Professional Documents

Culture Documents

Installation, Operation and Maintenance Parker Balston@ 75-83 Zero Air Generator

Uploaded by

Mauro Portugal LagardaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation, Operation and Maintenance Parker Balston@ 75-83 Zero Air Generator

Uploaded by

Mauro Portugal LagardaCopyright:

Available Formats

Installation, Operation and Maintenance

Parker Balston@ 75-83 Zero Air Generator

r--

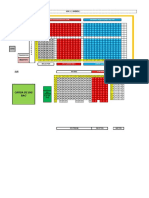

Figure 1 -Parker Balston 75-83 Zero Air Generator

These instructions must be thoroughly read and understood before installing and operating

this product. Failure to operate this product in accordance with these instructions could

present a safety hazard to the user and will void the safety certification of the product.

Modification of the unit will result in voiding the warranty. If you have any questions or

concerns, please call the Technical Services Department at 800-343-4048, 8AM to 5PM

Eastern Time (North America only). For other locations, contact your local representative.

Save all packaging materials from the shipment of the Parker Balston 75-83 Zero Air Genera-

tor.

General Description The Parker Balston 75-83 Zero Air Generator is an engineered system which will replace inconve-

nient high pressure gas cylinders as a source of hydrocarbon-free air. The 75-83 will purify on-site

compressed air to a total hydrocarbon concentration of less than 0.1 ppm (measured as methane).

The Zero Air Generator may be used to generate fuel air for Flame Ionization Detectors (FID's) or

for a zero reference for any instruments which measure hydrocarbon concentration. The 75-83 is

capable of producing up to 1000 cc/min of zero grade air and will serve up to three FID's.

These products are certified to the electrical safety requirements as specified by the IEC, CSA, and

Regulatory Compliance

UL standards. These units bear both the CSA and CUL markings on the product label. Product

supplied to Europe carries the CE mark (220/230/240 V AC units only). The product meets EMC

compliance.

The Parker Balston 75-83 Zero Air Generator includes all of the components necessary to purify

Engineered System

compressed air into zero-grade hydrocarbon-free air. The generator comprises three primary

functional groups: prefiltration, hydrocarbon removal, and final filtration (see Flow Schematic,

Figure 2).

Prefilb"ation A high efficiency coalescing filter has been incorporated into the design of the Parker Balston 75-83

Zero Air Generator as a prefilter to remove oil, water, and particulate contamination from the

incoming compressed air supply. The prefilter assembly is equipped with a manual drain to

eliminate any liquids which have accumulated within the filter housing.

Parker Hannifin Corporation Bulletin TI-7583W

Hydrocarbon Removal The catalyst module is a stainless steel housing filled with catalyst and assembled with a heater.

The catalyst module oxidizes hydrocarbons from the compressed air supply into carbon dioxide and

water. The module is sized to deliver 1000 cc/min. of zero-grade hydrocarbon-free air to the

instrumentation downstream.

Final Filtration The final filter on the Parker Balston 75-83 Zero Air Generator is a high efficiency sintered metal

filter which removes particulate contamination to 0.5 micron. This final filter ensures that the outlet

air from the Parker Balston 75-83 Zero Air Generator is particle-free.

HYDROCARBON

CATALYST

MODULE

.,.,

GRADE BX- d SINTERED METAL

PREFILTER I I FILTER

CO~RESSED AIR ~ '~=::> TO INSTRUMENT

(~0/125psi9) -H

"I;r'

AFTERCOOLER-I

Figure 2 -Flow Schematic

All installation, operation, and maintenance activities for the Parker Balston 75-83 Zero Air

Generator should be performed by suitable personnel using reasonable care.

General The Parker Balston 75-83 Zero Air Generator is designed to mount on the wall or rest on the

benchtop. The inlet and outlet ports are 1/4" female NPT. The inlet port is located on the left side

of the generator, at the inlet to the prefilter (see Figure 5). The outlet port is also 1/4" female NPT,

and it is located on the right side of the generator (see Figure 5). Male 1/4" NPT pipe fittings rated

for 125 psig (8.5 barg) line pressure should be used to connect to the generator.

