Professional Documents

Culture Documents

Liebert DM Series Air Conditioner Tech Manual

Uploaded by

Mohran HakimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebert DM Series Air Conditioner Tech Manual

Uploaded by

Mohran HakimCopyright:

Available Formats

Precision Cooling

For Business-Critical Continuity™

Liebert® DM Series Air Conditioner

Technical Manual

Liebert_DM Series Air Conditioner

Technical Manual

Version V1.0

Revision date

BOM

Emerson Network Power provides customers with technical support. Users may contact the

nearest Emerson local sales office or service center and company headquarters.

Copyright © 2012 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen

China

Postcode: 518057

Customer Service Hotline: 4008876510

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Contents

Chapter 1 Preface ............................................................................................................................................................... 1

1.1 Special Requirements On The Equipment Room Environment ............................................................................ 1

1.2 Liebert_DM Series AC – Designed For Equipment Room .................................................................................... 1

Chapter 2 Overview ............................................................................................................................................................ 3

2.1 Appearance .......................................................................................................................................................... 3

2.2 Model Description ................................................................................................................................................. 3

2.3 Product Introduction .............................................................................................................................................. 3

2.4 Main Components ................................................................................................................................................. 4

2.4.1 Indoor Unit ................................................................................................................................................. 4

2.4.2 Outdoor Unit .............................................................................................................................................. 4

2.5 Options ................................................................................................................................................................. 5

2.5.1 Humidifier .................................................................................................................................................. 5

2.5.2 Heater ........................................................................................................................................................ 5

2.5.3 Remote Monitor ......................................................................................................................................... 5

2.5.4 Energy-Saving Card .................................................................................................................................. 5

2.5.5 Power SPD ................................................................................................................................................ 5

Chapter 3 Technical Parameter .......................................................................................................................................... 6

3.1 Technical Parameter Of The Indoor Unit .............................................................................................................. 6

3.2 Technical Parameter Of The Outdoor Unit............................................................................................................ 7

3.3 Mechanical Parameter .......................................................................................................................................... 7

3.3.1 Indoor Unit ................................................................................................................................................. 7

3.4 Outdoor Unit.......................................................................................................................................................... 8

3.5 Operation Environment ......................................................................................................................................... 9

Chapter 4 Application Guidline .......................................................................................................................................... 10

4.1 General Arrangement ......................................................................................................................................... 10

4.2 General Principles............................................................................................................................................... 10

4.3 Piping .................................................................................................................................................................. 11

4.4 Model Configuration ............................................................................................................................................ 12

4.5 Cooling Circulation .............................................................................................................................................. 12

Chapter 5 Micro-Processing controller .............................................................................................................................. 13

5.1 Appearance ........................................................................................................................................................ 13

5.2 LCD Screen ........................................................................................................................................................ 13

5.3 Control Buttons ................................................................................................................................................... 13

5.3.1 Function Description ................................................................................................................................ 13

5.3.2 Operation Example .................................................................................................................................. 14

5.4 Control Screen .................................................................................................................................................... 14

5.4.1 ON Screen ............................................................................................................................................... 14

5.4.2 Normal Screen......................................................................................................................................... 14

5.4.3 Password Screen .................................................................................................................................... 15

5.5 Control Logic ....................................................................................................................................................... 15

5.5.1 Cooling logic ............................................................................................................................................ 15

5.5.2 Heating Logic........................................................................................................................................... 16

5.5.3 Dehumidifying Logic ................................................................................................................................ 16

5.5.4 Humidifying Logic .................................................................................................................................... 18

5.5.5 Outdoor Fan Control ................................................................................................................................ 18

5.5.6 Economy Mode Control ........................................................................................................................... 19

5.5.7 Sleep Mode Control ................................................................................................................................. 19

5.5.8 Host/Standby Unit Control ....................................................................................................................... 19

5.6 Alarm Function .................................................................................................................................................... 20

5.6.1 Alarm Category........................................................................................................................................ 20

5.6.2 Alarm State And History .......................................................................................................................... 20

5.6.3 Alarm Prerequisites And Handling Methods ............................................................................................ 20

5.7 Other Functions .................................................................................................................................................. 23

5.7.1 Real-Time Clock ...................................................................................................................................... 23

5.7.2 Operating Record .................................................................................................................................... 23

5.7.3 Parameter Protection ............................................................................................................................... 23

5.7.4 Password Protection ................................................................................................................................ 23

5.7.5 Shutdown Mode ....................................................................................................................................... 23

5.7.6 Diagnosis Output ..................................................................................................................................... 24

5.7.7 Sensor Calibration ................................................................................................................................... 24

5.7.8 Deployment Management........................................................................................................................ 24

Appendix 1 Menu Structure ............................................................................................................................................... 25

Appendix 2 Wiring Diagram............................................................................................................................................... 26

Appendix 3 Glossary ......................................................................................................................................................... 28

Chapter 1 Preface 1

Chapter 1 Preface

This chapter mainly introduces the special requirements on the equipment room environment and the features and

advantages of Liebert_DM series air conditioners (AC for short).

1.1 Special Requirements For The Equipment Room Environment

The precise environment control is very important for the operation of the computers , therefore, the computers have

strict requirements for the equipment room environment, which cannot be achieved by the commercial air conditioners

designed for comfort. The relevant requirements mainly include the following four aspects.

Temperature control: Huge amount of sensible heat is generated when computers and exchanges are operating in

the equipment room, whose density is 6 to 10 times of that of the general offices. To ensure that the computers and the

devices exert their optimal effect, the temperature of the equipment room is best controlled within 24°C±1°C; This

requires that the AC units have sufficient cooling capacity and timely response regulatory capacity to cope with drastic

changes in temperature, which cannot be implemented by the commercial air conditioners.

Humidity control: In computer room, ultra-high or ultra-low humidity will damage the computers. The ultra-high

humidity makes the air moisture condense to form condensation water in the computers, resulting in short-circuit or

damage of the host hardware. The ultra-low humidity will make the static electricity generate in the computer room,

making the computers unable to operate or even crash. The commercial air conditioners cannot control the humidity

within the required range.

Airflow / cleanliness control: Computers and exchanges will produce huge sensible heat during the operation. To

eliminate the heat rapidly, The ACs are required to have large enough large cooling cycle airflow and long blowing

distance. Besides, because of the strict requirement of air cleanliness, the AC should provide an airflow equivalent to

the ventilating rate of 30 times per hour, so as to filter the air. The commercial ACs cannot achieve these.

All-year-round running: The commercial ACs (cooling operation) are only used in summer and they only run for 8 ~

10 hours each day. In the equipment room, however, the ACs are required to work all year round even in winter when

the temperature reached -34°C outdoors.

1.2 Liebert_DM Series AC – Designed For Equipment Room

The Liebert_DM series AC includes units with a cooling capacity of 7.5kW and 12.5kW. You can configure them freely

to meet different requirements of large-, medium-, and small-sized equipment rooms and base stations. Besides, the

AC has precise temperature/ humidity control and reliability design, fully meeting the special use environment

requirement of the equipment rooms.

Special development: As a part of the integration solution to equipment room, the Liebert_DM series ACs are

specially designed for the electrical devices and provides a proper environment for the running of the precise devices,

such as sensitive devices, industry process devices, communication devices and computers.

Considerate design: Being concerned about inter-device practical applications, the Liebert_DM series ACs are

designed to keep the overall layout between devices and ensure onsite installation and maintenance.

2 2

Saving space: The Liebert_DM series AC occupies 0.3 m and a total of 1 m area is required plus the maintenance

space.

Precise control: The precise control system of the Liebert_DM series ACs implement precision control over indoor

environment, guaranteeing the safe working and stable running of devices to a maximum degree. For the indoor unit

control panel, see Figure 1-1.

