Professional Documents

Culture Documents

Batch Settling - AVIRAL

Uploaded by

saurabhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batch Settling - AVIRAL

Uploaded by

saurabhCopyright:

Available Formats

Dr. S.S.

B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

Title: Batch Settling.

Objective: To study batch settling and -

Plot a graph between height of interface and time.

A log-log graph between initial rate and concentration.

Theory:

Batch settling

There are several stages in the settling of a flocculated

suspension, different zones are formed as process proceeds. Usually, the

concentration of solid is high enough that sedimentation of individual particles is

hindered by other solids to such an extent that all solids at a given level settle at a

common velocity.

At first the solid is uniformly distributed in the liquid, after a short time

the solids have settled to a give a zone of a clear liquid and a zone of settled solids.

Above settled solids zone, there is a transition layer in which the solids content

varies from that in the original slurry to that in the zone of settled solids. In the

zone above it, the conc. of slurry is uniform and equal to that of original, since the

settling rate is same throughout the zone. The boundary between the zones of clear

liquid and that of uniform conc. is usually sharp.

As settling continues, the depth of zone of settled solids and that of

clear liquid increases. The depth of transition layer remains nearly constant and

that of zone of uniform concentration decreases. Eventually this zone disappear

and all the solids are in zone of settled solids and transition layer. Meanwhile, the

gradual accumulation of solids put stress on the material and the bottom, which

compresses solids in the bottom layer. Compression break down the structure of

aggregates and liquid is expelled into the upper zone. Finally, when the weight of

solid is balanced by the compressive strength of the flocs, the settling process

stops. This entire process is called sedimentation.

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

Gravity separation under hindered settling is often used to convert a

dilute slurry of fine particles into a clear liquid and a concentrated suspension. This

process is carried out in large open tank called thickeners or clarifiers.

Description of setup:

The setup consists of 4 long measuring cylinders of 1000ml each in which slurry of

calcium carbonate with water is fed. Four different concentration of slurry viz

5.5%, 7.5%, 9.5%, 11.5% w/v is fed to different cylinder.

Schematic Diagram:

Procedure:

Make the required concentration slurries in 4 different measuring cylinders

of 1000ml each.

Stir the content of the cylinder to get uniform concentration of suspension all

over.

Allow the suspension to settle under gravity.

Note the height of the interface between the clear liquid and suspension at

different time.

Take about 70-150 readings.

Repeat the same for other three solutions.

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

Observation table:

5.5% Solution

Time ( seconds) Height ( Cm) Time (seconds) Height(Cm)

11 29.5 401 12

22 29 413 11.5

33 28.5 426 11

44 28 439 10.5

54 27.5 452 10

64 27 468 9.5

73 26.5 484 9

84 26 498 8.8

94 25.5 515 8.6

105 25 535 8.4

115 24.5 562 8.2

125 24 591 8

136 23.5 617 7.8

147 23 643 7.6

159 22.5 671 7.4

170 22 702 7.2

181 21.5 729 7

192 21 763 6.8

203 20.5 799 6.6

214 20 837 6.4

225 19.5 875 6.2

236 19 918 6

246 18.5 963 5.8

257 18 1016 5.6

268 17.5 1071 5.4

280 17 1128 5.2

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

291 16.5 1186 5

302 16 1248 4.8

314 15.5 1322 4.6

326 15 1407 4.4

339 14.5 1502 4.2

352 14 1601 4

364 13.5 1726 3.8

377 13 1859 3.6

389 12.5 2004 3.4

9.5% Solution

Time ( Seconds) Height (Cm) Time ( Seconds) Height (Cm )

