Professional Documents

Culture Documents

Use the Methods - Specifications form to select the property method used to calculate properties such as K-values, enthalpy, and density. The Base method list contains various property methods built into Aspen Plus. The specific methods in the list depend on the chosen method. To see all the

Uploaded by

wakanda forever0 ratings0% found this document useful (0 votes)

24 views4 pagesThis patent describes a process for producing concentrated solutions of ammonium nitrate. When the production rate is lower than 150 kg/h/cm2, neutralization is performed in the presence of recycled concentrated ammonium nitrate solutions in a pipe reactor. When the production rate is higher than 150 kg/h/cm2, recycling is not necessary. The pipe reactor discharges a mixture that is easily separable into droplets of ammonium nitrate solution and steam.

Original Description:

Use the Methods - Specifications form to select the property method used

to calculate properties such as K-values, enthalpy, and density. The Base

method list contains various property methods built into Aspen Plus. The

specific methods in the list depend on the chosen method. To see all the

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a process for producing concentrated solutions of ammonium nitrate. When the production rate is lower than 150 kg/h/cm2, neutralization is performed in the presence of recycled concentrated ammonium nitrate solutions in a pipe reactor. When the production rate is higher than 150 kg/h/cm2, recycling is not necessary. The pipe reactor discharges a mixture that is easily separable into droplets of ammonium nitrate solution and steam.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views4 pagesUse the Methods - Specifications form to select the property method used to calculate properties such as K-values, enthalpy, and density. The Base method list contains various property methods built into Aspen Plus. The specific methods in the list depend on the chosen method. To see all the

Uploaded by

wakanda foreverThis patent describes a process for producing concentrated solutions of ammonium nitrate. When the production rate is lower than 150 kg/h/cm2, neutralization is performed in the presence of recycled concentrated ammonium nitrate solutions in a pipe reactor. When the production rate is higher than 150 kg/h/cm2, recycling is not necessary. The pipe reactor discharges a mixture that is easily separable into droplets of ammonium nitrate solution and steam.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

United States Patent (19) 11) Patent Number: 4,927,617

Villard et al. (45) Date of Patent: May 22, 1990

(54) PROCESS OF PRODUCING 4,308,049 12/1981 Mini .................................... 423/396

CONCENTRATED SOLUTIONS OF 4,699,773 10/1987 Ulrichs et al. ...................... 422/113

AMMONUMINTRATE FOREIGN PATENT DOCUMENTS

(75) Inventors: Alexandre Villard; Yves Cotonea, 813196 3/1937 France.

both of Rouen, France 1029010 5/1953 France .

(73) Assignee: Societe Chimique des Charbonnages 1093912 5/1955 France .

1356054 2/1964 France.

S.A., Paris, France 1426746 4/1966 France .

21 Appl. No.: 20,770 474181 United Kingdom ................ 423/396

10/1937

496847 12/1938 United Kingdom ................ 423/396

22 Fied: Mar. 2, 1987 1105466 3/1968 United Kingdom .

(51) Int. C. ................................................ CO6B 1/04 OTHER PUBLICATIONS

(52) U.S. C. .................................................... 423/396

(58) Field of Search ......................................... 423/396 Ammonium Nitride Technology, U. M. Olevski, pp.

193-198, (1978).

(56) References Cited

U.S. PATENT DOCUMENTS

Primary Examiner-John Doll

Assistant Examiner-Wayne A. Langel

2,551,569 5/1951 Strelzoff.............................. 423/396 Attorney, Agent, or Firm-Finnegan, Henderson,

2,568,901 9/1951 Stengel ................................ 423/396 Farabow, Garrett & Dunner

2,618,547 11/1952 Davenport et al. . 57 ABSTRACT

2,755,176 7/1956 Pearce et al. .

2,902,342 9/1959 Kerley, Jr. . Process for producing concentrated solutions of ammo

2,977,201 3/1961 Stephens . nium nitrate by neutralization of nitric acid with ammo

3,238,021 3/1966 Webber et al. .

3,301,657 1/1967 Dee et al. ............................ 423/396 nia in a pipe reactor.

3,310,371 3/1967 Lutz . When the global flow of reactives corresponds to an

3,362,809 1/1968 Tucker . output higher than 150 kg/h/cm2 neutralization is per

3,399,031 8/1968 McCarthy. formed in the presence of recycled concentrated solu

3,419,378 12/1968 Kearns.