Liebert DM Series Air Conditioner Technical Manual

2 Chapter 1 Preface

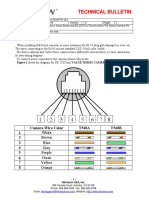

J13 Board power

supply input J34 Temp/Hum detection board J23 Pressure sensor

J14 Monitoring

ON

J12 Display board power supply

J18 SCR output J39 Display board data line

to contactor J21 Switch input, such as high

pressure switch

J31 DI input power supply

J28 Output, such as J19 Remote switch

electric heater output

Figure 1-1 Control board of the indoor unit

Outstanding man-machine interface: The Liebert_DM series ACs provide a large Chinese/English LCD, a

user-friendly man-machine interface and an expert diagnosis system, as well as implement multi-level password

protection (avoid misoperation) and intelligent display of running states.

High reliability: Relying on the excellent quality and considerate services of Emerson, the Liebert_DM series ACs

ensure 24-hour reliable running all year round.

Strong adaptability to power grid: The Liebert_DM series ACs allow a wide range of voltage and provide the

following distinctive functions: unique phase loss protection, phase-sequence detection and protection, automatic

high-voltage & low-voltage detection and protection, self-recovery upon power failure.

All-weather operation: According to the distinct heating load feature of equipment rooms, the Liebert_DM series ACs

implement 24-hour running all year round in temperature ranging from -15°C to +45°C. If a Lee-Temp outdoor unit is

configured, the allowed running temperature ranges from -34°C to +45°C.

Strong network management: Being configured with a standard RS485 monitor interface, the Liebert_DM series

ACs implement flexible automatic switchover between active and standby devices, work shift, remote turn-off and

turn-on, remote alarm, and fault query and troubleshooting over standard telecommunication protocols.

Easy maintenance: The Liebert_DM series ACs provide a full front maintenance structure, facilitating maintenance.

Table 1-1 describes the differences between the Liebert_DM series ACs and commercial ACs.

Table 1-1 Differences between the Liebert_DM series ACs and commercial ACs

Design focus Liebert_DM series AC Commercial AC

Precision ±1°C; ±1%RH Generally ±3°C

Temperature control Humidifying and dehumidifying control None in general

Monitoring Local and romote monitoring None

All-rear-round continually operating All-year-around cooling No cooling needed in winter

Testing before delivery Strict requirement Simple testing

Control design Precise control CPU

Cleanliness High Low

Liebert DM Series Air Conditioner Technical Manual

Chapter 2 Overview 3

Chapter 2 Overview

This chapter expounds the appearance, model description, product introduction, components and variety of accessory

options.

2.1 Appearance

Taking the indoor unit of the Liebert_DM series air conditioner as an example, the appearance as shown in Figure 2-1.

Figure 2-1 Indoor unit of the air conditioner

2.2 Model Description

The model description of the air conditioner is shown in Figure 2-2.

DM E 07 M C T 1

1: Standard; 2: High efficiency

Version code

C: cooling only; O: with heater; H: with heater and humidifier

Input power supply. M: 380V-3-ph-50Hz

Cooling capacity. 07: 7.5kW ; 12: 12.5kW

E: indoor unit; C: outdoor unit; L: Lee-Temp outdoor unit

Liebert_D series air conditioner

Figure 2-2 Model description

2.3 Product Introduction

The Liebert_DM AC is a small precise environment control system, specially designed for cooling the electrical

devices. It is applicable to environment control in equipement room and computer room. Featuring high reliability, it

can maintain a favorable environment for precise devices such as sensitive devices, industry process devices,

communication devices and computers.

The cooling kit is provided as standard and it can precisely control the ambient temperature. The heater and humidifier

are provided as options and they can precisely control the ambient humidity. If the AC unit is only available for cooling,

the options are not needed.

Liebert DM Series Air Conditioner Technical Manual

4 Chapter 2 Overview

The Liebert_DM AC provides a micro-processing controller that can automatically switch over to the required function

(cooling or heating, dehumidifying or humidifying), based on the programmed setpoints and room ambient conditions.

Each Liebert_DM AC consists of an indoor unit and an outdoor unit. Both units are installed on the floor separately.

Indoor unit

The Liebert_DM AC includes units with a cooling capacity of 7.5kW and 12.5kW, which are applicable to power supply

of 380V, 3-ph. You can select them according to the actual equipment room conditions.

Outdoor unit

The outdoor unit adopts air cooled mode. It is classified into two models: standard model and Lee-Temp model. The

Lee-Temp model can be used at lower temperature (see Table 1-1) than the standard model.

2.4 Main Components

2.4.1 Indoor Unit

The indoor unit consists of evaporator, compressor, fan, micro-processing controller, thermal expansion valve, strainer,

filter, heater (optional), humidifier (optional) and surge protective devices (SPD, optional). For option introduction, refer

to 2.5 Options.

Evaporator

Adopt a fin-tube heat exchanger with high efficiency. The distributor is designed and verified according to individual

model to ensure that the refrigerant is distributed evenly in each loop, improving the efficiency of the heat exchanger to

a great extent.

Compressor

Adopt a compressor with high efficiency ratio. It features low vibration, low noise and high reliability.

Fan

Adopt a centrifugal fan with high efficiency and high reliability. It features large airflow, long blowing distance, direct

driving and easy maintenance.

Micro-processing controller

Provide a simple-operation user interface with multi-level password protection, self-recovery upon power failure,

high-voltage & low-voltage protection, phase loss protection, automatic phase-sequence switching upon anti-phase

and rotate speed control of the outdoor fan. The expert-level fault diagnose system can automatically display current

fault information to facilitate equipment maintenance by maintenance personnel.

Thermal expansion valve

Adopt a thermal expansion valve with external equalizer type. It collects temperature and pressure signals at the same

time to accurately regulate the refrigerant flow.

Strainer

Filtrate the impurities generated during long-term system operation and ensure normal system operation.

Filter

Adopt nylon filter material with big mesh for Liebert_DM AC. The filter features compact structure and easy

maintenance. It can be washed repeatedly.

2.4.2 Outdoor Unit

The outdoor unit consists of fan and condenser. Other than the above components, the Lee-Temp model also includes

a low-temperature unit.

Fan

Adopt axial flow blades with low noise. The single-phase motor with high performance is customized based on the

power grid of base stations, so it can work over a wide voltage range with high reliability.

Liebert DM Series Air Conditioner Technical Manual

Chapter 2 Overview 5

Condenser

Adopt a fin-tube heat exchanger with high heat dissipation and wavy fins. It is free of dust accumulation, and can be

easily cleaned and maintained.

Low-temperature unit

Make the AC unit operate in cooling mode normally at the lowest outdoor temperature of -34°C.

2.5 Options

2.5.1 Humidifier

The humidifier can add pure water vapor (up to 2.5kg/hour) into the room to control the indoor humidity within ranges

required by devices and computer.

The humidifier consists of a steam canister with automatic flushing control function, inlet tube, drain tube, solenoid

valve and steam distributor.

Note

1. The electrode humidifier should be installed and tested in factory.

2. The Liebert_DM AC can control the ambient humidity only after a humidifier is installed.

2.5.2 Heater

A ceramic heater with positive temperature coefficient can be selected. It is safe and reliable. When the surface

temperature is too high, it will reduce the heating power to avoid danger caused by over-temperature. A temperature

switch is provided on the surface of the heater, and it will cut off the power of the heater when the surface temperature

is too high. When the surface temperature decreases to normal, the temperature switch will restore the operation of

the heater automatically.

2.5.3 Remote Monitor

The Liebert_DM AC communicates with the host computer through a configured RS485 port and receives the control

of the host software. You can also select and configure a monitoring card to realize different monitoring functions. For

the descriptions of the host monitoring software SiteMonitor developed by Emerson, refer to

Appendix 3 SiteMonitor Software Introduction.

2.5.4 Energy-Saving Card

The Liebert_DM AC can monitor the maximum room temperature with the energy-saving card located outside the unit

cabinet. The card is placed in position with high heat load and temperature. Up to four cards can be used for an AC

unit. When the temperatures measured by all energy-saving cards are lower than the setpoint in ‘Sleep Mod’ and only

indoor fan is running, if the ‘Sleep Mod’ is set to ‘ENAB’, the AC unit will turn off the indoor fan and enter the sleep

mode for saving the energy.