18 30 771 13.4

32 29.5 794 13.2

49 29 824 13

66 28.5 854 12.8

80 28 878 12.6

98 27.5 904 12.4

112 27 942 12.2

126 26.5 962 12

142 26 999 11.8

160 25.5 1030 11.6

176 25 1058 11.4

194 24.5 1101 11.2

212 24 1145 11

228 23.5 1188 10.8

246 23 1225 10.6

268 22.5 1268 10.4

283 22 1316 10.2

300 21.5 1357 10

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

317 21 1404 9.8

337 20.5 1462 9.6

356 20 1511 9.4

392 19.5 1560 9.2

415 19 1610 9

437 18.5 1673 8.8

459 18 1726 8.6

478 17.5 1784 8.4

485 17 1847 8.2

535 16.5 1920 8

563 16 1996 7.8

598 15.5 2067 7.6

612 15 2158 7.4

641 14.8 2235 7.2

654 14.5 2328 7

683 14.3 2442 6.8

712 14 2535 6.6

726 13.8 2649 6.4

747 13.6 2738 6.2

11.5% Solution

Time ( Seconds) Height(Cm) Time( Seconds) Height (Cm)

24 29.5 1405 14.5

46 29 1516 14

69 28.5 1561 13.8

94 28 1609 13.6

121 27.5 1658 13.4

143 27 1707 13.2

172 26.5 1756 13

199 26 1810 12.8

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

226 25.5 1871 12.6

255 25 1918 12.4

285 24.5 1979 12.2

314 24 2034 12

346 23.5 2093 11.8

378 23 2160 11.6

412 22.5 2222 11.4

446 22 2299 11.2

484 21.5 2380 11

512 21 2458 10.8

553 20.5 2549 10.6

602 20 2638 10.4

652 19.5 2736 10.2

704 19 2839 10

757 18.5 2947 9.8

815 18 3050 9.6

882 17.5 3162 9.4

953 17 3259 9.2

1028 16.5 3380 9

1112 16 3557 8.8

1204 15.5 3798 8.6

1299 15 4123 8.4

7.5% Solution

Time ( Seconds) Height( Cm ) Time( seconds) Height( Cm)

0.9 29 444 12.2

20 28.5 454 12

32 28 470 11.8

43 27.5 477 11.6

55 27 493 11.4

67 26.5 509 11.2

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

78 26 520 11

87 25.5 541 10.8

100 25 558 10.6

111 24.5 574 10.4

122 24 602 10.2

134 23.5 614 10

147 23 640 9.8

157 22.5 669 9.6

168 22 700 9.4

181 21.5 728 9.2

192 21 760 9

204 20.5 787 8.8

215 20 828 8.6

228 19.5 862 8.4

240 19 921 8.2

252 18.5 973 8

266 18 1027 7.8

279 17.5 1074 7.6

291 17 1118 7.4

306 16.5 1157 7.2

318 16 1202 7

332 15.5 1253 6.8

345 15 1306 6.6

353 14.8 1355 6.4

358 14.6 1402 6.2

362 14.4 1478 6

369 14.2 1566 5.8

373 14 1632 5.6

382 13.8 1717 5.4

389 13.6 1794 5.2

394 13.4 1891 5

402 13.2 2030 4.8

412 13 2229 4.6

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

421 12.8 2544 4.4

425 12.6 3072 4.2

437 12.4

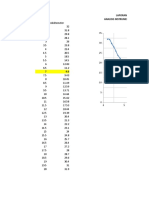

Graphs:

CONCENTRATION 5.5%

35

30

25

20

15

10

0

0 500 1000 1500 2000 2500

TIME (Seconds)

CONCENTRATION 9.5%

35

30

25

20

15

10

0

0 1000 2000 3000 4000 5000

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

CONCENTRATION 11.5%

35

30

25

20

15

10

0

0 1000 2000 3000 4000 5000

CONCENTRATION 7.5%

35

30

25

20

15

10

0

0 500 1000 1500 2000 2500 3000 3500

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

Dr. S.S.B UNIVERSITY INSTITUTE OF CHEMICAL ENGINEERING AND TECHNOLOGY,

PANJAB UNIVERSITY, CHANDIGARH

Settling curve:

dh/dt vs. Conc. (g/l)

1

10 100 1000

0.1

dh/dt

0.01

0.001

Concentration(gm/l)

Result:

As shown by the plot above, during the early stages of settling the velocity is

increasing, as shown by the first portion of the curve. Then rate of settling starts

decreasing and steadily drops until the ultimate height is reached. The velocity at

this transition is given critical settling velocity.

