Professional Documents

Culture Documents

Jv10044 Hot Rolled Mild Steel Plates Sheets and Strips

Uploaded by

Anonymous jefUrqfio0 ratings0% found this document useful (0 votes)

12 views6 pagesjv 10044

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjv 10044

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views6 pagesJv10044 Hot Rolled Mild Steel Plates Sheets and Strips

Uploaded by

Anonymous jefUrqfiojv 10044

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

— 2

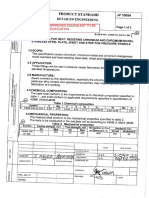

J] PRODUCT STANDARD Jv10044

3

= - DETAILED ENGINEERING

| Qua :

| Page 4 of 6

ao BASED ON JiS STD.

* JIS G 3131:2005, =

HOT ROLLED MILD STEEL PLATES, SHEETS AND STRIPS (SPHC)

1. SCOPE

This standard specifies hot rolled mild steel plates, sheets and strips intended for

general fabrication purpose and drawing

2. GRADE AND SYMBOL

The steel sheet and coil shall be denoted as follows

Table 1

‘Symbol of grade Applicable thickness mm Remarks.

‘SPHC 1.2 or over up to and incl. 14 | “Commercial quality

3. CI

/HEMICAL COMPOSITION

The steel sheets and coils shall be tested in accordance with 7.1 , and the cast

analysis values shall be as per Table 2

Table 2 Chemical composition

Symbol of Grades-| Cc Mn ie s- i

SPHC 0.15 max 0.60 max | 0.050 max | 0.050 max

el | TRAGTATEDBT

3 WORKED BY AB AS _oF-07.

3 Quality |FARoRA 7 | eeccen ay En K

bat NAME, * ‘SUPERVISED BY v

2 BolG

& | [Rev.no.00 raaPana slp oe

| [osteo

DATE

SIGN:

PRODUCT STANDARD

DETAILED ENGINEERING

Jv10044

Page 2 of 6

SIGN & .DaTE

INVENTORY No,

4. MECHANICAL PROPERTIES

4.1 tensile strength and elongation

The steel sheet and coil shall be tested in accordance with 7.2 and their tensile

strength and elongation shall be as specified in table 3.

4.2 Bendability

When the SPHC steel sheet and coil are tested in accordance with 8.2 and the

bendabilty conditions specified in table.3, there shall not be any cracks on the outer

Surface of the test piece, However, this bend test may be omitted unless itis requested

by the purchaser.

} Elongation % : Bendability i

ce Ee elle € Inside |

2 lg SE, SE) SE | SElSEls | 9 radius

@ /eSle E EX /ESle | 8] ©

& [s/t | EX | Es | Es /Es|é 2] Bloele |

3s |ZEINE| oS | od | od lave 3 § |aee 3

Se ie eae g Gk |} ae (Aso s! B Sala] 2

os |oE/ 5) $5] ws 6 ais s| 2 D Sal

2/27/82] $2] 82 | ge /gzige] 2] B lgs|es| 3

£ (2 | 88/88) 22) 82/9389) 2 | 3 f3/g8| 3

& & |Esl/es

@ \F 182/32) 2] 32 |sals ce] a iS eee

Es|25|e£3 | 25 Ege eps

FS FS Fs leglege ERE

No.5 No.3}

in riat | Tic | in

270 | 27 31 | 31 | colin | jap0 knes | rolin

SPHC min. min. 29 min. | 29min. | 29 min. min. | inin. 9 180° a sX 9

direct 05 | direc

! er | tion

Remarks 1. The following may be applied for upper limit of tensile strength as agreed

between the L&T-MHI and the manufacturer,

‘SPHC: 440 Nimm?

2. The values specified in table 3 shall not be applied to the irregular portion of

both ends of the steel coil

Wore by

AB i

REY. 00 lag Check by

ex _fepils

SIGN DATE

e

PRODUCT STANDARD

DETAILED ENGINEERING

.3V10044

Page 3 of 6

SUPERSEDES

ventory no

SIGN & "DATE

INVENTORY No,

5. Shape, dimensions, mass and tolerances

The shape, dimensions, mass and their tolerances of the steel sheet and coil shall

conform to JIS G 3193. However, the tolerances on thickness shall be in accordance

with table 4 and the measurement of edge camber shall be carried out when requested

by the purchaser.

With this respect, tolerances on length for the steel sheet and those on width for the

cut edged steel shalll, unless otherwise specified, be in accordance with the tolerance

A.

