Professional Documents

Culture Documents

Trailer Systems Troubleshooting Guide: How To Use This Chart

Uploaded by

PototoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trailer Systems Troubleshooting Guide: How To Use This Chart

Uploaded by

PototoCopyright:

Available Formats

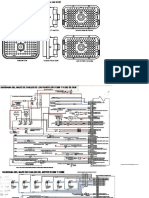

Trailer Systems

Troubleshooting Guide

SYSTEM “A” SYSTEM “F”

PRE-121 RELAY/EMERGENCY VALVE SYSTEM HOW TO USE THIS CHART MOD-I FULL FUNCTION ABS 2S/1M

The purpose of the chart is to help you solve a specific problem in the pneumatic portion of a trailer air brake system with the

assumption the foundation brake components and tractor pneumatics are in good repair.

Identify which system is malfunctioning. (Refer to how to check your system).

Identify your system from the schematics shown.

Identify the problem and select the solution recommended for that system.

CAUTION: WHEELS MUST BE BLOCKED.

CAUTION: SPRING BRAKE INSPECTION AND DISASSEMBLY MUST BE IN ACCORD WITH THE

MANUFACTURERS PROCEDURE.

HOW TO CHECK YOUR SYSTEM

The most important factor in trailer troubleshooting is to determine if the malfunction is in the vehicle’s “parking brake system” or

the “service brake system”. If the problem is “Neither air system is working”, the fault may be mechanical. All “Pre-121” or new “121”

trailers have a “parking/emergency system” and normally used “service brake system”. The parking system works from the

emergency (supply) line. The service system works from the service (control) line. You can determine if the parking emergency

brakes operate by charging and then disconnecting the tractor emergency (supply) line.

The service brakes will operate with apply and release air in the service (control) line by the tractor hand control or foot control valve.

HOW TO IDENTIFY YOUR SYSTEM

All types of trailer air brake systems can be identified for troubleshooting purposes by starting from the brake chamber or spring

brake assembly. This procedure will work for older “Pre-121” equipped trailers regardless of how many tanks and valves or types of

valves that you see. For ABS Troubleshooting, See ABS Diagnostic Troubleshooting Guide (L20293).

SYSTEM “B” If your trailer is equipped with chambers only - you are dealing with system “A” for a trailer and systems “C” and “D” for a converter SYSTEM “G”

PRE-121 RELAY/EMERGENCY VALVE SYSTEM dolly. A “four-wheel” trailer may have chambers on the steerable axle - identify axle as a dolly system “C” or “D”. If the vehicle is MOD-II ABS 4S/2M

WITH SPRING BRAKES equipped with spring brakes you must determine which hose is the “parking/emergency” and which is the “service”.

Follow the service hose from the service portion of the spring brake assembly, the hose will be connected to the service relay valve

and it is responsible for the application and release of the service brake only.

Follow the parking/emergency hose from the spring brake assembly and you will end up at the spring brake control valve. After you

have identified your system, go directly to the Problem and Solution Sections on the reverse side to remedy your situation.

SYSTEM “J”

TWO TANK - ONE VALVE TANDEM AXLE SYSTEM

For ABS Troubleshooting, See ABS Diagnostic Troubleshooting Guide (L20293).

SYSTEM “C” SYSTEM “H”

SINGLE AXLE DOLLY SYSTEM WITH CHARGING TYPE TWO TANK - THREE VALVE TANDEM SYSTEM MIDLAND RT4/RG2 (RG5) VALVES OR

RELAY/EMERGENCY VALVE SEALCO MULTI-FUNCTION WITH SERVICE RELAY VALVE

SYSTEM “D” SYSTEM “E”

TYPICAL 121 DOLLY SYSTEM WITH NON- TWO TANK - TWO VALVE SINGLE AXLE SYSTEM WITH MIDLAND

CHARGING TYPE RELAY/EMERGENCY VALVE RTF4/RG2 VALVE OR SEALCO MULTI-FUNCTION & RELAY

NOTE: Procedures suggested on this chart are merely suggested and should not be construed to be all inclusive nor should the schematics be regarded as typical of piping patterns on all vehicles.