2.5.5 Power SPD

The power SPD is used for second level (C level) lightning over-voltage protection of the AC power. It can be

maintained easily and provides status indicating and alarm function.

Note

The power SPD should be installed in factory.

Liebert DM Series Air Conditioner Technical Manual

6 Chapter 3 Technical Parameter

Chapter 3 Technical Parameter

This chapter expounds the technical parameter, mechanical parameter and operating environment of the

indoor/outdoor unit of the Liebert_DM series AC.

3.1 Technical Parameter Of The Indoor Unit

Table 3-1 Technical parameter of DME07 series indoor unit

Model

Type DME07 DME07 DME07 DME07 DME07 DME07

MCT1 MOT1 MHT1 MCP1 MOP1 MHP1

Cooling Cooling

24°CdB 7500 7500 7500 7500 7500 7500

capacity and capacity

sensible Sensible

cooling 50%RH cooling 6500 6500 6500 6500 6500 6500

capacity (kW) capacity

Standard airflow (m3/h) 1800 1800 1800 1800 1800 1800

Number 1 1 1 1 1 1

Fan

Static pressure outside

0 0 0 0 0 0

the fan (Pa)

Compressor Number 1 1 1 1 1 1

Front face area (m2) 0.25 0.25 0.25 0.25 0.25 0.25

Evaporator coil

Face air velocity (m/s) 2 2 2 2 2 2

Electric heater Power (kW) - 3.2 3.2 - 3.2 3.2

Electrode Humidifier water rate

- - 1.5 - - 1.5

humidifier (kg/h)

Front filter size (mm, 1 485 × 845 485 × 845 485 × 845 485 × 845 485 × 845 485 × 845

pcs) ×8 ×8 ×8 ×8 ×8 ×8

Filter Side filter size (mm, 1 312 × 317 312 × 317 312 × 317 312 × 317 312 × 317 312 × 317

pcs) ×8 ×8 ×8 ×8 ×8 ×8

Number 3 3 3 3 3 3

Liquid return pipe ID

9.52 9.52 9.52 9.52 9.52 9.52

(mm)

Discharge pipe ID (mm) 12.7 12.7 12.7 12.7 12.7 12.7

Port size Humidifier

- - 19 - - 19

Charging pipe OD (mm)

Condensed water drain

20 20 20 20 20 20

pipe OD (mm)

Net weight (kg) 90 92 95 90 92 95

Electrical Max. current (A) 6 8 20 6 8 20

parameter Air breaker 32 32 32 32 32 32

Note: all the cooling capacity is nominal, ±5% error exists in the actual capacity

Table 3-2 Technical parameter of DME12 series indoor unit

Model

Type DME12 DME12 DME12 DME12 DME12 DME12

MCT1 MOT1 MHT1 MCP1 MOP1 MHP1

Cooling Cooling

24°CdB 12500 12500 12500 12500 12500 12500

capacity and capacity

sensible Sensible

cooling 50%RH cooling 10200 10200 10200 10200 10200 10200

capacity (kW) capacity

Standard airflow (m3/h) 2800 2800 2800 2800 2800 2800

Number 1 1 1 1 1 1

Fan

Static pressure outside

0 0 0 0 0 0

the fan (Pa)

Liebert DM Series Air Conditioner Technical Manual

Chapter 3 Technical Parameter 7

Compressor Number 1 1 1 1 1 1

Front face area (m2) 0.37 0.37 0.37 0.37 0.37 0.37

Evaporator coil

Face air velocity (m/s) 2.1 2.1 2.1 21 2.1 2.1

Electric heater Power (kW) - 3.2 3.2 - 3.2 3.2

Electrode Humidifier water rate

- - 2.5 - - 2.5

humidifier (kg/h)

Front filter size (mm, 1 578 × 914 578 × 914 578 × 914 578 × 914 578 × 914 578 × 914

pcs) ×8 ×8 ×8 ×8 ×8 ×8

Filter Side filter size (mm, 1 376 × 427 376 × 427 376 × 427 376 × 427 376 × 427 376 × 427

pcs) ×8 ×8 ×8 ×8 ×8 ×8

Number 3 3 3 3 3 3

Liquid return pipe ID

12.7 12.7 12.7 12.7 12.7 12.7

(mm)

Discharge pipe ID (mm) 16 16 16 16 16 16

Port size Humidifier

- - 19 - - 19

Charging pipe OD (mm)

Condensed water drain

20 20 20 20 20 20

pipe OD (mm)

Net weight (kg) 140 142 145 140 142 145

Electrical Max. current (A) 10.5 10.5 22 10.5 10.5 22

parameter Air breaker 32 32 32 32 32 32

Note: all the cooling capacity is nominal, ±5% error exists in the actual capacity

3.2 Technical Parameter Of The Outdoor Unit

Table 3-3 Technical parameter of the standard outdoor unit

Model

Item

DMC07WT1 DMC12WT1

Airflow (CMH) 3800 7300

Condenser coil CSA (m2) 0.73 1.1

Number of the condenser coil row 2 2

Motor power (W) 170 340

Operating temperature range (°C) -15°C ~ +45°C -15°C ~ +45°C

Refrigerant charge quantity (g) 500 1000

Size of the liquid pipe (mm) 9.52 12.7

Size of the discharge pipe (mm) 12.7 16

Table 3-4 Technical parameter of the Lee-Temp outdoor unit

Model

Item

DML07W1 DML12W1

Airflow (CMH) 3800 7300

Condenser coil CSA (m2) 0.49 0.98

Number of the condenser coil row 2 2

Motor power (W) 150 300

Operating temperature range (°C) -34°C ~ +45°C -34°C ~ +45°C

Refrigerant charge quantity (g) 4870 7150

Size of the liquid pipe (mm) 9.52 12.7

Size of the discharge pipe (mm) 12.7 16

3.3 Mechanical Parameter

3.3.1 Indoor Unit

The mechanical parameters of the indoor unit are listed in Figure 3-1 and Table 3-6.

Liebert DM Series Air Conditioner Technical Manual

8 Chapter 3 Technical Parameter

600 50

510 38 0

5

1850

1750

510 600

510

600

DME07kW DME12kW

Figure 3-1 Dimensions of the indoor unit (unit: mm)

The shadows in Figure 3-1 indicate a reasonable installation and service space. For 7.5kW units, 510mm must be

reserved to facilitate maintenance; For 12.5kW unit, 600mm must be reserved to facilitate maintenance.

The AC unit equipped with a heater should be kept a distance of minimum 150mm from combustible substance. When

testing the AC unit, keep the external static pressure below 150Pa lest the air volume becomes too low and the heater

becomes too hot.

3.4 Outdoor Unit

The mechanical parameters of the outdoor unit are shown in Figure 3-2, Figure 3-3 and Table 3-6.

352 787

352 787

1240

829

Figure 3-2 Dimensions of standard outdoor unit (unit: mm)

Liebert DM Series Air Conditioner Technical Manual

Chapter 3 Technical Parameter 9

352 103

7

352 103

7

1240

829

575

575

Figure 3-3 Dimensions of Lee-Temp outdoor unit (unit: mm)

Table 3-5 Mechanical parameters of indoor unit and outdoor unit

Model Cooling capacity (kW) Dimensions (W × D × H, mm) Net weight (kg)

DME07*** 7.5 510 × 385 × 1750 90

Indoor unit

DME12*** 12.5 600 × 500 × 1850 145

DMC07WT1 - 787 × 352 × 829 40

DMC12WT1 - 787 × 352 × 1240 60

Outdoor unit

DML07W1 - 1037 × 352 × 829 53

DML12W1 - 1037 × 352 × 1240 95

3.5 Operation Environment

The operation environment requirements are listed in Table 3-7.

