacity (tons)

quality coking coal market, where there will material. Tirupathi Fuels Pvt ltd 110,000

be not enough resource to supply. The share United Coke Pvt Ltd

of high quality coking coal, in countries 2013 outlook Antai Balaji Coke 120,000

having significant coal deposits, is less than 1 Notwithstanding the long term expectations, Fairdeal suppliers 300,000

percent of proven reserves. The requirement the met coal market saw a softening of prices Narayani Coke 300,000

however is much above that percentage. in much of 2012. As of now, the big question

Also, there would be limited new Ennore Coke 180,000

is whether the spot prices in the international

production from countries like Mozambique, market will see a recovery in 2013. The Saurashtra Fuels 700,000

Indonesia and Mongolia, at least until 2015- analysts generally believe the prices would Krishna Coke

16. US may have already reached the stage of not show any major turnaround this year. Visa Steel 400,000

decline and is expected to see steady fall in Credit Suisse and Dahlman Rose & Co Bengal Energy Limited 600,000

exports, going forward. Canada may emerge see average prices remaining lower in the Carbonedge Industries 90,000

as a bigger player, but Australia’s shipping range of $171-180 per ton FOB Australia

Global Coke Pvt Ltd 600,000

constraints would pose a threat. when compared to 2012’s average of $191

A major factor leading to tightened supply OSD Coke Pvt Ltd

per ton FOB.

scenario could be the fast depletion of China’s While marginal improvements are Sathavahana Ispat Pvt Ltd 400,000

own reserves. Coking coal reserves comprise expected in terms of steel demand in 2013, BLA Industries

about 20 percent of the country’s total coal significant gains are thought to be unlikely. Uttam Galva 432,000

reserves, but in terms of production, its share Credit Suisse, for example, sees the met coal Maa Shakti Coke 1,100,000

is higher than that. According to industry market as “structurally well supplied”. It has Bhatia Coke & Energy Ltd 300,000

reports, the thick coal seams in Shanxi coal estimated that 2013 will see an excess of 10

mine is already showing significant thinning. Balaji Coke Industry Pvt Ltd 120,000

mt of met coal, so any gains should be “fairly

If the country decides to conserve its own Austral Coke & Projects

muted”.

resources for future, there would be massive Other banks appear to agree, though Gujarat NRE Coke pvt Ltd 1,434,000

pressure on the global market. This could differing in the magnitude of the over-supply, Shree Coke Pvt Ltd 110,000

be a likely scenario; given that the country’s which Morgan Stanley puts at 4 mt. Only Source: Insights Research

coking coal import has increased eight-fold Goldman Sachs sees a possible shortage of

in a gap of two years (2008-10). met coal, anticipating a net deficit of 1 mt

In the long run, the tightening of supply coal imports to make manufacture. Being

this year.

would intensify competition among the well aware of this weakness during contract

mining companies for tapping new sources. India Inc. looks elsewhere negotiations, Indian mills have embarked on

The recent fierce competition among mining an active hunt to diversify their coal supplies,

With insignificant coking coal reserves,

giants for long term rights of Mongolia’s and of late Mozambique has been the centre

India is substantially dependent on met

of their attention. Large mills such as JSPL,

JSW Ispat and Tata Steel are amongst the

Integrated steel plants with captive coke making plant (in mt)

big steel players to have secured supplies.

0.60 However logistical issues continue to

1.20 3.00

1.30 hamper Mozambique from becoming big

in the spot market, with supply estimates

2.50 2.60 recently downrated by some.

While India has Mozambique, China

has Mongolia, which since mid-2010 has

overtaken Australia as the top supplier of

2.50 met coal to China, contributing slightly more

than a third of Chinese imports (Australia

now supplies under 25%).

Some projects are also currently in the

pipeline to push landlocked Mongolian

Tata Steel Bhilai Bokaro RINL Durgapur Rourkela IISCO HCC to the seaborne market, with the

Source: Insights Research potential to give Australian miners a run

32 Steel Insights, February 2013

SPECIAL feature

currently facing huge challenge to meet its was the world's largest coke exporter in the

Major buyers in India coke requirements. Although most of the seaborne market (at 15 mtpa). While many

The major buyers in the Indian market integrated steel plants are already in the market participants feel that exports are

include the following players: process of increasing their coke making unlikely to revive to that level, a modest 6-8

capacities, the deficit of metallurgical coke in mt of coke is expected to be exported out of

1. Tata Steel

India is expected to increase from current 12 China this year.