PROBLEM SYSTEM LETTER AND SOLUTION NUMBER SOLUTION

A B C D E F G H J 1. Check service chamber at clamp housing, push rod 27. Assure spring brake is fully released with supply air at

AIR LEAK AT for damage. system pressure above 100 P.S.I. or emergency side of

spring brake.

2. Check service chamber diaphragm for rupture.

Service Brake Chamber 1-2-34 - 1-2-34 1-2-34 - - - - - 28. Excessive volume imposed in supply/emergency lines -

3. Check brake adjuster and chamber/spring brake ie: air pintle air chamber.

Spring Brake with Service Brakes Released & Park Brake Applied - 11-36-37 - - - - - - - push rod alignment for interference.

29. On a pre-121exempt trailer utilizing an emergency relay

6-11-36 6-11-36 6-11-36 6-11-36 6-11-36 6-11-36 4. Assure brake adjuster and chamber/spring brake valve, the spring brake emergency port should be

Spring Brake with Service Brakes Released & Park Brake Released - or 37 - - or 37 or 37 or 37 or 37 or 37 push rod angle 90° applied with proper adjustment. plumbed directly to the tank.

5. Check all lines, valves, reservoirs, actuators for 30. Observe and determine which specific device, fitting or

Spring Brake with Service Brakes Applied & Spring Brake Released - 6-25-36 - - 6-25-36 6-25-36 6-25-36 6-25-36 6-25-36 leakage. hose is leaking and replace.

33-36-37

Emergency Relay Valve with Service Brake Applied or Released 42 or 42 42 51 - - - - - 6. Check spring brake for damage or loose clamp. 31. Assure a leak free system by applying service brake and

7. Assure jumper hoses are not crossed. inspecting.

Emergency Relay Valve with Emergency Brake Applied 42 42 42 51 - - - - -

8 Assure functional return spring in service chamber 32. Note that some trailers may have the emergency/supply

Service Relay Valve with Service Brake Released & Spring Brake Applied - - - - 38 54 54 38 53 or spring break. line piped to a single check valve at both tanks - one

could be leaking.

Service Relay Valve with Service Brake Released & Spring Brake Released - - - - 33-38 33-54 33-54 33-38 33-53 9. Assure air chamber size and brake adjuster arm

length to original spec. 33. Check for failure in spring brake center seal.

Service Relay Valve with Service Brake Applied & Spring Brake Released - - - - 38 54 54 38 53 A. Block wheels and release park brake.

10. Assure spring brake control port has exhausted. B. Check for air pressure leakage at service port of

Spring Brake Control Valve with Spring Brake Applied or Released - - - - 40 54 54 40 53 each spring brake until the leaking assembly is

11. Check for ruptured spring brake diaphragm located. Replace leaking unit.

Trailer Service Gladhand on Disconnect (with Trailer Supply Pressurized) 42 42 42 51 24-40 54 54 24-40 53 (furthest from brake adjuster). C. If no spring brake leakage is found see #41.

Trailer Emergency Gladhand on Disconnect 42 42 42 51 or 52 - - - - - 12. Supply/emergency line must be at atmosphere. 34. Confirm and replace with Type 30 diaphragm, air

13. Assure emergency line exceeds 100 P.S.I. pressure; chamber Type 30

Trailer System Leakage Exceeds 2 P.S.I. per min. with Service Brakes Applied 30 30 30 30 30 30 30 30 30

check and maintain governor at max cut-in. 35. Confirm and replace/use rubber grommets with integral

SERV Valve with Service Brake Released & Park Brake Applied - - - - - - - - - 14. Assure air delivery to service gladhand. brackets.

SERV Valve with Service Brake Released & Park Brake Released - - - - - - - - - 15. Assure air delivery to service relay valve control port. 36. Confirm and replace with appropriate spring brake

assembly; Type 30/30 or Type 24/30. Diaphragm Type

SERV Valve with Service Brake Applied & Park Brake Released - - - - - - - - - 16. Assure air delivery to air chamber or spring brake. 24/30 PiggyBack.