Table 3-6 Operation environment requirements

Item Requirements

The maximum equivalent horizontal distance between the indoor unit and outdoor unit[1]: 50m;

Installation position

Vertical distance ΔH[2]: -5m ≤ ΔH ≤ 20m

Indoor unit: vertical mode; mounting base ≥ 150mm;

Installation mode

outdoor unit: horizontal airflow mode

Indoor: 0°C ~ 40°C

Ambient temperature

Outdoor: standard model, -15°C ~ +45°C; Lee-Temp model, -34°C ~ +45°C

Ambient humidity 30%RH ~ 80%RH

Protection level Outdoor unit: IPX4

Altitude < 1000m. Derating is required when the altitude exceeds 1000m

Operation voltage range 380V (-15% ~ +15%), settable according to different environments, the error is 3%

Note:

[1]: The value is positive if the outdoor unit is installed above the indoor unit; negative if the indoor unit is installed above the

outdoor unit.

[2]: ΔH = Altitude of the outdoor unit - Altitude of the indoor unit

[3]:Total transportation and storage time should not exceed six months. Otherwise, the performance needs to be re-calibrated

Liebert DM Series Air Conditioner Technical Manual

10 Chapter 4 Application Guidline

Chapter 4 Application Guidline

This chapter mainly introduces the general arrangement, general principle, piping, model configuration and cooling

cycle.

4.1 General Arrangement

The general system arrangement diagram is shown in Figure 4-1. The standard pipe sizes are shown in Table 4-1.

Figure 4-1 General arrangement diagram

Note

1. : Factory piping.

2. : Field piping (by technicians).

3. *: Check valve and traps are optional and not supplied by Emerson. But they are recommended for normal system operation

and easy maintenance. They should be installed on site by technicians.

4. +: Solenoid valve is a part of extended piping kit.

Table 4-1 Standard pipe sizes

Actual cooling capacity Pipe length (m) Discharge pipe OD Liquid pipe OD

7.5kW unit 5 1/2” (12mm) 3/8” (10mm)

Liebert_DM series

12.5kW unit 5 5/8” (16mm) 1/2” (12mm)

4.2 General Principles

1. Use copper pipes with quick thread connector to connect the indoor unit and the outdoor unit. If the pipe length

exceeds the standard pipe length (see Table 4-1) and straight copper pipe is used, piping joints must be brazed.

2. Follow standard industry procedures in selection and placement of pipe, system evacuation and charging with

refrigerant (only when pipeline is too long). The standard refrigerant of the AC unit is R22.

3. Give considerations to pipeline pressure drop, oil return to the compressor, to avoid oil leakage and clogging in parts

of the system and minimize noise and vibration to the greatest extend.

4. Consult Emerson before installation on whether measures such as using extended piping kit are needed, if the

equivalent length exceeds 50m, or if the vertical distance between the indoor unit and the outdoor unit exceeds the

values in Table 4-2.

Liebert DM Series Air Conditioner Technical Manual

Chapter 4 Application Guidline 11

Table 4-2 Vertical distance between indoor unit and outdoor unit

Relative position Value

Outdoor unit installed higher than indoor unit Maximum: 20m

Outdoor unit installed lower than indoor unit Maximum: 5m

5. The equivalent length of each part is given in Table 4-3. The resistance loss caused by elbows and valves has been

taken into consideration. The installer should confirm if these values are appropriate for site conditions.

Table 4-3 Equivalent length of each part

Equivalent length (m)

Liquid pipe OD (inch)

90° elbow 45° elbow T-type three way

3/8 0.21 0.10 0.76

1/2 0.24 0.12 0.76

5/8 0.27 0.15 0.76

3/4 0.3 0.18 0.76

7/8 0.44 0.24 1.1

1-1/8 0.56 0.3 1.4

4.3 Piping

All equipment must be installed vertically. The Liebert_DM AC is available in two installation modes: outdoor unit

installed higher than indoor unit and indoor unit installed higher than outdoor unit. See Figure 4-2 and Figure 4-3 for

details.

Outdoor unit

Liquid pipe (not be exposed to sun)

Indoor unit

Max. 20m

Trap

Protection Isolataion Humidifier canister water

7.5m

tube floor supply pipe (to water tap)

Sealed Discharge pipe (slope) Insulation Floor Condensation water

1:200 material drain pipe (to outdoor)

1:200

Figure 4-2 Outdoor unit above indoor unit

Liebert DM Series Air Conditioner Technical Manual

12 Chapter 4 Application Guidline

Indoor unit

Protection tube

Discharge pipe (slope)

1:200 Humidifier canister water

Sealed Isolation floor supply pipe (to water tap)

Liquid pipe (not be

exposed to sun)

Min. 5m

Outdoor unit

Insulation Floor Condensation water

material drain pipe (to outdoor)

1:200

Figure 4-3 Indoor unit above outdoor unit

4.4 Model Configuration

Table 4-4 Configuration of the indoor unit and the outdoor unit

Indoor unit Outdoor unit

Cooling

Main power With electric With humidifying Standard Lee-Temp

capacity Single cooling

heating and heating model model

7.5kW DME07MCT(P)1 DME07MOT(P)1 DME07MHT(P)1 DMC07WT1 DML07W1

380V/3P/50Hz

12.5kW DME12MCT(P)1 DME12MOT(P)1 DME12MHT(P)1 DMC12WT1 DML12W1

4.5 Cooling Circulation

As shown in Figure 4-4, the compressor (1) presses the high-temperature gaseous refrigerant into the air-cooled

condenser (2). The refrigerant is condensed as fluid in the condenser and sent to the evaporator (4) after being

throttled by the thermostatic expansion valve (3). In the evaporator (4), the refrigerant performs heat exchange with

the indoor air that is driven and circulated by the indoor fan (5) and then evaporates. The refrigerant is sent back to the

compressor (1) to start a new circulation. The system adjusts the rotation speed of the outdoor fan (6) to retain the

discharge pressure normal.

The compressor (1) is configured with a crankcase heating strip to prevent the refrigerant from flowing back from the

condenser in summer. This can protect the compressor from liquid strike during startup.

Figure 4-4 Schematic diagram of the system

Liebert DM Series Air Conditioner Technical Manual

Chapter 5 Micro-Processing Controller 13

Chapter 5 Micro-Processing controller

This chapter gives a detailed description on appearance, LCD screen, control buttons, control screen, control logic,

alarm function of the micro-processing controller of the Liebert_DM AC.

5.1 Appearance

The micro-processing controller panel is shown in Figure 5-1.

Figure 5-1 Micro-processing controller panel

5.2 LCD Screen

The LCD screen displays English menus with white backlight. When the system is operating normally, it displays the

current temperature & humidity (whether to display humidity is optional. Only the unit configured with a humidifier can

display humidity), unit output status (cooling, heating, dehumidifying and humidifying), unit status (single, host,

standby), unit operation status (running, standby, locked), alarm information and current date & time, as shown in

Figure 5-2.

21°C Heat SIG

50%rh Hum RUN

High Hum 1/4

2012/01/01 00:00

Figure 5-2 LCD screen

More detailed operating status of certain component and alarm information are available from the Main Menu screen.

The selected menu item will be highlighted while browsing. The digit to be changed will be highlighted while you are

changing setting.

5.3 Control Buttons

5.3.1 Function Description

The micro-processing controller provides five control buttons, as shown in Figure 5-3.

ON/OFF button

Up button

Enter button

Down button

Esc button

Figure 5-3 Control keypad

The functions of the control buttons are described in Table 5-1.

Table 5-1 Function descriptions of control buttons

Control button Function descriptions

Liebert DM Series Air Conditioner Technical Manual

14 Chapter 5 Micro-Processing Controller

ON/OFF button Press this button for 3s to turn on or off the unit

Enter button (ENT) Enter the selected menu screen. Validate the parameter setting value

Exit the current menu and return to the Normal screen or previous menu screen. Abort parameter change;

Esc button (ESC)

silence the audible alarm

Move the cursor up or increase the parameter value. For a toggle selection: scroll through the options. For a

Up button

multi-screen menu: scroll up the screen

Move the cursor down or decrease the parameter value. For a toggle selection: scroll through the options.

Down button

For a multi-screen menu: scroll down the screen

5.3.2 Operation Example

Example 1: Inputting password to enter the Main Menu

After the unit is started up, you can enter the Main Menu through conducting the following operations on the Normal

screen.