2. Steel Authority of India Ltd (SAIL) mt to 25 mt by 2015. Applying a widely accepted coal-coke

3. Jindal Steel & Power Ltd (JSPL) Besides low production, the logistics conversion factor of 1.3, this potentially puts

4. Adhunik Limited sector poses a major challenge. There is an increase of approximately 7.8-10.4 mt on

5. Concast Limited urgent need to increase the number of ports to Chinese coking coal demand.

on the coast line and dredge the river ports However, this increase is unlikely to

6. Other secondary steel manufacturers

to reduce cargo movements through rail and jolt seaborne prices as much of it would be

road. sourced from Mongolia, which is closer to

for their money. However, all is not rosy in The internal logistics cost in India is very many Chinese coke ovens located in the

Mongolia, with unattractive regulatory and high. The local freight for 100 km is equal to inland provinces of Shanxi and Hebei.

fiscal developments proving something of a 5,000 mile sea freight in eastern India where Another possible spill-over effect of

disincentive. major steel projects are on. Also, pilferages China's new ruling on coke exports could

Other suppliers, such as the USA, have (to an extent of at least 1 percent) need to be a possible displacement of some coking

continued to play an active role in the seaborne be controlled. There is need to enhance the coal supplies elsewhere if importers decide

met coal market from time to time, but the berthing facilities and regulate the intra-port to decrease their captive coke making

country has always been a swing-supplier to transportation of imported cargo. Allocation operations and import Chinese met coke

Asian-Pacific markets, since its home ground of more rail rakes for the speedy movement instead. Nevertheless, whether this trend

still remains the Atlantic region. of coal is yet another pressing need. will actually catch up with the Indian

However, as demand conditions in Over and above all these, the delay in market is still a matter of guess, industry

Europe faltered in 2012 due to the continuing getting environmental clearances poses a sources said.

economic malaise, US suppliers actively

major hurdle in implementing new and

pursued Asian customers, particularly when

expansion projects.

they saw opportunities to be price competitive

with Australian suppliers.

China’s coke

card

Current trend in Indian coke market

While the Indian

Along with coking coal, India also suffers

industry struggles to

from inadequate domestic production of met

meet its growing met

coke. Currently, the demand deficit in local

market is around 13 mtpa. With the expected coke requirement,

increase in demand (to the tune of 15~16 a new development

mtpa in next 4-5 years), the deficit is likely in neighbouring

to increase to 28 mtpa. Import of coke into China has come to

India stood around 2.1 mt in 2011-12. The take the market by

slow steel market is keeping the LAM coke surprise. Recently,

market slow too at present. China has allowed

full liberalisation

Coke plants across India & for its metallurgical

capacities coke export sector – a

development which

Currently, coke plants in India have an

may have varied

installed capacity close to 30 mt. The

implications for the

integrated steel mills have their coke making

domestic coking coal

capacities around 19 mt. The secondary steel

consumption.

producers have captive installed capacity of

4 mt. Merchant coke plants have installed Prior to 2008,

capacity of 7.2 mt. when a 40 percent

export duty was

Challenges in meeting coke demand slapped on met

coke exports, China

The Indian steel industry is currently is

Steel Insights, February 2013 33

SPECIAL feature

Steel consuming sectors

maintain sluggish growth

Steel Insights Bureau the Reserve Bank of India (RBI) by 25 basis to industry sources and trade data.

points. In the fourth quarter (Q4) ending March

M

uch to the dismay of the Indian The growth trend has been a little better 2013, around 1,700 projects are scheduled

steelmakers, the steel consuming for the construction sector, where industrial to get commissioned in various industries

sectors in the country have and infrastructural projects worth `1.8 such as steel, gas transportation, power

continued with sluggish growth in recent trillion have already been commissioned generation and distribution. It is expected

months. This was in line with the slow during April-November, 2012-13, according that construction activity will be in full

growth of the economy which is expected to

post modest growth numbers in the current Automobile sector growth

fiscal.

The slow growth was particularly