SYSTEM OR COMPONENT FAILURE 17. Assure air delivery to emergency gladhand 37. Confirm and replace with Type 30/30 PiggyBack or Type

3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- exceeds 100 P.S.I. 24/30 PiggyBack

Trailer Brakes Slow and Sluggish

44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 18. Assure air delivery to emergency relay valve 38. Confirm and replace with service relay valve 1/2 Supply

46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47 emergency port. or 3/8 Supply.

Trailer Brakes Drag 3-4-13- 3-4-13- 3-4-13- 3-4-13- 3-4-13- 19. Assure air delivery to all reservoirs at system 39. Confirm and replace with task spring brake control

3-4-13- 3-4-22- 3-4-22- 3-4-22- 22-23- 22-23- 22-23- 22-23- 22-23- working pressure. valve.

22-23-42 23-27 23-42 23-51 27-37 27-37 27-37 27-37 27-37 20. Assure air delivery to spring brake control valve 40. Confirm and replace with RT-4 spring brake control

control port. valve (replaces Sealco ratio valves).

Trailer Brakes Won't Apply (Service) 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14-

16-18-19 16-18-19 16-18-19 14-18-19 15-16-19 15-16-19 15-16-19 15-16-19 15-16-19 21. Assure air delivery to control port on spring brake 41. Assure adequate trailer brake function.

(port furthest from brake adjuster).

Trailer Emergency Application Too Slow 42. Confirm and replace with emergency relay valve,

22-28 22-28 22-28 22-28 22-28 22-28 22-28 22-28 22-28 22. Assure open lines - no kinks, bends, closed shut-off 1/4 Delivery or 3/8 Delivery.

cocks, restrictions, excessive elbows.

Park/Emergency Brakes Won’t Release 7-11-17- 7-17-18- 7-17-18- 7-11-17- 7-11-13- 7-11-13- 7-11-17- 7-11-13- 43. Confirm and replace with FFV (Full Function Valve)

7-17-18- 18-19 22 19-22- 19-22- 19-22- 17-19 17-19-22- 19-22- 17-19- 23. Check for trapped service air pressure at trailer System.

19-22-42 42 42 51 40 22- 54 40 40 53 service/delivery hoses. If air pressure is noted, check

for full release of all application valves 44. Assure adequate tractor brake function.

Park/Emergency Brakes Won’t Hold 3-4-36 or 3-4-36 3-4-36 3-4-36 or 3-4-36 or 3-4-36- (tractor/truck/trailer).

3-4-19 37 19- 32 19- 32 or 37 or 37 37 37 or 37 45. Assure adequate pressure and timing balance relative to

24. Trailer brakes which have a spring brake control valve tractor/trailer application.

Park/Emergency Brakes Won’t Apply 4-12-19- 4-10-12- 4-10-12- 4-10-12- 4-10-12- 4-10-12- can be compounded by the tractor air brake system. 46. Consider addition of “FAB Valve” to accelerate trailer

4-12-19- 36 or 37 4-12-19- 4-12-19- 36 or 37- 36 or 37- 36 or 37- 36 or 37- 36 or 37- The compounding occurs when service air pressure timing.

42 -42 42 51 40 54 54 40 53 is trapped in the trailer service line by the tractor

protection valve when the supply line is released to 47. Consider use of “jumper hose analyzer” and duplex

Air Reservoir Leaks or Loose Mounting 35 35 35 35 35 35 35 35 35 atmosphere. Compounding is prevented by gauge to pin-point brake imbalance.

connecting the trailer service line to the appropriate

port of the trailer spring brake control valve through a 48. Assure full mechanical release - foundation brake.