Nominal width |

1200 or | 1500 or | 1800 or

Nominal thickness | Under | overto | overto | over up

1200 and excl. | and to and

1500 | excl.1800 | incl.2300

Under 1.6 20.14 [20.15 | 20.461) :

1.60 or over to and

eal oo £0.16 [20.17 [40.18 | 40.21(2)

2.00 or over and excl. 2.50/#0.17 _|20.19 2021 | 20.25

| 2.50 or over and excl. 3.15/+0.19 [40.21 [20.24 | +0.26

3.15 or over and excl. 4.00 40.21 [20.23 | 40.26 | 40.27

4.00 or over and excl. 5.00 20.24 |0.26 [20.28 | 40.29 _|

5.00 or over and excl. 6.00 |#0.26 /40.28 | £0.29 | 40.31

6.00 or over and excl. 8.00/+0.29 [40.30 [20.31 | +0.35

8.00 or over and excl. 10.0[#0.32 [20.33 | 40.34 | 40.40

10.0 or over and excl. 12.5| 20.35 [20.36 [40.37 | 40.45

12.5 of over and incl. 14.0 |#0.38 | 20.39 | 40.40 __| +0.50

Notes (1) The values shall be applied to the steel sheets and coil under 1600 mm in width.

(2) The values shall be applied to the steel sheet and coil under 2000 mm in width

REY.00

vans | Tass foxondy

cecety KN Moy Ld plas

IGN & DATE.

Qua ‘DETAILED ENGINEERING ce

PRODUCT STANDARD uv10044

Page 4 of 6

#

eg

IGHT AND CONFIDENTIAL

copy!

SION & DATE

INVENTORY No.

Remarks 1. The thickness shall be measured at any point on the steel sheet and coil

Not less than 20 mm from a side edge. For the steel sheet and coil under 40 mm.

in width, measurement shall be made at the mid- width thereof.

2. The values specified in Table 4 shall not be applied to the irregular portion of both

ends of the steel coil

3. The tolerance on thickness of the steel which is not manufactured from the steel

coil may be agreed between.the L&T-MHI and the supplier.

6. APPREARANCE

The appearance of the steel sheet and coil shall conform to clause 6 of JIS G 3193.

7. TESTS

7.4 Chemical analysis

7.1.1 General requirements and sampling methods for chemical analysis

The chemical composition of the steel and coil shall be determined by cast analysis,

and the general requirements for chemical analysis and the sampling of specimen

for analysis shall be as specified in clause 8 of JIS G 0404.

7.1.2 Analysis method

‘The method for chemical analysis shall be in accordance with JIS G 0320

7.2 Mechanical test

7.2.1 General requirements of mechanical test

The general requirements for mechanical test shall be in accordance with

‘specification in clause 9 of JIS G 0404. With this respect , the sampling method of

sampling method of specimen shall conform to Class A of 7.6 of JIS G 0404, and the

number of test piece s and the sampling position shall be as follows.

a) Number of test pieces The number of test pieces shall be as follows

1) For steel coils and cut length there from

One test piece each for tensile and bend test shall be taken from each test lot of the

same heat rolled to the same thickness. When the mass of one test lot exceeds 50t ,

however, two sets of test pieces shall be taken from the lot,

REV.00

Worked by [* fash [o4-07-gq,

cman) KN WW Ahles

A : PRODUCT STANDARD | svt004

4 ay MHI DETAILED ENGINEERING |

3 ‘MHI e é

| : Page 5of 6 |

SUPERSEDES

z

g

2

2

8

3

2

z

&

2.

E

§

SIGN & DATE

INveNToRY No.

“b) The test methods shall be as specified in JIS Z 2241

2) For'steel sheet (Excluding cut length there from)

One test piece each for tensile and bend test shall be taken form each test lot of the

same heat where the maximum thickness of the steel sheet is with in twice the

maximum thickness therof When the mass of one test lot exceeds 50t , however ,

two sets of test pieces shall be taken from the lot.

5) Sampling position and direction of tensile test and bend test pieces

The test piece shall be taken parallel to the rolling direction and the center of the test

Piece shall be at a quarter width from a side edge. When itis infeasible to allow the

center of the test piece to be a quarter width from the side edge , the sampling

should be performed as close to the aforementioned position as possible.

7.2.2 Tensile test

The tensile test shall be carried out as given in the following.

a) As to a test piece No.5 test piece specified in JIS Z 2201 shall be used

7.2.3 Bend test

‘The bend test shall be carried as given follows.

a) As to a test piece, No.3 test piece specified in JIS Z 2204 shall be used.

b) The test methods shall be as specified in JIS Z 2248.

7.2.4 Deep draw ability test

The test method and sampling of test piece for deep draw ability test shall be as

agreed between L&T-MHI and the manufacturer.

8. INSPECTION

8.1 Inspection The inspection shall be carried out as follows.

a) The general requirements for inspection shall be as specified in JIS G 0404.

b) The chemical composition shall conform to the requirements specified in clause 3.

©) The mechanical properties shall conform to the requirements in clause 4.

d) The shape, dimensions and mass shall conform to the requirements specified in

clause 5.

REV. 00

Wark ty ae Kase oro#-of

Ales

pected y KN

SIGN & DATE

INVENTORY No.

® MHI . DETAILED ENGINEERING

PRODUCT STANDARD i | sronas

Page 6 of 6.