1. Press the Enter button to enter the Password screen.

2. Press the Enter button to highlight the input data field in the Password screen.

3. Press the Up or Down button to change the current password number.

4. Press the Enter button to confirm the password and enter the Main Menu screen.

Example 2: changing parameters

Taking Hi Temp in Alarm Output screen as an example, the procedures are as follows:

1. Press the Up or Down button to move the cursor on the Alarm Menu in the Main Menu screen.

2. Press the Enter button to enter the Alarm Menu.

3. Press the Up or Down button to move the cursor on Alarm Output in the Alarm Menu screen.

4. Press the Enter button to enter the Alarm Output screen.

5. Press the Up or Down button to move the cursor on Hi Temp.

6. Press the Enter button to highlight the parameter field of Hi Temp.

7. Press the Up or Down button to select the parameter option.

8. After selecting, press the Enter button to confirm. The parameter will take effect.

9. Press the Esc button to return to the previous menu screen.

Note

After changing the parameter, if you do not press the Enter button to validate the changed parameter, the change will be invalid.

5.4 Control Screen

5.4.1 ON Screen

After the AC unit is powered on, the LCD screen will display the ON screen, as shown in Figure 5-4.

Connecting

Please wait...

Figure 5-4 ON screen

5.4.2 Normal Screen

After the AC unit is powered on, the Normal screen will be displayed after 10 seconds (default) for heat startup delay or

through pressing the Enter button directly, as shown in Figure 5-5. The Normal screen displays the following

information: the current temperature and humidity, unit operation state (cooling, heating, dehumidifying, humidifying),

unit mode (single, host, standby), unit operation status (running, standby, locked, off, sleep), alarm information and

current date & time.

Liebert DM Series Air Conditioner Technical Manual

Chapter 5 Micro-Processing Controller 15

21°C Heat SIG

50%rh Hum RUN

No alarm 0

2012/01/01 00:00

Figure 5-5 Normal screen

5.4.3 Password Screen

Press the Enter button on the Normal screen, and the Password screen will appear, as shown in Figure 5-6.

Password: 1***

Figure 5-6 Password screen

Three levels of passwords are provided for accessing the menus. The detailed descriptions are listed in Table 5-2.

Table 5-2 Password level

Password level User Initial password Remark

Browse all menu information. Only set temperature and

Level 1 General operator 0001 humidity setpoints (see Figure 5-12) and cannot change any

values and settings

Level 2 Maintenance personnel - Set all parameters

Level 3 Factory technician - -

For detailed operation on entering the password, refer to 5.3.2 Operation Example. If entering a wrong password, you

can only view the menu, but cannot change the settings. In this case, you can press the Esc button to return to the

Normal screen, and then press the Enter button to enter the Password screen again.

Note

If pressing the Enter button in the Password screen instead of inputting any password, you can only view the menu settings but

cannot change any parameters.

5.5 Control Logic

5.5.1 Cooling logic

When the actual temperature = set temperature + temperature precision value, the cooling requirement reaches

100%.

When the actual temperature = set temperature, the cooling requirement is 0%.

When the actual temperature rises to the degree corresponding to the 100% cooling requirement, cooling starts; when

the actual temperature drops to the degree corresponding to the 0% cooling requirement, cooling stops (the

compressor is turned off).

Figure 5-7 shows the cooling logic diagram.

Liebert DM Series Air Conditioner Technical Manual

16 Chapter 5 Micro-Processing Controller

The compressor is The compressor

turned off is turned on

Indoor temperature

0% +100%

Set point

Figure 5-7 Cooling logic

5.5.2 Heating Logic

When the actual temperature = set temperature - temperature precision value, the heating requirement reaches 100%.

When the actual temperature = set temperature, the heating requirement is 0%.

When the actual temperature drops to the degree corresponding to the 100% heating requirement, heating starts;

when the actual temperature rises to the degree corresponding to the 0% heating requirement, heating stops (the

electronic heater is turned off).

Figure 5-8 shows the heating logic diagram.

Electric heater Electric heater

is turned on is turned off

Indoor temperature

-100% 0%

Set point

Figure 5-8 Heating logic

5.5.3 Dehumidifying Logic

1. Relative humidity control logic

Dehumidifying is activated when the cooling requirement is smaller than 125% and the dehumidifying requirement is

larger than 100%.

Dehumidifying is deactivated when the dehumidification requirement is no larger than 50%.

Figure 5-9 shows the dehumidifying activation and deactivation requirements.

Exit

Enter dehumidifying

dehumidify-

mode

ing mode

Indoor humidity

+50% +100%

Set point

Figure 5-9 Dehumidifying activation and deactivation requirements

Liebert DM Series Air Conditioner Technical Manual

Chapter 5 Micro-Processing Controller 17

In the dehumidifying mode, the fan switches to high gear immediately when the cooling requirement is larger than

125%. The fan switches back to low gear when the temperature drops normal.

Figure 5-10 shows the high/low gear switch diagram of the fan in the dehumidifying mode.

Switch to

Switch to low gear

high gear

Indoor

temperature

Set point +125%

Figure 5-10 High/low gear switch diagram of the fan in the dehumidifying mode

In the temperature compensation mode, the compressor is turned on when the cooling requirement is larger than 0%

and it is turned off when the cooling requirement is smaller than -100%; the electronic heater is turned on when the

cooling requirement is smaller than 0% and it is turned off when the cooling requirement is larger than 25%.

Figure 5-11 shows the control logic of the compressor in a) and the control logic of the electronic heater in b).

The

The compressor The electric heater The electric heater

compressor

is turned on is turned on is turned off

is turned off

-100% Indoor +25% Indoor

Set point temperature Set point temperature

a) Control logic of the compressor b) Control logic of the electronic heater

Figure 5-11 Dehumidification logic in the temperature compensation mode

In the non-temperature compensation mode, the compressor is turned on and the electronic heater is turned off when

the cooling requirement is no smaller than 0%; the compressor is turned off and the electronic heater is turned on

when the cooling requirement is smaller than -100%.

Figure 5-12 shows the control logic of the compressor in a) and the control logic of the electronic heater in b).

The The The electric The electric

compressor compressor heater is heater is

is turned off is turned on turned on turned off

-100% Indoor -100% Indoor

Set point temperature Set point temperature

a) Control logic of the compressor b) Control logic of the electronic heater

Figure 5-12 Dehumidifying logic in the non-temperature compensation mode

2. Absolute Humidity Control Logic

If absolute humidity control logic is used, users should calculate the absolute humidity based on the actual

temperature and humidity and perform humidity control by referring to 1. Relative humidity control logic in this section.

Liebert DM Series Air Conditioner Technical Manual

18 Chapter 5 Micro-Processing Controller

5.5.4 Humidifying Logic

1. Relative humidity control logic

When the actual humidity = set humidity - humidity precision value, the humidification requirement reaches 100%.

When the actual humidity = set humidity, the humidification requirement is 00%.

When the actual humidity drops to the value corresponding to the 100% humidification requirement, humidification

starts; when the actual humidity rises to the value corresponding to the 0% humidification requirement, humidification

stops.

Figure 5-13 shows the humidification logic diagram.

The The

humidifier is humidifier is

turned on turned off

0%

-100% Indoor

Set point temperature

Figure 5-13 Humidification logic

2. Absolute humidity control logic

If absolute humidity control logic is used, users should calculate the absolute humidity based on the actual

temperature and humidity and perform humidity control by referring to 1. Relative humidity control logic in this section.

5.5.5 Outdoor Fan Control

1. If the pressure sensor is faulty, the fan operates at full speed.

2. If frequency deviation happens, the fan stops operating.

3. If the compressor is supplied with power and the pressure in the condenser meets requirements for starting the fan,

the fan starts.

4. If the compressor is supplied with power and the pressure in the condenser meets requirements for stopping the fan,

the fan stops. Alternatively, if the compressor is stopped for more than one minute, the fan stops.

