Professional Documents

Culture Documents

ATB-104 - Adhesion Tests

ATB-104 - Adhesion Tests

Uploaded by

Cast VazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATB-104 - Adhesion Tests

ATB-104 - Adhesion Tests

Uploaded by

Cast VazCopyright:

Available Formats

ATB-104 Adhesion Tests

Adhesion Tests

Adhesion is one of the most critical aspects of any coating and provides a key indicator of the long term

performance of the coating system. Before using an Acrymax coating system it is recommended, and in

some cases required, that an adhesion test be performed on a properly prepared and representative

area of the substrate that is to be coated. The term substrate refers to the surface which a coating is

being applied to - be it steel, single-ply membrane, or another coating that is to be overcoated.

Adhesion tests are especially important if you are planning to coat a metal roof with an existing

fluoropolymer finish, a TPO membrane, or other materials that are difficult to adhere to.

Adhesion tests that may be used for coatings include the 180o Peel Test, the Tape Test, and the Knife

Test. The 180o Peel Test is the most common test used for elastomeric roof coatings. Procedures for

conducting these tests in the field are described below.

In addition to the tape test used to evaluate adhesion, there is also a tape test that is used to evaluate

how effectively a substrate has been prepared. Dirt and contaminates interfere with adhesion and will

adversely affect coating performance, so it is important to make sure that the cleaning process has been

effective. After verifying that the substrate is dry, 2” wide masking tape is pressed on to the surface, and

then the tape is peeled off. If the tape is removed easily and the adhesive side of the tape shows an

excessive amount of contamination, then further cleaning is necessary.

180o Peel Test

A quantitative measure of adhesion is

performed through an 180o peel test. This is

the best test to evaluate the adhesion of

elastomeric roof coatings, both in the field

and in laboratory setting.

In this evaluation, the coating to be tested is

applied to the substrate such that the

coating adequately coats the surface. Into

this wet coating 1” wide strips of fabric are

embedded leaving a 3-4 inch “tail” at the

end of each strip. The fabric is then

saturated with additional coating leaving the

tail uncoated. Two or three strips should be

Figure 1 - Polyester Test Strips embedded into coating. used to verify results.

After two weeks of curing, the adhesion test is ready to be conducted. This is done by peeling the fabric

sample back at an 180o angle. In the lab this is done with a tension-testing machine that runs at a rate of

2 in/min. Adhesion results are an average of the tests and are typically reported in pounds per linear

inch (PLI).

ATB-104 (2-1-11) Page 1 of 2

In the field the adhesion test can be done using a

small fish scale such as the one shown in Figure 2.

Attach the scale to the “tail” that was left

uncoated and pull slowly on the scale, pulling the

1” wide fabric away from the substrate. Record

the weight (force) that is required as the fabric

strip is pulled away.

Figure 2 - Digital scale used to evaluate adhesion

In a qualitative aspect of this test, the mode of

failure, either adhesive or cohesive, is recorded to

provide the evaluator additional information. As

seen in the Figure 3, the test coating failed by

cohesively. This means that the polymer was

pulled apart, before it was pulled from the

substrate, indicating a high degree of adhesion to

substrate.

ASTM C-794 is the standardized test methodology

that provides the basis for these adhesion tests.

Figure 3 - Cohesive Failure

Tape Test

The basic procedure to perform this test is to use a razor blade to make cuts in the coating down to the

substrate. The cuts can be made in either an “X”, generally used on job sites, or a cross hatch, which is

generally used in lab settings and on thinner film coatings. Pressure sensitive tape is then applied over

the test area, pressed firmly onto the coating, and then the tape is rapidly removed. The test area is

then inspected for removal of the coating from the substrate. ASTM D3359 is the standard for this test

method.

Knife Test

To perform this test a utility knife is used to make two cuts into the coating to

form an “X”. At the vertex, the point of the knife is used to attempt to lift up the

coating from the substrate. The evaluation of adhesion is based on both the

degree of difficulty to remove the coating from the substrate and the size of

removed coating. ASTM D6677 is the standard for this test method.