A shut-off valve and a pressure regulator should be installed directly upstream from the Parker

Balston 75-83 Zero Air Generator. The shut-off valve isolates the unit from the air line for mainte-

nance and troubleshooting tasks. The pressure regulator controls the inlet air pressure and should

be set to maintain a constant pressure between 40 psig and 125 psig (2.7 barg and 8.5 barg).

Maintaining a constant inlet air pressure will minimize any system pressure fluctuations which may

affect the purity of the zero grade air generated. Parker Balston offers a pressure regulator,

complete with a pressure gauge, as an accessory (PIN 72-130-V883).

Location The 75-83 should be located in close proximity to the compressed air supply, the electrical power

supply, and the downstream equipment which it supplies. There is no limit to the distance between

the generator and the point of use as long as tubing size, cleanliness, and pressure drop are taken

into consideration. The generator should be located indoors, protected from severe weather

conditions. The installation location should also be free from excessive ambient dust or dirt. Do

not install the generator outdoors. The ambient temperature of the air surrounding the generatol

must be between 60°F and 100oF (16°C and 40°C} to ensure optimal operation of the unit.

--

Parker Hannifin Corporation Bulletin TI-7583W

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 11-Purificador 2Document4 pages11-Purificador 2Mauro Portugal LagardaNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- MK 7840Document9 pagesMK 7840Delarenus SianiparNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- N2 Generator System PDFDocument12 pagesN2 Generator System PDFNguyễn Ngọc100% (1)

- S11-936 Rev 2Document80 pagesS11-936 Rev 2Salomón BolañosNo ratings yet

- Technical Information: Parker Compressed Air DryerDocument4 pagesTechnical Information: Parker Compressed Air DryerRagu RajanNo ratings yet

- SB Exlar Bleed VlaveDocument5 pagesSB Exlar Bleed VlavemdoNo ratings yet

- Air BlowerDocument5 pagesAir BlowerFishNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- Installation and Operation Instructions For The Bluestar Infra-Red Salamander BroilerDocument18 pagesInstallation and Operation Instructions For The Bluestar Infra-Red Salamander BroilerJose JuanNo ratings yet

- AP Specs 2008Document39 pagesAP Specs 2008Ghiban ConstantinNo ratings yet

- Air Inlet FiltersDocument6 pagesAir Inlet FiltersP.p. Arul IlancheeranNo ratings yet

- CAR-II - (R) - Constant Airflow Regulator - Prod Specs Tech DataDocument4 pagesCAR-II - (R) - Constant Airflow Regulator - Prod Specs Tech DataSantiago J. ramos jrNo ratings yet

- PQT Rheem Rlmb-A150clDocument92 pagesPQT Rheem Rlmb-A150clGerardo ZamoranoNo ratings yet

- Hvac SpecificationsDocument46 pagesHvac SpecificationsAnkush Nayar100% (1)

- Rheem Commercial Value Series Package Air Conditioner: RLKL-B Standard Efficiency SeriesDocument48 pagesRheem Commercial Value Series Package Air Conditioner: RLKL-B Standard Efficiency SeriesJesus RequenaNo ratings yet

- 38AUM 60Hz PDC V9Document40 pages38AUM 60Hz PDC V9hgogoriyaNo ratings yet

- Aire Acondicionado CARRIER 24ABC6 - Product - DataDocument84 pagesAire Acondicionado CARRIER 24ABC6 - Product - DatajoapmeNo ratings yet

- SPDS Series - Literature - IND - Oil-FreeDocument6 pagesSPDS Series - Literature - IND - Oil-Freecao van daiNo ratings yet

- Es2184d - Cleaning and Flushing of Hydraulic Systems & ComponentsDocument9 pagesEs2184d - Cleaning and Flushing of Hydraulic Systems & Componentsferfilho100% (2)