5. Figure 5-14 shows the voltage control curve during fan operating, which is on the basis of FSC1P control curve.

V

Vin F E L2

100%

MaxV B

C D

A

Vx

L1 100% output

Condensation pressure point

H G

MinV

Pband Pv100 = (Pset + Pband + 5)

I

Poff Pset Px Pmaxv Pv100 P

Figure 5-14 FSC1P control curve

During fan startup, the voltage is obtained based on the pressure-voltage curve if the pressure is kept within the set

range and the voltage is the value of MaxV if the pressure exceeds the set range. During fan operating, the power

system stops supplying power to the fan if the condensation pressure is smaller than (Pset - 1), namely Poff. The

Liebert DM Series Air Conditioner Technical Manual

Chapter 5 Micro-Processing Controller 19

control process is A -> B -> C -> D -> E -> F -> C -> B -> A -> G -> H -> I (point A corresponds to the pressure ranging

from B to G). In the case of 100% voltage output, the voltage restores to MaxV after the pressure drops by 2 bars to

the point of Pmaxv. Table 5-3 lists the voltage and pressure parameters.

Table 5-3 Voltage and pressure setting table

Parameter Lower limit Upper limit Default

Min. power supply voltage (%) 30 50 30

Max. power supply voltage (%) 60 100 100

Start pressure (Bar) 11 15 13

Pressure bandwidth (Bar) 4 6 5

5.5.6 Economy Mode Control

1. The AC units enter the Economy mode after this mode is enabled.

2. When the system starts to operate in this mode, the temperature control precision is added with the precision

amplification value. When the system exits this mode, the normal precision value recovers.

Table 5-4 lists the parameter setting in the Economy mode.

Table 5-4 Parameter setting in the Economy mode

Parameter Default value Lower limit Upper limit

Economy mode OFF (0) OFF (0) ON (1)

Start At 22: 00 18: 00 3: 00

Start At 7: 00 5: 00 10: 00

Zoom (°C) 2 2 10

5.5.7 Sleep Mode Control

1. The AC units enter the Sleep mode when there is one energy-saving card or more.

2. In this mode, the fan stops operating when the following conditions are met:

1) All the other moving parts do not need to operate except for the indoor fan.

2) The temperature of all energy-saving cards (four at most) is lower than the sleep temperature.

3) The energy-saving cards are kept in the temperature for 600 seconds.

3. The AC units exit the Sleep mode when either of the following conditions is met:

1) The temperature of an energy-saving card exceeds the value of sleep temperature plus 2 and the energy-saving

card is kept in the temperature for 30 seconds.

2) No energy-saving card is available.

Table 5-5 lists the parameter setting in the Sleep mode.

Table 5-5 Parameter setting in the Sleep mode

Parameter Default value Lower limit Upper limit

EngySave Cd Num 0 0 4

Sleep At 27°C 15 40

5.5.8 Host/Standby Unit Control

1. The host unit automatically switches as a standby unit after a rotate cycle ends.

2. The host unit switches as a standby unit and the standby unit switches as an host unit after a fault occurs in the host

unit or standby unit, such as high pressure locking, low pressure locking, or discharge locking.

3. The standby unit works as a host unit after a high temperature alarm is generated by the host unit.

Table 5-6 lists the parameter setting for host/standby unit control.

Table 5-6 Parameter setting for host/standby unit control

Parameter Lower limit Upper limit Default Remark

Unit Status 0 2 0 0: SIG; 1: HST; 2: Standby

Switch Mod 0 1 0 0: Standby; 1: Rotate

The number indicates the interval days

Rt Time By day (1, 2, 3, 4, 5, 6, and 7) 1

between two polling cycles.

Liebert DM Series Air Conditioner Technical Manual

20 Chapter 5 Micro-Processing Controller

Rt At 0: 00 23: 00 12: 00 -

5.6 Alarm Function

5.6.1 Alarm Category

Alarms fall into the following categories: high pressure alarm, low pressure alarm, discharge temperature alarm, high

temperature alarm, low temperature alarm, high humidity alarm, low humidity alarm, humidifier fault, fault of return air

temperature sensor, high pressure locking, low pressure locking, discharge temperature locking, floor wetting, power

loss, over-voltage alarm, under-voltage alarm, frequency deviation, loss phase alarm, negative phase alarm, custom

alarm 1 (lightning protection), energy-saving card fault, air flow loss, pressure sensor fault, humidity sensor fault, air

flow sensor fault, and custom alarm 2.

5.6.2 Alarm State And History

1. Alarm state recording

1) Alarms are recorded based on alarm occurrence time.

2) Both the alarm category and alarm time are recorded.

3) Alarm states are cleared upon power failure.

2. Alarm history recording

1) Historical alarms are recorded based on alarm occurrence time.

2) A maximum of 200 historical alarms are recorded.

3) A historical alarm includes the alarm SN., alarm category, alarm time, and alarm clearance time.

4) Historical alarms are saved upon power failure.

5) Historical alarms can be manually cleared.

6) Two-level password protection is enabled for historical alarms.

5.6.3 Alarm Prerequisites And Handling Methods

Table 5-7 Alarm prerequisites and handling methods

Alarm

reporting

No. Alarm Alarm Prerequisite Alarm Mode Clearance Method Alarm Output

delay (unit:

second)

The alarm is

The high pressure switch is Keep the high

High triggered and

kept open-circuited for a pressure switch turned Enabled/

1 pressure the 3

duration of alarm reporting off for a duration of disabled

alarm compressor is

delay alarm reporting delay

forcibly closed

The low pressure switch is

kept open-circuited for a

duration of alarm reporting

The alarm is

delay in the case of Keep the low pressure

Low triggered and

compressor operating. The switch turned off for a Enabled/

2 pressure the 30

state of the low pressure duration of alarm disabled

alarm compressor is

switch is ignored for 180 reporting delay

forcibly closed

seconds. The duration is

configurable, ranging from

30 seconds to 600 seconds

The discharge temperature The alarm is Keep the discharge

Discharge switch is kept turned off for a triggered and temperature switch

Enabled/

3 temperature duration of alarm reporting the turned off for a 3

disabled

alarm delay in the case of compressor is duration of alarm

compressor operating forcibly closed reporting delay

High The fan is enabled for 10 The alarm is Keep the return air Enabled/

4 temperature minutes and the return air triggered and temperature lower 30 disabled/

alarm temperature is kept higher the electronic than the value (current closed

Liebert DM Series Air Conditioner Technical Manual

Chapter 5 Micro-Processing Controller 21

Alarm

reporting

No. Alarm Alarm Prerequisite Alarm Mode Clearance Method Alarm Output

delay (unit:

second)