B.E. CHEMICAL IInd Year AVIRAL SELI CH12111

You might also like

- 14 - Liquid Measurements With OrificeDocument5 pages14 - Liquid Measurements With OrificekumarNo ratings yet

- Air Filter Element Flow Analysis 1.5Document15 pagesAir Filter Element Flow Analysis 1.5Mohamed Abderrahim FellaouineNo ratings yet

- Pola TanamDocument63 pagesPola TanamGunawanNo ratings yet

- Recommended Winding TensionsDocument1 pageRecommended Winding TensionsDeaferrantNo ratings yet

- Laporan Praktikum Konduktimetri Analisis Instrumental Kelompok 8 1C D3 Teknik KimiaDocument2 pagesLaporan Praktikum Konduktimetri Analisis Instrumental Kelompok 8 1C D3 Teknik KimiaSyah DabotNo ratings yet

- Generator Fuel Consumption As Per LoadDocument1 pageGenerator Fuel Consumption As Per LoadJason SecretNo ratings yet

- Demag CC600Document4 pagesDemag CC600Reza SalimiNo ratings yet

- Hdpe Pipe Chart1Document3 pagesHdpe Pipe Chart1BENJAMIN UNALANNo ratings yet

- Approximate Fuel Consumption ChartDocument1 pageApproximate Fuel Consumption ChartMohammed AlkhawlaniNo ratings yet

- Air QualityDocument4 pagesAir QualityMario JuradoNo ratings yet

- Calibration-20 KLDocument4 pagesCalibration-20 KLkishore90% (20)

- Ejercicio 4: Individuo Distancia CM R Obs Cuadrilla R Esp R Area (cm2) PDocument5 pagesEjercicio 4: Individuo Distancia CM R Obs Cuadrilla R Esp R Area (cm2) PDavidGutierrezNo ratings yet

- Modelo de Monod Vs HaldaneDocument30 pagesModelo de Monod Vs Haldanebrodriguez.1704No ratings yet

- Purge Time 7-00Document1 pagePurge Time 7-00Mohamad ArrajNo ratings yet

- Vinidex PE Pipe Capability MatrixDocument1 pageVinidex PE Pipe Capability MatrixguslohNo ratings yet

- Vinidex Capability & Pe100 Polyethylene Pipe Dimensions: (Based On AS/NZS 4130)Document1 pageVinidex Capability & Pe100 Polyethylene Pipe Dimensions: (Based On AS/NZS 4130)Christopher Kenneth ChoaNo ratings yet

- Pipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Document6 pagesPipe Sizes According To Schedule Input Value Unit: Pipe Table - Extracted From Asme B36.1Richard ObinnaNo ratings yet

- Excel Two ClusterDocument5 pagesExcel Two ClusterNisrina Aprilia KamilaNo ratings yet

- HDPE Pipe Flow RatesDocument2 pagesHDPE Pipe Flow Ratesalaa sadikNo ratings yet

- Full Load Motor CurrentsDocument2 pagesFull Load Motor CurrentsJoel DirinNo ratings yet

- Hartley PDFDocument1 pageHartley PDFPaola Rivera DiazNo ratings yet

- Tumbukan (N) Pemb. Mistar (MM) Penetrasi (MM) Tumb (Per 25 MM) Nilai CBR (%) Grafik 1 Grafik 2Document4 pagesTumbukan (N) Pemb. Mistar (MM) Penetrasi (MM) Tumb (Per 25 MM) Nilai CBR (%) Grafik 1 Grafik 2Marcellino ArifinNo ratings yet

- General Average (26 Credits)Document30 pagesGeneral Average (26 Credits)chill kinokoNo ratings yet

- D1051191072 - Wira Anggara - Tugas 1 HLDocument2 pagesD1051191072 - Wira Anggara - Tugas 1 HLGunawan DemianNo ratings yet

- Data Stunting Per Puskesmas 31 Desember 2019Document2 pagesData Stunting Per Puskesmas 31 Desember 2019Amishya DebbylaNo ratings yet

- Fuel Consumption ChartDocument1 pageFuel Consumption ChartMannyBaldonadoDeJesusNo ratings yet

- Fuel Consumption ChartDocument1 pageFuel Consumption Chartuzair faridNo ratings yet