BRAKE BALANCE tee. Early spring brake control valves are equipped

49. Assure “push-out” pressure or initial brake adjuster

4-22-45- 4-22-45- 4-22 46- 4-22 46- 4-22-45- 4-22-45- 4-22-45- 4-22-45- 4-22-45- with a shuttle valve between the supply and service

Semi-Trailer “RUNS-UP” on Tractor 46-47-49 46-47-49 47-49 47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 connections at the cover. The RT-4 has a one- way

motion at 3 to 7 P.S.I. - at all brakes.

check valve which prevents supply pressure from 50. Proceed per problem “trailer brakes drag.”

Uneven Brakes 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- entering the service lines; but will allow service

31-49 31-49 31-49 31-49 31-49 31-49 31-49 31-49 31-49 pressure to vent at trailer supply coupling. Systems A, B, 51. Confirm and replace with emergency relay valve

C, D will not compound the trailer brake system if (non-charging).

Trailer Brake Lining Wear Excessive connected as shown on this chart.

48-50 27-44-50 44-50 44 27-44-50 27-44-50 27-44-50 27-44-50 27-44-50 52. Confirm and replace with pressure protection valve with

one-way check, 50 P.S.I. or 75 P.S.I.

25. Check for ruptured service brake diaphragm in spring

Trailer Brake Lining Wear Insufficient When Compared to Tractor 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- brake (clamp nearest brake adjuster) after attention to 53. Confirm and replace with full function valve (FFV). FFV

46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 damage or loose clamps. has built-in anti-compounding feature.

Trailer Brakes Slow to Apply 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 26. Proceed same as for service relay valve. 54. Confirm and replace with spring brake priority or

46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47 service brake priority (FFABS) ABS full function valve.

Trailer Brakes Slow to Release 8-22-42- 8-22-42- 8-22-42- 8-22-47- 8-22-38- 8-22-38- 8-22-38- 8-22-38- 8-22-38-

47-48 47-48 47-48 48-51 47-48 47-48 47-48 47-48 47-48 NOTE: FOR FURTHER TECHNICAL ASSISTANCE CONTACT YOUR HALDEX SERVICES

Damaged Foundation Components Due to Brake Compounding DISTRIBUTOR, DISTRICT MANAGER, A TECHNICAL SERVICE REPRESENTATIVE OR

- 29 - 24 24 54 54 24 53 CALL (800) 643 -2374 AND ASK FOR A TECHNICAL ADVISOR.

Commercial Vehicle Systems

www.haldex.com Haldex Brake Products Corporation

10707 N.W. Airworld Drive

Kansas City, MO 64153 -1215

Haldex Limited

525 Southgate Drive, Unit 1

Guelph, Ontario CANADA N1G 3W6

Phone: (816) 891- 2470 Phone: (519) 826- 7723

Fax: (816) 801-4198 Fax: (519) 826-9497

L60040 US Rev 10/08 5M CUT

You might also like

- Volvo VNL Diagramas Electricos Completos PDFDocument200 pagesVolvo VNL Diagramas Electricos Completos PDFAnonymous OrZIZ1Bpg92% (59)

- QuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualDocument2 pagesQuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualjengandxbNo ratings yet

- Section Schematic and Routing Diagrams: ECM Wiring Diagram (1.4l/1.6L DOHC - 1 OF 6)Document30 pagesSection Schematic and Routing Diagrams: ECM Wiring Diagram (1.4l/1.6L DOHC - 1 OF 6)Ivan Leonardo Acevedo Galan94% (16)

- Volvo VNL Trucks Usa 2017 PDFDocument29 pagesVolvo VNL Trucks Usa 2017 PDFdionisio emilio reyes jimenez100% (1)

- R-134a Auxiliary Power Unit Installation ManualDocument50 pagesR-134a Auxiliary Power Unit Installation ManualTommy RoachNo ratings yet

- Freightliner Coronado SD: SectionDocument23 pagesFreightliner Coronado SD: SectionhoangnhuphuocNo ratings yet

- Service Manual: Airglide 400 / 460 / 690 Air Spring SuspensionDocument21 pagesService Manual: Airglide 400 / 460 / 690 Air Spring Suspensionj100% (2)