- AA Bard 5.0 TonRDocument12 pagesAA Bard 5.0 TonRCarlos GudiñoNo ratings yet

- Daikin 1Document17 pagesDaikin 1Rizal RyamizardNo ratings yet

- Operator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpDocument12 pagesOperator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpNashrullah AhmadNo ratings yet

- 92 23577 122 00 - RheemDocument36 pages92 23577 122 00 - RheemIshfaqAhmedMayoNo ratings yet

- 1 VFB IomDocument22 pages1 VFB IomshambhoiNo ratings yet

- Rheem PKG RLNL-B - S11-937 - Rev1 PDFDocument56 pagesRheem PKG RLNL-B - S11-937 - Rev1 PDFWESHIMNo ratings yet

- Rheem Commercial Classic Series Package Air Conditioner Featuring Humididry TechnologyDocument60 pagesRheem Commercial Classic Series Package Air Conditioner Featuring Humididry TechnologyIshfaqAhmedMayoNo ratings yet

- TFP1586 11 2023Document12 pagesTFP1586 11 2023fassart.jNo ratings yet

- Drives Td001 en PDocument6 pagesDrives Td001 en Persanjeeb_456No ratings yet

- Diesel Engines and Equipment For Hazardous Areas: Cat Explosion ProtectionDocument16 pagesDiesel Engines and Equipment For Hazardous Areas: Cat Explosion ProtectionJeff L100% (1)

- LiftAire I and II Installation Manual 02-15-2013Document20 pagesLiftAire I and II Installation Manual 02-15-2013alanbrann0% (1)

- RACOR Fuel Water SeperatorDocument27 pagesRACOR Fuel Water SeperatorDmitriy AntonenkoNo ratings yet

- ARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid SectionDocument12 pagesARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid Sectionduc tranNo ratings yet

- Car-Ii: Constant Airflow RegulatorDocument4 pagesCar-Ii: Constant Airflow RegulatorLuis GiaganteNo ratings yet

- Curso Caterpillar Material Del Estudiante Dispositivos ElectronicosDocument109 pagesCurso Caterpillar Material Del Estudiante Dispositivos ElectronicosWilmar Raul Hancco ZaraviaNo ratings yet

- Fs Curtis E57 Compressor ManualDocument56 pagesFs Curtis E57 Compressor ManualJustin Carrier100% (1)

- Drives Td001 - en P Ultima VersionDocument6 pagesDrives Td001 - en P Ultima VersionCristian Yesid Pachon HernandezNo ratings yet

- Aftercooler - Test: Shutdown SIS Previous ScreenDocument7 pagesAftercooler - Test: Shutdown SIS Previous ScreenKeron Trotz100% (1)

- 24abs3 4pdDocument66 pages24abs3 4pdleonardo_suarez_82No ratings yet

- 38aum 50hz PDC v4Document36 pages38aum 50hz PDC v4khaled salahNo ratings yet

- Richland, Michigan 49083 269-629-5000: Pneumatic DivisionDocument4 pagesRichland, Michigan 49083 269-629-5000: Pneumatic DivisionJavierLugoNo ratings yet

- Hidronicos 2Document17 pagesHidronicos 2Gerardo Zumbado MNo ratings yet

- FHP Apseries WSHPDocument16 pagesFHP Apseries WSHPsajuhereNo ratings yet

- RP, GP, XP Pro Series: Installation InstructionsDocument8 pagesRP, GP, XP Pro Series: Installation InstructionsSai Sunil ChandraaNo ratings yet

- Parker Dual-Bed Nitrogen Generation Systems: Installation, Operation, and Maintenance ManualDocument48 pagesParker Dual-Bed Nitrogen Generation Systems: Installation, Operation, and Maintenance ManualgokulNo ratings yet

- AGN 066 - Alternator IP Protection: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDocument7 pagesAGN 066 - Alternator IP Protection: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesariwibowoNo ratings yet

- TRC Unit SpecDocument12 pagesTRC Unit SpecJohn ChirinosNo ratings yet

- Operator'S Manual Px15X-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpDocument12 pagesOperator'S Manual Px15X-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpMECANICA ELECTRICA TSAVINGNo ratings yet