- Alex ProcessingDocument11 pagesAlex Processingsaniyag_1No ratings yet

- Mobile Crane Grue Mobile: Technical Data Caractéristiques TechniquesDocument20 pagesMobile Crane Grue Mobile: Technical Data Caractéristiques TechniquesAmine OthmaneNo ratings yet

- 5 4 3 2 1 TotalDocument10 pages5 4 3 2 1 Totalrenzon272No ratings yet

- Marion Lake DataDocument36 pagesMarion Lake DatakinnafishNo ratings yet

- Laporan Pws KB (Program KB)Document4 pagesLaporan Pws KB (Program KB)winwinNo ratings yet

- A1C To Blood Glucose Conversion TableDocument1 pageA1C To Blood Glucose Conversion TableJeff LentiniNo ratings yet

- Tabel NPS Dan SCH Pipa Carbon - Stainless SteelDocument3 pagesTabel NPS Dan SCH Pipa Carbon - Stainless SteelAdhi Erlangga0% (1)

- Length Wedth Result Length Wedth Result: S.No S.NoDocument2 pagesLength Wedth Result Length Wedth Result: S.No S.NoSheeraz KhanNo ratings yet

- Ltm1090-4.1 Liebherr SpecificationsDocument3 pagesLtm1090-4.1 Liebherr SpecificationsclaudobaNo ratings yet

- Pipe (OK)Document1 pagePipe (OK)Black AutumnNo ratings yet

- Español: A1-Ring Adelaide Ahvenisto Anderstorp AustinDocument10 pagesEspañol: A1-Ring Adelaide Ahvenisto Anderstorp AustinzarvaoriyoNo ratings yet

- Pipe Friction Loss Charts Pipe and EquivDocument1 pagePipe Friction Loss Charts Pipe and EquivDoaa HassanNo ratings yet

- Approximate Fuel Consumption ChartDocument1 pageApproximate Fuel Consumption ChartMykeNo ratings yet

- Fuel Consumption ChartDocument1 pageFuel Consumption ChartLupul50No ratings yet

- Top Ten Scores For 2007 State TourneyDocument1 pageTop Ten Scores For 2007 State TourneyMutoha ArkanuddinNo ratings yet

- Top Ten Scores For 2007 State TourneyDocument1 pageTop Ten Scores For 2007 State TourneyMutoha ArkanuddinNo ratings yet

- Untitled-2 Merged PDFDocument5 pagesUntitled-2 Merged PDFKazekage MinatoNo ratings yet

- Untitled-2 Merged PDFDocument5 pagesUntitled-2 Merged PDFKazekage MinatoNo ratings yet

- Inspection Timings of M&M Clutch HousingDocument2 pagesInspection Timings of M&M Clutch HousingaNo ratings yet

- Basic College Mathematics 2nd Edition Miller Solutions ManualDocument8 pagesBasic College Mathematics 2nd Edition Miller Solutions Manualknackishfantigue.63von100% (24)

- Ceklis Klaim Rs Anna Medika Bulan Pelayanan Maret 2019Document1 pageCeklis Klaim Rs Anna Medika Bulan Pelayanan Maret 2019syaiful rinantoNo ratings yet

- Numero de Calidad QVDocument6 pagesNumero de Calidad QVJuanRamosNo ratings yet

- For Constant CBR Value of Embankment 1.5 2 2.5 3 5 7 Effective CBR of SubgradeDocument1 pageFor Constant CBR Value of Embankment 1.5 2 2.5 3 5 7 Effective CBR of SubgradeAkshay Aithal KandoorNo ratings yet

- Fuel Consumption Chart Diesel GeneratorsDocument1 pageFuel Consumption Chart Diesel GeneratorsYasir MehmoodNo ratings yet

- KWH FQHT Oktober 2022Document3 pagesKWH FQHT Oktober 2022Todi Dwi SaputraNo ratings yet

- Dimensions of Chinese Standard Equal Leg AnglesDocument3 pagesDimensions of Chinese Standard Equal Leg AnglesJJGM120No ratings yet