3,464,808 9/1969 Kearns . tions of ammonium nitrate. When the global flow is

3,482,945 12/1969 Legal, Jr. . higher than 150 kg/h/cm2 recycling is not necessary.

3,502,441 3/1970 Hudson ............................... 423/396

3,503,706 3/1970 Legal, Jr. . 4 Claims, 1 Drawing Sheet

U.S. Patent May 22, 1990 4,927,617

4,927,617

1. 2

When the global flow of reactives is such that the

PROCESS OF PRODUCING CONCENTRATED production is higher than 150 kg/h/cm, it is no longer

SOLUTIONS OF AMMONUMNTRATE necessary to recycle ammonium nitrate solutions. No

smoke is produced. It must however be noted that it is

The present invention relates to a process for produc advantageous to introduce, on commencing operation,

ing concentrated solutions of ammonium nitrate by a certain quantity of ammonium nitrate solution. Thus,

neutralization of nitric acid with ammonia. at that time, the opening of the valves is not instanta

The present invention relates to a process for produc neous and takes about ten seconds during which plenty

ing concentrated solutions of ammonium nitrate charac of smoke is produced. Furthermore it is preferable to

terized in that neutralization is carried out in a pipe O

reactor. provide a device for recycling ammonium nitrate solu

The pipe reactor or tubular reactor is a length of pipe tions in order to be able to modify the global flow of the

having a rather small diameter and containing no inside reactives according to need.

stuffing. These tubular reactors have been used for the 15 The process of the invention can be carried out in the

manufacture of ammonium phosphates by neutraliza following unit.

tion of phosphoric acid with ammonia. The reaction is This unit is essentially characterized by the fact that it

quite instantaneous and vaporization of the water con comprises at least a pipe reactor provided with feed

tained in phosphoric acid takes place. The use of a pipe means for introducing reactives (HNO3-NH3), at least

reactor for the production of ammonium phosphate has a separator for separating steam from the reaction prod

been described in many patents such as the following: 20 uct (concentrated aqueous solution of ammonium ni

FR-B 1426746, USA 2618547, USA 2755176, USA trate) and optionally recycling means of part of the

2902342, USA 297720, USA 3238021, USA 3310371, reaction product into pipe reactor. The pipe reactor has

USA 3362809, USA 3399031, USA 34.19378, USA feed means for recycled solution.

3464808, USA3482945, USA3503706. The pipe reactor Other characteristics and advantages of the invention

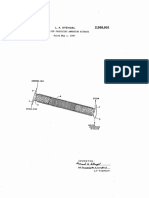

used is horizontally set or stands at small angle to an 25 will be better understood from the following descrip

horizontal line. The pipe reactors most generally used tion with reference to the accompanying diagrammatic

have a diameter ranging between 200 mm and 10 mm drawing.

and a length ranging between 1.50 meter and 10 meters. Pipe reactor (R) is provided at one of its ends with

The ratio length/diameter is usually not below 50. Ac 30 three feed means for NH3, HNO3 and NH3NO3 recy

cording to the present application neutralization of cled solutions. The feed means are preferably built up in

nitric acid with ammonia is performed with or without order to cause a turbulent flow. At the other end of the

recycling of concentrated solution of ammonium nitrate pipe reactor, a concentrated solution of ammonium

as a function of the global flow of reactives. Thus when nitrate is discharged and fed into separator (S). At the

the global flow of reactives corresponds to an output 35 bottom part of the separator (S), concentrated solutions

lower than 150 kg/h/cm2, the reaction leads to the of ammonium nitrate are separated and stored. Part of

formation of an aerosol of droplets or of solids mi these solutions are optionally recycled after neutraliza

croparticles generating an important cloud of smoke or tion with NH3 fed at (C). Storage tanks (G) may be

fog from which it is very difficult, if not possible, to heated by inside heating means (V) in order to maintain

separate the desired product. The applicant has found the solutions in a liquid state in case of unit stopping. In

that, in such a case, when concentrated nitric acid is the upper part of separator (S), steam is carried off

injected together with ammonia, into a flow of recycled following arrow (F). Condensate is discharged at H.

solutions of ammonium nitrate, the pipe reactor product Preheating of NH3 and HNO3 takes place in heat ex

is an easily separable mixture of droplets of ammonium changers (ECH1, ECH2) before introduction in reactor

nitrate solution and steam. Nitric acid is injected in the 45 (R). The amount of NH3 added in storage tank (G) a

presence of a volume of ammonium nitrate ranging function of the acidity of the product solutions, which is

between 1 and 5 times the volume of produced ammo a function of the amount of HNO3 used. An excess of

nium nitrate solution. The lower the global flow of HNO3 is necessary to maintain acidity in the product

reactives, the higher the recycling rate. issuing from the reactor in order to avoid loss of NH3.