- OC442012e FN72-00 (F2000) SPECIFICATIONS 11-00Document7 pagesOC442012e FN72-00 (F2000) SPECIFICATIONS 11-00profistarNo ratings yet

- Ottawa Air Brakes Service ManualDocument32 pagesOttawa Air Brakes Service ManualcbudkuleyNo ratings yet

- Peterbilt - Flex-Air Service Bulletin (fsb0102) PDFDocument3 pagesPeterbilt - Flex-Air Service Bulletin (fsb0102) PDFJonathan Luiz PolezaNo ratings yet

- DDC SVC Bro 0001 - 2018Document39 pagesDDC SVC Bro 0001 - 2018David PomaNo ratings yet

- MM 0112Document112 pagesMM 0112Rob PenndotNo ratings yet

- Air Brake SystemDocument23 pagesAir Brake SystembalabooksNo ratings yet

- Heavy Equipment Mechanic: Passbooks Study GuideFrom EverandHeavy Equipment Mechanic: Passbooks Study GuideRating: 5 out of 5 stars5/5 (1)

- 3UZ-FE Engine Specs and Major DifferencesDocument34 pages3UZ-FE Engine Specs and Major Differencesbob loblaw100% (1)

- Diagnostic Codes CatDocument5 pagesDiagnostic Codes Catcatmand8No ratings yet

- Ford Tempo Topaz 1984-1994 Repair GuideDocument11 pagesFord Tempo Topaz 1984-1994 Repair GuideFer VN100% (2)

- Engine D-4S. LexusDocument59 pagesEngine D-4S. LexusThanh DanhNo ratings yet

- L30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-OnlyDocument99 pagesL30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-Onlyenzo7259No ratings yet

- 2011 Mad PogDocument81 pages2011 Mad PogBruno Pilieci100% (1)

- Hydro-Boost: GM Full Size Vans 1987-1997 Repair GuideDocument7 pagesHydro-Boost: GM Full Size Vans 1987-1997 Repair GuideEndry Enrique Rincón VargasNo ratings yet

- 2013-01!26!194634 Peterbilt Model 387 Operators Manual Prior To 12-06 LowDocument188 pages2013-01!26!194634 Peterbilt Model 387 Operators Manual Prior To 12-06 LowyamilmrNo ratings yet

- Bendix D-2 GovernorDocument4 pagesBendix D-2 GovernormarcrunnerNo ratings yet

- DDC SVC Bro 0001Document38 pagesDDC SVC Bro 0001David PomaNo ratings yet

- Wabco Wall Chart For Trailer and Truck AbsDocument1 pageWabco Wall Chart For Trailer and Truck AbsJay RitschardNo ratings yet

- Heavy-Duty Diagnostic: Product CatalogDocument12 pagesHeavy-Duty Diagnostic: Product CatalogSonthi MooljindaNo ratings yet

- Clutch PDFDocument12 pagesClutch PDFIzz BaharNo ratings yet

- Commercial Vehicles Air Brake AdjustmentDocument14 pagesCommercial Vehicles Air Brake AdjustmentMohamed SeifNo ratings yet

- 9800i Spec Sheet PDFDocument2 pages9800i Spec Sheet PDFAl FbaNo ratings yet

- Freightliner Coronado 122SD and 132SD Driver's Manual PDFDocument183 pagesFreightliner Coronado 122SD and 132SD Driver's Manual PDFAram MorenoNo ratings yet

- 8700 RangeDocument14 pages8700 RangePhilippine Bus Enthusiasts SocietyNo ratings yet

- Service Manual Trucks Group 87 Air Heater Espar D1LC CompactDocument58 pagesService Manual Trucks Group 87 Air Heater Espar D1LC CompactNeojai jaiyuNo ratings yet

- Parts For Trucks Trailers and Buses HVACDocument473 pagesParts For Trucks Trailers and Buses HVACHARISHKIRTHI MECHNo ratings yet