than the high temperature heater is high temperature

threshold for a duration of closed threshold - 2°C) for a

alarm reporting delay while duration of alarm

the return air temperature reporting delay

sensor operates normally

The fan is enabled for 10

Keep the return air

minutes and the return air

The alarm is temperature higher

temperature is kept lower

Low triggered and than the value (current Enabled/d

than the low temperature

5 temperature the cooling low temperature 30 isabled/

threshold for a duration of

alarm system is threshold + 2°C) for a closed

alarm reporting delay while

closed duration of alarm

the return air temperature

reporting delay

sensor operates normally

The fan is enabled for 10

minutes and the return air Keep the return air

humidity is kept higher than The alarm is humidity lower than

High Enabled/

the high humidity threshold triggered and the value (current high

6 humidity 30 disabled/

for a duration of alarm humidification humidity threshold -

alarm closed

reporting delay while the stops 2%) for a duration of

return air humidity sensor alarm reporting delay

operates normally

The fan is enabled for 10

minutes and the return air Keep the return air

humidity is kept lower than The alarm is humidity higher than

Low Enabled/

the low humidity threshold triggered and the value (current low

7 humidity 30 disabled/

for a duration of alarm dehumidificati humidity threshold +

alarm closed

reporting delay while the on stops 2%) for a duration of

return air humidity sensor alarm reporting delay

operates normally

Keep the humidifier

The humidifier switch is kept Enabled/

Humidifier The alarm is switch turned off for a

8 turned off for a duration of 10 disabled/

fault triggered duration of alarm

alarm reporting delay closed

reporting delay

The alarm is Keep the return air

Fault of the The return air temperature is

triggered and temperature within the Enabled/

return air kept out of the allowed range

9 the cooling allowed range for a 10 disabled/

temperature for a duration of alarm

system is duration of alarm closed

sensor reporting delay

forcibly started reporting delay

The high pressure alarm is The alarm is

High reported for three times triggered and

Manually clear the Enabled/

10 pressure within an hour or the alarm is the /

alarm disabled

locking kept uncleared within 10 compressor is

minutes locked

The low pressure alarm is The alarm is

Low reported for three times triggered and

Manually clear the Enabled/

11 pressure within an hour or the alarm is the /

alarm disabled

locking kept uncleared within 10 compressor is

minutes locked

The discharge temperature The alarm is

Discharge alarm is reported for three triggered and

Manually clear the Enabled/

12 temperature times within an hour or the the /

alarm disabled

locking alarm is kept uncleared for compressor is

20 minutes locked

The alarm is Keep the floor wetting

Floor The floor wetting switch is Enabled/

triggered and switch turned off for a

13 wetting kept turned off for a duration 10 disabled/

humidification duration of alarm

alarm of alarm reporting delay closed

stops reporting delay

Liebert DM Series Air Conditioner Technical Manual

22 Chapter 5 Micro-Processing Controller

Alarm

reporting

No. Alarm Alarm Prerequisite Alarm Mode Clearance Method Alarm Output

delay (unit:

second)

The alarm is Enabled/

Power loss occurs when the The alarm is

14 Power loss automatically cleared / disabled/

AC units are in operation triggered

one second later closed

The alarm is

Enabled/

Over-voltag The input voltage increases triggered and Restore the input

15 3 disabled/

e alarm by 15% the system is voltage

closed

locked

The alarm is

Enabled/

Under-volta The input voltage decreases triggered and Restore the input

16 3 disabled/

ge alarm by 15% the system is voltage

closed

locked

The alarm is

Enabled/

Frequency The input frequency is triggered and

17 Restore the frequency 3 disabled/

deviation deviated by 5Hz the system is

closed

locked

The alarm is

Enabled/

Open phase triggered and

18 Open phase occurs Manual restoration 3 disabled/

alarm the system is

closed

locked

The alarm is

Enabled/

Negative triggered and

19 Negative phase occurs Manual restoration / disabled/

phase alarm the system is

closed

locked

Custom The set polarities are kept Keep the set polarities

Enabled/

alarm 1 inconsistent with those input The alarm is consistent with those

20 30 disabled/

(lightning for a duration of alarm triggered input for a duration of

closed

protection) reporting delay alarm reporting delay

The alarm is

The number of normally triggered and

online energy-saving cards the dormancy Keep the number of

Energy is less than the set number mode cannot the cards consistent Enabled/

21 saving card or more than one be activated if with the set number 30 disabled/

fault energy-saving card exceed all and keep the cards in closed

the allowed temperature energy-saving normal temperature

range cards are

faulty

The value (temperature

measured by using the

sensor NTC0 - return air

temperature) is kept larger

Keep the value

than the set temperature for The alarm is

(temperature

a duration of alarm reporting triggered and

measured by using the

delay when the fan is in shut down all Enabled/

22 Air flow loss sensor NTC0 - return 10

normal operation. The air the devices disabled

air temperature)

flow detection thermal except for the

smaller than the value

resistor output is closed fan

(set temperature - 2°C)

when the fan is shut down.

This alarm is not reported if

the fan is closed and the

temperature sensor is faulty

Fault of Keep the condensing

The condensing pressure is

pressure pressure within the

kept out of the allowed range The alarm is Enabled/

23 sensor 1 allowed range for a 3

for a duration of alarm triggered disabled

(lightning duration of alarm

reporting delay

protection) reporting delay

24 Humidity The return air humidity is The alarm is Keep the return air 10 Enabled/

Liebert DM Series Air Conditioner Technical Manual

Chapter 5 Micro-Processing Controller 23

Alarm

reporting

No. Alarm Alarm Prerequisite Alarm Mode Clearance Method Alarm Output

delay (unit:

second)

sensor fault kept out of the allowed range triggered humidity within the disabled/

for a duration of alarm allowed range for a closed

reporting delay duration of alarm

reporting delay

Keep the temperature

The temperature measured

measured by using the

by using the air flow loss

air flow loss sensor Enabled/

Air flow sensor (NTC0) is kept out of The alarm is

25 (NTC0) within the 10 disabled/

sensor fault the allowed range for a triggered

allowed range for a closed

duration of alarm reporting

duration of alarm

delay

reporting delay

Note:

1. Alarm reporting delay is a fixed configuration.

2. In the case of system locking, the compressor, heater, humidifier, and outdoor fan are locked.

5.7 Other Functions

5.7.1 Real-Time Clock

1. Set and display the system date and time.

2. This function provides the accurate time of data recording.

5.7.2 Operating Record

1. Device startup and stop record

A maximum of 50 records about device startup and stop are recorded, including the fan, compressor, electronic heater,

and humidifier.

2. Operating time record

The operating time of the fan, compressor, electronic heater, and humidifier is recorded by hour.

5.7.3 Parameter Protection

1. All parameters that need to be protected are saved in the internal EEPROM.

2. Default parameter settings can be restored.

3. Two-level password protection is enabled.

5.7.4 Password Protection

1. A password consists of four digits, ranging from 0000 to 9999. Password protection is classified into three levels.

2. Level 1 password is available for ordinary users. They can modify password protection parameters and level 1

password.

3. Level 2 password is available for operators. They can modify password protection parameters and level 1 and level

2 password.

4. Level 3 password is available for maintenance personnel. Except for level 3 password, they can modify password

parameters and level 1 and level 2 password.

5.7.5 Shutdown Mode

1. Shutdown modes fall into local shutdown, monitor shutdown, and remote shutdown.

2. Local shutdown is implemented by pressing the on/off button on the display panel.

3. Monitor shutdown is implemented through the background monitor RS485-1.

4. Remote shutdown has the highest priority and is in serial relationship with the other shutdown modes.

Liebert DM Series Air Conditioner Technical Manual

24 Chapter 5 Micro-Processing Controller

5.7.6 Diagnosis Output

1. In the diagnosis mode, devices such as the primary fan, compressor, electronic heater, and humidifier can be

tested.

2. A tested device can be automatically or manually shut down when it diagnoses another load.

3. If a device is not manually shut down within an hour, the device automatically exits the manual shutdown mode.

4. The fan must be always in operation. If the fan stops operating, the other devices are forcibly shut down. The

system must be protected in the case of major alarms, such as air flow loss, high pressure alarm, low pressure alarm,

discharge alarm and locking, and power fault.

5.7.7 Sensor Calibration

1. The temperature calibration range is ±5°C.

2. The humidity calibration range is ±10%.

5.7.8 Deployment Management

Deployment management is required during initial system operating.

