Professional Documents

Culture Documents

Aluminium Bronze To Bs 1400: Ab2

Uploaded by

benabdallah1310 ratings0% found this document useful (0 votes)

18 views1 pageOriginal Title

BronzeAB2AluminiumBronze.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageAluminium Bronze To Bs 1400: Ab2

Uploaded by

benabdallah131Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

NON-FERROUS METALS

ALUMINIUM BRONZE to BS 1400: AB2

AB2 Aluminium Bronze, offering high CHEMICAL COMPOSITION

strength, good wear resistance, good Copper (Cu) 79% min

corrosion resistance, with high Tin (Sn) 0.10% max

resistance to oxidation and good Zinc (Zn) 0.50% max

strength at elevated temperatures. Nickel (Ni) 4.00 – 5.00%

TYPICAL APPLICATIONS: Aluminium (Al) 8.50 – 9.50%

Marine, oil and chemical industry as high strength (Fe) 3.50 – 4.50%

Iron

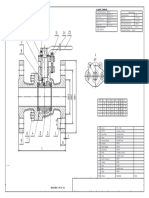

propellers, propeller shafts, valve fittings, worm

wheels, pump rods, bolts, spark plug bodies, Manganese (Mn) 0.80 – 1.50%

heavy duty bearings, gear wheels, valve seats, Lead (Pb) 0.05% max

non-sparking tools and pinions etc.

RELATED SPECIFICATIONS:

PRODUCTION RANGE:

AS 1565 C95810

Continuous Cast: Solid & Hollow

Outside diameter 12mm – 305mm ASTM B505 & B271 958

Inside diameter 12mm – 254mm

SAE CA958

Length 305mm – 3100mm

In multiples of 305mm – 1000mm UNS C95800

Round/hexagon/octagon

Electrical conductivity 8%

Rectangular: Solid only

Freezing range 1055 - 1065°C (approx.)

Centrifugal Cast: Hollow only OTHER:

Outside diameter 330mm – 560mm

Activity Rating

Inside diameter 175mm – 500mm

Length 305mm – 1000mm Machinability 3

NB: Smaller I/D produced to order

Pressure Tightness 1

Weldability (Mig) 1

1–4 in decreasing order of merit

TYPICAL MECHANICAL PROPERTIES

0.2% Proof Stress Tensile Strength Elongation Hardness

MPa MPa % HB

240 - 260 590 - 655 18 - 25 150 - 170

Typical Mechanical Properties are for guidance only.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Document25 pagesIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007ANILNo ratings yet

- Sintef PDFDocument80 pagesSintef PDFANILNo ratings yet

- Prototype: Build Review Refine & IterateDocument7 pagesPrototype: Build Review Refine & IterateANILNo ratings yet

- Name: Nilesh Ashok Wagh Mobile No.: +91 7588930595/7020322853 Technical AchievementsDocument2 pagesName: Nilesh Ashok Wagh Mobile No.: +91 7588930595/7020322853 Technical AchievementsANILNo ratings yet

- Season Classification Chart 2017: Alleppey Munnar Coorg Binsar Kanatal Shimla Kanha JaipurDocument2 pagesSeason Classification Chart 2017: Alleppey Munnar Coorg Binsar Kanatal Shimla Kanha JaipurANILNo ratings yet

- L9 Nominal Taguchi 1Document38 pagesL9 Nominal Taguchi 1ANILNo ratings yet

- CarbideDocument1 pageCarbideANILNo ratings yet

- What Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyDocument10 pagesWhat Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyANILNo ratings yet

- Refrigeration and Airconditioning by S K Mondal T&Q .0001Document133 pagesRefrigeration and Airconditioning by S K Mondal T&Q .0001ANILNo ratings yet

- GD & T Stack Up Analysis PDFDocument12 pagesGD & T Stack Up Analysis PDFANILNo ratings yet

- ASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingDocument1 pageASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingANILNo ratings yet

- Body Language For InterviewDocument5 pagesBody Language For InterviewANILNo ratings yet

- Courses Welingkaronline Org Newlogin Subjectlist PortionDocument1 pageCourses Welingkaronline Org Newlogin Subjectlist PortionANILNo ratings yet

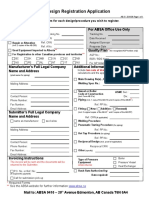

- AB-031 Design Registration ApplicationDocument1 pageAB-031 Design Registration ApplicationANILNo ratings yet

- Curriculum Vitae: ObjectiveDocument4 pagesCurriculum Vitae: ObjectiveANILNo ratings yet

- ThermodynamicsDocument57 pagesThermodynamicsANILNo ratings yet

- Application Form For LIFE Corporate Membership: 1. Corporate Name (In Block Letters)Document3 pagesApplication Form For LIFE Corporate Membership: 1. Corporate Name (In Block Letters)ANILNo ratings yet

- HSBC - Call LetterDocument1 pageHSBC - Call LetterANILNo ratings yet

- Meeting Feedback: How Productive Was The Meeting?Document4 pagesMeeting Feedback: How Productive Was The Meeting?ANILNo ratings yet