- Yukon Air Brake Manual SectionsDocument58 pagesYukon Air Brake Manual SectionsJennifer ParkerNo ratings yet

- Air Brake 2016Document96 pagesAir Brake 2016api-359742263No ratings yet

- Freightliner M203ChassisFrameDocument46 pagesFreightliner M203ChassisFrameott1167100% (2)

- Air Brake Adjustment GuideDocument14 pagesAir Brake Adjustment GuideqwertyuiopNo ratings yet

- Recommended Procedure For Cutting Brake Chamber Push-Rod: Service BulletinDocument2 pagesRecommended Procedure For Cutting Brake Chamber Push-Rod: Service BulletinFernando PadillaNo ratings yet

- 2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551Document1 page2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551juanNo ratings yet

- Heavy-Duty Diesel Engine ToolsDocument6 pagesHeavy-Duty Diesel Engine ToolsManji BladeNo ratings yet

- Check and Test J1939 and Truck CAN NetworksDocument9 pagesCheck and Test J1939 and Truck CAN NetworksJOHN Wright100% (1)

- Road RangerDocument466 pagesRoad RangerGiapy Phuc Tran0% (1)

- Cummins Gearing Recommendations for On-Highway VehiclesDocument40 pagesCummins Gearing Recommendations for On-Highway Vehicleskamikazeee100% (1)

- Fruitland Vacuum Pump Operation and Maintenance ManualDocument48 pagesFruitland Vacuum Pump Operation and Maintenance ManualALEXNo ratings yet

- EGR Cooler, Replacement D13Document28 pagesEGR Cooler, Replacement D13htayooNo ratings yet

- QuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFDocument6 pagesQuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFmds9185No ratings yet

- 27volvod13engine 1 en PDFDocument12 pages27volvod13engine 1 en PDFSudipta DubeyNo ratings yet

- Air BrakeDocument56 pagesAir BrakeAlexanderNo ratings yet

- 003-004 Overhead Set: General InformationDocument16 pages003-004 Overhead Set: General InformationIgoen YandriNo ratings yet

- SAP Catalog HeavyDutyDivision LDocument176 pagesSAP Catalog HeavyDutyDivision LUrias SanchezNo ratings yet

- Argosy Driver's ManualDocument222 pagesArgosy Driver's ManualRodolfo Alberto Muñoz CarcamoNo ratings yet

- TS 35Document4 pagesTS 35Philippine Bus Enthusiasts SocietyNo ratings yet

- Air Disc BrakesDocument4 pagesAir Disc BrakesArijeet Sen0% (1)

- Pressure Testing The Intake & Exhaust Sys at One TimeDocument2 pagesPressure Testing The Intake & Exhaust Sys at One Timejaime roblesNo ratings yet

- Webasto Manual IndepthDocument36 pagesWebasto Manual IndepthbarnumlivesNo ratings yet

- Power Steering PDFDocument25 pagesPower Steering PDFGanesh KambleNo ratings yet

- Trucks Rear Axle SystemsDocument6 pagesTrucks Rear Axle SystemsAyman OsamaNo ratings yet

- Cylinder Head Install D13A 211 78 1-8-06Document13 pagesCylinder Head Install D13A 211 78 1-8-06Minn Thet NaingNo ratings yet

- Axial Power Turbine (09TS13)Document2 pagesAxial Power Turbine (09TS13)ПавелNo ratings yet

- Service Bulletin Trucks: Instrumentation TroubleshootingDocument4 pagesService Bulletin Trucks: Instrumentation Troubleshootingsetiup holjiNo ratings yet

- DAF XF105 Infosheet Cab enDocument5 pagesDAF XF105 Infosheet Cab enMarko PajićNo ratings yet

- Kenworth Range Australia Line UpDocument2 pagesKenworth Range Australia Line UpDIONYBLINKNo ratings yet

- ECM KodiacDocument3 pagesECM KodiacPototoNo ratings yet

- Bendix TP-3DC Tractor Protection Valve With Double Check: DescriptionDocument8 pagesBendix TP-3DC Tractor Protection Valve With Double Check: DescriptionPototoNo ratings yet