It was already known to react concentrated nitric 50 The advantages of the process of the present inven

acid and ammonia inside a high volume of aqueous tion are the following:

solution of ammonium nitrate. The reactives are in

jected in an apparatus comprising two distinct chambers small investment cost for the reactor as it is very

connected by vertical tubes. The reactives are intro simple and has a small diameter,

duced at the bottom of the lower chamber and the reac 55 a very small inertia of the unit as the amounts of

tion heat leads to vaporization of the water contained in ammonium nitrate solutions circulating are small,

concentrated nitric acid. This boiling takes place in the risks due to acid nitrate are lowered as the volume of

second chamber disposed above the first chamber and circulating solutions is small.

communicating with the latter through vertical tubes. A The following examples illustrate the invention.

phenomenon of thermosiphon makes the product go up 60 EXAMPLE 1 (comparative)

in some vertical tubes and down in others. In this type

of apparatus the recycle rate (calculated as the ratio of In a pipe reactor having a diameter of 15 mm are fed

the volume of recycled ammonium nitrate to the vol per hour:

ume of produced ammonium nitrate solution) is about 157 liters of 57.5% nitric acid,

100/1. Installations using this type of reactor are cum 65 33.5 kg of gaseous ammonia at 20 C.

bersome and contain a large volume of a rather danger A dense smoke is obtained and the test is stopped

ous product maintained at elevated temperatures after a few minutes. The estimated loss of ammonium

(140-160 C). nitrate is about 40%.

3

4,927,617

4.

EXAMPLE 2 97.5 kg of gaseous ammonia at 58 C.

The output is 518 kg per hour of a weakly acidic

In an unit as illustrated in the annexed figure with the ammonium nitrate solution) having a concentration of

same pipe reactor as in example 1 are fed per hour: 88.3% and a temperature of 148 C.

218.4 liters of 57.5% nitric acid at 20' C., The total losses of N amount to 0.6%.

46 kg of gaseous ammonia at 60' C., We claim:

1000 kg of recycled ammonium nitrate solution hav 1. Process for producing concentrated solutions of

ing a 92% concentration and a temperature of 150 ammonium nitrate which comprises neutralizing nitric

C. acid with ammonia in a substantially horizontal pipe

An output of 1230 kg/h of ammonium nitrate solution reactor containing no packing wherein the global flow

10

having a 91.2% concentration and a temperature of 140 of reactants is less than 150 kg/h/cm2 and a recycled

C. is obtained. The total N losses are 5.8% of the total flow of ammonium nitrate solution is present having a

amount of N provided by HNO3 and NH3. recycling ratio ranging between 1:1 and 5:1.

EXAMPLE 3 2. Process according to claim 1 further comprising

15 supplying reactants (HNO3 and NH3) to said pipe reac

In the same unit as in example 2 are fed per hour: tor, separating said produced concentrated solution of

373 liters of 57.5% nitric acid at 20' C., ammonium nitrate from steam in a separator and recy

76.8 liters of gaseous ammonia at 80' C., cling said ammonium nitrate solution from said separa

700 kg of recycled ammonium nitrate solutions hav tor into said pipe reactor.

ing a concentration of 92% and a temperature of 20 3. Process for producing concentrated solutions of

150' C. in which was introduced at C 1,2 kg of ammonium nitrate which comprises neutralizing nitric

NH3. acid with ammonia in a substantially horizontal pipe

The output is 1120 kg/h of a weakly acidic solution reactor containing no packing wherein the global flow

(free acidity 6 g of HNO3 per liter of solution) having a of reactants is greater than 150 kg/h/cm2 and no recy

concentration of 92.4% and a temperature of 155 C. 25 cling of ammonium nitrate solution is carried out.

The total losses of Namount to 0.15%. 4. Process according to claim 3 further comprising

EXAMPLE 4 supplying reactants (HNO3 and NH3) to said pipe reac

tor, and separating said concentrated solution of ammo

In the same unit as in example 2 are fed per hour: nium nitrate from steam in isa separator.