- Modal Dengan Pertumbuhan Perhari: Hari Ke Invest ($) 5% Perhari Saldo ($) Hari Ke Invest ($) 5% Perhari Saldo ($)Document6 pagesModal Dengan Pertumbuhan Perhari: Hari Ke Invest ($) 5% Perhari Saldo ($) Hari Ke Invest ($) 5% Perhari Saldo ($)Muhammad ZaiSantNo ratings yet

- Hdpe Pe80 Din 8074 / Iso 4427Document79 pagesHdpe Pe80 Din 8074 / Iso 4427Steve WanNo ratings yet

- Tarea 1 - Introducción A Los Modelos Probabilísticos de Decisión Y OptimizaciónDocument17 pagesTarea 1 - Introducción A Los Modelos Probabilísticos de Decisión Y OptimizaciónAyda Luz Lopez AlvisNo ratings yet

- Earned Value AnalysisDocument33 pagesEarned Value AnalysisFahad ZulfiqarNo ratings yet

- Memanjang Tipe Panjang Tinggi Luas Kusen Luas Dinding: MelintangDocument3 pagesMemanjang Tipe Panjang Tinggi Luas Kusen Luas Dinding: MelintangAfishyNellyArifiantyNo ratings yet

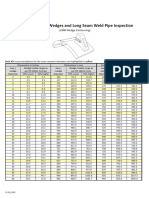

- Chart For Curved Wedges and Long Seam Weld Pipe Inspection v4Document1 pageChart For Curved Wedges and Long Seam Weld Pipe Inspection v4david montillaNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Case Study of An Ethical DilemmaDocument4 pagesCase Study of An Ethical Dilemmasaurabh100% (3)

- Earnings Quality - MeasuringDocument3 pagesEarnings Quality - MeasuringsaurabhNo ratings yet

- Fraudulent Financial Reporting - Definition - ExampleDocument1 pageFraudulent Financial Reporting - Definition - ExamplesaurabhNo ratings yet

- Earnings ManagementDocument15 pagesEarnings ManagementsaurabhNo ratings yet

- Quality of Earnings in AccountingDocument2 pagesQuality of Earnings in AccountingsaurabhNo ratings yet

- How To Write A Statement ProblemDocument1 pageHow To Write A Statement ProblemsaurabhNo ratings yet

- 4 PDFDocument10 pages4 PDFAnonymous jAem9SVNo ratings yet

- AINI 2008 Apple S Pricing StrategyDocument13 pagesAINI 2008 Apple S Pricing StrategyBeiYun XiaoNo ratings yet

- VixDocument1 pageVixsaurabhNo ratings yet

- Andreason Pipette - AviralDocument7 pagesAndreason Pipette - AviralsaurabhNo ratings yet

- Tittle SheetDocument1 pageTittle SheetsaurabhNo ratings yet

- Variation of Magnetic Field by Helmholtz GalvanometerDocument7 pagesVariation of Magnetic Field by Helmholtz Galvanometerbestmadeeasy0% (1)

- Environmental EthicsDocument2 pagesEnvironmental EthicssaurabhNo ratings yet

- Variation of Magnetic Field by Helmholtz GalvanometerDocument7 pagesVariation of Magnetic Field by Helmholtz Galvanometerbestmadeeasy0% (1)

- 1508878271three Month Strategy Guide For CATDocument15 pages1508878271three Month Strategy Guide For CATAbhinav SainiNo ratings yet

- Case 2 InvmDocument8 pagesCase 2 InvmsaurabhNo ratings yet

- ProgrammeDocument5 pagesProgrammefred2000leviNo ratings yet

- Rheology: ViscosityDocument14 pagesRheology: ViscosityalbertofgvNo ratings yet

- 09 01ChapGereDocument12 pages09 01ChapGereJhon Nolbert Echeverry MuñetonezNo ratings yet

- Exp 4.1 (Form 4)Document2 pagesExp 4.1 (Form 4)IMELDANo ratings yet

- The Ultimate Mathematics of The QuranDocument188 pagesThe Ultimate Mathematics of The Quranindiapower19No ratings yet

