Professional Documents

Culture Documents

Brochure AVEVA E3D For Marine 11-18

Uploaded by

Vinay Sharma0 ratings0% found this document useful (0 votes)

28 views11 pagesdssdsdsdsdszxzcddsdfdfd

Original Title

Brochure AVEVA E3D for Marine 11-18

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdssdsdsdsdszxzcddsdfdfd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views11 pagesBrochure AVEVA E3D For Marine 11-18

Uploaded by

Vinay Sharmadssdsdsdsdszxzcddsdfdfd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

AVEVA EVERYTHING3D

The most advanced 3D design application for the

accurate and clash-free outfitting design of ships and

offshore vessels.

To deliver high-quality projects within ime and budget, you need a

clash-free design and accurate production information that covers hull

and outfitting disciplines.

With increasing size and complexity of end products, short project

lead times that force demand for concurrent engineering with unclear

and changing specifications, and cost pressures that lead to globally

distributed design and production running 24/7, complex marine

projects are challenging to deliver.

aveva.com

BROCHURE

AVEVAEVERYTHING3D

Design and construction engineers need to:

+ Quickly identify design changes

+ Issue and revise drawings mapped directly o the 3D mode!

+ Work with multiple design teams around the world

‘+ Handle changes in design phase and maintain a consistent, error-free 3D model

IF any of the above fall. costly rework is generated during fabrication and production.

AVEVA Everything3D”™ (AVEVA E3D™) is the world’s mast technologically advanced and

powerful 3D design solution for the shipbuilding, process plant and power industries. t

offers best in class productivity and capability, while retaining seamless compatibility with

existing solutions.

AVEVA ED readily integrates with AVEVA products ike the Integrated Engineering &

Design (AVEVA Marine), providing extensive functions. The integrated design also facilitates

information exchange with many third-party systems. enabling it to be implemented into

existing technical infrastructure with minimal risk.

‘A multi-discipline outfitting design based on rea hull data,

any marine projec

lution fulfils three essential req

fre

BROCHURE

AVEVAEVERYTHING3D

Efficient Collaboration and High Productivity

‘An extensive catalogue enables predefined parametric components and objects to be

uickly selected and positioned within the model, then automaticaly checked for clashes

and for compliance with configurable design rules,

‘As the design evolves, changes can be highlighted and tracked which make it easier to

identify, manage and cornmunicate the change across different disciplines.

The result is an accurate, high-quality design that minimises construction costs and time,

and avoids errors that can lead to costly rework in production.

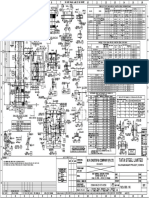

‘lipped and detalled view of how you can medel all your cutting elements inthe same environment

Business Benefits

Reduce design man-hours

+ Reduce design effort and man-hours with the highly efficient graphic user interface for

both first-time modelling and modifications

* Accurate-first-time design with design rules and checking functions, with fewer design

iterations and minimised design rework

+ Efficient. comprehensive clash detection enables costly on-site rework to be eliminated in

the design stage

© Integration with Hull Structure for references and penetrations

BROCHURE

AVEVAEVERYTHING3D

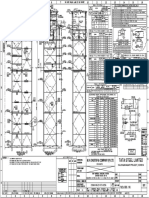

Detailed vew of Machinery, Piping and Structures designed in AVEVA E30.

Improve Productivity

* Autornatic, just-in-time creation of drawings and other production information direct frorn

the project model minimises revision work

* atts fit right-frst-time in production due to design for production concept, design rules

and comprehensive production checks

+ Photorealisic laser scan data integrated into the design environment enables rapid

intuitive and accurate design of vessel modifications, and verification of construction

stafus against the design intent as constructions progresses

'* Optimum materials and resource use for maximum efficiency

Increase Collaboration

+ Enable geographically separate design tearns to work together as ifin a single

office

* The use of a common model database avoids design clashes by enabling

better communication between hull and outfiting disciplines

* Build libraries of design assemblies or commonly used modules for

reuse on new projects

BROCHURE

AVEVAEVERYTHING3D_

Compliance

+ Compare-and-Update with Schernatics and engineering lists, enabling higher-quality

design in fewer man-hours

* Change highlighting, tracking and status management enable efficient, collaborative

compliance with design rules, best practice and contractual requirements

* AVEVA ED isa scalable solution with no limit on project size or complexity

Easy to adopt and rapid project start-up

* Intuitive, easy to deploy steff training that enables rapid ramp-up to full productivity

* Set up new projects in hours. not days, with efficient system administration

‘Separate view ofa frame that you can workin deta

Key Features

Faster and more intuitive user interface

Fully interactive outfitting. easy-to-use 3D design environment provides every designer on the

project with modern 3D graphical interaction tools

Ful visibility of the entire design created in both the hull and outfiting applications of AVEVA's

software.