Liebert DM Series Air Conditioner Technical Manual

Appendix 1 Menu Structure 25

Appendix 1 Menu Structure

Main Menu

Alarm Menu Set Points System Status Temp Calib System Menu Help Menu LCD Setting

Temp Stpt Analog Hum Calib Mntr Prtcl

Version Info Contrast

Temp Sens Time/Date NTC0 Calib Mntr Addr

Enab Open Language

Hum Stpt In/Out Status In Fan SS Record Setup Baut Rate

Alarm Hum Sens Run Time Comp SS Record System Over Press

Status

SS Record Heat SS Record Under Press

Alarm

History Hi Temp Hum SS Record Pwr Freq Devia

Alarm Lo Temp Out Fan SS

Min. Volt

Setpoint Record

Hi Hum

Max. Volt

Lo Hum Outdoor

Out Volt

Unit

Air Loss

Start Press

Press BdWdth

Heat Num

Hum Num

Select CostSave Mod

Options EngySave Cd Num

Unit Mode

Switch Mod

Change Password

Factory Reset

Figure 1 Menu structure

Liebert DM Series Air Conditioner Technical Manual

Appendix 2 Wiring Diagram 26

Appendix 2 Wiring Diagram

Black Yellow Fuse

Red Yellow

Transformer T2

Indoor connection

Black Yellow Fuse

terminal TB1

TB1-N

NN Black Yellow

Grounding point of the NN

TB1-N Transformer T1 23 24 Indoor connection

electrical control box NN

TB1-N TB1-N 2122 terminals TB2

NN

TB1-1 TB1-11

TB2-21

TB2-22

1 11

TB1-2

TB1-3

2 12 TB1-13

3 13

J3-1

J3-2

Yellow-green

TB1-4

4 14

TB1-5 TB1-15

KM2-A1

5 15

J28-4

PE Yellow-green

6 16

Black

Black

Black

Black

Black

Black

Black

Black

TB1-7

J28-7 7 17

Black

Black

Black

Black

TB1-8 Standby unit is available

8 18

Black

Black

J28-8

TB1-9

J28-9 9 19

QF-1

QF-3

QF-5

Public alarm

SPD-N

SPD-1 TB1-10

SPD-2

SPD-3

J28-10 1020

PE

N

Black J18-1

J01-1

J01-3

J01-5

J01-7

1 3 5 Power 1 1 2 1 2

N L1 L2 L3 Black J18-2

Black 2 J13 J31

PE1L1N1 PE N MCB ALARM

Power SPD KM1-A1 J18-3

3 J18 1 2 3 4 5 6 7 8

2 4 6 SPD/D

COM NC

4

5

J01 J14 2

1

J14-2

J14-1

DB9

Monitoring

Black

Black

card

Black

Black

Black

Black

Power

J2-2

J2-1

Black J02

J1-N

2 1 2 2

J1 Black J02

J19-2

J19-1

1 J1-L

1

board

TB2-21

To outdoor 380V/50Hz 3N~ J2 GND GND

J18-3

KM1-21

Filter J12 2 12V 12V

4

Display

KM1-1

KM1-3

KM1-5

KM2-1

KM2-3

unit 1 Gray 3

A A

2 J4

J03 J39 2

A1 1 3 5 21 A1 1 3 5 13 board Yellow-green J03

2 J29 1

B B

1 board

1 1 2 3 4 5 6 7 8

KM1 KM2

J3

A2 2 4 6 22 A2 2 4 6 14 5 4 3 2 1

J34

Gray Temp/Hum

KM1-22

KM1-2

KM1-4

KM1-6

J3-4

J3-1

J3-2

detection board

J3-4

J28-3

1 2 3 4 5 6 7 8 1

Brown

Black

J30

Gray

Grounding point 2

KM1-A2 N1 L1 of the electrical J28-3 Black

3 KM2-A2

Brown

Brown Black

White

Black

control box J28-4

Blue

Blue

4 TB2-22

Control board J28 5

T1

T2

T3

6 Black

J28-7

7 TB1-7

J28-8 Black

8 TB1-8

Compr- Electric Indoor J19-1 91

J28-9 Black TB1-9

Yellow-green

SPD-NC 1 J28-10 Black

heater J19-2 TB1-10

SPD-COM 2

essor fan 3

0

1

Black

4 Black High pressure switch

J19

Brown

Brown

J19-5 2

5 Blue

Remote turn on/off J19-6 3

6 Blue Low pressure switch

Electric heater belt J19-7 4 Black

Grounding point of the Grounding point 7 J21 J21-5

Standby unit request 5

of the electrical Start capacitor

J19-8

of the compressor 8 J21-6 Brown Air discharging switch

electrical control box 6

control box J23 J36 7

3 2 1 Floor overflow

8

GND

+5V

VIN

Cable description:

Green

Connection cables between indoor

Black

Red

and outdoor connection terminal

Factory supplied line

Energy- +12V

Field supplied line L L1 Indoor

saving card

GND

CANH

CANL

N N1 connection

Parts supplied line PE1 terminal Pressure sensor

Inserted terminals Outdoor

connection

Connection description: terminal

1. This diagram is only for 7.5kW model.

2. There is no electric heater contactor KM2, electric heater and the corresponding cables in the single cooling unit.

3. There are transformer T2 and connection terminal TB2 Only when the heating function is select; The single cooling model is not equipped with transformer T2 and

connection terminal TB2.

4. The energy-saving card and the monitoring card are options; If you need them, field connection is essential.

5. The power SPD is equipped with T version unit; P version unit does not have power SPD and corresponding cables, J19-1 and J19-2 of the control board is shorted using cable.

Figure 2 DME07 model

Liebert DM Series Air Conditioner Technical Manual

Appendix 2 Wiring Diagram 27

Black Yellow Fuse

Red Yellow

Transformer T2

Indoor connection Black Yellow Fuse

terminal TB1

N N Black Yellow

TB1-N

Grounding point of the

TB1-N

N N

TB1-N Transformer T1 272829303132 Indoor connection

electrical control box N N

TB1-N TB1-N 21 2223242526 terminal TB2

N N

TB1-1 TB1-11

1 11

TB2-28

TB2-21

TB2-22

TB2-23

TB2-24

TB2-25

TB2-26

TB2-31

TB1-2

2 12

J3-1

J3-2

TB1-3 TB1-13

3 13

TB1-4

4 14

PE Yellow-green

TB1-5 TB1-15

5 15

TB1-6

PE Yellow-green

6 16

KM2-A1

KM3-A1

J28-6

KA1-3

TLR

J28-4

G0

G

QF-1 Black

QF-3 Black

QF-5 Black

Black

Black

Black

Black

Black

Black

Black

Black

J28-7 TB1-7 7 17

Black

Black

Blue

TB1-8

8 18 Standby unit is available

J28-8

TB1-9

J28-9 9 19

SPD-N

Public alarm

SPD-1

SPD-2

SPD-3

TB1-10

J28-10 10 20

N

Black J18-1

1 3 5 1

J01-1

J01-3

J01-5

J01-7

1 2 1 2

PE1 L1N1

Power N L1 L2 L3

Power SPD

Black J18-2

2 J13 J31

PE N Black J18-3

MCB ALARM KM1-A1 3 J18 1 2 3 4 5 6 7 8

2 4 6 COM NC SPD/D Black J18-4 J14-2

4

J01 J14 2 J14-1

5 1 DB9 Monitoring card

Power

Black

Black

Black

Black

J02

J2-1

J2-2

KM1-1 Black

Black

Black

KM1-21 Black

Black

2 J1-N J02-2 2

J19-2

J19-1

To outdoor unit 380V/50Hz 3N~ J1 J1-L Black

TB2-28

2 1

board

TB2-21

TB2-22

1 1 GND GND

J18-3

J2 J12 2 4

Display

KM2-1

KM2-3

12V 12V

KA1-4

Gray

KM1-3

KM1-5

1

KM3-1

KM3-3

3

J4

Filter J03 J39 2

1

A

B

A

B

2

1 board

A1 1 3 5 21 A1 1 3 5 13 A1 1 3 5 13 3 6 4 board Yellow-green J03 2

1

J29

1 2 3 4 5 6 7 8

KM1 KM2 KM3 KA1 J3

A2 2 4 6 22 A2 2 4 6 14 A2 2 4 6 14 1 5 2 5 4 3 2 1 J34

Gray Temp/Hum

J3-1

J3-2

detection board

J3-4

KM1-22

KM1-2

KM1-4

KM1-6

KM3-3

KM3-6

J3-4

TLR

J28-3

J28-5

1 2 3 4 5 6 7 8 J28-1 Black

1 +VR

Grounding point J30 J28-2 Brown

Black

Black

Black

2 SET

KM1-A2 N1 L1 of the electrical J28-3 Black

Brown

Brown

White

KM2-A2

Black

3

Blue

J28-4 Black

Blue

Blue

control box

HUM-N

4 TB2-24

HUM-L

Control J28-5 Black KA1-1

J28 5 J28-6

T1

T2

T3

Black TB2-31

6

J28-7 Black

7 TB1-7

8 J28-8 Black TB1-8

Comp- Humidify Indoor J19-1

board J28-9 Black

Yellow-green

SPD-NC 1 9 TB1-9

J19-2 J28-10 Black

SPD-COM 10 TB1-10