- Safety by Correct Assembly, Proper Operation, Careful Maintenance and CareDocument23 pagesSafety by Correct Assembly, Proper Operation, Careful Maintenance and CaremkpqNo ratings yet

- Astm Parte 5Document5 pagesAstm Parte 5Jimmy David Espinoza MejiaNo ratings yet

- 02-04-2023 SR - Super60 Nucleus & All BT Jee-Main-Gtm-33 Key & Sol'sDocument14 pages02-04-2023 SR - Super60 Nucleus & All BT Jee-Main-Gtm-33 Key & Sol'sK R I S HNo ratings yet

- Is 516 (Part-2 Sec-IV) - 2021 Determination of The Carbonation Resistance by Accelerated Carbonation MethodDocument18 pagesIs 516 (Part-2 Sec-IV) - 2021 Determination of The Carbonation Resistance by Accelerated Carbonation MethodArun Gupta100% (2)

- Ganache Formulation PDFDocument4 pagesGanache Formulation PDFtavibasti100% (1)

- Aerospace Materials Processes and Environmental TechnologyDocument125 pagesAerospace Materials Processes and Environmental TechnologyLuigiNo ratings yet

- Production Engineering: (Third Edition)Document20 pagesProduction Engineering: (Third Edition)Rishabh Gehlot0% (1)

- Q4 P. Task 1 - RocksDocument2 pagesQ4 P. Task 1 - RocksJhonazel SandovalNo ratings yet

- Chapter 1 Azeotrope and Multicomponent DistillationDocument32 pagesChapter 1 Azeotrope and Multicomponent DistillationMUHAMMAD LUQMAN HAKIMI MOHD ZAMRINo ratings yet

- Report Mini ProjectDocument8 pagesReport Mini ProjectqairulNo ratings yet

- Lab Report 1 Sku 3043Document9 pagesLab Report 1 Sku 3043Nelviana NahNo ratings yet

- Addition Polymer (1b)Document32 pagesAddition Polymer (1b)sriNo ratings yet

- Astm d6730 AppDocument5 pagesAstm d6730 AppRuồi SữaNo ratings yet

- Automotive High Heat Paint: Technical Data ATO-15Document2 pagesAutomotive High Heat Paint: Technical Data ATO-15HillNo ratings yet

- PLUG VALVE - Full Bore - Technical BulletinDocument28 pagesPLUG VALVE - Full Bore - Technical BulletinRenzo Conde Montenegro100% (1)

- A Simple Method For HPLC Retention Time Prediction: Linear Calibration Using Two Reference SubstancesDocument12 pagesA Simple Method For HPLC Retention Time Prediction: Linear Calibration Using Two Reference Substancesjeline raniNo ratings yet

- Laminarin Review ReportDocument18 pagesLaminarin Review ReportMelinda AndersonNo ratings yet

- Thermodynamic Processes: Analysis of Thermodynamic Processes by Applying 1 & 2 Law of ThermodynamicsDocument10 pagesThermodynamic Processes: Analysis of Thermodynamic Processes by Applying 1 & 2 Law of Thermodynamicsmohdmehrajanwar1860No ratings yet

- Carr 5ton 24abb360a003Document106 pagesCarr 5ton 24abb360a003Gabriel A. Gabriel MarmolejosNo ratings yet

- NFT 58-000Document10 pagesNFT 58-000arun123123100% (3)

- TFF Embryo Pituitary - PosterDocument1 pageTFF Embryo Pituitary - PosterahumblereaderNo ratings yet

- Are Polyphenols Antioxidants or Pro-Oxidants What Do We LearnDocument6 pagesAre Polyphenols Antioxidants or Pro-Oxidants What Do We LearnDiana Maria Amaya CruzNo ratings yet

- Insulation Material List (Rock Wool)Document16 pagesInsulation Material List (Rock Wool)Atiq_2909No ratings yet

- Report UV-3600 Plus UV-VIS-NIR Spectrophotometer From ShimadzuDocument5 pagesReport UV-3600 Plus UV-VIS-NIR Spectrophotometer From ShimadzuWaqar ShehbazNo ratings yet

- BS en 12396-1-1999Document12 pagesBS en 12396-1-1999DoicielNo ratings yet