BROCHURE

AVEVAEVERYTHING3D

Easy configuration

‘The AVEVA E3D design application can be customised by the user to suit individual.

industry or project requirements, or to add further design rules or automation functions,

Object-centric data management

Designers construct highiy inteligent database for the whole ship, creating their specialists)

parts of the design by placing instances of parametric cornponents from a controlled

catalogue. Each object. such as a valve. pumnp or pipe, has an associated, extensive library

of attribute and association data. The project database that your team will create in this way

becomes a digital asset of huge value to your business planning and modelling

Design quality assurance

Infeligent lash detection and clash highlighting, both between individual design objects and

between design objects and laser scans of as-built stucture, help designers avoid clashes

as they work.

Change management

Conventional design issue, revision, and change contol processes can all be applied

efficiently, even on projects which have many hundreds of users. AVEVA E3D provides

robust change management functions that enable designers fo make and accommodate

changes in a controlled manner, identifying at-2-glance things that have changed, and

automatically creating an audit trall of changes as they work

Integration with AVEVA engineering tools

‘The design process translates engineering information into 3D reality. AVEVA E3D

enables data from engineering and schematic applications to be imported and to

autornatically create the corresponding 3D objects. ready for positioning in the model

‘Three-nay association between schematic, engineering and 3D data ensures that

changes or inconsistencies are reflected in all until accepted or corrected. Compliance

with open and industry standards further enables AVEVA ED to work with data

originating in many third-party applications.

AVEVA ESD is able to work alongside AVEVA Marine. enabling you to create a

fully clashable and drawable hull madel,

BROCHURE

AVEVAEVERYTHING3D

Integration of laser scan data into the design environment

Laser scans of individual fabrications. modules or the current status of the as-built site

can be rapidly imported for verification against the design model, identify and resolve

non-compliances and keep your project on schedule, using a design model which can be

progressively updated fo accurately reflect the true as-built construction

Laser data in drawings

Replace the huge number of hours wasted on rnodeliing old vessels by adding up-to-date

point cloud laser data directly into existing drawings.

Laser data integrated wth tho 3D model.

In-context access to the full Digital Asset

Design in Context™ enhances the design process by sharing relevant content fram your

Digital Asset with your design teams within AVEVA E3D, improving the speed and reliability

of their design decisions, The Design in Context capability creates a direct connection to the

centralised Digital Asset repository if available) When an object is selected in AVEVA ED.

the Context panel dynamically updates a list of available content relevant to the selection,

such as datasheets, vendor documentation, purchase orders. planning charts and calculation

sheets, This content can then be opened. in context to the selected object, via a new

embedded universal viewer, ensuring your team can draw on complete, correct information

to make decisions

BROCHURE

AVEVAEVERYTHING3D

Optimum use of design automation and rules

AVEVA ESD features extensive capabilities for design automation through the configuration

of rules. These rules respect engineering boundaries and access rights. They build on

the productivity advantages of rule-based design automation while ensuring that design

authority for changes remains with the relevant responsible disciplines

For example, autornatic routing of pipes and cable trays in accordance with preconfigured

rules is @ popular feature in 3D design solutions, Yet this approach rarely creates an

optimum design by itself. AVEVA E3D enables a designer to switch between automatic

routing to save time on simple or repetitive work, and intuitive manual adjustment tools to

refine the routes ensuring the best overall-quality of the complete design.

Looking through cipped view of machinery foom and various decks ofthe ship.

Unrivalled design reuse

AVEVA ED enables extensive sharing and reuse of data between

projects as standard, Design and component inforrnation from previous

outfitting projects can be reused or shared across rutile projects.

Uttities for changing pipe sizes or specifications enable rapid adjustment

to the new project.

BROCHURE

AVEVAEVERYTHING3D_

Configurable automation of deliverables

All deliverables - drawings. piping isometrics, BoMs or reports - are generated directly from

the definitive 3D design model, ensuring they are accurate and complete, AVEVA ESD

DRAW module also includes advanced 2D drafting tools that interact with the design model.

enabling customers to quickly and easily add notes, sketches and dimensions without the

need for a separate 2D drafting system,

|

DRAW - Drafting intograted with modo

‘Automatic cable routing

This standard feature enables instrumentation andjor electrical cables to be automatically

routed into cable trays in accordance with preconfigured rules defining such parameters

as tray fil levels, route selection and signal/ power cable separation. Cable definitions can

be obtained from AVEVA Electrical and AVEVA Instrumentation and even imported via