480 liters of 57.5% nitric acid preheated at 45 C., 30 it is is k

35

45

50

55

65

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Federalregister - Gov/d/2020-20527, and On Govinfo - GovDocument24 pagesFederalregister - Gov/d/2020-20527, and On Govinfo - GovForkLogNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- PC403210920090210Document2 pagesPC403210920090210wakanda foreverNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Continuous Dryers, Ovens, and Furnaces For 760 CDocument3 pagesContinuous Dryers, Ovens, and Furnaces For 760 Cwakanda foreverNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Chemical Engineering Dept Webinar on Sustainable Industrial DevelopmentDocument1 pageChemical Engineering Dept Webinar on Sustainable Industrial Developmentwakanda foreverNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- EconomizersDocument4 pagesEconomizerswakanda foreverNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Energy Performance Assessment of FurnacesDocument14 pagesEnergy Performance Assessment of FurnacesCatinca GeorgianaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Waste Water Treatment PlantDocument3 pagesWaste Water Treatment Plantwakanda foreverNo ratings yet

- Assignment PUEMDocument1 pageAssignment PUEMwakanda forever0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Columnenergy ManagDocument2 pagesColumnenergy Managwakanda foreverNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CHDocument2 pagesCHDebottamSarkarNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- ASME - PTC4.1 .Boiler Efficiency TestDocument29 pagesASME - PTC4.1 .Boiler Efficiency TestBC Harish92% (13)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Chapter-Waste Heat RecoveryDocument18 pagesChapter-Waste Heat Recoveryapi-19908130No ratings yet

- (DH/DT) - (D/D) (2gh)Document5 pages(DH/DT) - (D/D) (2gh)wakanda foreverNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 2.3 Steam Distribution &utilisationDocument35 pages2.3 Steam Distribution &utilisationBambang HermawanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Waste Water Treatment - FiltrationDocument7 pagesWaste Water Treatment - Filtrationwakanda foreverNo ratings yet

- Ground Water PollutionDocument2 pagesGround Water Pollutionwakanda foreverNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Water Quality - Estimations of Physical ParametersDocument6 pagesWater Quality - Estimations of Physical Parameterswakanda foreverNo ratings yet

- Homogeneous and Heterogeneous Catalysts For Multicomponent ReactionsDocument43 pagesHomogeneous and Heterogeneous Catalysts For Multicomponent Reactionswakanda foreverNo ratings yet

- Antoine Equation Graph For Benzene and P-Xylne: MIN MAXDocument5 pagesAntoine Equation Graph For Benzene and P-Xylne: MIN MAXwakanda foreverNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Catalyst Preparation Methods: Catalysis Today 34 (1997) 281-305Document25 pagesCatalyst Preparation Methods: Catalysis Today 34 (1997) 281-305wakanda foreverNo ratings yet

- Benzene and P-XyeleneDocument5 pagesBenzene and P-Xyelenewakanda foreverNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Bachmann1949 PDFDocument4 pagesBachmann1949 PDFwakanda foreverNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TXY Graph Version 2.1Document10 pagesTXY Graph Version 2.1wakanda foreverNo ratings yet

- Sept. 25, 1951 L. A. Stenge 2,568,901: Eles. 44tagedDocument4 pagesSept. 25, 1951 L. A. Stenge 2,568,901: Eles. 44tagedwakanda foreverNo ratings yet

- Sridhar An 2010Document45 pagesSridhar An 2010wakanda foreverNo ratings yet

- 10 1016@j Biotechadv 2010 03 002Document19 pages10 1016@j Biotechadv 2010 03 002Aris ApriantoNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Pour Javad I 2003Document7 pagesPour Javad I 2003wakanda foreverNo ratings yet

- United States Patent (19) : (22 Filed: Jun. 18, 1982Document5 pagesUnited States Patent (19) : (22 Filed: Jun. 18, 1982wakanda foreverNo ratings yet

- United States Patent Office: Patented June 3, 1969Document9 pagesUnited States Patent Office: Patented June 3, 1969wakanda foreverNo ratings yet

- Eclipse E300 ExampleDocument7 pagesEclipse E300 ExampleJie Lucas TzaiNo ratings yet

- Kurdonia Structural Design ReportDocument341 pagesKurdonia Structural Design ReportAnonymous nQ9RqmNo ratings yet