8.2 Re inspection

The steel sheet and coil having failed the requirements of the mechanical test may

be subjected to a retest for final acceptance according to the specification of 9.8 of

JIS G 0404

9. MARKING

The steel sheets and coil having passed the inspection shall be marked with the

following details foe each bundle by suitable means. The steel sheets which are not

bundled shall be marked for each sheet.

a) Symbol of grade

b) Heat number or inspection number

©) Dimensions

4) The number of sheets for each bundle or mass.

) The manufacturer's name or its identifying brand.

10. REPORT

‘The report shall be in accordance with the requirements of clause 13 in JIS G 0404.

When requested by L&T-MHI in advance, the manufacturer shall submit an

inspection documents including the test results, the manufacturing method, the

ordered size and quantity, and manufacturing record, etc. The type of inspection

document shall be, unless otherwise specified, 2.3 or 3.18 in table JIS G 0415

11. REFERRED STANDARDS

JIS G 0320 JIS G 2201

JIS G 0404 JIS G 2204

JIS G 0415 JIS G 2241

JIS G 3193 JIS G 2248

REV. 00

Fin 5 . | Aaush loxoa-0h

oe KN Ho kd |Thlo9

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Check List For Argon GasDocument1 pageCheck List For Argon GasAnonymous jefUrqfio0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Audit Report: Veer Steel MillsDocument8 pagesAudit Report: Veer Steel MillsAnonymous jefUrqfioNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- For Export Orders Only Approved Equivalent To Be Procured Against This SpecificationDocument5 pagesFor Export Orders Only Approved Equivalent To Be Procured Against This SpecificationAnonymous jefUrqfioNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 1.0 Table of ContentDocument2 pages1.0 Table of ContentAnonymous jefUrqfioNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- JV 10054 Spec PDFDocument2 pagesJV 10054 Spec PDFAnonymous jefUrqfioNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Audit Report: Veer Steel MillsDocument8 pagesAudit Report: Veer Steel MillsAnonymous jefUrqfioNo ratings yet

- Details of Lab InstrumentDocument1 pageDetails of Lab InstrumentAnonymous jefUrqfioNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Is.8737.1995 0 PDFDocument20 pagesIs.8737.1995 0 PDFSchneider S TamilNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Sans - 282 - 2004bending PDFDocument27 pagesSans - 282 - 2004bending PDFAnonymous jefUrqfioNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Is.1598.1977 IzodDocument16 pagesIs.1598.1977 Izodbhavin178No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Is.1598.1977 IzodDocument16 pagesIs.1598.1977 Izodbhavin178No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- E407-07 (2015) E1 Standard Practice For Microetching Metals and AlloysDocument22 pagesE407-07 (2015) E1 Standard Practice For Microetching Metals and AlloysOlss BbzoNo ratings yet

- BSENDocument19 pagesBSENAnonymous jefUrqfioNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Bs Steel CodeDocument14 pagesBs Steel CodeA.K.A. HajiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- DIN 933 ISO 4017: Hex Head ScrewsDocument6 pagesDIN 933 ISO 4017: Hex Head ScrewsAnonymous S3WI5scyNo ratings yet

- Astm D695 PDFDocument8 pagesAstm D695 PDFThales Lorencini Amorim100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- F 1554 - 99Document9 pagesF 1554 - 99Kartik SolankiNo ratings yet

- For Export Orders Only Approved Equivalent To Be Procured Against This SpecificationDocument2 pagesFor Export Orders Only Approved Equivalent To Be Procured Against This SpecificationAnonymous jefUrqfioNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Is 210Document16 pagesIs 210Debopriyo GhoshNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- For Export Orders Only Approved Equivalent To Be Procured Against This SpecificationDocument2 pagesFor Export Orders Only Approved Equivalent To Be Procured Against This SpecificationAnonymous jefUrqfioNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- JV 10054 Spec PDFDocument2 pagesJV 10054 Spec PDFAnonymous jefUrqfioNo ratings yet

- (JV10057) Carbon Steel Pipes For High Temperature Service (STPT370) PDFDocument10 pages(JV10057) Carbon Steel Pipes For High Temperature Service (STPT370) PDFAnonymous jefUrqfioNo ratings yet

- Astm A519Document14 pagesAstm A519PrakashNo ratings yet

- ASTM E384-11e1Document43 pagesASTM E384-11e1vangoetheNo ratings yet

- September 12, 2000 01:05:32 Information Handling Services, 2000Document5 pagesSeptember 12, 2000 01:05:32 Information Handling Services, 2000Said ChrouhNo ratings yet

- A 105.2011 PDFDocument5 pagesA 105.2011 PDFAnonymous jefUrqfioNo ratings yet

- Astm A6Document59 pagesAstm A6Rajan Steeve100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- May 27, 2000 07:27:39 Information Handling Services, 2000Document31 pagesMay 27, 2000 07:27:39 Information Handling Services, 2000Said ChrouhNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)