- Equipment For Trailer Braking SystemsDocument35 pagesEquipment For Trailer Braking SystemsPototoNo ratings yet

- Ag Turf EW Maintenance Guide Bcffe4ebDocument3 pagesAg Turf EW Maintenance Guide Bcffe4ebPototoNo ratings yet

- TP3 Tractor Protection ValveDocument4 pagesTP3 Tractor Protection ValveJaime A GomezNo ratings yet

- Exhaust+manifold+isx+15 PDFDocument10 pagesExhaust+manifold+isx+15 PDFPototoNo ratings yet

- Taib 0873 PDFDocument2 pagesTaib 0873 PDFPototoNo ratings yet

- Eaton Fuller: TransmissionsDocument2 pagesEaton Fuller: TransmissionsPototoNo ratings yet

- Bendix PP-7 Trailer Supply Valve: Function and DescriptionDocument7 pagesBendix PP-7 Trailer Supply Valve: Function and DescriptionPototoNo ratings yet

- Every Part. Genuine.: Isx / QSX Overhaul Kit Quick Reference GuideDocument1 pageEvery Part. Genuine.: Isx / QSX Overhaul Kit Quick Reference GuidePototo100% (1)

- Illustrated Parts List: RTLO-12713A November 2012Document48 pagesIllustrated Parts List: RTLO-12713A November 2012PototoNo ratings yet

- Number: 08 Ddec Vi-18 Rev S.M. REF.: 5.8 Engine: Epa07 Mbe 4000 DATE: NovemberDocument4 pagesNumber: 08 Ddec Vi-18 Rev S.M. REF.: 5.8 Engine: Epa07 Mbe 4000 DATE: NovemberPototoNo ratings yet

- Cam Install PDFDocument1 pageCam Install PDFPototoNo ratings yet

- Tmib 0210 PDFDocument2 pagesTmib 0210 PDFPototoNo ratings yet

- Taib 0873 PDFDocument2 pagesTaib 0873 PDFPototoNo ratings yet

- BW1396 - 003 - US Cropped PDFDocument2 pagesBW1396 - 003 - US Cropped PDFPototoNo ratings yet

- Dokumen - Tips - 2012 Luk Repset Catalog Connolly Sales Clutch Job Can Take Up To 7 Hours of Labor PDFDocument372 pagesDokumen - Tips - 2012 Luk Repset Catalog Connolly Sales Clutch Job Can Take Up To 7 Hours of Labor PDFPototoNo ratings yet

- Transmission Interchange Section Header Descriptions: Reman Unit Part Number With Integral Oil PumpDocument2 pagesTransmission Interchange Section Header Descriptions: Reman Unit Part Number With Integral Oil PumpPototoNo ratings yet

- Cam Install PDFDocument1 pageCam Install PDFPototoNo ratings yet

- Driver Instructions: Video Instruction AvailableDocument30 pagesDriver Instructions: Video Instruction AvailablePototoNo ratings yet

- BendixTch003043UsersManual682762 619045789 PDFDocument1 pageBendixTch003043UsersManual682762 619045789 PDFPototoNo ratings yet

- Every Part. Genuine.: Isx / QSX Overhaul Kit Quick Reference GuideDocument1 pageEvery Part. Genuine.: Isx / QSX Overhaul Kit Quick Reference GuidePototo100% (1)

- Tmib 0210 PDFDocument2 pagesTmib 0210 PDFPototoNo ratings yet

- Transmission Interchange Section Header Descriptions: Reman Unit Part Number With Integral Oil PumpDocument2 pagesTransmission Interchange Section Header Descriptions: Reman Unit Part Number With Integral Oil PumpPototoNo ratings yet

- BendixSd033652UsersManual682491 1882992110 PDFDocument4 pagesBendixSd033652UsersManual682491 1882992110 PDFPototoNo ratings yet