- ARB Compressor DualDocument5 pagesARB Compressor DualSteveNo ratings yet

- 24abr3 4pdDocument30 pages24abr3 4pdHugo OnoroNo ratings yet

- Installation Instructions: GP/GPC, XP/XPC, XR SeriesDocument8 pagesInstallation Instructions: GP/GPC, XP/XPC, XR SeriesSai Sunil ChandraaNo ratings yet

- RKNL-H (15-20 Ton)Document72 pagesRKNL-H (15-20 Ton)Meghana BuchiNo ratings yet

- Air Blower ManualDocument16 pagesAir Blower ManualshaiknayeemabbasNo ratings yet

- RKNL-G (15-25 Ton)Document64 pagesRKNL-G (15-25 Ton)Meghana BuchiNo ratings yet

- Operator'S Manual Px10P-Xxs-Xxx-Axxx: 1" Diaphragm PumpDocument12 pagesOperator'S Manual Px10P-Xxs-Xxx-Axxx: 1" Diaphragm PumpjarosNo ratings yet

- Air 3-101Document24 pagesAir 3-101753rgsNo ratings yet

- Mtto Fan Clutch Pro StarDocument1 pageMtto Fan Clutch Pro StarOscar MillanNo ratings yet

- RKNL-C (15 - 25 Ton)Document84 pagesRKNL-C (15 - 25 Ton)Meghana BuchiNo ratings yet

- Carga de Big BAG: Via 1 (Anden)Document2 pagesCarga de Big BAG: Via 1 (Anden)Mauro Portugal LagardaNo ratings yet

- 2009 Caliber SRT4Document411 pages2009 Caliber SRT4Mauro Portugal LagardaNo ratings yet

- Group Approval Rules Presentation June 22 2017Document28 pagesGroup Approval Rules Presentation June 22 2017Mauro Portugal LagardaNo ratings yet

- Steren Usb Serial DriverDocument3 pagesSteren Usb Serial DriverMauro Portugal LagardaNo ratings yet

- Carga de Furgones: Envase, Logística y Distribución AHR0Document5 pagesCarga de Furgones: Envase, Logística y Distribución AHR0Mauro Portugal LagardaNo ratings yet

- Multi-Component FTIR Emission Monitoring System: Measurement Made EasyDocument12 pagesMulti-Component FTIR Emission Monitoring System: Measurement Made Easyhoangtien1991No ratings yet

- Split Spherical Roller Bearings in Fans: Examples of Application Engineering WL 22 503 EADocument2 pagesSplit Spherical Roller Bearings in Fans: Examples of Application Engineering WL 22 503 EAMauro Portugal LagardaNo ratings yet

- Refacciones Cems ACF5000Document1 pageRefacciones Cems ACF5000Mauro Portugal LagardaNo ratings yet

- 7162 en 06Document10 pages7162 en 06Mauro Portugal LagardaNo ratings yet

- en 01Document2 pagesen 01Mauro Portugal LagardaNo ratings yet

- Programación en Listado de InstruccionesDocument63 pagesProgramación en Listado de InstruccionesMauro Portugal LagardaNo ratings yet

- GoProStudio2.5 User Manual WindowsDocument107 pagesGoProStudio2.5 User Manual Windowsmiguel suarezNo ratings yet

- Inside Job: Worldwide Economic Catastrophe "2008 Crisis": Mauro Portugal LagardaDocument1 pageInside Job: Worldwide Economic Catastrophe "2008 Crisis": Mauro Portugal LagardaMauro Portugal LagardaNo ratings yet

- 9814 Material 1 1625049897Document7 pages9814 Material 1 1625049897AadityaNo ratings yet

- PracticeExamRegression3024 PDFDocument13 pagesPracticeExamRegression3024 PDFdungnt0406100% (2)

- StressCrete Spun Concrete Utility Poles BrochureDocument16 pagesStressCrete Spun Concrete Utility Poles BrochureRet GenandoyNo ratings yet