Results from this test are fairly subjective, and evaluation of adhesion depends not

only on the results, but on the ability of the inspector to accurately interpret them

as well. As such, this test should be used only as initial screening of adhesion with

further evaluation through another method.

ATB-104 (2-1-11) Page 2 of 2

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CAPE Chemstry 2012 U1 P2 - Cram SheetDocument2 pagesCAPE Chemstry 2012 U1 P2 - Cram SheetDenison DwarkahNo ratings yet

- Elongation TestDocument14 pagesElongation TestAinil Hawa MusaNo ratings yet

- Mud Gas SeparatorDocument3 pagesMud Gas SeparatorDuong DuongNo ratings yet

- En 673 LectureDocument12 pagesEn 673 LectureCristian SabauNo ratings yet

- Bentonite SpecificationDocument2 pagesBentonite SpecificationPritha Das100% (1)

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- Excel SheetDocument13 pagesExcel SheetDamien NaiduNo ratings yet

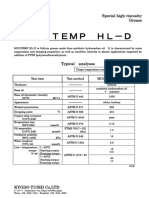

- Multemp HL-DDocument1 pageMultemp HL-DVishal AmleNo ratings yet

- Tractor Transmission and Hydraulic Oil-GHS SDSDocument6 pagesTractor Transmission and Hydraulic Oil-GHS SDSRyan JX PakatangNo ratings yet

- Properties Measurement PVT ManuscriptDocument5 pagesProperties Measurement PVT ManuscriptAtqh AzmnNo ratings yet

- Thesis 2013 AlhutmanyDocument178 pagesThesis 2013 AlhutmanyMohammed Zahir Al-KilaniNo ratings yet

- Study The Mechanical Behaviour of Al 7075 With Silicon Nitride by Computer Analysis & Stir CastingDocument4 pagesStudy The Mechanical Behaviour of Al 7075 With Silicon Nitride by Computer Analysis & Stir CastingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 8.10.2 Paraffin Dispersant Screening (STP 11-02)Document4 pages8.10.2 Paraffin Dispersant Screening (STP 11-02)Citlali MoraNo ratings yet

- Khan 2014Document11 pagesKhan 2014Hidayat Jamalul INo ratings yet

- Visualizing Environmental Science 4th Edition Berg Test BankDocument28 pagesVisualizing Environmental Science 4th Edition Berg Test Bankconvenerlollwctta100% (21)

- Chemistry Investigatory ProjectDocument17 pagesChemistry Investigatory ProjectParthiv MandalNo ratings yet

- CopyDocument1 pageCopyRinaldi Putra ButarNo ratings yet

- Rankine and Carnot NumericalsDocument59 pagesRankine and Carnot NumericalsBhargav PrajwalNo ratings yet

- Job Safety Assessment FormDocument161 pagesJob Safety Assessment FormFadhlan Rasyid RNo ratings yet

- A597 7Document2 pagesA597 7sandeep acharNo ratings yet

- Press Work TerminologyDocument5 pagesPress Work TerminologySenthil Kumar GunasekaranNo ratings yet

- Stella-Aerosol - WD Spray - MSDSDocument4 pagesStella-Aerosol - WD Spray - MSDSseitoikeshi9No ratings yet

- Fire Craft Compiled Group1Document54 pagesFire Craft Compiled Group1tiqah mlNo ratings yet

- Bestway Cement Limited ChakwalDocument42 pagesBestway Cement Limited Chakwaltarehman7595No ratings yet

- Final Chapter 1 and 2Document26 pagesFinal Chapter 1 and 2Val LlameloNo ratings yet

- PD TopicDocument6 pagesPD TopicAnonymous Flh0GZNo ratings yet

- Dutta Et Al., 2022 - Antioxidant Paradox PDFDocument17 pagesDutta Et Al., 2022 - Antioxidant Paradox PDFDr.Pallav SenguptaNo ratings yet

- Objectives: Terms of Use Privacy Policy Notice AccessibilityDocument16 pagesObjectives: Terms of Use Privacy Policy Notice AccessibilityJuan Sebas OspinaNo ratings yet

- Additive 510 m14Document5 pagesAdditive 510 m14MohsenNo ratings yet