- BW5057 Us 004Document92 pagesBW5057 Us 004davoodnasehi1No ratings yet

- BendixSd033652UsersManual682491 1882992110 PDFDocument4 pagesBendixSd033652UsersManual682491 1882992110 PDFPototoNo ratings yet

- BW1396 - 003 - US Cropped PDFDocument2 pagesBW1396 - 003 - US Cropped PDFPototoNo ratings yet

- Haooidb C DaamsdDocument53 pagesHaooidb C DaamsdGuevaraCustodioSaulNo ratings yet

- Diagnose Steering and Brake MalfunctionsDocument3 pagesDiagnose Steering and Brake Malfunctionstecnicogato27No ratings yet

- Case Combine 2388 (2006) Parts Catalog (PDF, RUS, 12 MB) PDFDocument771 pagesCase Combine 2388 (2006) Parts Catalog (PDF, RUS, 12 MB) PDFVlad Ptashnichenko100% (2)

- C100 Service Training Manual: Instructor GuideDocument6 pagesC100 Service Training Manual: Instructor GuideDangLuyenNo ratings yet

- DG743 PDFDocument977 pagesDG743 PDFtechnical trainer 011cNo ratings yet

- 3gr-Fse-Em21-Engine Assembly-RemovalDocument12 pages3gr-Fse-Em21-Engine Assembly-RemovalHuỳnh Minh ĐứcNo ratings yet

- Combination MeterDocument1 pageCombination MeterWildanNo ratings yet

- CSX Abth Rules 7-1-2004Document72 pagesCSX Abth Rules 7-1-2004oliveira1305No ratings yet

- Caterpillar d5b Crawler Parts Manual SN 26x878 and UpDocument8 pagesCaterpillar d5b Crawler Parts Manual SN 26x878 and UpCarmen GarciaNo ratings yet

- Service Manual Full, 2012 Tribeca, 3.6 Liter, 5EAT, AWDDocument2,971 pagesService Manual Full, 2012 Tribeca, 3.6 Liter, 5EAT, AWDDaniel Tapia HenríquezNo ratings yet

- A319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)Document38 pagesA319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)A WongNo ratings yet

- Lubricants and Fluids: NO. Lubrication Points LubricantDocument2 pagesLubricants and Fluids: NO. Lubrication Points LubricantDoc ImportNo ratings yet

- Banco de Preguntas A320Document8 pagesBanco de Preguntas A320Leonardo RoldanNo ratings yet

- (1922) Automobile Trade TrainingDocument636 pages(1922) Automobile Trade TrainingHerbert Hillary Booker 2nd100% (2)

- Connecting Rod and Piston Mercedes Om442laDocument6 pagesConnecting Rod and Piston Mercedes Om442laYolanda GutierrezNo ratings yet

- Despiece MaxionDocument84 pagesDespiece Maxionnelsonreus100% (1)

- VMGP Paper - 6Document1 pageVMGP Paper - 6Er Samkit ShahNo ratings yet

- Air Compressor #1-2 PDFDocument2 pagesAir Compressor #1-2 PDFLukasNo ratings yet

- Clutch Echo 2002Document17 pagesClutch Echo 2002Tomas DominguezNo ratings yet

- Toyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument14 pagesToyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairEutério SilvaNo ratings yet

- Axial Piston Motors GuideDocument4 pagesAxial Piston Motors GuideFernando RíosNo ratings yet

- Chery SQR7080R Engine Service ManualDocument57 pagesChery SQR7080R Engine Service ManualUmar ShamsudinNo ratings yet

- Watchkeeping and TroubleshootingDocument16 pagesWatchkeeping and TroubleshootingAditya JoglekarNo ratings yet

- Critical Parts List 1255 Vs 1418Document2 pagesCritical Parts List 1255 Vs 1418Massey FergusonNo ratings yet

- CYLINDER HEAD AND ENGINE ASSEMBLY PARTSDocument15 pagesCYLINDER HEAD AND ENGINE ASSEMBLY PARTSchuck lancer AlquisolaNo ratings yet