Microsoft Excel” from third-party systerns. Accurate cable lengths, including any excess

allowances, can be relumed in the sarne way for the creation of BoMs and drumming

Import function

A general import function from Microsoft Excel allows large volumes of data from external

sources to be analysed online and bulk-loaded into the design,

A

BROCHURE

AVEVAEVERYTHING3D

Efficient management of subcontract work packages

Subcontracting work is common practice but requires the ability to manage the interface

with the subcontractor and to validate their work before accepting it. AVEVA ED provides,

a unique Extract functionality that allows a subcontractor to work independently. developing

a package of design without impact on the master project model, Follawing approval of the

work, it can be automatically incorporated into the project rnodel.

Additional Products

For new adopters of AVEVA E3D. with no existing AVEVA infrastructure, the following

additional products are included to provide immediate and full value from the technology:

= AVEVA Administration” for systern administration and configuration

* AVEVA Catalogue” for the definition of engineering specifications and component

catalogues,

The following optional products are particularly recormmended to extend capabilities and

efficiency:

* AVEVA Global” for the management of distributed, muti-location working

* AVEVAE3D Insight for anytime. anywhere review and approval of a live AVEVA ED.

design.

For mare information. visit wwwaveva.com or contact us at contact@avevacom

AVEVA Worldwide Offices | www aveva.comioffices

AVEVAtlaas re mani publestni cova a ela dle Rarer pet emgec.h ton

vogue @ inked comveomoarylavers

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Vinay Sharma - FTC Employment AgreementSignedDocument11 pagesVinay Sharma - FTC Employment AgreementSignedVinay Sharma100% (1)

- Tata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaDocument1 pageTata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaVinay SharmaNo ratings yet

- View Looking North On Gridline CDocument1 pageView Looking North On Gridline CVinay SharmaNo ratings yet

- Licensing GettingStartedDocument10 pagesLicensing GettingStartedVinay SharmaNo ratings yet

- 08 Z2 STD 0263Document1 page08 Z2 STD 0263Vinay SharmaNo ratings yet

- 08 Z2 STD 1201Document1 page08 Z2 STD 1201Vinay SharmaNo ratings yet

- 08 Z2 STD 1204Document1 page08 Z2 STD 1204Vinay SharmaNo ratings yet

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Tata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaDocument1 pageTata Steel Limited M. N. Dastur & Company (P) LTD.: Kalinganagar Project, OdishaVinay SharmaNo ratings yet

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Pipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Document10 pagesPipe Thickness Calculation (Internal Pressure Design Thickness) As Per ASME B31.3Vinay SharmaNo ratings yet

- Syllabus of p3dDocument3 pagesSyllabus of p3dVinay SharmaNo ratings yet

- Introduction To Gate Valves and Gate Valve TypesDocument16 pagesIntroduction To Gate Valves and Gate Valve TypesVinay Sharma100% (1)

- Tata Steel Limited: M. N. Dastur & Company (P) LTDDocument1 pageTata Steel Limited: M. N. Dastur & Company (P) LTDVinay SharmaNo ratings yet

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDocument9 pagesButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNo ratings yet

- Butterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentDocument9 pagesButterfly Valves: Uses, Types, Working, Advantages, Symbols: Skip To ContentVinay SharmaNo ratings yet

- Talk Like A Boss:: How To Communicate Assertively in The Job SearchDocument37 pagesTalk Like A Boss:: How To Communicate Assertively in The Job SearchVinay SharmaNo ratings yet

- Administrator Command Reference ManualDocument201 pagesAdministrator Command Reference ManualĐình NamNo ratings yet

- Syllabus of p3dDocument3 pagesSyllabus of p3dVinay SharmaNo ratings yet

- W 52751Document1 pageW 52751venkatagopiNo ratings yet

- E3d-Module Equipment in Aveva E3d PDFDocument12 pagesE3d-Module Equipment in Aveva E3d PDFRobles Dresch71% (7)

- Vinay Sharma-PipingDocument5 pagesVinay Sharma-PipingVinay SharmaNo ratings yet

- AVEVA Plant 12.1.SP4.29 Partial Fix Release 52447 Windows XP or Windows 7Document143 pagesAVEVA Plant 12.1.SP4.29 Partial Fix Release 52447 Windows XP or Windows 7Vinay SharmaNo ratings yet

- E3d-Module Equipment in Aveva E3d PDFDocument12 pagesE3d-Module Equipment in Aveva E3d PDFRobles Dresch71% (7)

- RepaymentDocument5 pagesRepaymentVinay SharmaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)