- Badger RCDL DatasheeDocument2 pagesBadger RCDL Datasheeابزار دقیقNo ratings yet

- Instrument Tubing Selection Guide: Contact InformationDocument4 pagesInstrument Tubing Selection Guide: Contact InformationdagauthamNo ratings yet

- Certificate of Quality: MOGAS-95Document1 pageCertificate of Quality: MOGAS-95Basant Kumar SaxenaNo ratings yet

- JIC Course Catalog 19062014Document42 pagesJIC Course Catalog 19062014dawn.devNo ratings yet

- CAR RUBBER TESTING PARAMETERSDocument3 pagesCAR RUBBER TESTING PARAMETERSBharat ChatrathNo ratings yet

- Commissioning Responsibilty Matrix Rev.0 12-Nov-2014Document4 pagesCommissioning Responsibilty Matrix Rev.0 12-Nov-2014Dinesh Radhakrishnan100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CIGRÉ 2008 - Corrosive Sulfur in FR3Document8 pagesCIGRÉ 2008 - Corrosive Sulfur in FR3Felipe VargasNo ratings yet

- 25.0 ML of Aqueous Sodium Hydroxide Solution of Unknown Concentration Was Placed in TheDocument2 pages25.0 ML of Aqueous Sodium Hydroxide Solution of Unknown Concentration Was Placed in TheThaarvena Retina100% (1)

- Heavy EquipmentDocument35 pagesHeavy EquipmentAntonius BithNo ratings yet

- GFGHHJDocument18 pagesGFGHHJsssadangiNo ratings yet

- Racor FiltryDocument32 pagesRacor FiltryMuhammadObaidullahNo ratings yet

- Alloying Elements of Steels and PropertiesDocument3 pagesAlloying Elements of Steels and PropertiesdaimaheshNo ratings yet

- Diesel Cycle: P-V Diagram T-S DiagramDocument3 pagesDiesel Cycle: P-V Diagram T-S DiagramJJ100% (1)

- RP HPLCDocument9 pagesRP HPLCGoutam GhoshNo ratings yet

- Jetmatic Pump vs Prime Water: Which is a Better Source of Potable WaterDocument46 pagesJetmatic Pump vs Prime Water: Which is a Better Source of Potable Waterjohn raphael javate33% (3)

- General Guidelines Structural Silicone Glazing With Sikasil AdhesivesDocument28 pagesGeneral Guidelines Structural Silicone Glazing With Sikasil AdhesivesfasdfaNo ratings yet

- Thermomechnical Properties of Textile FiberDocument2 pagesThermomechnical Properties of Textile FiberEhtasham Javed100% (1)

- PVC Pipes & Fittings ManufacturerDocument5 pagesPVC Pipes & Fittings ManufacturershandgroupNo ratings yet

- MineralsDocument18 pagesMineralsPhi Deppezz100% (1)

- ChE 195 Problem Set No. 2Document1 pageChE 195 Problem Set No. 2Jahz ChannelNo ratings yet

- Combined Polymer-Surfactant Flooding and Low Salinity Water For Enhanced Oil Recovery in Dolomite Reservoirs Using Local and Synthetic PolymersDocument25 pagesCombined Polymer-Surfactant Flooding and Low Salinity Water For Enhanced Oil Recovery in Dolomite Reservoirs Using Local and Synthetic PolymersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Arenium IonDocument2 pagesArenium Ionanon_966842741No ratings yet

- List of Written Confirmation Numbers for Pharmaceutical CompaniesDocument42 pagesList of Written Confirmation Numbers for Pharmaceutical CompaniesyoganaNo ratings yet

- PET Recycling Literature ReviewDocument69 pagesPET Recycling Literature ReviewPrachi ShahNo ratings yet

- Painting Standard For DCVS Ombilin 20190926Document5 pagesPainting Standard For DCVS Ombilin 20190926fendiNo ratings yet

- Chemical Bonding - Fajan's RuleDocument5 pagesChemical Bonding - Fajan's RuleVarsha YadavNo ratings yet

- German ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFDocument51 pagesGerman ATV DVWK A 168E Corrosion of Wastewater Systems Wastewater 1998 PDFJosip Medved100% (1)

- Adsorption of Gases On SolidsDocument20 pagesAdsorption of Gases On SolidsVinh Vật VãNo ratings yet

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)