- Cyclone Nargis Research ProjectDocument3 pagesCyclone Nargis Research ProjectShaun WhiteNo ratings yet

- Ielts ReadingDocument15 pagesIelts ReadingAn Ốm NhomNo ratings yet

- Blower Door Test Procedures: Preliminary Comparison Between EN 13829:2002 and ASTM 779-03Document11 pagesBlower Door Test Procedures: Preliminary Comparison Between EN 13829:2002 and ASTM 779-03Sathiaram RamNo ratings yet

- 1974-Predictability, Constancy, and Contingency of Periodic Phenomena PDFDocument6 pages1974-Predictability, Constancy, and Contingency of Periodic Phenomena PDFqilongwuNo ratings yet

- Magical States of Consciousness: Secrets of Pathworking: by Osborne PhillipsDocument21 pagesMagical States of Consciousness: Secrets of Pathworking: by Osborne PhillipsMadeleiGOOGYXNo ratings yet

- Chap 18Document44 pagesChap 18Suleman Ayub100% (1)

- Aerodrome Meteorological Observation and Forecast Study Group (Amofsg)Document4 pagesAerodrome Meteorological Observation and Forecast Study Group (Amofsg)Tuha MohammedNo ratings yet

- Zebra Current Capacity Calculation SheetDocument1 pageZebra Current Capacity Calculation SheetbinodeNo ratings yet

- Tropical Fruit Tree Species and Climate ChangeDocument142 pagesTropical Fruit Tree Species and Climate ChangeManuel VegasNo ratings yet

- Automated Irrigation With Advanced Seed Germination and Pest ControlDocument4 pagesAutomated Irrigation With Advanced Seed Germination and Pest ControlOlatomide OlaosebikanNo ratings yet

- CAE Practice Tests TBDocument160 pagesCAE Practice Tests TBAkaal Moorat Kaur74% (46)

- Humidity Effects On Gas Turbine PerformanceDocument7 pagesHumidity Effects On Gas Turbine PerformanceTolgahan ŞahinNo ratings yet

- Bair Hugger 505 OM-EnGDocument14 pagesBair Hugger 505 OM-EnGCarl AzzopardiNo ratings yet

- De Thi Olp Tieng Anh 11Document10 pagesDe Thi Olp Tieng Anh 11bongdentrithuc100% (1)

- Read Married by Mistake - Mr. Whitman's Sinner Wife by Sixteenth Child Chapter 461Document9 pagesRead Married by Mistake - Mr. Whitman's Sinner Wife by Sixteenth Child Chapter 461psdflj1985No ratings yet

- Learning AI Development With UXDocument41 pagesLearning AI Development With UXA RaoNo ratings yet

- Sir James Edward Alexander - Transatlantic Sketches... With Notes On Negro Slavery and Canadian Emigration (1833)Document392 pagesSir James Edward Alexander - Transatlantic Sketches... With Notes On Negro Slavery and Canadian Emigration (1833)chyoungNo ratings yet

- 7th Standard - GeographyDocument26 pages7th Standard - GeographyRamesh SinghNo ratings yet

- Module 6 Answers - JunGil M. CasquejoDocument3 pagesModule 6 Answers - JunGil M. Casquejojungil casquejoNo ratings yet

- Chinese Pharmaceutical ForecasteDocument5 pagesChinese Pharmaceutical ForecasteGreggi RizkyNo ratings yet

- Verb To BeDocument9 pagesVerb To BeIbrahim LotfyNo ratings yet

- Writing The Natural Way-2Document2 pagesWriting The Natural Way-2alansi92004100% (1)

- Ring and Ball TestDocument4 pagesRing and Ball TestMuhd Farhan Bin IbrahimNo ratings yet

- The Ultimate Actionable Guide of Anchoring A ShipDocument19 pagesThe Ultimate Actionable Guide of Anchoring A ShipstamatisNo ratings yet

- FrozenDocument2 pagesFrozenPetar Pan100% (1)

- FRS-25NC Manual ServicioDocument57 pagesFRS-25NC Manual ServicioCiclismo Sexta Región100% (2)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)